High-quality sandwich panel garage: secrets of craftsmanship and step-by-step construction instructions

A large garage made of sandwich panels is used to store various things, organize a home workshop, and solve other household tasks. With the help of the recommendations of the homemaster.techinfus.com/en/ editorial office, you can build a high-quality building with your own hands. We will help you prepare a technical assignment and give clear recommendations what you need to know about when building a turnkey structure.

The content of the article [Hide]

- 1 Advantages and disadvantages of a sandwich panel garage

- 2 What determines the performance of sandwich panels for a garage

- 3 Overview of projects for garages made of sandwich panels and metal frames

- 4 Preparatory stage for the construction of a do-it-yourself garage from sandwich panels

- 5 How to build a garage from sandwich panels with your own hands

- 6 Features of the operation of a garage made of sandwich panels

- 7 The price of a garage made of "turnkey" sandwich panels - an overview of the market offers with comments

- 8 Do-it-yourself video of installing a garage made of sandwich panels

Advantages and disadvantages of a sandwich panel garage

These building materials are created in the factory with careful verification of the technical parameters of each batch. Responsible manufacturers ensure the service life of finished products up to 50 years or more. In addition to durability, other important benefits should be noted:

- Low weight of structural components, which means lower transportation costs and lower requirements for base strength.

- Simplicity of assembly operations and disassembly. Secondary use of sandwich panels for their intended purpose is acceptable.

- Excellent insulating properties do not need to be improved if the correct preliminary calculation is made taking into account the climatic characteristics of the region.

- The flawless appearance also does not have to be changed if there are no special wishes.

- Environmentally friendly components do not pollute the environment and indoor atmosphere.

The disadvantage is the high price of quality products. However, taking into account similar costs for the construction of housing from other materials, the cost of a garage made of sandwich panels can be called democratic. Brick walls, for example, you need to insulate.

There is an opinion about the limited strength of the panels. However, this problem is completely solvable if you use a suitable power frame. The work on sealing the joints should also not be difficult. After all, such work is done practically during the installation of many structures.

What determines the performance of sandwich panels for a garage

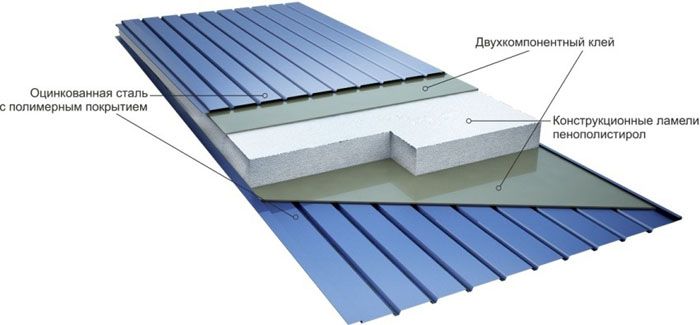

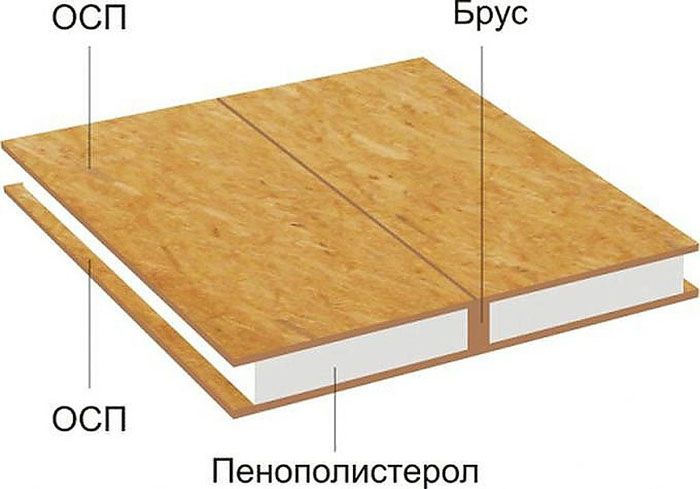

The outer thin walls are made of durable materials. A filler with voids is placed between them, which has improved insulating characteristics.

Walls and roofs are made from such slabs. In low-rise construction, vertical installation of elements is used. Tall structures are erected using a horizontal scheme.

