Technical characteristics, sizes and prices of foam blocks

During the construction of objects, the task of many projects is to reduce the load of the building on the foundation and maintain the basic technical and operational characteristics. Therefore, many design engineers try to apply block construction technologies based on aerated concrete, one of which is the foam block. It has all the advantages of modern technology and meets building codes. At the same time, the sizes and prices of foam blocks are in an optimal ratio, which makes it possible to erect both economical and energy efficient buildings.

The content of the article [Hide]

- 1 Features of the structure of foam concrete

- 2 Advantages of foam blocks

- 3 The main areas of application of foam blocks

- 4 What is more profitable to use in the construction of objects: aerated concrete block or foam block?

- 5 Sizes and prices of foam blocks

- 6 Advantages and disadvantages of houses and baths from foam blocks

- 7 Conclusion

- 8 Video: the pros and cons of foam concrete blocks

Features of the structure of foam concrete

Foam concrete belongs to the class of cellular concrete. It is made from concrete solutions that meet certain strength standards, with the addition of substances that contribute to abundant foaming.When a foaming composition is added to the solution, the volume of the finished product increases several times, compared to the original, due to the occurrence of a chemical reaction.

The use of synthetic or organic foaming agent is allowed. Synthetics allows you to get a block with a uniform distribution of pores within the volume and increased strength. It is inexpensive and therefore the most acceptable to manufacture.

The organic composition is environmentally friendly and completely safe for human health, in contrast to the synthetic one. Organic components interact better with the concrete composition and therefore the pore shells are thicker.Therefore, for construction, foam blocks made with the use of organic foaming substances are more acceptable, but at a cost they are more expensive than synthetic ones.

Advantages of foam blocks

When choosing the main building material for the erection of the supporting frame of a low-rise building, many builders and designers stop at foam blocks. This decision is influenced by the following factors:

- Standardized block sizes. The designer will be able to select the optimal geometry and significantly reduce the construction costs of the facility.

- The surface of the blocks is smooth, which will allow you to create the thinnest connecting joints when laying them and save cement mortar. At the same time, the strength characteristics of the object will also increase.

- The uniform porosity of foam concrete creates quite comfortable conditions for their processing with special cutting tools. This makes it possible to create complex architectural forms on the facades of buildings.

- Low density of the material, compared to a monolith, brick or cinder block, has a positive effect on its weight. When building houses, there is no need to lay a buried foundation, since the density value roughly corresponds to the value for a wooden beam.

- Minimum thermal conductivity, compared to other block materials. This characteristic allows you to lay out walls much thinner than when using silicate bricks, provided that the same energy-saving properties are obtained.

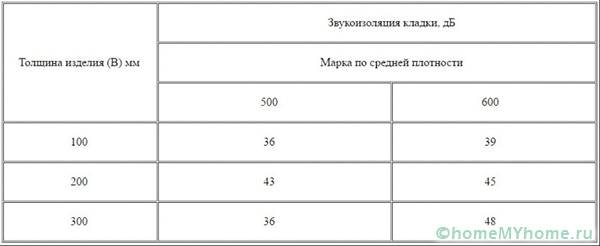

- High level of sound insulation. When building houses near industrial areas or in noisy areas, it is not necessary to install a soundproofing layer.

Table 1. The level of sound insulation depending on the thickness of the foam concrete masonry

- High moisture resistance due to the special structure of the material, which prevents moisture adsorption. Therefore, the material is resistant to sudden temperature changes and severe frosts without losing its properties or cracking.

- A high level of fire resistance will ensure the fire safety of the building. Substances released during heating are non-toxic.

