Multifunctional household woodworking machine - pros and cons, features, prices, brands and models

Handicraft is always valuable. This applies to any product, including wood. But woodworking requires more than skill and effort, it will take a lot of time and effort. To reduce production costs, you just need to purchase a multifunctional household woodworking Machine, with which you can carry out several basic woodworking operations. This small equipment with several functions will increase the speed of production and the quality of the final product.

The content of the article [Hide]

Is it worth buying a machine

Let's start with the fact that multifunctional woodworking machines (household) operate on an alternating current with a voltage of 220 V. That is, this is actually household equipment, with the connection of which there are no problems, only an outlet is needed. But the term "household" does not mean that such a unit is used only in everyday life. Many small workshops, for example, furniture making, acquire such machines that fully meet the required quality of manufactured products.

In addition, this type of equipment has other advantages:

And a few disadvantages:

First, such a machine cannot be altered. Even if you make some changes to it, it will certainly affect the quality of the operations. Secondly, compared to professional models, the quality of household ones is much lower. Thirdly, if the electric motor fails, then it is impossible to carry out any operations, because one motor is responsible for the operation of all tools (drill, milling cutter, circular saw).

Classification of woodworking machines for home

All woodworking machines for the home are divided into two main categories: specialized (narrowly focused) and multifunctional. The first are aggregates with which you can perform just one operation.

But at home, install several specialized machine tools - the problem. They will take up a lot of space, for which you will have to organize a whole workshop. And they will cost a lot of money. In this regard, the multifunctional variety is better. These machines are compact and can be used to perform several woodworking operations.

For example, to highly specialized machines with which you can saw wood, there are four types at once: circular, jigsaw, end and format-cutting. To carry out planing, you will have to purchase one more machine of these three: planer, thickness planer or jointer. And you can get a multifunctional view in which, in addition to these two operations, you can drill and make grooves using mills. In this case, all operations are carried out on one desktop from one electric motor.

That is, in terms of versatility, the multifunctional view is many times better. But it should be noted that the unit must be selected taking into account the required processes. For example, the main part of multifunctional woodworking machines in their arsenal has 4-5 positions:

Related article:

Machine selection by power

Equipment power is one of the most important selection criteria. It depends on it how thick the workpiece can be processed, what dimensions the grooves and holes can be made.Therefore, manufacturers offer several types of woodworking machines for home use with different powers. But there is another characteristic - the number of revolutions of the electric motor, which is often directly related to the power of the motor.

Other characteristics

What else should you pay attention to when choosing a combined woodworking machine:

All these data can be found in the equipment passport. By choosing the maximum dimensions, you increase the capabilities of the machine in terms of processing various workpieces on it. But this increases the power of the electric motor, which means both the power consumption and the dimensions of the machine itself.

Related article:

Types of universal woodworking machines

Basically, all universal woodworking machines are divided into two groups: stand-alone and desktop. It should be noted that the first group cannot be classified as amateur equipment. That is, by purchasing it, you confirm your skill in woodworking. Typically, such machines have a power of 3 ÷ 5 kW, in which not one, but 2 ÷ 4 motors are used. They are installed on a solid floor base and connected to a 380 volt network.