Insulation materials

The price of a modular garage made of sandwich panels largely depends on the chosen filler.

| Material / Manufacturing Standard (GOST) | Benefits | disadvantages |

|---|---|---|

| Mineral wool / 32603-2012 | Fire safety, reasonable cost, dense filling of cavities with complex shapes. | Low strength. Rapid deterioration of useful characteristics when moisturized. Considerable weight. |

| Expanded polystyrene / 15588-2014 | Minimum cost, low weight, moisture resistance. | Without special additives (fire retardants), the foam is highly flammable. With the use of such components, the ignition temperature is increased. |

| Foamed polyurethane / 23486-79 | Low thermal conductivity. The material does not allow water to pass through, therefore it is capable of performing the functions of a waterproofing layer. High strength. | Destroyed by ultraviolet radiation. |

| Foamed polyisocyanurate / 23486-79 | Increased resistance to sunlight, open flame, aggressive chemical compounds. Excellent thermal insulation performance. | The cost of the material is higher compared to the options above. |

Sandwich panel cladding

The affordable price of pre-fabricated garages for their sandwich panels is explained by the low cost of typical cladding. A profiled steel sheet with a thickness of 0.4-0.5 mm is used. It is protected from corrosion by cold or hot zinc plating. Additionally, create a protective and decorative layer of powder paint, polymeric materials. Special fireproof materials are often used.

Technical parameters of sandwich panels

To build a high-quality sandwich panel garage, you need to carefully study the load and features of use. Wall and roof sandwich panels for a garage are produced in widths of 100 and 120 cm. Lengths range from 50 cm to 13.5 m. For a fairly large order, the manufacturer will create a product with the required dimensions.

| Insulating material | Panel type | Weight with different thickness of the sandwich panel, kg / m2 | ||

|---|---|---|---|---|

| 50 | 100 | 150 | ||

| Mineral wool | Wall | 16,5 | 22 | 27,2 |

| Roofing | 17,5 | 24 | 30,5 | |

| Expanded polystyrene | Wall | 11,7 | 12,5 | 14,2 |

| Roofing | 12,2 | 13,5 | 14,7 | |

| Polyurethane foam, expanded polyisocyanurate | Wall | 9,2 | 11,2 | 14 |

| Roofing | - | 12,4 | 14,4 | |

With effective sound insulation, noisy work in the garage workshop will not disturb the residents of the house and neighbors

| Insulation | Characteristics of 100 mm thick sandwich panels | |||

|---|---|---|---|---|

| Density, kg / m³ | Thermal conductivity, W / Mk | Sound insulation, dB | Thermal resistance (Rt) | |

| Mineral wool | 105-140 | 0,05 | 32 | 2,08 |

| Expanded polystyrene | 10-25 | 0,042 | 32 | 2,56 |

| Polyurethane foam, expanded polyisocyanurate | 41 | 0,022 | 32 | 4,76 |

With such a thickness, the fire resistance of a sandwich panel with mineral wool / expanded polystyrene fillers complies with the EI 90 / EI 15. This means that in case of fire or high temperature exposure, the integrity is maintained for 90/15 minutes, respectively.

| Roof span length, cm | Bearing capacity under uniform load for sandwich panels of different thickness, kg / m² | ||

|---|---|---|---|

| 50 mm | 100 mm | 150 mm | |

| 150 | 214 | 115 | 95 |

| 250 | 251 | 172 | 141 |

| 300 | 272 | 213 | 188 |

The distance between the wall supports is set no more than the values below. The calculation is made for a wind load of no more than 45 kg / m²:

Overview of projects for garages made of sandwich panels and metal frames

When a ready-made set of a garage made of sandwich panels with installation is purchased, the price is checked for individual items. Detailed drawings will help you compile a list of materials.

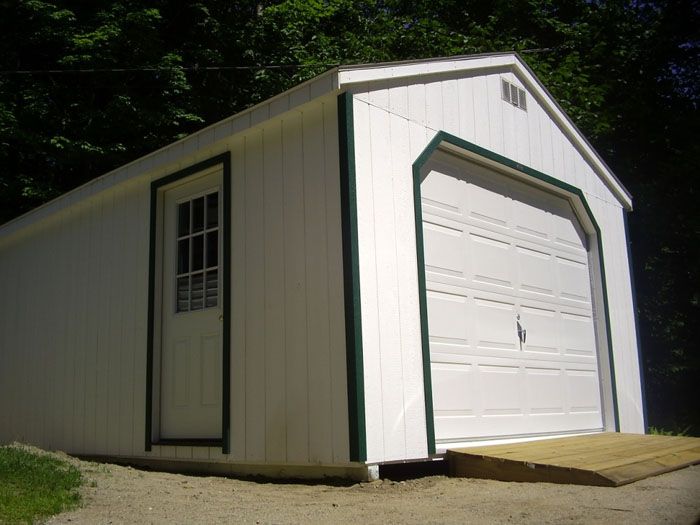

Single-storey sandwich panel garages

Such structures do not create a large load. In some situations, a ready-made asphalt area or other surface with a sufficiently hard and even surface is used.

