Wood prefab house: how to make sustainable housing economical and not burn out during construction

The emergence of new technologies and materials has not spared the construction industry, which has led to the growth of individual housing construction in all regions of our country. Nevertheless, the use of traditional, environmentally friendly materials remains a popular trend, especially in regions where wood is not a scarce commodity, but is affordable and in the required range. A prefabricated house made of wood - types, advantages and disadvantages, new and traditional construction technologies, as well as operating features and turnkey construction costs - this is the topic of this article by homemaster.techinfus.com/en/.

The content of the article [Hide]

- 1 The role and significance of the construction of wooden houses

- 2 Advantages and disadvantages of wooden country houses

- 3 Types of prefabricated wooden houses with photo projects

- 4 How to choose material to build a wooden house

- 5 Technologies for building a wooden house

- 6 Dangers and pitfalls of operating wooden houses

- 7 How much does it cost to build a turnkey wooden house - price overview

- 8 Video: what tree to build a house from

The role and significance of the construction of wooden houses

Wood is the building material that has been used by man for the construction of housing since ancient times, and to this day it is one of the most demanded. Elements of building structures are made from various tree species, houses are built on a turnkey basis, interior and exterior decoration is carried out. The reason for this popularity is the valuable properties of wood of different species:

Advantages and disadvantages of wooden country houses

Any building material has its own advantages and disadvantages, which determine its relevance and the possibility of using it in certain situations. In this regard, wood is no exception, both when used as individual elements of building structures, and in the construction of country houses in a full cycle.

The advantages of wooden houses, in comparison with the options for using other building materials, include the following indicators:

Wooden houses made using frame technology are distinguished by short terms of construction and installation work and low cost, compared to other options for wooden housing construction.

The disadvantages of houses made of wood include:

Types of prefabricated wooden houses with photo projects

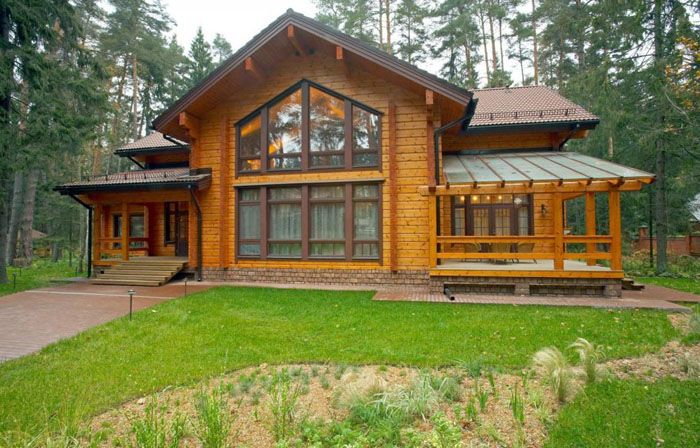

In the construction of wooden houses, various technologies are used that determine the sequence and timing of work, as well as the appearance of the finished structure. This section of the article will consider the most popular options for building a country house made of wood.

House made of rounded logs

A rounded log is a log that has been processed on special woodworking equipment and has the same diameter along its entire length.

The advantages of using rounded logs are:

Among the shortcomings, it should be noted:

The ease of performing work using this building material allows you to make buildings of various configurations and purposes from it.

The two-storey house "Arbazh" assumes in its design the presence of a second light in the hall of the building

Wooden houses from profiled lumber

Profiled timber is a lumber manufactured in the factory from round timber as a result of mechanical processing of the latter. At the exit, a product is obtained - a bar, the cross-section of which differs from the rectangular one and has grooves of the “thorn-groove” type.

Distinctive features of houses made of profiled timber are:

In the manufacture of profiled timber, spruce and pine, cedar and aspen, as well as larch are used. The choice of raw materials depends on the location of the woodworking enterprise and the availability of stocks of certain species of trees.

Profiled timber is classified according to the degree of moisture content and geometric dimensions.

The standard geometric dimensions for this lumber are:

Related article:

Glued laminated timber houses

A distinctive feature of the glued profiled beam from the solid one, made from a tree trunk, is that it is created from strips of wood, called lamellas, glued together according to a certain technology.

The advantages of glued laminated timber are similar to those of other building materials made from natural wood, and the main disadvantage, in comparison with them, is the high cost due to the costs of its production.