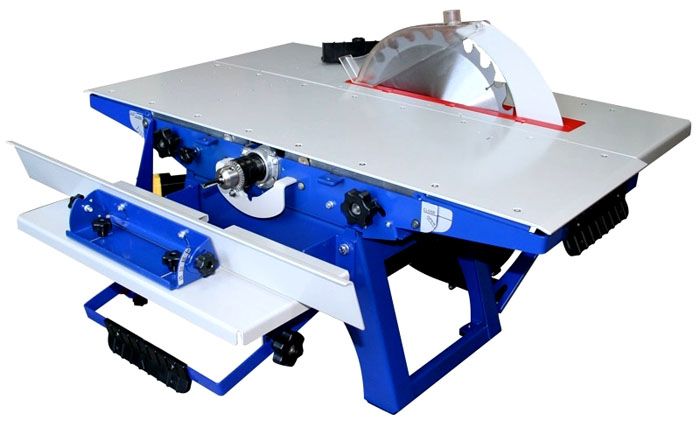

Desktop woodworking multifunctional machines (household) with a thickness gauge

These are universal woodworking machines that are used at home. Their main purpose is sawing and planing. All other features are considered optional. In this case, the adjustment of the planer (plane) in most models is played by the upper clamp. But manufacturers today offer machines with a separate adjustment device, which increases the quality and accuracy of sawing wood.

From the name itself it becomes clear that the machines of this group are installed on tables. That is, they have a small height size, not enough to work comfortably on it. In all other respects, this is a conventional unit with an electric motor and working bodies for woodworking.

Now, regarding the choice of a woodworking household multifunctional machine with a thickness gauge. Everything will depend on what needs it is purchased for:

This will directly relate to the technical characteristics. For home use, choose machines with a cutting depth of 3 mm and a width of 330 mm. The power of such a machine will not exceed 1.5 kW. And it will weigh within 30 kg.

Complete set of multifunctional machines

The name multifunctionality is primarily the variety of operations performed. But each woodworking process requires its own working tool. In different machines of this type, the equipment may be different, but the main tools are: a planer shaft, a milling cutter, a drill and a grinding wheel.

In some models, others may be used instead of these tools.For example, instead of a cutter, a knife module, instead of a grinding wheel, a belt. At the same time, the installation of these devices differs from the standard ones. For the sanding belt in the machine design, special rolls are provided, on which it is installed. This primarily clutters the structure and increases its weight and dimensions. Because the grinding disc is installed in place of the drill. In fact, this is a kind of unification.

In addition to the above-described tools, other devices are often installed in machine tools that increase the comfort and functionality of their use. These include:

Machine table

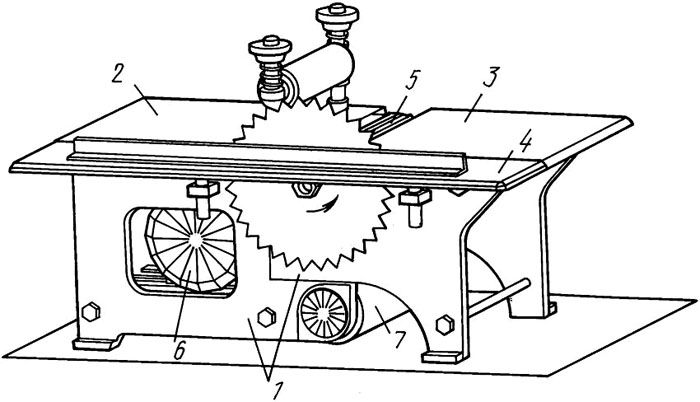

This part of the combined woodworking machine requires special analysis. Let's start with the fact that it is made from either cast iron or steel. The first material is used in professional machines, the second in amateur. The latter are an assembly model, often welded. The table most often consists of three parts: fixed (acting as a stand), movable or receiving, with which you can change the parameters of planing workpieces, and saw. It is on the latter that the workpiece with cutting parameters is installed.

Three parts of the table: 1 - two parts of a split-type bed, 2 - movable table, 3 - fixed table, 4 - saw table, 5 - drum with knives, 6 - electric motor, 7 - sanding drum

The table itself can be raised or lowered, that is, by adjusting it to the height of the person. At the same time, in some models, this is how the depth of wood cutting is regulated. Reduced the height of the table, increased the thickness of the cut, and vice versa. It should be added that the quality of wood processing will largely depend on the rigidity of the tabletop. Therefore, in professional varieties, cast beds are used. Because this design can withstand high vibrations of the apparatus, which are transmitted to the workpiece.