In this version, an additional support is created by the main wall of the house. However, during operation, gaps may appear for the following reasons:

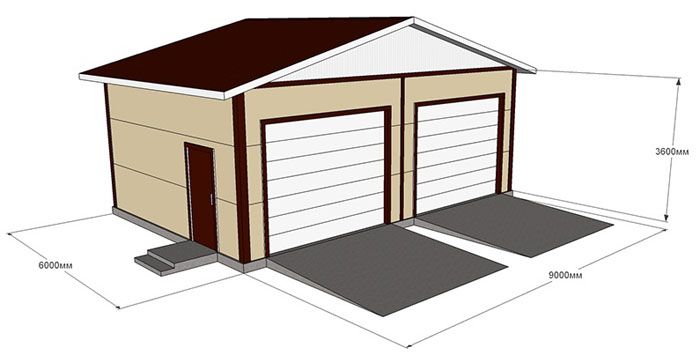

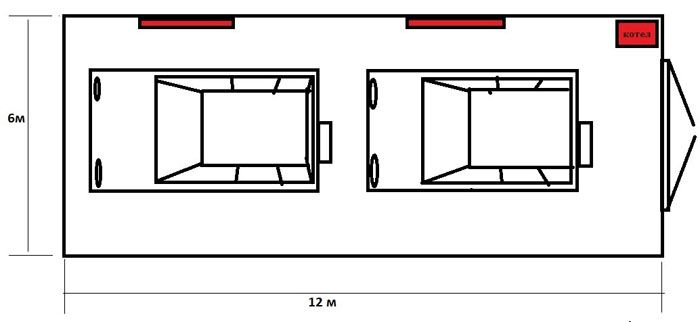

The length of the walls is chosen so that after placing the car inside, there is a free distance of 100-150 cm from all sides. The standard solution is 400 × 600 cm with a gate width of 2.4-2.7 m.

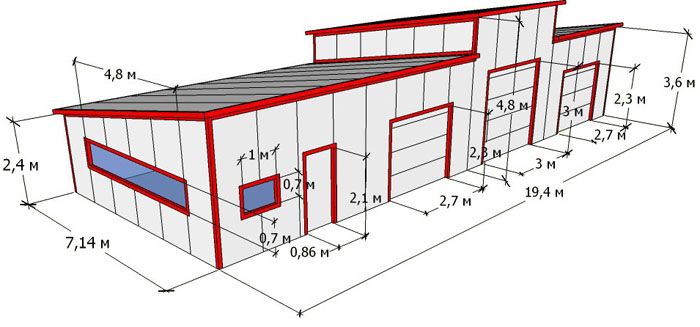

With the help of such a drawing, it is easy to determine how many wall and roof sandwich panels will be needed to build a garage.

With a lack of free space, such narrow structures are used. You should consider the mode of use in order to minimize inconvenience during operation.