The main areas of application of foam blocks

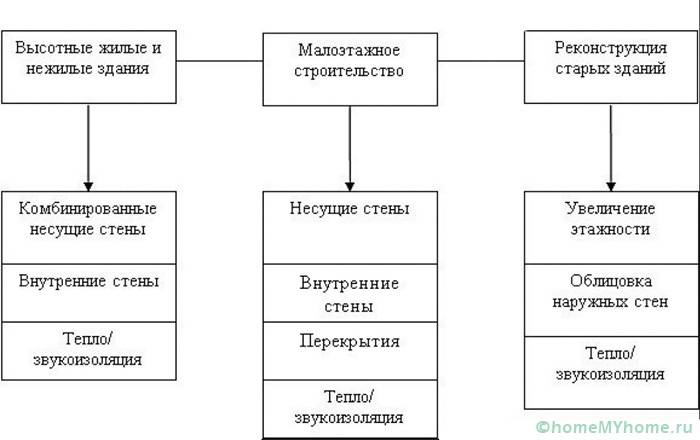

Various sizes of foam blocks for building a house and a price in a fairly wide range allow them to be used for the following purposes:

- For the construction of residential low-rise buildings.

- Construction of utility and non-residential facilities.

- For strengthening existing walls and increasing their insulation performance.

- For construction fences, interior partitions, as well as non-loadable structures.

What is more profitable to use in the construction of objects: aerated concrete block or foam block?

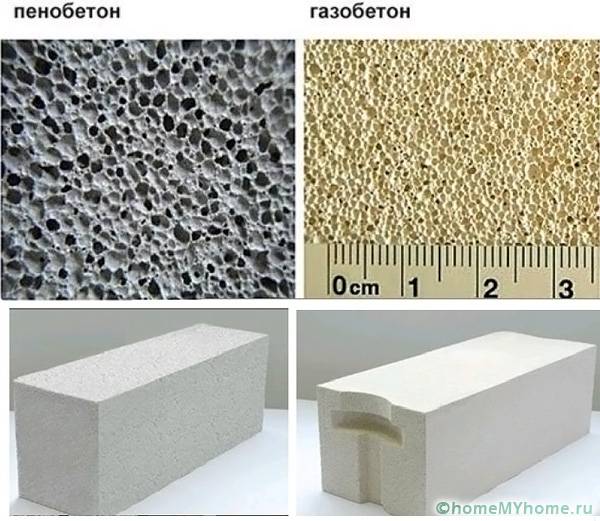

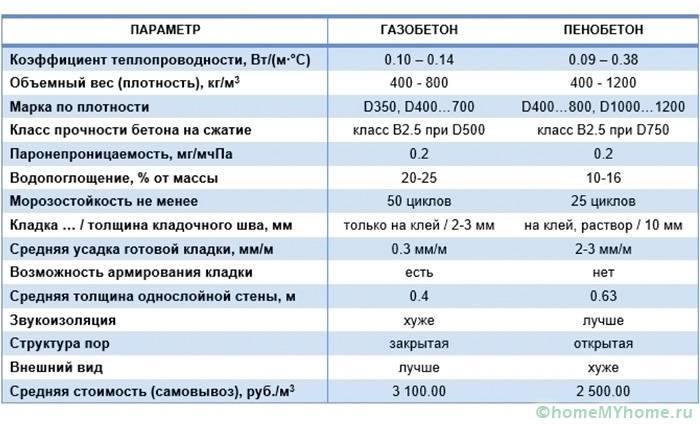

Aerated concrete blocks also belong to aerated concrete and are direct competitors of foamed concrete. Therefore, the choice between foam blocks or gas blocks is not so obvious: what is better to take into account when selecting them, and what to neglect? This is due to the fact that they have almost the same compositions, however, the mechanical and insulating properties differ significantly due to the difference in production technologies.

Aerated concrete production

Gas blocks are made from concrete mortars with the use of special additives. The composition of the solution includes: sand, cement, lime, gypsum, water and a chemical for gas formation. Usually, aluminum paste or powder acts in its role.

Aerated concrete production is carried out by autoclave or non-autoclave method. Autoclave is to provide special conditions for hardening - high pressure, and non-autoclave - in natural conditions. Foam concrete hardens only at normal temperatures and ambient pressure. That is, the production of aerated concrete by the autoclave method is possible exclusively in the factory, while aerated concrete can also be produced in a handicraft way. Therefore, if we compare gas blocks and foam blocks, sizes and prices per unit, then the latter win thanks to a simple manufacturing technology.

