Adjusting the water pressure switch for the pump and troubleshooting in-house

The corresponding engineering system will perform its functions flawlessly if the adjustment is made correctly pressure switch water for the pump. This procedure can be performed independently without seeking help from specialists. It will increase the accuracy of the equipment and prevent premature failure of its individual components.

The content of the article [Hide]

- 1 Design and features of work

- 2 Parameters of products from different manufacturers

- 3 Method of adjusting the water pressure switch for the pump

- 4 Diagnostics, troubleshooting after setup and upgrades

- 5 General conclusions

- 6 Video: adjusting the pressure switch of the pumping station is nothing complicated

Design and features of work

Automatic memorization of the algorithm of certain actions is useful only in standard situations. In practice, various malfunctions occur, therefore in-depth knowledge is required. They will also be useful in order to buy a new pressure switch for a pump without annoying mistakes and unnecessary expenses.

What is the exact setting of the pressure switch of the pumping station for?

The following are the reasons for maintaining a normal pressure level in the water supply system:

How the relay works

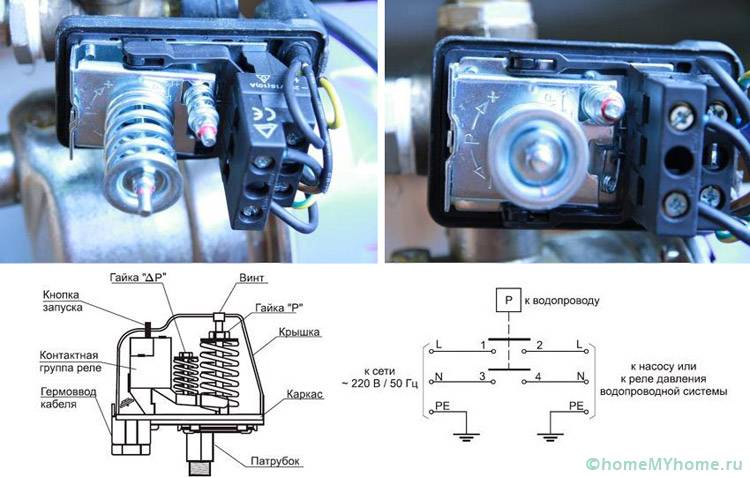

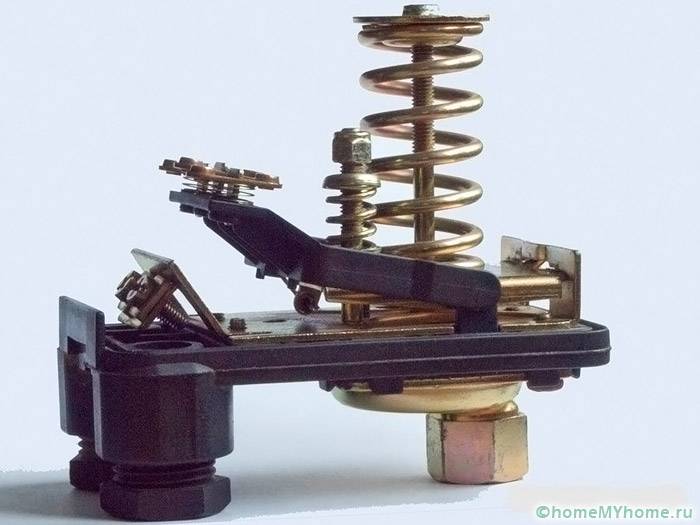

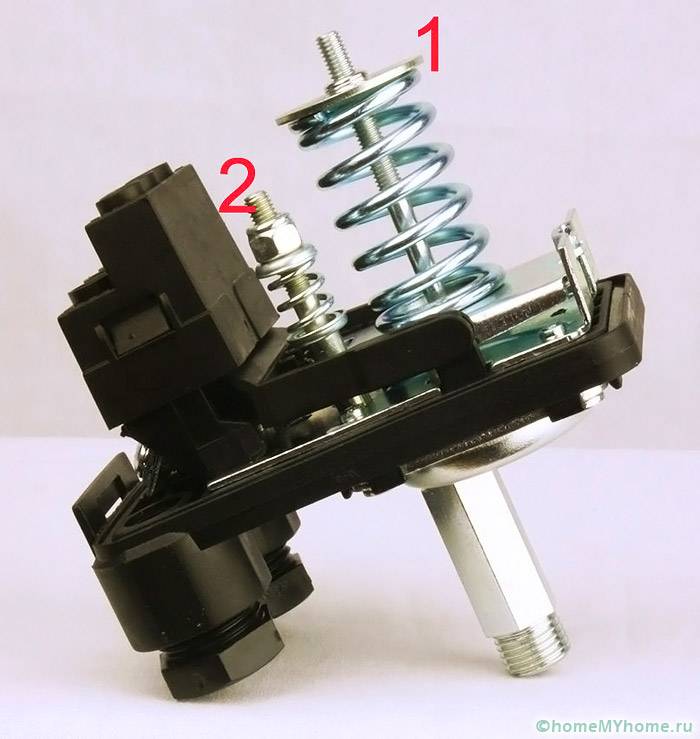

Any of the devices of this group is designed to quickly fix the fluid pressure in the pipeline. When the threshold values are crossed to the higher or lower side of the nominal range, the power supply network of the pump motor is opened (closed). To solve this problem, the following construction is used:

The height of the springs is changed with a nut and washer. When compression is large, the pressure level increases, at which power is supplied to the pump motor. Similar actions with a smaller spring will set the pressure at which the relay contacts open.

Wiring diagram of the water pressure switch for the pump and operating cycles

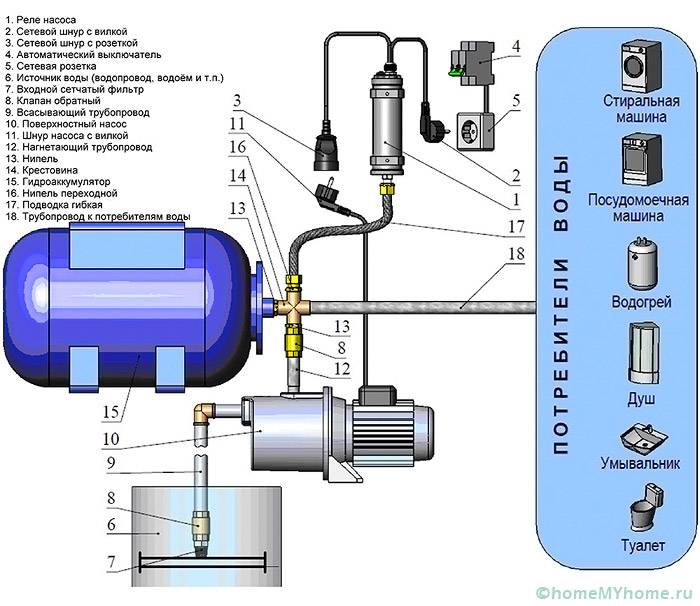

The following figure shows a typical stand-alone system private house water supply.

It functions as follows:

These cycles are repeated automatically, without user intervention.

Parameters of products from different manufacturers

The following table shows the data of specialized control relays for water stations.

Table 1. Data of specialized control relays for water stations.