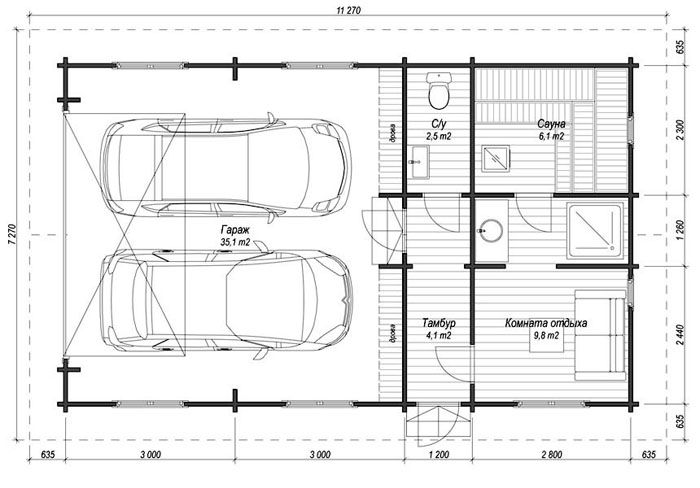

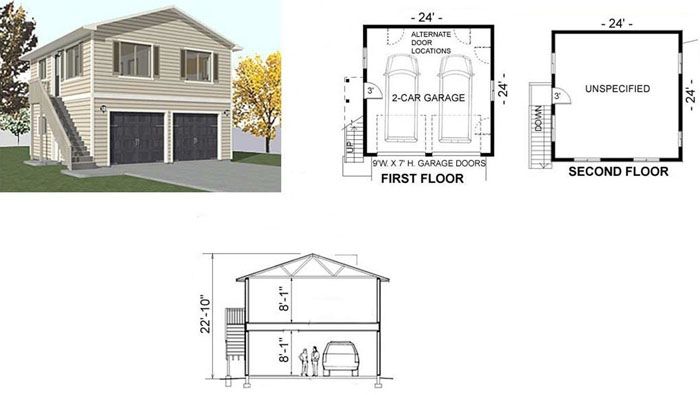

Two-storey sandwich panel garages

In this design, the structure takes up less space on the land. The additional usable area is useful for placing a workshop, warehouse and other technical premises.

This example shows a staircase that is installed outside. It must be understood that such solutions are suitable for southern latitudes. The use of an open lift in a frosty snowy winter is significantly difficult.

Two-story buildings are constructed from solid sandwich panels, which are installed vertically. In this version, the floor is strengthened, which is expected to withstand certain loads with a margin. Be sure to take into account the weight of furniture, equipment.

Preparatory stage for the construction of a do-it-yourself garage from sandwich panels

If you buy a prefabricated garage made of sandwich panels, the price will include a standard project. For self-construction, they use ready-made solutions or prepare design documentation based on an individual technical assignment.

Tools and supplies

For a garage, sandwich panels with steel profiled sheathing are suitable.It is recommended to choose basalt fiber filler to increase fire resistance. In domestic climatic conditions, walls made of materials 100-150 mm thick will provide reliable protection from the cold. But the roof is additionally insulated.

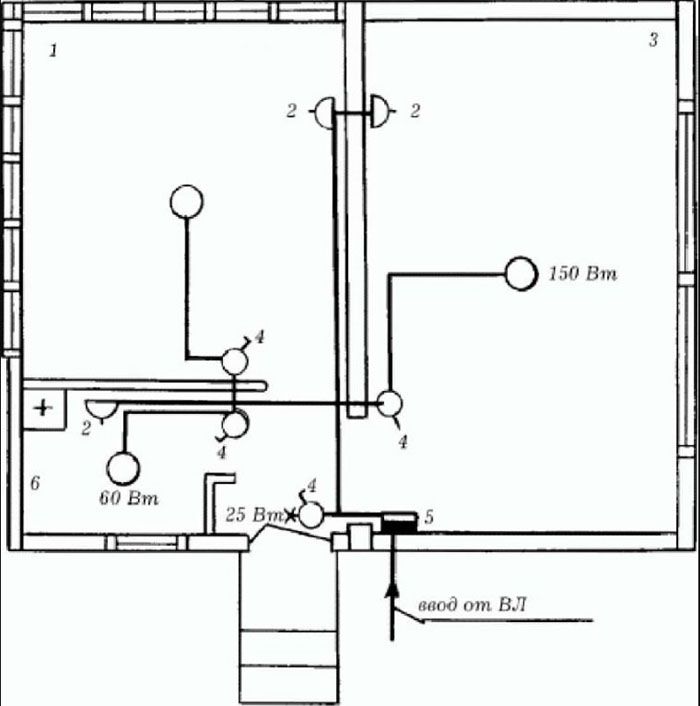

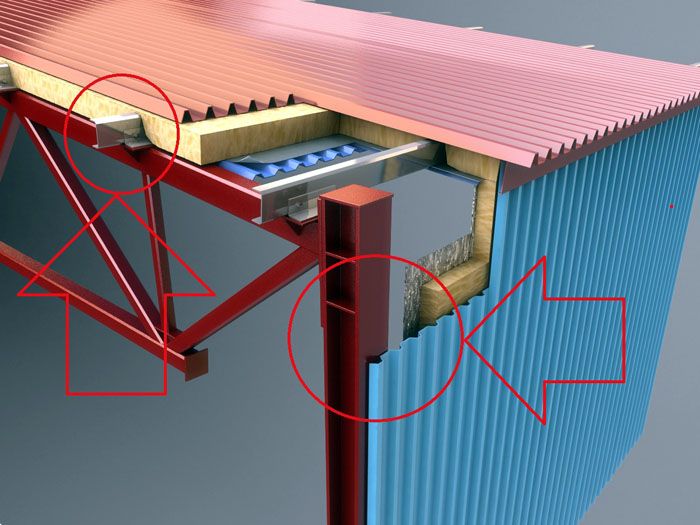

However, it should be understood that cold bridges are formed in the places marked in the figure. They significantly degrade the insulating characteristics of the structure. Steel channels and other parts of the frame are selected taking into account the requirements of the project. You must first prepare:

