How to choose an epoxy resin for creativity: editorial advice

Among variety of materialsused to decorate rooms and furniture making, as well as products for various purposes, epoxy takes a special place due to the physical properties of this material and its versatility. Epoxy for creativity is the topic of this article.

The content of the article [Hide]

- 1 Epoxy resin - what is it

- 2 Creative Applications of Epoxy

- 3 Basic properties

- 4 Chemical composition and components for epoxy resin

- 5 How to use epoxy

- 6 Characteristics of the popular variety - brand ED-20

- 7 Safety rules when working with ED-20

- 8 At what price to buy epoxy resin for creativity

- 9 Video: "How to work with epoxy resin"

- 10 Epoxy resin products

Epoxy resin - what is it

Epoxy resin, or "epoxy", is known to almost every person, at least once faced with the need to glue something, while the assembled structure must be strong and reliable. However, not everyone knows what epoxy is made of and how it can still be used for other purposes. Epoxy is a type of resin made from synthetic materials based on oligomeric compounds.

It is not used in its pure form, therefore, it must be polymerized before use, for which a special hardener is used. By keeping the different proportions in the epoxy-hardener mixture, a product can be created that differs in its physical properties and types of application. Distinctive features of this material are: strength and resistance to chemically active substances, lack of unpleasant odor and slight shrinkage after drying.

Creative Applications of Epoxy

Epoxy resin is a versatile material that allows you to make beautiful products in various fields of use: jewelry and bijouterie, interior decoration elements and furniture. For different purposes, different types of epoxy resin are used - transparent or colored, differing in the type of filler added to the composition before use.

Transparent

Transparent epoxy resin is used in the production of advertising and souvenir, decorative and jewelry items, as well as in the creation polymer floors with 3D effect.

In addition, transparent epoxy is used at different stages of construction and installation work in the construction of objects of various types. The industry produces epoxy resin in a liquid and solid state, which determines the sequence of work with its use.

The most popular among users are the following grades of transparent epoxy:

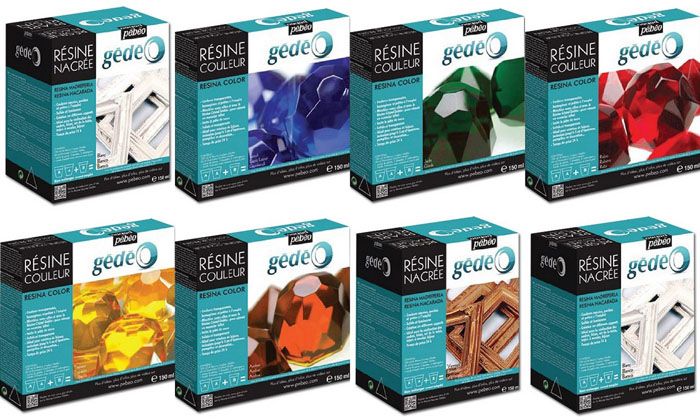

Colored

This type of epoxy resin differs from transparent only in that during its preparation, special fillers are used, which give the final product a certain color.

Fillers (surfactants) can be sold separately from epoxy, allowing you to choose a colorant according to the desired color or be factory-ready for further use.

Basic properties

The distinctive properties of epoxy, which make it a unique material, are the following:

All positive properties become inherent in the resin only after adding a hardener. The polymerization process takes place at an ambient temperature of -15 to + 80 ° C.

Chemical composition and components for epoxy resin

As already mentioned above, epoxy resin is a synthetic material based on oligomeric compounds. For its competent use, especially when performing creative ideas, it is necessary to have information about hardeners and plasticizers, fillers and solvents, using which you can expand the possibilities of using this material, as well as secure the performance of work with its use.

Hardeners

The hardener serves to polymerize the composition, under its influence the resin acquires a stable structure. Carboxylic acids and their anhydrides, as well as diamines can act as a hardener. Hardeners are classified as:

Amine - this is the most popular type of hardeners, characterized by ease of use and the absence of the need for special equipment for the preparation of the composition. The most popular brands are hardeners: "PEPA" and "DEET", "CHS-Hardener P-11" and "RC-19", and "Epilox H 10-40".

Plasticizers

The addition of a plasticizer gives the created composition plasticity and the ability to withstand external mechanical loads in the form of impact or impact on fracture. The most common plasticizers are:

Plasticizers for epoxy resins:

Excipients

Fillers can be used for technical and decorative purposes. Technical ones provide the necessary viscosity to the created composition, which is required when performing puttying and filling voids in building structures. The most demanded in this group of materials are Aerosil and "Microsphere".

Decorative - give the created product a certain color and texture. It could be quartz sand or a crumb of a different color. Colored fillers are especially in demand for a creative approach to the manufacture of products, regardless of whether they are pieces of furniture or decor, flooded floors or jewelry.

