Geotextile for drainage (geotextile) - a permeable layer with an important function

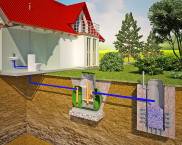

With a high level of groundwater on the territory of a suburban area, work is often carried out to drain moisture using pipelines. In modern systems, geotextiles for drainage (geotextile) are necessarily used. The use of a water-permeable layer makes it possible to protect elements with perforation from contamination, and the bulk material from creeping.

The content of the article [Hide]

- 1 Considering the general benefits of the material

- 2 Drainage geotextile (geotextile): a suitable type of product and some manufacturers

- 3 What geotextile to use for drainage on the site

- 4 The process of laying the sheets and the device of drainage

- 5 The cost of products from well-known manufacturers

- 6 Summarizing

- 7 Video: what density to choose geotextile for the drainage system

Considering the general benefits of the material

An important advantage is a high level of resistance to aggressive environments, so the service life of products when in the ground is very high. Due to sufficient elasticity, the sheets of the material do not break against stones and other objects that come across during laying.

The strength of the geotextile is very high. Plant roots, stones, soil movements and other light mechanical influences are not capable of violating the integrity of such canvases. Despite the increased strength characteristics, the material is well cut with a conventional knife.

The polymer layer retains its basic characteristics in the temperature range from -60 to +110 degrees, that is, abnormal heat or severe frosts do not have a negative effect on it.

Drainage geotextile (geotextile): a suitable type of product and some manufacturers

Non-woven geotextiles made of threads or fibers located in a chaotic or ordered state are more suitable for the device of drainage systems. The fastening of the elements is most often carried out using a needle-punched or thermal method.

The main raw materials are usually:

Two types of threads can be used in the manufacture:

The laid sheets of long fibers are pulled out when the ground is displaced, and not torn, ensuring reliable water drainage. As for the staple threads, they may not withstand the load when the soil moves, therefore they are used where the earth does not crumble much.

Related article:

Dornit nonwoven geotextile

The products of this manufacturer, with high quality, are quite affordable. The production is based on polyester fiber. To appreciate all the advantages, it is necessary to familiarize yourself with the technical characteristics of Dornit geotextiles in more detail.

Table 1 . Technical characteristics of geotextile Dornit

Non-woven analogue Geotex

Geotex products can be used as an alternative. In terms of its characteristics, it is similar to the aforementioned material. However, in the manufacturing process, polypropylene fibers are used, not polyester. As for the cost, the presented products are quite comparable by this criterion.

What geotextile to use for drainage on the site

Each of the listed manufacturers offers different weights to suit specific situations. The scope of application of the polymer layer is very wide. Webs of the material are also used in paving, building geotechnical structures and strengthening slopes.

How to choose the density of geotextiles when draining a site

For the construction of a system for removing excess moisture directly from the site, a material is needed that will combine rigidity, elasticity and good throughput. With an increase in the density of the membrane, its strength characteristics increase, but at the same time water permeability decreases, so something in between should be chosen.

Best of all, a canvas with a density of 200 to 300 g / cc copes with the drainage function. m. If you choose a layer with lower rates, then the risk of damage will be very high. With an increase in density, the membrane surface will quickly silt, which will significantly reduce the efficiency of the entire system.

Additional recommendations for the choice of material

The process of laying the sheets and the device of drainage

In order for geotextiles for drainage (geotextile) to reliably perform the functions that are assigned to it, certain rules and a certain sequence of actions should be followed during laying.

The cost of products from well-known manufacturers

Consumers, immediately before arranging moisture removal systems from their own site, should study the cost of all elements. As for the prices for drainage geotextile per m2, they are presented in the table. Products of all brands have a density of 200 g / sq. m.

Table 2. Average cost of geotextile for drainage

Summarizing

If we refuse to use geotextiles for drainage (geotextiles) when carrying out work, then in the near future we can expect a decrease in the efficiency of the entire system. Modern moisture removal networks cannot be imagined without the use of this material, which plays an important role in the drainage network of pipelines.

Video: what density to choose geotextile for the drainage system