Pile foundation: calculation of the number of piles, bearing capacity and load

Often there are situations when a strip or slab foundation is not suitable for the conditions of a particular land plot. The reasons may be different: too complex relief surface, weak bearing properties of the soil or a significant level of freezing. These and other factors make the construction of the base of the building overly complicated and its cost can exceed the cost of building the entire house. In this seemingly hopeless situation, experts recommend using a pile foundation. Calculation of the number of piles, their bearing capacity, the dimensions of the pillars, their depth and location - all this must be found out in advance.for the arrangement of the pile structure. You can make these calculations yourself, using the information, algorithms and recommendations that are offered in our material.

The content of the article [Hide]

- 1 Screw pile foundations technology and their advantages

- 2 Varieties and features of the pile grillage

- 3 How to choose the right screw piles and calculation of permissible loads

- 4 Permissible loads on screw piles, taking into account the characteristics of the site

- 5 Bearing capacity calculator for pile supports

- 6 The simplest calculation of the pile foundation, without formulas and complex schemes

- 7 Load calculator for the whole structure

Screw pile foundations technology and their advantages

Basis of the device

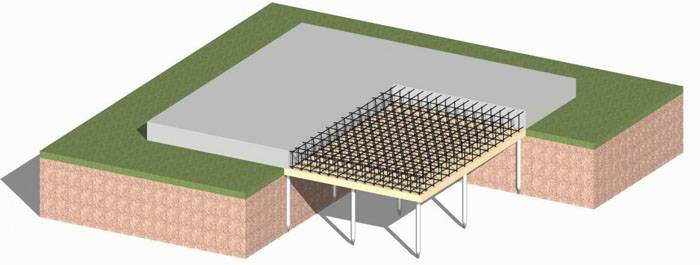

A pile-screw base is a set of metal supports installed in the soil. On the surface, they are fastened into a single whole with the help of a grillage. Each pile has specially shaped blades. They help the support easily enter the soil and, in addition, simultaneously compress the soil and provide a solid foundation that resists increased stress.

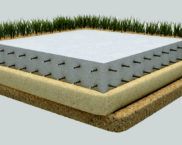

The structure of the pile allows it to easily pass all levels of weak and unstable soil to dense layers. The support is deepened so that it is not afraid of surface deformations from getting wet and freezing.As a result, we get an exceptionally solid foundation of the house, which does not depend on the vagaries of the weather, terrain and soil structure.Inside, the metal support is poured with concrete mixture.

No additional reinforcement required, no metal inside the support to prevent internal corrosion damage

On the upper part, the pillars are cut along a single horizontal level. A metal mounting platform is attached to the cut point, on which the grillage will subsequently be fixed.

Scope of application

Such foundations are suitable not only for the home. Pile foundations are used for baths, carports, garages, construction of the foundation for the oven. This prefabricated base is used in the construction of lightweight structures: for gazebos and for fences... Piles can be safely used for the construction of premises with high humidity, for example, for a greenhouse. Such a base has proven itself well for sliding gates.At the same time, such structures are so reliable that they are used for metal overpasses of road bridges.

You can imagine what kind of loads such foundations can withstand if they are installed during the construction of bridges along which road and rail transport moves.

Advantages and disadvantages of a pile foundation

What you need to know when deciding to build a pile foundation

The task of screwing in the supports will be greatly simplified by a special installation. She will do all the work in a matter of hours and with high quality

Do not use supports for grounding power supply at home... In the event of a short circuit, the current passing through the metal of the support will provoke the development of rust in the welding areas.

Varieties and features of the pile grillage

In the construction of private houses, a pile-grillage foundation is mainly used. This foundation allows you to significantly save on construction and further reduce operating costs.

If a residential building needs to be installed on loose soil, construction experts recommend using a screw-pile foundation.

The foundation strapping is divided into three types:

Grillages can also be conditionally divided into three main types.

Shallow bored grillages-piles evenly distribute the weight of the building not only on the piles, but also on the soil itself

How to choose the right screw piles and calculation of permissible loads

Screw piles: standard sizes and basic principles of selection

Screw piles vary in pipe diameter. Depending on this indicator, the purpose of the support is determined:

Welding or Casting?

The poles are available in two types - they can be welded or cast. The production of these elements is different, consider the basic principles:

Before you buy the poles, check the quality of the product carefully. In the construction market, you can run into fakes that look like cast ones, but are actually made by welding and using used or defective materials. To ensure the quality of the product, ask the sellers for quality certificates. Do not be too lazy to check the pile wall thickness - it should be 4 mm for a high-quality support. The fake will have less. Look inside the tube with a flashlight - traces of use may be visible to the naked eye.

Number of blades

Piles can have a different number of blades. Supports should be sized according to the expected load.

Coating

What else should you pay attention to when choosing a support? It turns out that piles differ in the type of coverage:

Permissible loads on screw piles, taking into account the characteristics of the site

We examined in detail the types and sizes of piles, it is time to talk about their bearing capacity. How many supports will be required for a reliable foundation of your structure depends on this indicator.

The bearing capacity of piles depends not only on their size, but also on the characteristics of the soil.When designing the foundation, it is necessary to carefully examine the site and take into account the peculiarities of the local climate.

