When the beauty and durability of the coating come together: porcelain stoneware for floors

Porcelain stoneware for floors is a derivative of ceramic tiles, with improved characteristics of strength, wear resistance and a whole range of decorative and applied qualities. This floor covering is increasingly found in interiors. The homemaster.techinfus.com/en/ editorial board decided to explain this popularity. Let's find out the secret of porcelain stoneware tiles and all their advantages.

The content of the article [Hide]

- 1 Production technology: how to make high-quality flooring

- 2 Operation of porcelain stoneware for the floor: qualities and characteristics

- 3 What are the types of porcelain stoneware floor tiles

- 4 Advantages and disadvantages of porcelain stoneware flooring

- 5 Format and thickness information

- 6 Additional features of the decorative floor: imitation of different materials with porcelain stoneware tiles

- 7 Tips for choosing a porcelain stoneware coating

- 8 Installation of floor porcelain stoneware: stages of work

- 9 Do I need to care for the porcelain stoneware floor

- 10 Leading manufacturers: who to trust

- 11 Video: how to choose porcelain stoneware products

Production technology: how to make high-quality flooring

The parameters for the production of porcelain stoneware are similar and, at the same time, different from the production of ceramic tiles. The result is the strongest products.

To obtain a porcelain stoneware coating, the recipe uses refractory clay as a binder, kaolin as a substance for strength, quartz sand as a filler, crushed feldspar to reduce the sintering temperature and the substance responsible for the "vitreous" phase in the process, and, of course, pigments that color products.

Production is carried out in several stages. First, the necessary ingredients are kneaded in certain proportions, the whole mass is crushed to a certain fraction. Then everything is mixed with water and electrolyte, then the composition is to be dried at a temperature above + 600 ° C.

The entire mixture with a moisture content of up to 7% enters the mold. First, air is removed from the powder mixture under pressure, then the pressure is increased to 400 kg / cm². As a result, products have low porosity and high density.

The next step is painting and applying substances that make the tiles glazed and polished. After that, drying begins at temperatures of + 500-600 ° C, then the most important firing phase begins.

Operation of porcelain stoneware for the floor: qualities and characteristics

All characteristics correspond to GOST R 57141-2016 “Ceramic slabs (porcelain stoneware). Specifications "(current standard as of January 2019).

Consider the characteristics that make this coating so attractive for flooring.

Durability and abrasion resistance

The strength of porcelain stoneware is so high that it can be laid outdoors: the declared figure is 100 cycles. This number says more if you look at the concrete frost resistance index: only 55 cycles.

If we take the Mohs scale, then the indicator is 7-8, like corundum. Porcelain stoneware does not damage quartz sand, which is considered a hard natural abrasive.

The thickness of the cladding should be at least 8.5 mm, since the impact elasticity of this material is equal to that of conventional ceramics. But the flexural strength exceeds ceramics by 1.5 times, and natural granite by 3 times.

Basically, they produce porcelain stoneware with wear resistance classes 4 and 5, so the pedestrian load is, in fact, unlimited. If a class 3 product is found, it is most likely glazed: kitchens, bathrooms, and toilet rooms are lined with this coating.

Moisture resistance and resistance to loads

The moisture absorption is reported by the number 0.05%. This also indicates high frost resistance, the possibility of calm contact with household chemicals of any type and sea water.

The moisture resistance parameter plays an important role where the cladding is made in an unheated room or in places where there is a high humidity level... Water that seeps inside gradually destroys the material, therefore this indicator is very important.

Glazed and unglazed porcelain stoneware has different moisture resistance indicators, you should always pay attention to this when choosing a coating.

Speaking about the hardness of porcelain stoneware, they are guided by an indicator of 7 points out of 10 in terms of resistance to loads. Here the density is important, which is equal to 1400 kg / m³ with a specific gravity of 2.25-2.45 g / cm³.

Other characteristics

It is important to know how slippery the floor will be. Matt unpolished grades give a value in R10, glazed in R7.

The dry state of the tiles gives an electrical conductivity equal to zero, when wet, this indicator is equal to the electrical conductivity of the liquid.

There is also a chemical resistance parameter with a maximum value and EAA marking.

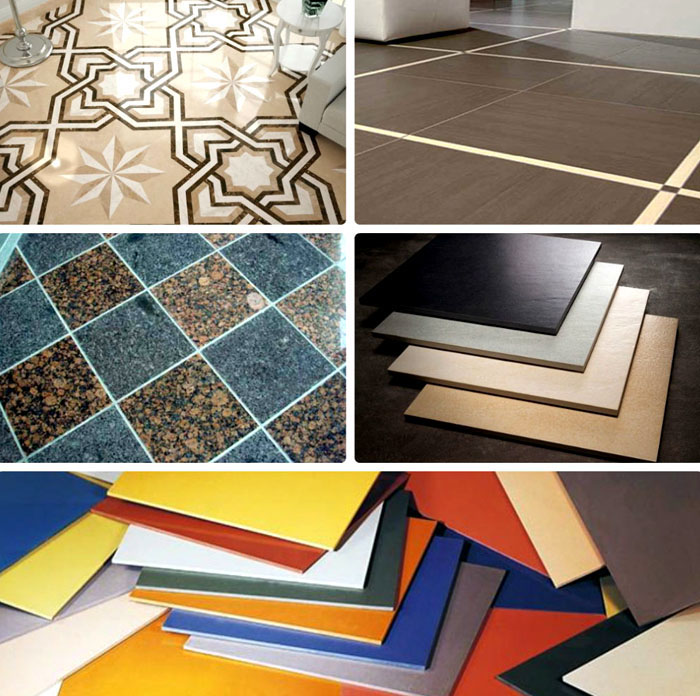

What are the types of porcelain stoneware floor tiles

The production method and raw materials greatly influence the decorative effect of the products. You can buy slabs that are homogeneous in composition, in which the pigment is added even at the kneading stage, or two-layer, with partial coloring. In this case, the color is applied only to the front layer of the product.

