Rostwerk: what is it, its types and purpose

Before building a house and deciding what foundation to create - columnar or pile, novice builders are faced with such a concept as a grillage. Below we will consider what a grillage is and its need for building foundations of a building.

The content of the article [Hide]

- 1 Rostwerk - what is it?

- 2 Materials used

- 3 Types and purpose of grillages

- 4 Pile-grillage foundations

- 5 Main dimensions and dimensions

- 6 Main manufacturers and standard series of pile grillages

- 7 Basic provisions for the design and calculation of the pile grillage

- 8 Creating a pile-grillage foundation with your own hands

- 9 Conclusion

Rostwerk - what is it?

A grillage is a horizontally located element of the pile foundation of a structure (a kind of belt or pillow), which takes on the entire load of the building and, evenly distributing it, transfers it to the supporting columns. This is achieved by tying the piles into an integral structure. Since the grillage on the pile foundation increases the strength of the building, it is necessary to provide sufficient rigidity to all joints.

The advantage of such a base for a building is its durability, strength and the possibility of installation on sandy and clay soils, as well as on quicksand. In addition, due to the insignificant amount of preparatory work and the concrete solution used, such a construction of the base of the house is considered a less costly option compared to other types of foundations.

To better understand what a grillage is, you need to know its classification into the following types:

By location:

By constructive decision:

Dealing with the fact that this is a grillage foundation, it is also worth considering the materials used in the structure.

Materials used

The structural features of buildings and the magnitude of the resulting loads dictate the use of materials for creating grillages:

Pile foundations with monolithic grillages

Reinforced concrete belt has high stability, rigidity, reliability, durability and can withstand high loads. These qualities have become the reason for the widespread use of pile grillage with monolithic overlap. The structure consists of iron reinforcement, which increases the strength characteristics of the foundation, and concrete. Strengthening of a monolithic grillage on piles can be done with hotel rods fastened into a flat frame or with volumetric frames.

Concrete grillages are similar in structure to reinforced concrete belts, the only difference is the lack of reinforcement in the structure of the former. The entire load is laid down and distributed by concrete. The heads of the foundation piles must be recessed by 100 mm in the concrete of the grillage. Such belts are used only in the construction of one-story buildings.

Lumber structures

The wooden structure is mainly used in the construction of lumber houses. Laying a wooden grillage on a columnar foundation is performed on a special waterproofing pad made of roofing felts or roofing felt Also, in order to exclude premature damage to wood, the structure should be treated with special bioprotective impregnations. The timber is fixed on the piles by means of brackets or bolts.

There are two options for arranging a lumber belt:

Video: grillage device for a wooden house

Metal belt for foundation

The metal lathing is made of channel, I-beam or square profile and has high strength and rigidity. As a rule, this design is used when constructing pile-screw bases for one-story houses. The channel is installed on the head of the supports and fixed by means of a welding joint.

A metal belt is used mainly in a hanging version. However, in recent years, such designs have been used very rarely, since, due to the severity of the material, it is required to attract lifting special equipment, which is economically unprofitable. In addition, the metal is at risk of corrosive processes.

Types and purpose of grillages

Grillage structures differ in type and purpose. Many factors are taken into account when choosing the required design.

Strip foundations with grillages

For buildings, a fairly strong and reliable support is pile foundations with a tape grillage, for the construction of which two technologies are used. One of them is used when arranging foundations above ground level, and the second is used at the stage of creating a lattice structure, which takes part of the load.

A strip foundation is the best option for constructing a foundation on slopes and areas with difficult terrain, since it does not require complex preparatory work for planning the site with the involvement of special equipment. This design is perfect for the construction of structures made of lightweight materials.

Using a strip foundation during the construction of a house is necessary:

When arranging the foundation, you must carefully calculate the number and pitch of piles in a tape grillage, as well as its thickness and other parameters.

For the fence

The device of a grillage for fences is necessary for full protection of the structure, which the plane of the fence cannot provide. The creation of the belt is due not only to the provision from external factors, but also so that, for example, pets cannot get out of the site. The reasons can be any, but the performance must always be of high quality, to ensure the strength and durability of the structure.

In principle, the grillage for the fence practically does not differ from the belt used in the arrangement of the foundations of houses. It uses the same construction, building materials and performs similar functions.

For pile foundation

The need for a columnar foundation with a grillage is determined directly by the specific structure of the building, its weight and the rigidity of the structure frame. In order to prevent the supporting columns from collapsing, they are obliged with a monolithic reinforced concrete, metal or even wooden belt.