The stability of the pile foundation is achieved through the active resistance of the supports to the action of the compressive and buoyant forces of the soil

Approximate parameters of the bearing capacity of the pile in different soils:

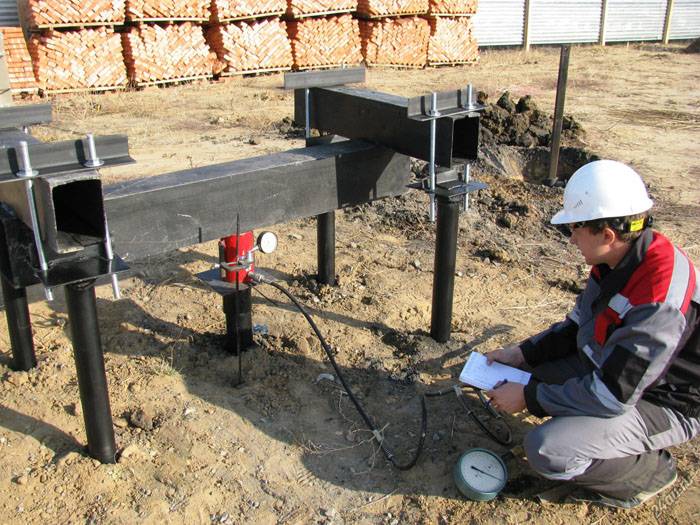

One of the basic building rules is not to bring the load on the foundation to the maximum. To determine the behavior of the future foundation during operation, a test is carried out with a reference pile with a diameter of 114 millimeters. This composite support is driven into the ground and subjected to various types of loads: pulling, indentation, displacement. Using this method, data on soil resistance is obtained and the dimensions of the supports and their depth are determined.

All studies are carried out using special equipment that records changes in the state of the reference element

The load-bearing capacity can be calculated using the proven formula:

W = O / k, Where

W Is an indicator of the permissible load on the support;

O - calculation of the permissible load taking into account the size of the support and the characteristics of the soil;

k - coefficient of the operational reserve of the foundation.

First, let's calculate the value ABOUT... The following formula is required:

O = S x Ro, Where

S Is the cross-section of the support blade;

Ro - soil resistance at a depth to which the screw part of the pile will sink.

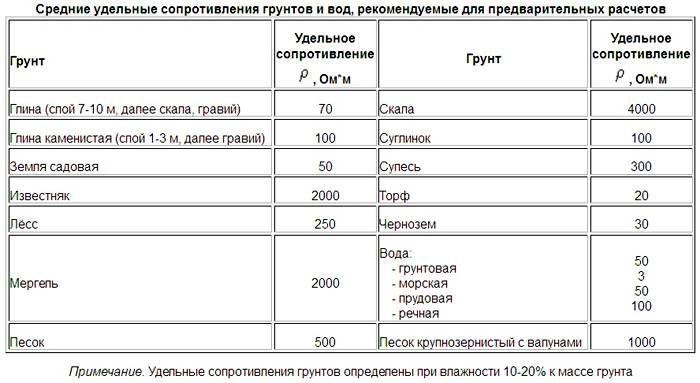

Find the last value can be for this or other tables containing general information on the characteristics of the soil in your area.

Returning to the value of k will explain that it has records of 1.2 to 1.7. In this case, 1.2 - the lowest figure, characteristic of the most stable ground.

Bearing capacity calculator for pile supports

We offer you to simplify the calculations use the online calculator bearing capacity of piles. This program is designed taking into account the requirements of SNIP and SP for pile foundations.

The above method, as in the formula of which we spoke earlier, based on the size of the trunk and the support screws, installation depth and composition of the soil at the site.

Geometric data of supports is available to everyone, but data on soil properties can only be obtained as a result of professional research. If there is no such information, the program can calculate according to the average indicators included in the snippet. This option will help to get approximate calculation of data for the design to be used with caution, putting margin.

It can be used for calculations of special programs - SCAD or Lear. Members forumhouse note that the lyre more simple and intuitive interface, and Scud have the necessary calculations for sections of the designer. Furthermore, scad 21 is the possibility of visual imaging calculation results. In any case, and she and the other programs are available and understandable only to professionals. Not having the basic knowledge, the rookie is unlikely to deal with all the necessary to work with the program parameters.

So, for self-calculations, we suggest you use the example of a calculator from this material.Having calculated the bearing capacity of each support, you can easily calculate the cost of the entire foundation.

Related article:

The simplest calculation of the pile foundation, without formulas and complex schemes

Once identified all the features of the soil on the site and calculated the carrying capacity of screw piles for the foundation, one can start planning the foundations for a house.

We offer little benefit calculation for individual construction:

Using this simple guide, it is not difficult to correctly plan a pile structure for a simple structure.

Returning to the topic of how to calculate the load on the foundation, we can recommend another version of the online calculator. It will help determine the total load on the entire foundation structure.

Load calculator for the whole structure

So, the following program will help to calculate the total load on the base of the building, taking into account all important factors: the dimensions of the internal and external walls, the mass of the floors, the features of the rafter system and the roof covering. These indicators are important for determining the type and strength of the foundation. Even after rough calculations, you will see how different the results will be for a frame house and, for example, a foam concrete structure.

Let's look at everything in order:

The final result will be in tons. Final calculations can be made without special tools. In the first calculator, you got the size of the load on one pile, taking into account the characteristics of the soil. In the second, the total mass of the structure. It remains to divide the second result by the first and get the required number of piles.

And at the end of the topic about the pile foundation, some more useful information:

Video tips for proper planning of the pile foundation