Aerated concrete blocks: sizes and prices per piece, features and advantages

Aerated concrete blocks have unique properties that make it possible to successfully use this material in the construction of various buildings. Before choosing products, you need to find out the most common aerated concrete blocks, the sizes and prices of which are of great importance. Brick and stone are traditional building materials, but they are not available to everyone. Aerated concrete has a low cost, which affects the growth of its popularity. Even novice builders can work with such material.

The content of the article [Hide]

- 1 What is aerated concrete and its scope

- 2 Material specifications

- 3 Pros and cons of aerated concrete blocks

- 4 Aerated concrete or foam concrete: which is better?

- 5 Features of the calculation of aerated concrete blocks for construction

- 6 Aerated concrete block calculator for home

- 7 Aerated concrete blocks: sizes and prices per piece

- 8 Material tips

- 9 Video: building a house from aerated concrete blocks

What is aerated concrete and its scope

Aerated concrete block is an artificial stone that belongs to the group of cellular concrete, consisting of cement and sand. This material is produced using gassing technology. In some cases, lime and ash are added.

When choosing aerated concrete blocks, sizes and prices per unit are taken into account, as well as the following criteria:

- planned load on the walls;

- thermotechnical characteristics;

- block sizes and overall dimensions of the building;

- options for simplifying installation work.

Gas blocks are used for the construction of various buildings: baths, garages, houses and even gazebos. Made from this raw material fences, foundations and basement.

Material specifications

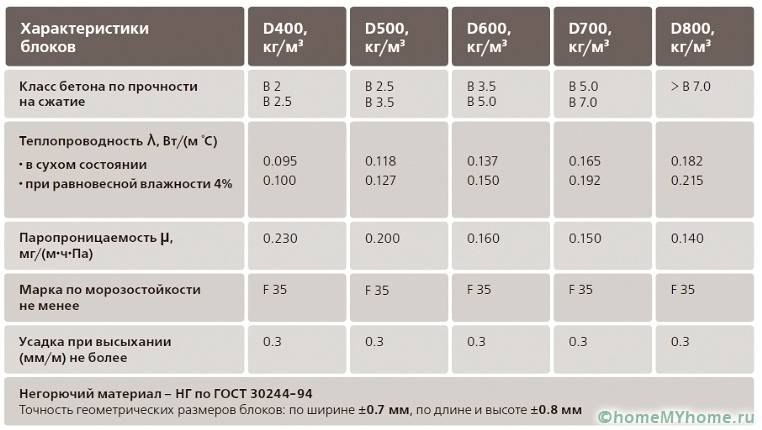

When choosing aerated concrete blocks, as well as studying their sizes and prices per piece, you must have an idea of the main technical characteristics.This material is characterized by the following indicators:

- Blocks with smooth edges have standard parameters.The length varies within 500-600 mm, the height is 200 mm, and the thickness can be 75-500 mm.

- Differs in a small mass, which is facilitated by a special density. This indicator has the following markings: D 500, 600 and 700. Indicator D 600 means that the weight of the block is 600 kg.

- The thermal conductivity of aerated concrete is 0.13 W / m ° C. The walls of the material are warm and warm up quickly.

- Differs in low strength from 1.5 MPa to 4 MPa.

- Aerated concrete is a non-combustible material.

- Compared to alternatives, these blocks are highly resistant to frost.

- Many manufacturers provide a warranty of up to 80 years.

- Aerated concrete is characterized by good bearing capacity.

Types of aerated concrete material

Depending on the manufacturing technology, the following types of blocks are distinguished:

- Autoclave or synthetic hardening process. The solidification process takes place in special autoclaves at high temperatures.

- Non-autoclave or hydration solidification is created in a saturated vapor environment using an electric heating device.

Also, depending on the main binder, products can be divided into:

- Cement, consisting of half of cement mortars.

- Calcareous are high in lime.

- Slag contains more than half of the mixtures of gypsum and slag.

- Ash is characterized by a significant content of highly basic ashes.

There are also mixed blocks. Containing lime, slag and cement.

Pros and cons of aerated concrete blocks

The demand for aerated concrete depends on the numerous advantages of the material. The following advantages are worth highlighting:

- The material is easy to process. Any shape can be made from it.

- Low weight with significant dimensions.

- Good level of heat saving.

- Tall sound insulation index... This property is provided by cells filled with air.

- Aerated concrete does not burn and is characterized by increased frost resistance.

- Good environmental performance.

Also, the material has certain disadvantages:

- The higher the density index, the lower the thermal insulation performance.

- It is characterized by inelasticity, therefore cracks may appear when the foundation is deformed.

- In construction, products are used only with a density of more than 500 kg per cubic meter. meter.

- The porosity of the structure does not allow the use of conventional fasteners.

- It is imperative that vapor barrier sheets are laid during the installation process.

