DIY foundation on screw piles: phased construction

Budget construction requires a smart approach to materials and savings. The foundation is one of the most costly construction stages, accounting for about a third of all costs. Is it possible to somehow reduce spending? It turns out there is! Moreover, this method of arranging the base of the house not only allows you to save money, but also guarantees high strength and durability of the building. Meet the foundation on screw piles. To make such a structure with your own hands is quite within the power of any more or less competent builder. Its advantages and disadvantages, installation and finishing features are all about this in our material.

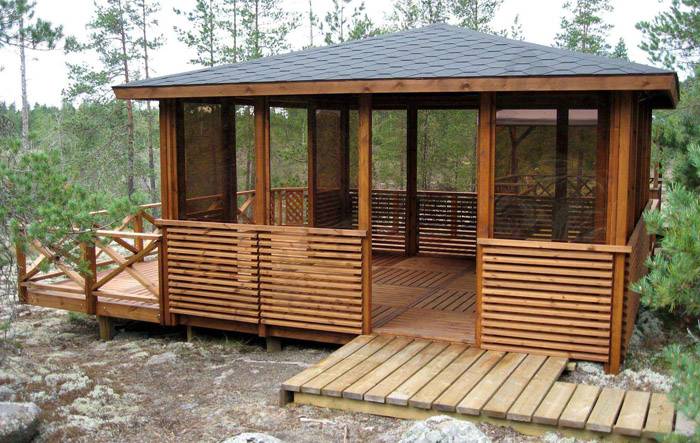

The use of pile supports allows you to create original structures without disturbing the natural landscape

The content of the article [Hide]

- 1 Screw pile foundation: main advantages

- 2 Pile foundation with monolithic grillage: reliable and durable

- 3 Cons of the pile-screw foundation and ways to eliminate them

- 4 How to choose screw piles for the foundation

- 5 Calculation of the pile-screw foundation

- 6 DIY pile foundation: step by step instructions, video

- 7 Construction of communications in the pile foundation

- 8 Foundation repair with screw piles: basic methods

- 9 SVF finishing

- 10 Outcome

- 11 Video: replacing the foundation during the reconstruction of a wooden house

Screw pile foundation: main advantages

The pile-screw foundation is suitable for wooden, frame houses and foam block buildings. This technology cannot be called new - it has long been used in industrial construction. For individual developers, such foundations are still a novelty, but they are gaining popularity more and more rapidly due to an impressive list of advantages. Let's consider in more detail why it is worth dwelling on this type of foundation:

Minimal, targeted intervention in the ecosystem will allow you to install a house even in the forest among century-old trees, without disturbing the natural landscape

And if you still have any doubts about the advisability of choosing in favor of a pile foundation, let's compare two types of structures:

After all these arguments in favor of screw piles, only the following questions remain:

Related article:

Pile foundation with monolithic grillage: reliable and durable

The foundation on piles with a monolithic concrete grillage is usually placed in areas with complex soil. Pile supports transfer the load from the building to denser soil layers, and the monolithic grillage evenly distributes this load. Such bases are suitable for almost any type of building: from foam blocks, wooden, frame.A similar foundation can be used not only for a residential blockhouse, but also for baths, for fence brick, garage or carport.

Such a construction on the site will be useful to any motorist. An overpass can be installed from 9-14 piles without the use of concrete pouring. A metal welded grillage is enough.

The combined reinforced concrete foundation on pile supports is far superior in strength to a conventional shallow foundation. The wood or metal of the grillage is subject to the adverse effects of external factors, and cast concrete structures can stand for centuries.

Types of SVF with concrete grillage:

Drives are rarely used under a house in private construction. Their installation requires the use of special equipment. But screw and boring is a more common option. They can be installed manually. Screws are screwed in by the efforts of two people, and for borers they drill wells, install formwork in them, reinforce and fill with concrete.

Experts recommend using a combined base for a stove or fireplace. Such a heavy structure in a wooden or frame house requires a separate foundation. For this purpose, the piles are placed by the cluster method - several pieces next to them with a minimum distance, and then tied with a reinforced concrete sole.

This correct approach will ensure the stability of the structure and the absence of skewing of the entire base due to uneven load distribution.

It makes no sense to install concrete grillages for a greenhouse, for a gazebo or for sliding gates. The loads on these objects are too small, and the costs of reinforcing and pouring reinforced concrete will not be justified. In all these cases, it is easier to use the light eco option - the usual screw piles, selecting their bearing capacity for a specific object.

Cons of the pile-screw foundation and ways to eliminate them

We examined in detail all the advantages of the SVF. But it would be correct not to forget along with the pros and cons. Forewarned is forearmed. Keeping this principle in mind, let us study the possible disadvantages of the pile foundation. If you take them into account and compensate for all the weaknesses during the installation process, you can not worry in the future whether the foundation is reliable, subsides or not, and what is its durability.

Moisture in the soil can "eat" your foundation in a matter of years if it is not protected by a reliable coating

Having considered all the arguments, we can say with confidence that when asked which is better, a strip foundation or screw piles, we can confidently say that SVF is more economical and easier to install, but on the condition that the piles are reliably protected and the house does not have a basement.