Solvents

There are times when the resin gets on the finished product or clothing during the manufacture of something, and it must be removed, while it has time to dry out. In this case, solvents come to the rescue, which can be used as acetone, toluene, ethyl acetate, butyl acetate or nail polish remover. In addition, solvents are used to reduce the viscosity of the resin, which is necessary when performing some operations with its use.

When using solvents, remember that:

How to use epoxy

When working with epoxy resin, certain proportions must be observed, because the ratio of hardener and resin affects the physical properties of the resulting product and the timing of its hardening.

How to dilute epoxy with hardener

The proportions of the hardener and resin, as a rule, are always indicated by the manufacturers of these substances on their packaging or in the accompanying documentation, which simplifies the process of preparing the final product. The general cooking procedure can be described as follows:

Preparation and use in large quantities

When pouring the floor or the manufacture of large structural elements of furniture, as well as interior items, a large amount of epoxy is required. In this case, the complexity of the work is to ensure uniform heating of the required volume and maintain a given temperature for a certain time required for its use. The desired result can be achieved using a water bath, with which the resin is heated to a temperature of +50 .. + 55 ° C with constant stirring, after which this temperature is maintained.

Preparation and use for small items

When preparing small volumes of epoxy resin, mixing is carried out in a cold way.

For normal bonding, the ratio of resin to hardener is 1:10, i.e. one measured part of the hardener contains ten parts of resin. Works are performed at room temperature. Stirring must be carried out with special care, the resulting composition should not contain air bubbles, it must have a uniform and viscous consistency.

Characteristics of the popular variety - brand ED-20

ED-20 grade is a two-component epoxy resin created on the basis of an oligomeric compound, for which a variety of bioorganic substances serve as a hardener. Depending on the hardener used and the proportion used, the physical properties of the resulting composition, as well as technical and operational characteristics, can vary significantly.

Epoxy grade ED-20 can be used for:

ED-20 is a non-explosive material, but when exposed to open fire it sustains combustion. According to the degree of danger to human health, ED-20 belongs to the 2nd hazard class, because contains in its composition toluene and epichlorohydrin in small amounts.

Safety rules when working with ED-20

In order to competently work with epoxy resin, you need to know what safety rules must be observed in the process of their implementation:

At what price to buy epoxy resin for creativity

Epoxy for creativity is a specific product that cannot be bought in a supermarket or a convenience store.The sale of such goods is carried out by trade organizations specializing in products of the chemical industry, selling paints and varnishes and goods for creativity. The price of epoxy resin in different organizations can vary greatly, therefore, before purchasing, it is necessary to study the market for these products, both when selling them live and through Internet resources.

In specialized companies, a fairly wide range of different types of resins and components for them is presented.

The following table shows the cost of various types of epoxy used for creativity, when sold over the Internet, as of the beginning of Q2 2018.

Video: "How to work with epoxy resin"

Epoxy resin products

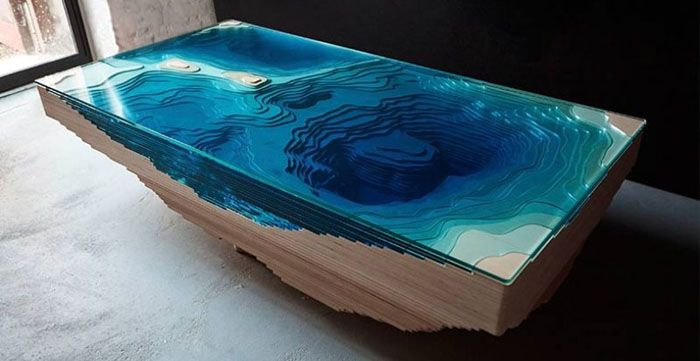

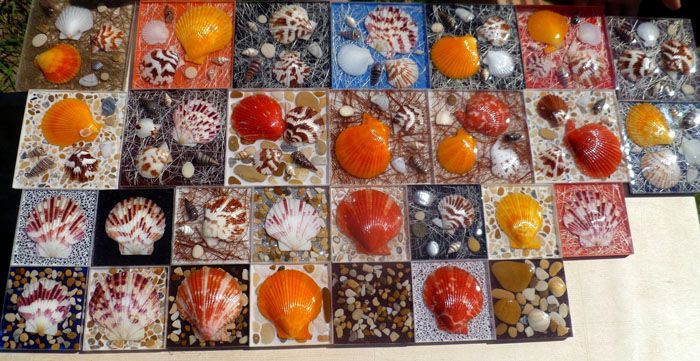

If you want to get creative, epoxy can be a very handy material, and here's what you can do with it.

Various room decor elements:

Furniture:

Jewelry and bijouterie:

In conclusion, I would like to note that epoxy resin is an easy-to-use material, therefore, when you want to start doing homework with its use, you should not put this business on the back burner, but get down to business right away. The flight of imagination and the experience of experienced craftsmen will help in solving the tasks.