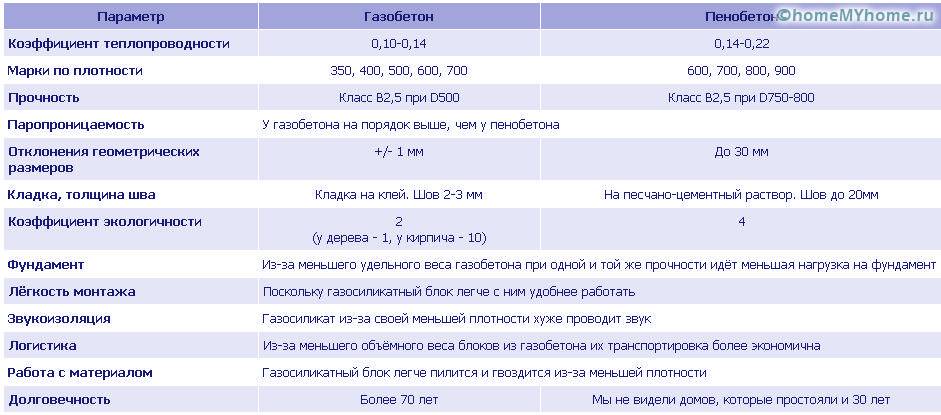

Aerated concrete or foam concrete: which is better?

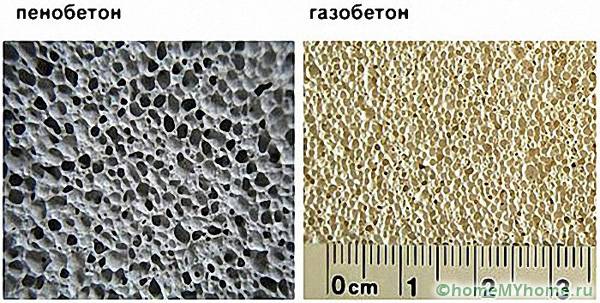

When deciding which gas blocks or foam blocks are better, you should know that both artificial stones have almost equal characteristics. They have a similar composition, light weight, but differ in manufacturing technologies. Foam concrete hardens in a natural way, and heat treatment is used for aerated concrete.

Foam blocks can be made in artisanal conditions, which is not always good for the end user. Gas blocks are manufactured at the factory, where the required production standards are observed.

Related article:

Foam concrete can have toxic properties, since with the natural method of hardening, some chemical processes may not go through all the stages to the end. Aerated concrete is considered a more durable material.

Video: comparison of aerated concrete, foam concrete and polystyrene concrete blocks

Features of the calculation of aerated concrete blocks for construction

A correctly performed calculation will help to save you from acquiring unnecessary material. The following formula is used to calculate the amount of material:

V = (H * L-S) * 1.05 * B, Where

H - the height of the walls made of aerated concrete.

L - the total length of the walls.

S - the value of the area of all door and window openings.

1,05 Is a factor that takes into account a 5% trim margin.

IN - the thickness of the blocks.

V - the amount of material required for the building.

Aerated concrete block calculator for home

Aerated concrete blocks: sizes and prices per piece

A large number of companies are engaged in the production of this material. Among the well-known manufacturers, it is worth highlighting: SilAbit, Eco, Bonolit and Poritep. The companies have large production facilities.Material price depends on thermal conductivity coefficient and the density of aerated concrete. Aerated concrete blocks are popular, the size and price per m3 of which is 2500-2700 rubles.

Products should be inspected for external damage and uniformity prior to purchase. Also, you need to ask the seller for documents of the quality of the goods.

Related article:

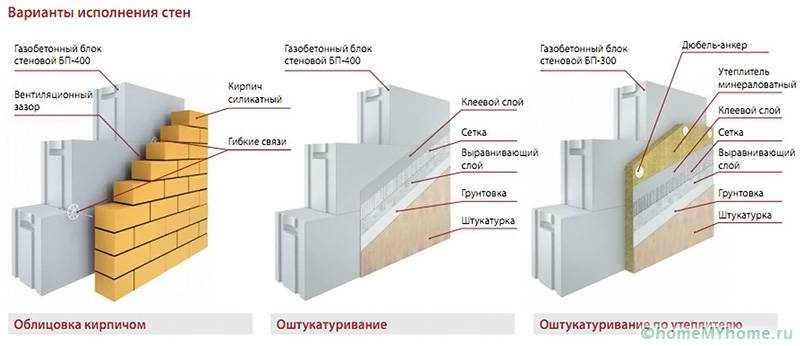

Material tips

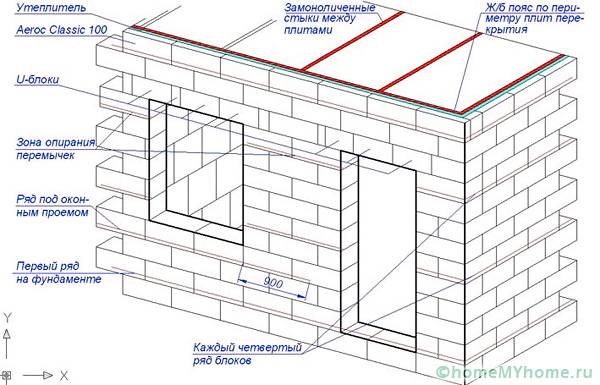

The following recommendations will help to build a house using gas blocks:

- The blocks are mounted on glue. A special trowel is used to create seams.

- To perform the strobe, a grinder with a diamond disc is used.

- To speed up the construction process, you can use special blocks of a suitable shape to create openings.

- Laying of rows of aerated concrete is carried out using a level. This will ensure smooth surfaces and no deformation in the future. A grinder is used to adjust the blocks.

- It is not recommended to install from two corners at once.

- For cutting aerated concrete, you should not use an ordinary hacksaw, you should use a special saw.

An overview of the technical characteristics, properties and dimensions of the material will allow you to make the right choice for the construction of inexpensive and comfortable housing.

Video: building a house from aerated concrete blocks