Aerated concrete is produced in massive formwork, and aerated concrete - in specially prepared forms. Aerated concrete blocks are cut directly to the specified dimensions with minimal deviations from the standard by a fraction of a millimeter, while for foam blocks this value can be up to 5 mm.

The structure of aerated concrete is characterized by the presence of unevenly distributed cells throughout the volume, which, unlike foam concrete, can have not only a closed structure, but also a through one. That is, theoretically, if the proportions of the gas-forming mixture are exceeded, there is a high probability of obtaining a block with increased fragility and moisture adsorption.

Related article:

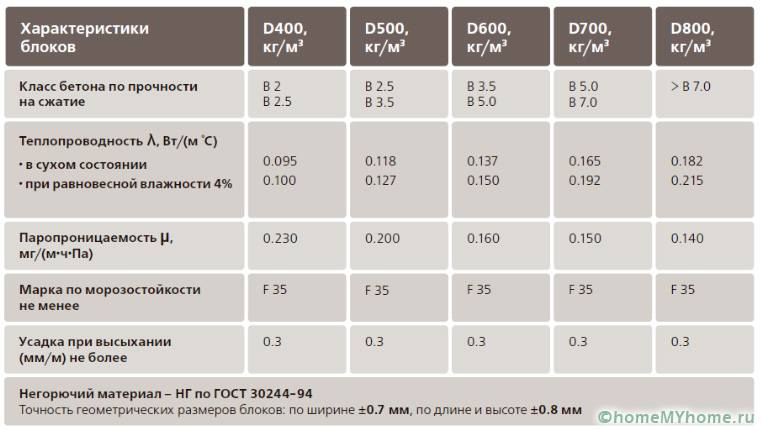

Comparison of strength characteristics

The size and price of the foam block and gas block are not the only determining factors when choosing them. It is imperative to take into account their density, which can vary in the range of 300-1200 kg / m3... In theory, the two types of blocks should have approximately the same strength. But in reality, not everything is so simple. In blocks of foam concrete, the pores are evenly distributed and they have approximately the same size, in contrast to aerated concrete. Therefore, it is logical to assume that the former are stronger than the latter. However, when comparing autoclaved and conventional products, aerated concrete products benefit. This is due to the possible shrinkage of blocks during operation, which can reach up to 3 mm per running meter and introduce a number of inhomogeneities in the structure.

Comparison of block geometry

When performing masonry, one of the important parameters is the geometry of the block, since it allows you to create connecting joints of minimum thickness and, accordingly, save mortar. Since the gas blocks are cut according to the specified dimensions with a stretched string, the deviations can be no more than a few fractions of a millimeter. Foam concrete blocks are produced in finished forms, therefore, deviations from the specified values are up to 3 mm or even 5 mm. If you look from the other side, the gas blocks are more fragile and with improper transportation, more breakage can form even during their delivery to the construction site.

The quality of thermal insulation properties

The quality of thermal insulation depends on the density of the material, that is, the denser it is, the higher the thermal conductivity. In this case, foam concrete loses to aerated concrete, although not significantly. The density of foam blocks is from 600 to 700 kg / m2, and gas blocks - 400-500 kg / m3.

Foam blocks or gas blocks - which is better?

In the course of the comparative characteristics, it was found that foam concrete blocks are inferior to gas blocks in terms of characteristics and properties.However, it is worth noting that foam concrete blocks can be produced directly at the construction site with their own hands, significantly saving finances and at the same time obtaining building materials that are sufficiently reliable in operation. That is, what is better for construction: a foam block or a gas block, the designer chooses independently, taking into account the features of the project, the loads on the walls and foundation, as well as the results of the engineering surveys carried out.