In construction, several schemes of the pile foundation of buildings are used:

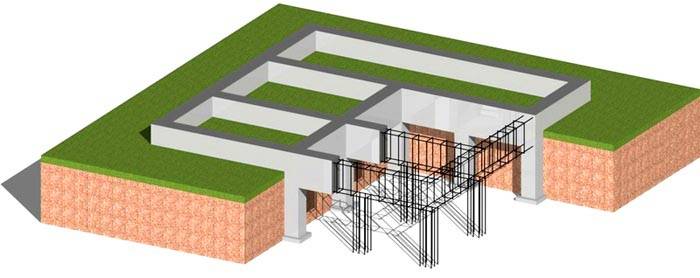

Pile-grillage foundations

Grillage technology with bored piles

Arrangement of foundations with a grillage on bored piles is mandatory when erecting buildings on uneven terrain, slopes and unstable soils. These structures are the best option for the construction of both small houses and medium-sized capital structures. Bored foundations with a grillage have a higher bearing capacity than monolithic and tape bases, and they are cheaper.

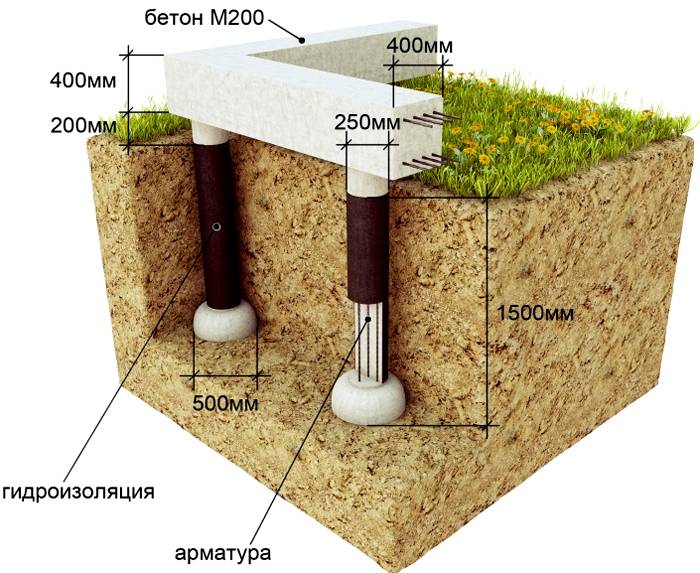

Bored piles, able to withstand a load of about 1500 kg. To erect a medium-sized structure, you will need several dozen columns, the diameter of which can reach 150 cm and the length up to 40 m.

To equip the base of the building, no major earthworks are required. Each pile is waterproofed with two layers of roofing felt or roofing felt and fixed in a frost-free soil layer. Waterproofing protects concrete from destruction and reduces soil pressure on the supports.

Advantages of the foundation on bored supports:

The tops of the installed pillars are cut at the same level, after which they are united by a common belt. A grillage on bored piles allows for an even distribution of the load exerted by the weight of the structure throughout the entire base of the building. The device of the pile-grillage foundation can be seen in the video below:

The disadvantage of this design is the fact that due to the presence of free space between the floor and the ground, the bored foundation with a grillage must be insulated. This leads to additional labor and material costs.

Grillage on screw piles

The advantage of foundations on screw piles is that they do not require excavation to be installed, and they are usually used on clay and heaving soils. After the supports are installed, their heads are cut into one level and a lattice belt device is made.

Monolithic reinforced concrete and concrete structures for screw piles are made extremely rarely, since this type of supports is used for the construction of light structures. Most often, the pile-screw grillage is made from a metal corner or channel.

Before installing the grillage on the heads screw piles, metal platforms are welded to them, the size of which should make it possible to correct the axial displacement of the supports.Further, all piles are strapped with a channel or a corner, as a result of which a strong and reliable structure is created.