And it would be possible to end the conversation on this about the shortcomings of SVF, but today, literally on the heels of this technology, know-how in construction is coming: the TISE method. This installation option involves the use of a special drill, which creates depressions in the ground with an extension at the end, the so-called "cup".

Let's consider which is better: TISE or screw foundations:

Considering all of the above, it should be admitted: screw piles are the best foundation option for a lightweight house. Their few shortcomings can be easily compensated for by a competent installation.

How to choose screw piles for the foundation

The correct selection of materials is the key to the strength of the entire structure. This also applies to screw supports. How to choose the right screw piles for the foundation?

Blades

Piles are of two types:

Multi-blade piles have an additional level of fixation and are used on difficult, floating soils. They have good resistance to pressing and pulling out. At the same time, the installation of such supports requires additional effort and control. When deciding which piles are better to choose, it makes sense to focus on multi-blade.

Handpieces

Metal pile caps can be cast or welded. Welded ones are made of heavy plate iron. Their blades are welded to the tip. Such attachments are less resistant to stress and may deform during installation.In addition, weld spots are an additional risk factor for corrosion.

Cast tips will cope even with stony soil, their safety margin is higher than that of the pipe itself

Metal

Steel marked CT3 is suitable for soils with a low level of chemical activity. For aggressive environments, it is better to use CT20.

Coating

A high-quality coating will not only facilitate the process of installing the support, but also keep it for a long time. Manufacturers offer four types of support processing:

Each of the listed coatings has its own characteristics. The most durable are piles and galvanized and covered with heat shrinkage.

Calculation of the pile-screw foundation

An online calculator can be used to calculate the bearing capacity of a support.

Calculator for calculating the bearing capacity of a screw pile

The basic principle for studying the permissible load is based on data on the nature of the soil and the dimensions of the support. If you do not have complete information about the nature of the soil on the site, the calculator will make calculations based on the average values laid down in the SNiP. When deciding on the installation of the structure on site, it is worth laying additional support points for greater confidence in the strength of the base. Now you have an idea of how to calculate the bearing capacity of one pile.

Calculator for calculating the total load on the pile foundation

After calculating the bearing capacity of one support, it is easy to calculate the required number of piles. To do this, you need to find out the load of the entire building. The second calculator will help to calculate the weight of the building. It takes into account the weight of walls, ceilings, roofs and even the finishing of the building.

For calculations, you should indicate the dimensions of the future structure, the materials that are planned to be used for the construction of the house. The program will offer to select the types of floors from several options, as well as the shape and materials of the roof. For accuracy in the calculation, it is proposed to take into account the types of finishing of the building (ideally, the weight of people and furniture should be added to the result obtained). The result will be the result in tons.

To calculate the number of piles, it only remains to divide the total mass of the building by the bearing capacity of one support.

DIY pile foundation: step by step instructions, video

SVF is easy to install with your own hands. The technology is extremely simple and does not require any special skills and knowledge.

Step-by-step instruction:

In more detail the whole process of installing the SVF foundation in the video:

Construction of communications in the pile foundation

SVF pipes rise at a level from half a meter to a meter above the ground. This distance between the piles and the ground allows you to install all the necessary engineering networks without any problems:

What else is important to know when equipping a SVF:

Foundation repair with screw piles: basic methods

Sometimes there are situations when the existing foundation cracks or begins to sink rapidly. If the foundation is not strengthened in a timely manner, the entire structure may suffer.

All these symptoms require immediate treatment - reconstruction of the foundation. And it is better to do this before cracks appear on the walls and basement.

Reasons for damage to the foundation:

The easiest way to solve the question of how to strengthen the existing base is to use screw supports. This technique is the most economical and easy to implement.

There are two methods for repairing a foundation:

Before choosing one or the method, it is necessary to study the state of the structure and the possibility of its transportation to a new place or lifting on jacks. Dilapidated buildings may not withstand such procedures

After repairing the foundation, it is necessary to decide how to close the new foundation. Roofing material should be used to cover all joints of walls and grillage. All metal parts of the foundation must be painted with epoxy paint, and the wooden parts with anti-mildew and insect repellent.

It remains only to choose a way to finish the base. There are many interesting solutions for the design of SVF, which should be discussed separately.

SVF finishing

The screw foundation can be designed in different ways. For cladding, basement siding, stone tiles, polyvinyl chloride panels, and ceramic tiles are used.

In order not to add loads to the base, experts recommend using light materials for decorating the basement

Decorative materials are attached to metal or wooden planks. For insulation of the foundation, you can use expanded polystyrene skirting or stone wool. The last stage of finishing will be the creation of a high-quality blind area that diverts storm water from the house.

More details on how to insulate and how to finish a pile foundation in the next video.

Video: finishing the pile foundation

Outcome

The pile-screw foundation is an easy-to-install and cheap construction. With all this, the base on screw piles is distinguished by its reliability, durability and maintainability. When choosing piles, you should pay attention to the quality of the material. It is better if the screws are cast, the coating is zinc or polymer. All installation work can be done by hand, but you should first study the nature of the soil at the construction site.

Video: replacing the foundation during the reconstruction of a wooden house