Wooden houses from gun carriage

A carriage is, in the classical version of consideration, a log, from which from two sides, lying in planes parallel to each other, a part of the tree is cut off, called a "slab". Currently, a profiled beam having a similar shape in section is also called a carriage.

The use of a carriage requires certain work skills, because for assembly, you must be able to manufacture and assemble individual structural elements in the so-called "Norwegian castle"

The appearance of the connection of the crowns from the gun carriage in the manufacture of walls of a country house according to the principle of "Norwegian castle"

Related article:

Timber frame houses

Frame technology construction sites are confidently winning over their customers, and there are several reasons for this:

There are several different technologies for the construction of frame houses: Swedish and Canadian, German and Scandinavian, as well as a double frame, American and a number of other varieties. The basis of all of the above technologies is the construction of a frame, which is a supporting structure for all other elements of the house being assembled.

Depending on the chosen construction technology, houses made in this way are classified into:

Related article:

Projects of frame houses, photos and prices. Why is frame technology so popular? How much is such a house worth? Read more in a separate publication on our portal.

How to choose material to build a wooden house

The timing of its operation, as well as the periods of repair work necessary to maintain the building in trouble-free condition, depend on the correctly selected material used in the construction of a house. The selection criteria for the construction of a wooden house will be the following indicators:

- Wood species - must correspond to the type of use and purpose.

- Forest harvested in winter is more durable, both during storage and use.

- The quality of wood - determines the terms of its operation and the amount of waste in the process of production of work, as well as the thermal characteristics of the finished structure

- Cost - depends on the type of wood and its quality, and also determines the amount of costs going to the construction of a country house.

When choosing a tree for building a house, it is necessary to take into account the selected construction technology and the selection criteria given above

Technologies for building a wooden house

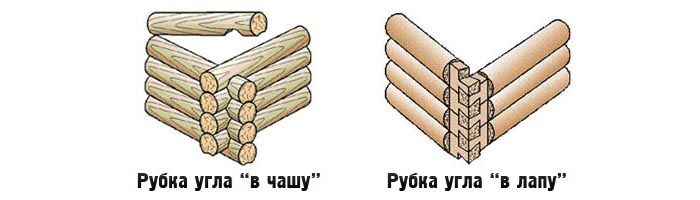

In wooden housing construction, both traditional construction technologies and new ones that are successfully winning their admirers are used. The category of traditional technologies includes:

The category of new technologies includes:

- CLT (Cross Laminated Timber) - presupposes cross-gluing of prefabricated wooden panels by joining dried boards (lamellas) delivered to the construction site in assembled form.

- Unipanel - domestic development, involving the manufacture of wood panels with deep longitudinal cuts on both sides, which reduces the internal overvoltage of the material and improves its thermal performance.

- MHM (Massiv-Holz-Mauer - massive wooden wall) - involves the manufacture of boards from wooden boards in production conditions, after which the finished products are delivered to the construction site, where they are assembled by means of aluminum pins.

- NATURI - involves the manufacture of building structures from bars of a special shape, installed vertically and connected to each other by means of grooves on their surface.

Related article:

Dangers and pitfalls of operating wooden houses

Any wooden structures have inherent advantages and disadvantages due to the technologies used in their construction and, of course, the properties of the tree itself. In this case, the main hazards for wooden houses will be:

How much does it cost to build a turnkey wooden house - price overview

Turnkey construction of a wooden house depends on factors such as:

Different construction technologies involve the use of different construction equipment, which ultimately determines the costs associated with this cost item

The following table shows the average prices for the construction of a wooden house made using different technologies. Prices are indicated as of the III quarter of 2018 in the category of "turnkey" construction.

| House construction | Construction cost (as of August 2018), RUB per 1 m2 area |

|---|---|

| From rounded logs | 30000 |

| From a profiled bar | 12000 |

| Glued laminated timber | 20000 |

| From the gun carriage | 30000 |

| Frame type | 12000 |

The use of ready-made house kits significantly reduces the time required for construction and installation work

In addition to the above parameters, the cost of building a turnkey wooden house depends on the nature of the soil at the construction site, the presence of ground and melt water, as well as the depth of freezing in winter, which determine the design of the foundation used.

Video: what tree to build a house from

Having chosen the construction technology and the project of a country house, you should decide on the type of wood used for this. In this matter, the following video can become an assistant to a novice developer.