PVC floor tiles: varieties, characteristics, styling features

Today, traditional floor coverings such as linoleum, carpet, laminate or ceramic tiles can no longer meet the specific requirements of consumers. Therefore, manufacturers are developing new composite materials that combine the performance characteristics of several types of coatings. One such material is PVC floor tiles. Otherwise, it can be called vinyl, quartz-vinyl, laminate or linoleum tiles, LVT coating (LVT - Luxury Vinyl Tile).

The content of the article [Hide]

- 1 Structure - main layers, their composition and purpose

- 2 Format

- 3 Where is applied

- 4 Varieties of PVC coating by laying method

- 5 Key Features - Operational Advantages and Disadvantages

- 6 Criterias of choice

- 7 Leading manufacturers

- 8 Features of laying tiles

- 9 Consumer reviews

- 10 Summing up

- 11 Video: flexible vinyl tiles - overview, layout, installation

Structure - main layers, their composition and purpose

PVC tiles consist of the following layers:

- The outer (front) protective layer is a transparent polyurethane hardened by ultraviolet radiation.

- The decorative layer is a drawing on a polymer film.

- The main layers are PVC with mineral (quartz) chips.

- Fiberglass - used in high quality expensive composites. Prevents thermal deformation of the product.

- Finishing layer made of PVC or adhesive. Depending on what material is in the base, different laying methods are practiced.

The thickness of multi-layer tiles, depending on the brand, can vary between 1.5-3.5 mm. Monolithic, as a rule, has special stiffening ribs that increase the thickness of the product, but at the same time reduce the volume of raw materials used.

Format

The most widespread are the following formats of PVC tiles:

Where is applied

The scope of PVC tiles is quite diverse. As a rule, these are premises, the floors of which are subjected to intense mechanical influences of various nature: pressure, abrasion, shock deformations, in combination with high humidity and other pollution factors. The use of an LVT coating depends on its class.

Varieties of PVC coating by laying method

In addition to the classification by the degree of load, PVC tiles are distinguished by the method of installation.

The highest quality fasteners, according to experts, give the following adhesive mixtures:

The disadvantage of such a coating is the need for thorough preparation of the base.

Of the advantages of such tiles, it should be noted that they are quick and easy to install. However, according to the reviews of most experts, such a coating requires perfect surface preparation, in addition, it is quite sensitive to external influences. In particular, it has a narrow range of temperature and humidity conditions of operation, and in case of their systematic violation, the tile can come off the base.

Installation can be carried out in several ways:

According to the assurances of the manufacturers, such elements are held together and on the basis due to the geometric stability of their shape, as well as the spongy structure of the lower layer. The thickness of such products ranges from 4.5-7 mm. Due to the large thickness, certain defects of the base surface are allowed, the wear resistance and the period of operation increase. The installation itself is done very quickly and does not require knowledge or any skills. However, such products are the most expensive PVC floor coverings on the market.

Key Features - Operational Advantages and Disadvantages

Criterias of choice

It is recommended to choose PVC tiles according to the following criteria:

To determine the value of the parameters, it is necessary to analyze the intensity of the operation of the room. Most manufacturers, in addition to the numerical indicators of the strength of the product, give more detailed explanations, designed for non-professionals. For example, household, semi-commercial, flooring for warm floor etc.

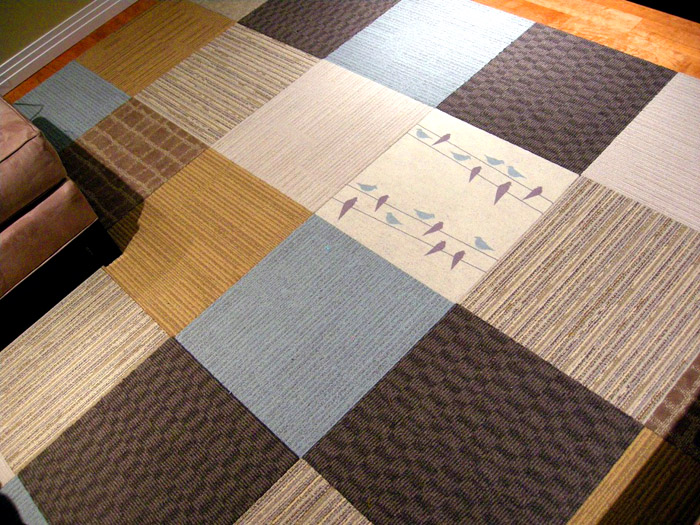

A wide choice of colors and textures of PVC tiles, combined with precise geometric dimensions of various batches, allow you to create a unique flooring design

As for the tile format, it all depends on the characteristics of the room where the flooring needs to be installed:

Leading manufacturers

Rating of manufacturers holding leading positions in the Russian market:

- Vinilam - Belgium.

- Decoria from South Korea.

- LG Decotile - South Korea.

- PERGO - China.

- Fine Floor - Ukraine.

- Tarkett is a Russia-Belgium joint venture.

- Forbo is an international company headquartered in Switzerland. Production facilities are located in several countries of the world, including Russia

Features of laying tiles

Laying PVC tiles is much less time consuming than installing most floor coverings. However, it also requires careful preparation of the surface, as well as special care when installing the starting rows. Depending on the type, there are three main techniques for laying vinyl flooring.

Various design options for laying PVC coverings, layout of elements and view in the interior:

Tools used

Most of the tools that may be needed when laying PVC tiles are at the disposal of any self-respecting home craftsman. No specialized or expensive devices are required. This is another advantage of PVC coating. For ease of use, some tools undergo minor upgrades:

Foundation preparation

A cement-sand screed can be used as a base material, moisture resistant plywood, OSB, Fiberboard and other sheet materials. They must be pre-treated with a primer (especially the screed) to normalize moisture absorption. In some cases, laying on old flooring such as tiles is acceptable. However, all intercellular spaces must be carefully sealed at the same level as the tiles.

The best option is to use a new subfloor made of moisture-resistant plywood 15-18 mm thick.Plates are laid with displaced joints. Gaps up to 2 mm wide are left between them to compensate for thermal expansion. Seams are carefully sealed with acrylic sealant.

Styling process

Consumer reviews

Despite the fact that PVC tiles have been used for a relatively short time, there are many consumer reviews on the Internet describing their operation:

Summing up

Undoubtedly, quartz-vinyl tiles in their characteristics are worth paying attention to. Manufacturers are doing everything possible to expand the range of use and transfer this flooring from technical rooms, hallways and kitchens to living rooms and bedrooms. However, in places of permanent residence, it is advisable to use only high-quality and expensive types of PVC tiles as flooring.

Video: flexible vinyl tiles - overview, layout, installation