Calculation of the number of sandwich panels, concrete and reinforcement

Manufacturers offer special calculator programs on their official websites. With their help, you can make an accurate calculation of material consumption and its cost. Let's give an example. Let's say you want to create a building with the following initial parameters:

If you order such a garage made of sandwich panels, the price of the set will be determined according to the following table.

| product name | Quantity, pcs. | Average price (as of June 2018), in rubles |

|---|---|---|

| Wall sandwich panel 3000 × 150 mm | 12 (36 m²) | 61920 |

| Wall sandwich panel 3700 × 150 mm | 4 (14.8 m²) | 25456 |

| Wall sandwich panel 4000 × 150 mm | 2 (8 sq. M.) | 13760 |

| Roof sandwich panel 2300 × 200 mm | 14 (32.2 m²) | 67298 |

| Galvanized channel 3000 × 38 × 152 mm | 6 | 3900 |

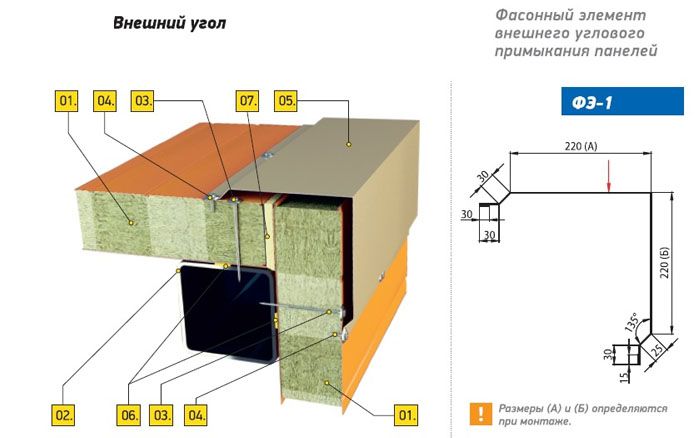

| Outer corner 3000 × 180 × 180 mm | 4 | 2800 |

| Inner corner 3000 × 40 × 40 mm | 7 | 1050 |

| End roof plugs | 14 | 3640 |

| Upper ridge | 3 | 2250 |

| Lower ridge | 3 | 1800 |

| Roof insulation gasket | 14 | 700 |

| Self-tapping screws for wall panels | 100 | 1700 |

| Bolt caps | 100 | 1200 |

| Self-tapping screws for roof panels with plugs | 100 | 9800 |

| Screws 8 × 16 | 1000 | 800 |

| TOTAL | 201674 | |

The calculation of concrete consumption can be done using the simplest mathematical formulas. For the installation of a one-story garage made of sandwich panels, a strip foundation with a width / height of 30/40 cm is suitable.It is not difficult to calculate the total length (300 × 2 + 600 × 2 = 1800 cm) and the volume of the building mixture (0.3 × 0.4 × 18 = 2.16 m³). Similarly, the values for the slab base are obtained: 3 × 6 × 0.2 = 3.6 m³. The amount of reinforcement is calculated taking into account the dimensions of the space lattice being formed. For the structures under consideration, a rod pitch of 15-20 cm is used.

Related article:

How to build a garage from sandwich panels with your own hands

After careful preparation, the assembly of the structure will take no more than two days. The only delay is the period of solidification of the foundation. In summer at temperatures from +18 to + 22 ° C, approximately 80% of the nominal strength will be gained in 14-20 days. For accurate calculation, use specialized tables. Below are the features of the most important assembly operations.