Main dimensions and dimensions

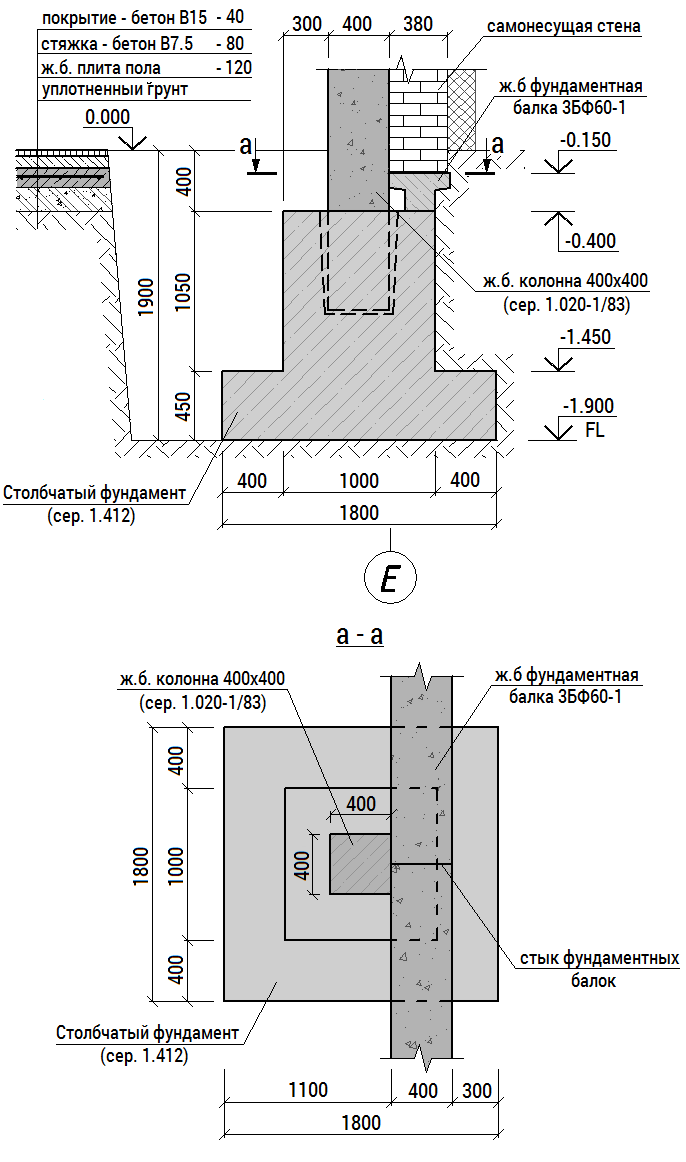

To create a solid and durable foundation, it is necessary to make the correct calculations. The shape and dimensions of the grillage used are determined by the structural features of the building being erected, loads on the foundation, the number and location of piles.

The grillage is created, as well as the construction of the strip foundation. The height of the grillages for pile foundations directly depends on the level to which the structure should be raised from the ground, as well as on its weight. You can independently perform the calculation of a structure based on the ground or slightly deepened. In the case of a hanging belt device, it is better to entrust the calculations to specialists, since they are very difficult for a non-professional.

You can independently calculate the dimensions of the pile foundation grillage using the formula B = M / (L × R)where:

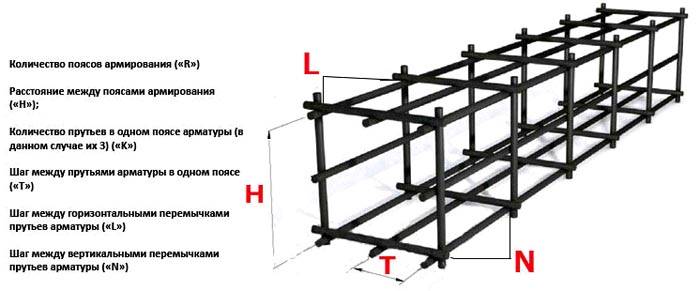

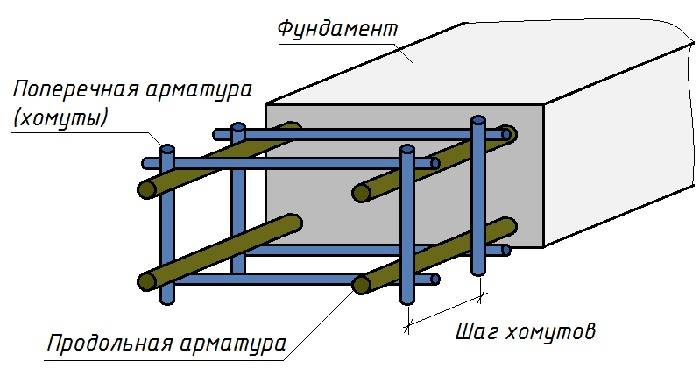

Reinforcement cages for belts on a pile foundation are created in the same way as for a structure on a strip foundation. In the structure, it is necessary to carry out longitudinal (working), horizontal and vertical transverse reinforcement. The total section of the longitudinal reinforcement must be at least 0.1% of the section of the belt. To select the cross-section of each rod and their even number, an assortment of reinforcement is used.