Of course, in this regard, combined woodworking machines for a house for 220 V lose. They have an assembly table.

Safety rules when working on the machine

It does not matter on which machine the work is carried out: professional or household. The requirements for carrying out work on them are the same:

Popular models and manufacturers

The modern market is simply crammed with multifunctional machines from different manufacturers: domestic and foreign. It is difficult for a consumer to choose a specific model, so it is worth understanding them. The statistics assure that there are popular brands on the market, the sales of which are very high. And these are mainly domestic machines.

Machine tools "Ant"

Woodworking machines "Ant" are the brainchild of JSC "Algorithm" from the city of Rybinsk. The company offers seven models, which differ from each other in power, speed of rotation of the electric motor and functionality. Accordingly, their price is different.

| Operations | SD-3 | SD-3-02 | SD-3-03 | SD-4 | SD-4-01 | SD-5 | SD-6 |

|---|---|---|---|---|---|---|---|

| Saw cut | + | + | + | + | + | + | + |

| Jointing | + | + | + | + | + | + | + |

| Circular saw milling | + | + | + | + | + | + | + |

| Shaped milling | + | + | + | + | + | - | - |

| Drilling | + | + | + | + | + | - | - |

| Thicknessing | + | + | + | - | - | - |

At the same time, the technical characteristics do not differ much from each other.

| Specifications | Options |

|---|---|

| Cutting depth, mm | 85 |

| Planing width, mm | 200-250 |

| Workpiece thickness during thicknessing, mm | 5-75, for SD-6 10-100 |

| Thicknessing depth in one pass, mm | 0-3 |

| Groove depth when milling with a circular saw, mm | 50 |

| Width | 40 |

| Electric motor power, kW | 2 |

| Shaft rotation speed, rpm | 4200 |

Machine "Master-Universal"

Woodworking machines "Master-Universal" are manufactured by a Moscow company LLC "UniMaster"... It offers six models of multifunctional wood processing equipment for domestic use. There are both floor structures and tabletop in the model line. For the latter, you can purchase a bed, that is, turn them into floor ones.

But among all the options offered, the most functional is the Master-Universal R brand. It can be used for: sawing (longitudinal, transverse and at an angle), thicknessing, planing (horizontally and at an angle), drilling, milling.

| Specifications | Options |

|---|---|

| Workpiece thickness during thicknessing, mm | 250 |

| Planing width, mm | 250 |

| Maximum planing depth, mm | 3,5 |

| Maximum cutting depth, mm | 85 |

| Sawing angle, degree | 0-45 |

| Number of knives | 2 |

| Electric motor power, kW | 2,2 |

| Motor shaft rotation speed, rpm | 5500 |

Of course, one cannot be limited only to domestic brands of multifunctional woodworking machines. The market offers a huge assortment of foreign counterparts. For example, woodworking machines "Mogilev" from the Belarusian manufacturer of the plant Belmash, Japanese and Chinese equipment is very popular today. European firms are also trying to gain a foothold in the Russian market.

Prices for universal household woodworking machines for the home, where to buy

Firstly, buying a universal household woodworking machine for the home today is not a problem. They are sold by specialized stores, online stores, and dealers of well-known manufacturers. The pricing policy for each seller is different, so in different regions the cost indicator varies significantly. The cost from the manufacturers themselves is the lowest. Let's give an example of prices for machines of the "Ant" brand by model:

| Model | SD-3 | SD-3-02 | SD-3-03 | SD-4 | SD-4-01 | SD-5 | SD-6 |

|---|---|---|---|---|---|---|---|

| Average price, rub. | 47530 | 47530 | 51510 | 37530 | 40750 | 27630 | 32690 |

Video: demonstration of the capabilities of the Master-Practician machine

Useful Tips

The safety requirements have already been mentioned above. But the masters give their advice to help beginners.

Considering these simple recommendations, you can guarantee the high quality of the final result, plus the long-term operation of the equipment.