Self-tapping screws for wood: a table with dimensions, features of choice and nuances of use

The market for fasteners for fixing various structural elements made of various materials is quite extensive. These are screws and anchors, bolts and studs, as well as brackets and other fasteners. When installing products and structures from lumber, self-tapping screws for wood are often used. Dimensions, table and price of these products, features of use on different materials - these issues will be discussed in this publication homemaster.techinfus.com/en/.

The content of the article [Hide]

- 1 Advantages and disadvantages

- 2 Types of wood screws

- 3 Documents regulating the production of wood screws

- 4 How and with what screws are fixed

- 5 How to choose - editorial recommendations homemaster.techinfus.com/en/

- 6 What is the difference between self-tapping screws for wood and metal

- 7 How much are wood screws - price overview for 1 kg

- 8 Video: overview of wood screws

Advantages and disadvantages

Self-tapping screws for wood are the type of fasteners that almost every user is familiar with, regardless of place and region of residence, type of activity and place of work. This is due to ease of use, variety of sizes and low cost. In addition, the advantages of using self-tapping screws for wood include such indicators as:

The disadvantages of wood screws are:

Self-tapping screws - confirmations used in furniture production and for joining structures made of board materials (chipboard, MDF, etc.)

Types of wood screws

The industry produces various types of fasteners designed for different types of materials, while self-tapping screws for wood, in addition, are classified according to such indicators as the nature of the outer surface treatment and shape, by the type of thread and geometric dimensions.

By the nature of the outer surface treatment

The raw materials used in the manufacture of self-tapping screws of this type are carbon and stainless steel, as well as brass. To impart strength and durability to the final product during the production process, the surface of the self-tapping screw is treated with special chemical compounds during operations such as:

In addition to black products, manufacturers produce brands of self-tapping screws with an additional anti-corrosion coating:

By form

This type of fasteners is produced by manufacturers for various purposes of use, which leads to differences expressed in the form of a self-tapping screw, namely:

By thread type

The type of thread is one of the main differences between different types of self-tapping screws. There are three types of threads in total:

Self-tapping screws with different thread pitches are used on various types of materials, depending on their structure and density. For example, products with a wide pitch are used when installing soft materials (spruce, pine, drywall, etc.), and with small ones when using dense materials. products made of birch, plastic and metal.

Dimensions of wood screws

The assortment of self-tapping screws by geometric dimensions is very extensive, which is expressed in different diameters and lengths, depending on the shape of the product and the thread that determine their purpose.

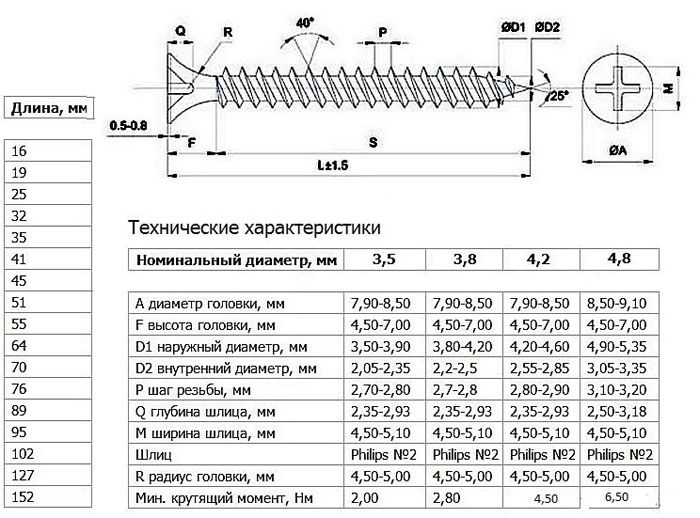

The diameter can be 1.6 mm - for black and galvanized grades with a wide thread pitch, up to 12 mm - for confirmations and wood grouses. The length of a self-tapping screw equipped with a countersunk head is determined by its full length, and for products with a convex head, by the length of its rod. The length and technical characteristics of black wood screws with a wide pitch are shown in the following figure.