| Rebar type | Belt length, m | Diameter, mm |

|---|---|---|

| Longitudinal (working) reinforcement | Until 3 | from 10 |

| Over 3 | from 12 | |

| Horizontal reinforcement (transverse) | from 6 | |

| Vertical reinforcement | Up to 0.8 | from 6 |

| Over 8 | from 8 |

Main manufacturers and standard series of pile grillages

For private or small buildings, you can make lattice belts yourself directly at the construction site, but when erecting industrial buildings, multi-storey buildings, etc. use factory-made designs. Among the main manufacturers of reinforced concrete grillage from 35 tons, the following companies can be distinguished:

| Series | Description | |

|---|---|---|

| Monolithic reinforced concrete grillages series 1.411.1-1 / 89 | For the construction of bases for prefabricated reinforced concrete columns of one- and multi-storey industrial buildings of the II 20-1 / 70, II 20-2 / 70, II 20-3 / 70 series. | Supports of structures of the II 20-1 / 70, II 20-2 / 70, II 20-3 / 70 series have a section of 400 * 400 and 400 * 600 mm. and must be embedded in the foundation by 600 mm. |

| Series 1.011-6 | Made of heavy concrete, class B 12.5 | Square piles 300 * 300 and 350 * 350 mm. |

| Series for metal grillage: 3.407-115 3.407.2-162 3.407.9-146 3.407.9-1581 | For the operation of the structure at a temperature: ● up to - 40˚C, the grillage is made of carbon steel grade ВСт 3, corresponding to GOST 380-71; ● below - 40˚C for the grillage, low-alloy steel of 09G2S grade is used, which corresponds to GOST 19281-73 and 19282-73. | |

The name, which designates typical grillages for pile foundations, includes the mandatory letter indices RS and RB and serial numbers. PC1 - PC5 markings are used on square supports, and RB markings are used for rectangular piles.

Basic provisions for the design and calculation of the pile grillage

When constructing a pile-grillage foundation, it is necessary to know the basic requirements for a grillage and to carry out competent calculations of the entire structure. It is also necessary to have an executive scheme for grillages, on which all the main structural elements are indicated. An important point in designing the base of a building is the exact calculation of the required number of supports for each specific type of structure. The calculation is based on the total weight of the structure and the bearing capacity of the soil. The mass of the house must be divided by the bearing capacity of the soil and, we get the value of the area of the projected base. To determine the safety factor, the foundation area should be increased by 30%. To calculate the required number of support columns, the base area must be divided by the volume of each pile, while the following conditions must be met:

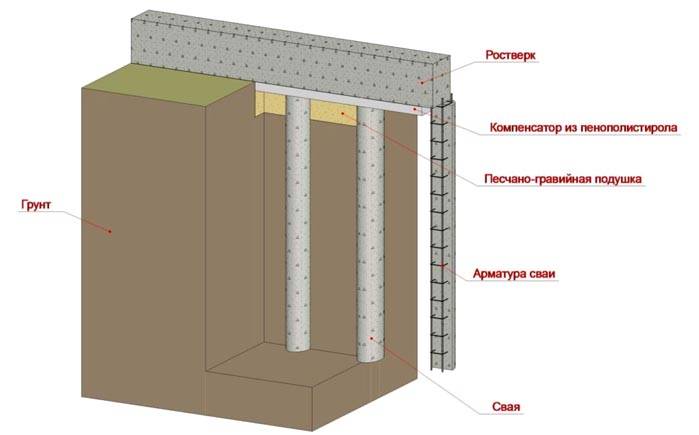

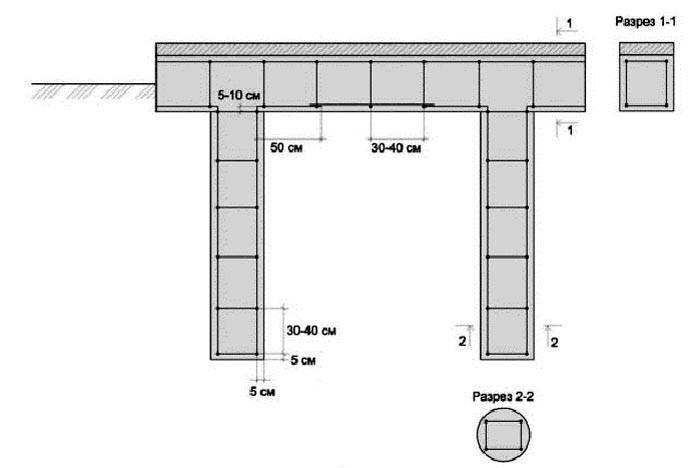

The connection of the pile to the belt can be rigid or free. In the case of a free connection, the heads of the supports enter the grillage to a depth of 50-100 mm. This type of fastening is suitable for centrally loaded support columns.

