If you don't want to disassemble the floor or how to choose the right pipes for a warm water floor

It is unpleasant, leaving the bathroom or shower, to step with bare feet on the cold tiled floor. In addition to uncomfortable sensations, this also harms health, because hypothermia of the legs leads to a cold. This problem requires a solution, which can be a water floor heating device. But here another possible problem arises: if it is wrong to select and mount pipes for a warm water floor, then the effect of such a solution will be extremely low. After all, for this you need to correctly calculate the length, laying step and diameter of the pipes. We will dwell on this in more detail today.

The content of the article [Hide]

- 1 Which pipes for a warm floor are better: the basics of the right choice

- 2 Requirements for pipes for underfloor heating

- 3 Classification of pipes for underfloor heating by material

- 4 How to calculate the step of laying pipes for a water-heated floor and their length

- 5 The nuances of installing pipes for a warm water floor

- 6 Where to buy pipes for a water-heated floor and what is their cost in the Russian market

- 7 Finally

- 8 Video: which pipe for a warm floor is better and stronger

Which pipes for a warm floor are better: the basics of the right choice

The question of which pipe to use for a water-heated floor requires detailed consideration. It is clear that after complete installation, it is no longer possible to repair the track, which means that it is worthwhile to approach the choice carefully. The first thing to understand is that for such purposes it will not be possible to use the trimmings remaining after the repair by soldering or welding the parts. Welding is out of the question - steel products should be forgotten. It doesn't matter if they are galvanized or even made of stainless steel (although there are options here that we will discuss too). There is a seam on them, and this is already unacceptable when installing a warm floor.

Not considered and plumbing plastic productssold in 4 or 6 m lengths. This involves connections (welds, elbows or fittings), which is no longer acceptable. Firstly, the seam is a weak point, and secondly, it is the point where plaque collects, which leads to blockage of the line. The only right solution would be to purchase a solid pipe with flexibility, according to a pre-calculated length.

Requirements for pipes for underfloor heating

There are only three requirements for highways for underfloor heating:

If at least one of them is violated, the consequences will be dire. When a line is leaking, which is flooded screed, the owner will not notice anything. The first one to find it is the neighbor below - water drips from its ceiling. But this is not the worst thing. Worse if it closes wiring - this could cause a fire. And in order to find and repair the damaged area (see - replace the highway), you will have to open the floors. The result can be imagined.

Let's deal with the listed requirements in more detail.

Material for making pipes for underfloor heating

The material for the warm water floor can be copper, stainless steel (in the form of a corrugated hose), polypropylene, cross-linked polyethylene or metal-plastic.The heat-conducting qualities of copper and its ability to deform put this material in first place in terms of quality. Outline of copper pipes will provide the required heat transfer, the distribution will be uniform. Despite the complex installation, other characteristics are close to ideal. Modern products are coated with polymers that protect the product from the aggressive environment of cement. Only the high cost frightens off the buyer.

Geometric dimensions of pipes for a water-heated floor

Speaking about the diameter, experts advise using a pipe with a diameter of 16 mm, but you need to understand that this parameter depends on the length of the line. Sometimes it is necessary to use a diameter of 13 mm. Pipes thicker than 16 mm are not used in such systems. Otherwise, it is necessary to install an additional pump, which is not advisable.

Physical and mechanical properties: what is it

This term denotes the ability of a product to bend without overstressing. The durability of the system in those places where the turns of the highway are made depends on this. The screed pressure also affects the outer walls - this cannot be ignored. In other words, physical and mechanical properties are the ability of a material to withstand the effects of external factors.

Classification of pipes for underfloor heating by material

It has already been mentioned what materials a pipe for a warm floor can be made of. Now let's try to consider each of them in detail.

Polypropylene: advantages and disadvantages of the material

If we consider this material from the point of view of applicability specifically to the device of a warm floor, then it will be in last place, even though it is cheap. Despite the fact that heat transfer is high, such materials do not bend well. Even when heated, the swing angle is too large. Soldering is required using corners, which is unacceptable if quality installation is planned.

The device of such a system is possible only in the absence of self-leveling screed... This can be done in a room or hallwaywhere the parquet is being laid. But in kitchen or bathroomwhere the flooring is tile, this option will not work.

Corrugated stainless steel hose

This is already an acceptable option. Modern technologies make it possible to manufacture such products with high quality and durable. They bend along a smaller radius, which ensures that the line is laid as it was intended. If you choose which pipe for a warm floor is better - polypropylene or corrugated stainless steel, then the first clearly loses.

Stainless steel is durable and has good heat dissipation. This means that the floor will warm up evenly.

XLPE pipes: what's good about them

Of these, this material is the most popular. It has the same characteristics as polypropylene, but the line can bend in any direction. Among the advantages we can note the possibility of operation at temperatures up to + 1200 ° C and the fact that the material has a "shape memory". This means that at increased pressure, even if the pipe is deformed, when the original parameters are restored, it will return to its original state. For this reason, these pipes must be secured during installation.