The principles of operation of the above products are the same. The mechanism in the figure provides a relatively low information content. It is more accurate and easier to set the pressure using a specialized device, a manometer.

The price of electronic water pressure switches for the pump is higher. These devices should be considered separately as they differ significantly from the models presented in this article. Their equipment includes: micro-turbines for measuring the fluid flow rate, special pressure sensors and data transmission units to external display devices.

Method of adjusting the water pressure switch for the pump

This algorithm is used in an “ideal” situation when the water supply system is in good working order.

The following steps will help you set up a new regulator:

- Disconnect the pump from the 220 V network and drain the water completely.

- Power is supplied to the engine and the pressure rise is monitored on the pressure gauge and the level of automatic shutdown is recorded. Open the valve so that the pressure drops slowly. The readings of the device are recorded, at which the relay contacts are closed.

A small spring does not set a certain pressure to turn off, but the difference between the values for turning on and off the pump

Diagnostics, troubleshooting after setup and upgrades

If the above scheme does not work, loosen both nuts with a preliminary increase in pressure, for example, to 3.3 atm. Slowly drain the liquid to the required level (2, 3 atm.), Close the valve. A nut on a large spring is clamped to a position until the relay turns off. After - repeat the steps from the previous section.

Standard regulators (type Italtecnica PM / 5) can be upgraded:

General conclusions

With these instructions, self-adjusting the water pressure switch for the pumping station will not be difficult. When choosing a new product for replacement, you should pay attention to the following parameters:

Related article:

Of course, the manufacturer's name has a definite meaning. In some situations, it is wiser to pay more, but provide increased reliability during operation.

Some pumping stations are created only from certain component parts, so the choice of an alternative product will be difficult

Despite the well-proven design, it is permissible to make improvements to it. The corresponding work is performed on disconnected equipment in compliance with the safety rules.

Video: adjusting the pressure switch of the pumping station is nothing complicated