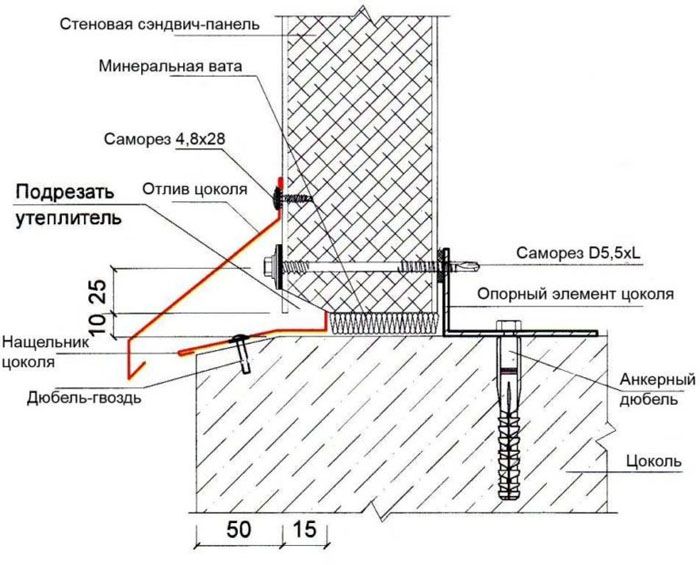

Creation of a foundation for a garage from sandwich panels

To mark the base, use wooden stakes and a rope of suitable length. Dig a trench with dimensions for the design foundation. The bottom is leveled, covered with moistened sand. The backfill is rammed until a dense layer of 10-12 cm is obtained. Gravel is placed on top. The formed structure provides damping in severe frosts, preventing damage to the foundation by soil heaving.Additionally, a local drainage system.

The bottom and walls are covered with roofing material or other insulating material. Pour concrete mixture, level the surface. Alternatively, you can make a solid base from concrete blocks. Slab and pile foundations are used on soft soils.

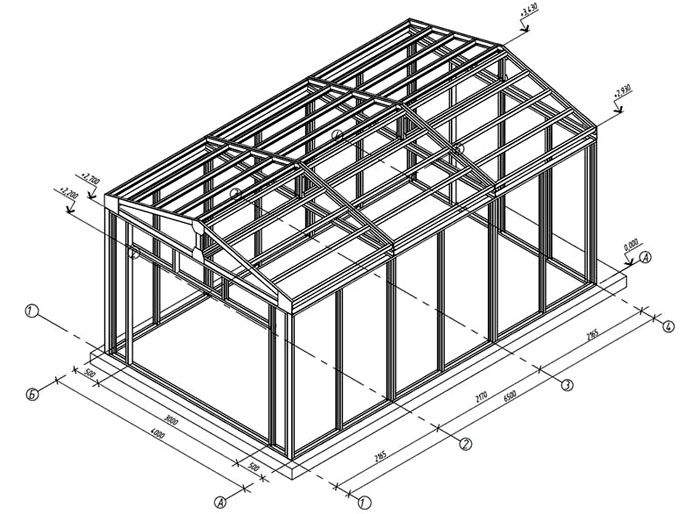

Erection of a frame for a garage from sandwich panels

The power part of the structure can be made of wooden beams with a cross-sectional area of 10 × 10 cm. It is easier to work with such a material than with metal. However, it will need to be well protected from decay. For this, specialized deep impregnation is used.

The metal parts of the frame are bolted or welded. In the first case, standard simple tools are used. The second will require specialized technological equipment.

Installation of wall and roofing elements

When performing these working steps, pay attention to the following nuances:

- The edges of the garage sandwich panels are insulated from direct contact with the foundation.

- The top and bottom profiles are used for connection. At high heights, an additional horizontal crosspiece is used.

- Self-tapping screws with rubber gaskets are used to prevent moisture penetration.

- The distance between them is kept no more than 50 cm.

- A sealant is applied to the joints between the plates. A specialized sealing tape is also used.

- At the end of the roof overhang, a gutter is installed to collect and drain rainwater.

Polymers are easily damaged by high temperatures, so the grinder is used only on a steel shell. To exclude wrong actions, it is recommended to order products with the required dimensions directly from the manufacturer (seller).

Features of the operation of a garage made of sandwich panels

Sandwich panels are not used as load-bearing structures, they must be fixed to the frame! It is better to choose materials with a special coating that prevents corrosion. To remove dirt, use detergents that do not contain aggressive chemical compounds and abrasive components.

Related article:

The price of a garage made of "turnkey" sandwich panels - an overview of the market offers with comments

It is necessary to remember that when building a garage from sandwich panels, the final price depends not only on the configuration. The basic cost does not indicate delivery, installation work. The type of foundation chosen, the composition of engineering equipment and networks are of certain importance.

Use the post comments for more information. Post your own thematic notes and tips here.

Do-it-yourself video of installing a garage made of sandwich panels