Documents regulating the production of wood screws

At present GOST 1145-80 (ST SEV 2327-80) “Countersunk head screws. Design and dimensions (with amendments N 1, 2) ". This document defines the geometric dimensions and shape of the head, the mass of products and their quality characteristics, as well as the characteristics of the slot (number, radius, depth). In addition, GOST regulates the labeling of self-tapping screws, which greatly simplifies the selection of the desired fastener from the catalog for specific use cases.

How and with what screws are fixed

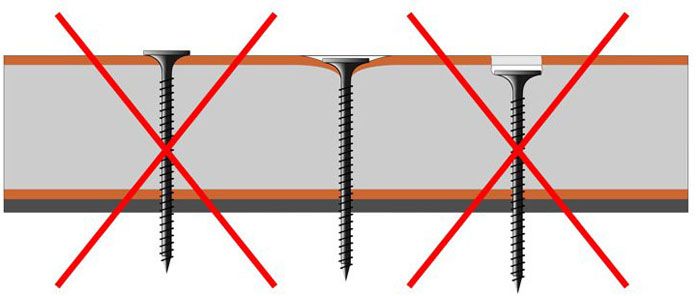

To drill self-tapping screws, a hand-held locksmith tool (wrenches, heads, hexagons, screwdrivers) and an electric hand tool (screwdriver, electric drill) equipped with a set of special bits and accessories are used.When performing work, the marking of the installation locations of the fasteners is initially performed, after which, using a sharp object (awl, drill, etc.), a depression is made in the wooden surface, into which a self-tapping screw should be placed. When using confirmations and wood grouses, as already written above, it is necessary to drill a hole with a drill with a diameter smaller than the used fastening element.

After that, the self-tapping screw should be drilled into the marked place or prepared hole using the selected hand or electric tool.

How to choose - editorial recommendations homemaster.techinfus.com/en/

Due to the fact that the range of fasteners is quite extensive, sometimes it is not easy to choose the right product the first time. In this case, you should contact the professionals who can tell you what to look for when choosing, so as not to be mistaken.

Our editorial staff formulated their recommendations as follows, namely:

- The geometrical dimensions of the fasteners must correspond to the dimensions of the products to be mounted and their mass.

- For use in a humid and other aggressive environment, self-tapping screws with a protective layer should be used, and its presence can be determined by the color of the product.

- The thread pitch must correspond to the strength of the material to be mounted, which should be taken into account before choosing fasteners.

- The notch on the head of the self-tapping screw is also a selection condition, because the convenience of installation work and the type of tool used depend on its type.

- The quality of self-tapping screws is guaranteed by their manufacturer, so it is better to choose a product made by a well-known company that has proven itself only from the good side.

What is the difference between self-tapping screws for wood and metal

The main difference between self-tapping screws for wood and analogs intended for metal is the thread pitch, which is due to the density of these materials. Another difference between self-tapping screws for metal is the presence of a self-tapping head that allows you to mount metal without pre-drilling it.

How much are wood screws - price overview for 1 kg

Fasteners are sold both in stores within walking distance, and in retail chains of building materials and metal products, as well as in organizations specializing in similar products. If in small stores self-tapping screws are sold by the piece and by weight, then in specialized organizations they are sold only by weight. The following table shows the average cost of various types of self-tapping screws, as of the beginning of the third quarter of 2018, when sold through retail chains.

| Product type | Average cost (as of July 2018) for 1 piece, rubles | Average cost (as of July 2018) per 1 kg, rubles |

|---|---|---|

| Black phosphated | 0,28-3,76 | 180 |

| Black oxidized | 0,55-3,62 | 195 |

| Galvanized | 0,15-4,63 | 200 |

| Yellow passable | 0,18-5,58 | 210 |

| With press washer | 5-340 | - |

| "Capercaillie" | 0,96-46,44 | 500 |

| Roofing | 0,6-5,75 | 220 |

| Confirmates | 1,5-15 | 150 |

In hardware and fastener stores, you can always find self-tapping screws of the required standard size and in accordance with the intended use

Video: overview of wood screws

In order to imagine what wood screws are and what are their differences, the following video will tell.