With a rigid connection, the pile head breaks, and the reinforcement is exposed, after which it is monolithic into a concrete or reinforced concrete grillage. A similar type of attachment is performed in cases where:

Calculation example

Consider an example of calculating a pile foundation with grillages for a one-story brick house with a hip roof made of metal tiles. The building has two reinforced concrete floors with a thickness of 220 mm. The dimensions of the house in the plan are 6 * 9 m, the thickness of the bearing walls is 380 mm. The total floor height is 3.15 m, from floor to ceiling - 2.8 m, and the total length of partitions inside the building is 10 m (there are no internal walls in the premises). The site contains a refractory-plastic mixture with a porosity of 0.5 and a depth of 3.1 m.

| Load type | Coefficient |

|---|---|

| Wood | 1,1 |

| Metal | 1,05 |

| Backfill, insulation, reinforced concrete, screeds | 1,1 |

| Manufactured items | 1,2 |

| Elements manufactured directly on site | 1,3 |

| Equipment, furniture, people | 1,2 |

| Snow | 1,4 |

We preset the grillage width 400 mm. and a height of 500 mm. The length of the support is 3 m, and the cross-section is 50 cm.We are guided by the step of the support piles - 1.5 m.To determine the total number of piles, it is necessary to divide the length of the grillage by the step of the supports and add 1 (if necessary, the resulting value is rounded down to a whole numbers - 30 / 1.5 + 1≈21).

To calculate the volume of the grillage and other parameters, it is necessary to determine the mass of the structure without foundation supports. As a result, we get M = 204 t.The width of the salting is equal to M / (L * R) = 204 / (30 * 75) = 0.09 m. Such a belt cannot be used for construction, in this case, since the overhangs of brick walls should not be more than 40 mm. Therefore, we assign the width - 400 mm, and the height remains - 500 mm.

Calculation and drawings of reinforcement of the grillage of pile foundations

The cross-section of the horizontal (working) reinforcement must be 0.1% * 0.4 * 0.5 = 0.0002 m2 = 2 cm2... In this case, 4 metal rods Æ 8 mm are enough, but according to the standards, it is necessary to use the minimum allowable Æ 12 mm. For vertical and transverse reinforcement, bars Æ 6 mm are used.

Calculations take some time, but they can significantly save money and time during the construction of a house. For a better understanding of the importance of the calculation process, you should watch this video:

Creating a pile-grillage foundation with your own hands

For an independent device of the pile-grillage foundation, it is necessary to perform the following stages of work:

In the event that a metal grillage is used in the foundation, then it is welded to the heads of the supporting columns. When installing the belt, the horizontal should be strictly observed so that the load from the building is evenly transmitted to the foundation.

When arranging a recessed structure made of reinforced concrete, it will be necessary to fill in crushed stone with a fraction of 20-60 mm, and compact it using a vybroplat. The layer of crushed stone must be at least 150 mm. To improve the bearing capacity of the soil under the belt, crushed stone should be laid in small layers, which must be compacted with a vibrator. Formwork for the grillage is installed on the crushed stone substrate, the width of which should slightly exceed the thickness of the walls, and the height of the formwork panels should also take into account the size of the future basement.

In the scheme of reinforcing the grillages of pile foundations, just as in the construction of the foundations, two upper and lower belts of metal reinforcement are used, as well as vertical and longitudinal rods of a smaller diameter. At the stage of reinforcement, it is necessary to lay boxes and pipes for the subsequent laying of utilities. Since, if this is not done, then later you will have to hammer in the concrete, which will lead to a violation of the integrity of the monolith.

Filling the belt with concrete, you need to vibrate the solution. It is difficult to achieve uniformity and high strength without following this procedure. That is why the processing of concrete with a vibrator when pouring the foundation and the belt is extremely necessary and obligatory. The formwork can be removed after 4 days if the air temperature was + 20˚C after pouring. By this time, the design strength of concrete will reach 50%, which is quite enough to start the next stage of construction work. At a temperature of + 10˚C this period will be about 2 weeks. At lower temperatures, the poured monolith needs insulation or heating.

Typical mistakes made when creating a bored foundation with a grillage can be seen in the video below:

Related article:

Consider the pros and cons of a pile foundation with a grillage at a freezing depth, and why this type of foundation is preferred.

The advantages include:

Among the disadvantages of the pile-grillage foundation are the following:

Conclusion

In almost all cases, when constructing foundations for one- and multi-storey buildings, it is necessary to create a grillage. The use of a belt when creating foundations is a rather laborious process, however, if all requirements are taken into account and met, the necessary calculations are made and high-quality and compatible building materials are used, then the reliability of the entire building structure is guaranteed.