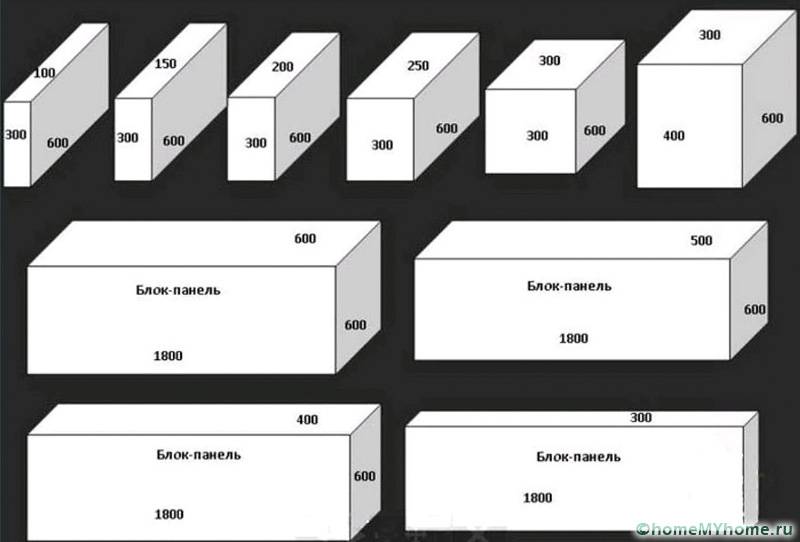

Sizes and prices of foam blocks

In the construction of buildings, in many cases, the size and prices of foam blocks have a significant impact on the implementation of the project. Therefore, it is necessary to evaluate how to correctly combine them and get a reliable and durable building or structure.

Foam blocks: sizes and prices per piece

The data on the average cost of blocks in Russia are shown in Table 2. It shows that the price increases along with the increase in material density and dimensions. Quite a standard pattern is observed, inherent for any other materials. However, in this situation, it initially becomes possible to select the most optimal parameters and reduce the amount of waste or rejections due to the variety of standard sizes.

Table 2. Cost of foam concrete blocks depending on their size

| Size, mm | Density, kg / m3 | Price per piece, rub. |

|---|---|---|

| 600x300x100 | D600 | 53 |

| 600x300x120 | D600 | 63 |

| 600x300x150 | D600 | 77 |

| 600x300x200 | D600 | 98 |

| 600х200х400 | D600 | 132 |

| 600x300x250 | D600 | 125 |

| 600x300x200 | D500 | 78 |

| 600x250x150 | D600 | 90 |

| 600x250x50 | D500 | 35 |

| 600x250x75 | D500 | 45 |

Advantages and disadvantages of houses and baths from foam blocks

The construction of houses or baths from foam blocks is the construction of environmentally friendly facilities with minimal costs for the building material itself and the foundation, obtaining high-quality insulating properties and a long service life. Among the arguments in favor of foam concrete blocks are the following:

- The ability to quickly erect an object, in comparison with brick buildings, due to the large size of one block.

- There is no need to involve additional assistants, since all stages of work can be done by hand.

- Easy workability of the material even with hand tools with acceptable performance, which makes it possible to build even on such sites where electricity has not yet been supplied.

- The porosity of the material will create a unique indoor climate, as it will "breathe".

- Possibility of construction even in unfavorable conditions, especially at low temperatures or gusts of wind, since the blocks have increased resistance to external factors.

- Minimum requirements for the foundation due to the low weight of the wall material.

The disadvantages of foam blocks include fragility, a possible change in structure in specific operating conditions, the impossibility of building objects above 2 floors, as well as shrinkage.

Conclusion

Foam concrete is a modern material for the construction of various low-rise buildings. Differs in high insulating properties, allowing to refuse the installation of additional heat and sound insulation materials. Various sizes of foam blocks for building a house and the price for 1 m3 lower than a brick, allow you to significantly save on the construction of houses without deteriorating the performance or strength of the structure. When compared with gas blocks, this material loses, but not much.

Video: the pros and cons of foam concrete blocks