The aesthetics of glazed porcelain stoneware match those of ceramic tiles, only with a much greater wear resistance of the top layer.

The front surface is matte, that is, unpolished. This variety does not look particularly aesthetically pleasing, but the performance is high.

The gloss on the surface of polished tiles is obtained by sintering to a glassy structure on the surface, or the finished material is ground with diamond discs.

The polished version is obtained with mineral salts and acids, which are applied to the front side before the firing process. The result is an interesting satin-like surface.This option is less wear-resistant than others, and is only suitable for home flooring.

Lappated porcelain stoneware is quite expensive; to obtain a decorative effect, you need to treat the products with special acids and grind everything. The patterns will be unique.

Textured tiles repeat with their surface the texture of wood, stones, textiles.

An interesting option is rectified. This type can be applied to any porcelain stoneware. The bottom line is to perfectly match the edges of the tiles with no visible seams. The coating becomes monolithic, but despite its external beauty, this option is not suitable where there are temperature fluctuations or floor heating.

Mosaic the most durable floor covering. Such a finishing option will withstand external and mechanical influences without problems. The aesthetics of the mosaic floor are also unrivaled.

Advantages and disadvantages of porcelain stoneware flooring

Let's weigh the pros and cons of porcelain stoneware flooring.

Pros:

Minuses:

Format and thickness information

Manufacturers have different formats. A covering of 60 × 60 cm² requires a perfectly leveled base. Products 30 × 30 cm² can be laid on the floor with slight unevenness in the plane, hiding them. The universal plate with 45 cm sides can be mounted on any area. But the size 5 × 5 cm² was created for mosaics.

You can also find non-standard sizes, if they are relevant. As for the thickness of the products, it ranges from 7 to 30 mm.

Additional features of the decorative floor: imitation of different materials with porcelain stoneware tiles

To make the design of the apartment even more original, you can initially consider options for acquiring imitation of natural textures. You can buy marbled porcelain stoneware, or other natural stone.

The wood grain looks very noble, which is complemented by the quality of durability.

Imitation leather is new, often such products are used under space zoning and blend in with another type of surface or texture.

Imitate the same and laminate, and concrete, and brick.

Tips for choosing a porcelain stoneware coating

When choosing, everyone usually looks at the appearance of the coating, at the same time, more attention should be paid to the thickness of the tiles. For home use for many years, products with a thickness of over 8 mm are suitable.

It is also necessary to consider the location: inside or outside the building. The stores sell universal options. But the slipperiness parameter differs. If the tiles will be laid in a dry room, you can take the R6 marking. For outdoors or wet rooms, look for the R9 marking.

When buying, you should check the geometry of the products. To do this, take out 3-5 samples from different packages and put them in a stack. After alignment, the presence or absence of defects will be visible.

Installation of floor porcelain stoneware: stages of work

Laying a porcelain stoneware floor is almost identical to installing ceramics, with the exception of some nuances.

An important role is played by the weight of each tile, which together will make up a rather heavy coating. It requires a solid non-deformable base. As a base for such a massive floor, a cement-sand screed is made. When working, you constantly need to use the building level.

The base must be prepared: cleaned of debris, remove materials that interfere with adhesion, and treat the surface with a deep penetration primer. After it dries, they begin to lay the floor.

The glue should be marked that it can be used for working with porcelain stoneware - the adhesive is applied both to the tile and to the base itself with a notched trowel of a suitable size.

To control the thickness of the seam, use crosses. The usual pitch between tiles is 1 mm indoors and 2 mm on an open terrace. Do not walk on freshly laid floors. You need to wait 24 hours.

Do I need to care for the porcelain stoneware floor

Despite the declared long service life and resistance to abrasion, it will not be superfluous to monitor the condition of the floor.

It is advisable to perform surface treatment with wax, and wash the floor with the addition of lemon oil to the water. To polish the slabs, you need to work with felt.

Leading manufacturers: who to trust

The main domestic manufacturer of this coating is "Ural porcelain stoneware"... The company is engaged in the manufacture of matte and polished material. This includes structured and rectified slabs.

Another significant manufacturer is called Italon... The company is Russian-Italian, its catalog contains more than 35 collections.

Keramamarazzi is also a Russian-Italian manufacturer renowned for its wide range of products for floors and stair treads.

From foreign brands are popular Zeus Ceramica, Keramin, REFIN, ARIOSTEA.

Video: how to choose porcelain stoneware products

What kind of porcelain stoneware flooring do you think is the most elegant and luxurious?