Copper as an ideal material for such systems

You can talk about copper pipes for underfloor heating for hours, but today we will only highlight the main points. We have already spoken about thermal conductivity, but as for kinks, the question is more complicated. Copper requires a special approach. The pipe bends in a certain way using a special device. This is done so that it does not go to the "kink". Then it only remains to throw it away. But a correctly laid copper highway will outlive the house - this can be said with confidence. Only during the first period of operation, copper is covered with the thinnest layer of patina. This is where the aging process ends.

Reinforced plastic pipes for underfloor heating

The differences between these materials are insignificant for some uninformed people. However, in fact, metal-plastic is even better suited for underfloor heating lines than cross-linked polyethylene. The pipe bends along small radii without losing its strength, and the aluminum layer inside not only allows it to keep its shape, but also ensures uniform heating over the entire area.

If we talk about the popularity of underfloor heating devices made of this material, then they are in second place, after cross-linked polyethylene, only because they appeared relatively recently. But every day the number of fans is growing. No wonder. Indeed, in addition to all the positive physical and mechanical characteristics, they are inexpensive.

Summarizing the information, we can say that in order to resolve the issue of which pipe to choose for a warm floor, you need to rely on financial capabilities. Copper will be perfect, but it is expensive, XLPE is cheap, but its heat transfer is inferior to other materials. And metal-plastic can be called optimal in terms of price-quality ratio.

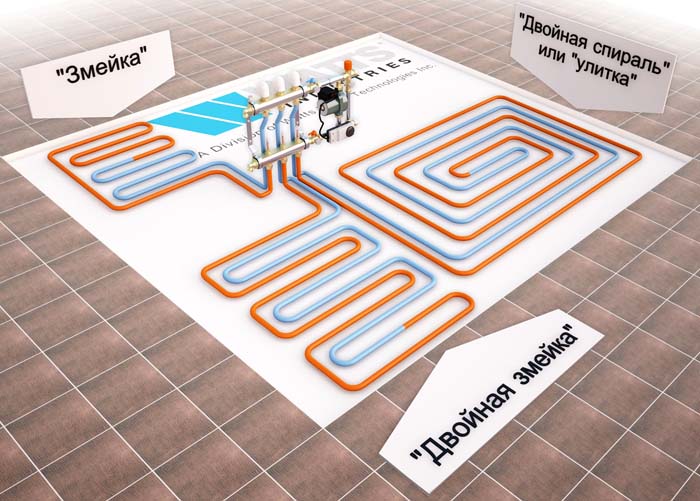

How to calculate the step of laying pipes for a water-heated floor and their length

The exact calculation of the length of the pipe and the pitch of its laying over the area is very important. The quality of the subsequent heating of the floor covering and its uniformity depend on this. On average, the consumption of material per 1 m2 of area is 5 m. In this case, the laying step will be 20 cm. To calculate the total amount of material, we will use the formula:

L = S / N × 1.1where

The length of the pipe, if we take into account metal-plastic with a diameter of 16 mm, should not exceed 100 m per circuit. The optimal value will be 80 m.

Installation of a warm floor is possible without a concrete screed, but the heat transfer will be lower

Related article:

The nuances of installing pipes for a warm water floor

Installation of the entire underfloor heating system is a complex and time-consuming process. The main task here is to bring all possible connections to the surface so that they do not remain under the concrete screed. Let's consider the main points.

Laying pipes for a water floor: how to do the job correctly

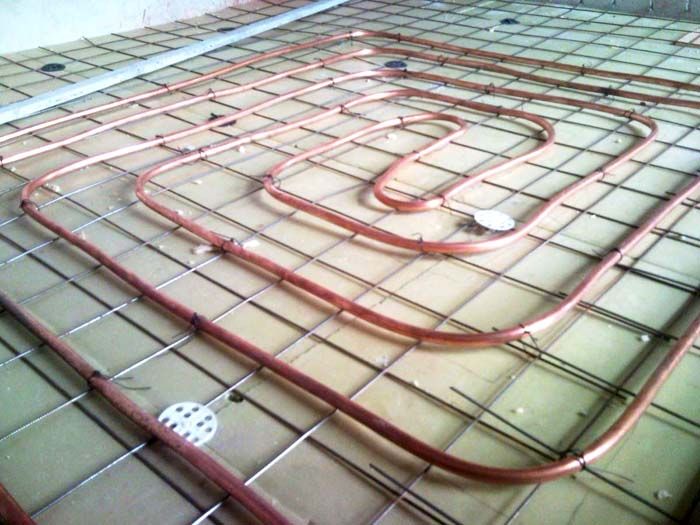

When laying it is important to observe the step. If this parameter is violated, the floor heating will be uneven. It is obligatory to fasten the line to the reinforcement mesh by means of plastic clamps or stretch marks. This will prevent you from shifting the pitch when filling. concrete screed.

Docking and connecting the pipeline

The underfloor heating main is connected to the outlets from the collector already above the level of the future concrete screed. The connection is made using special fittings. If metal-plastic is chosen for the warm floor, the joints are welded. After the completion of these works, the entire system is pressurized. This is done before pouring the concrete screed. The system is supplied with water at the pressure that will be maintained during operation. Pressing continues for at least 24 hours. This action allows you to identify possible defects that will become irreparable after pouring the floor with a concrete screed. If no leaks are found after a day, you can proceed to the last stage.

Related article:

Where to buy pipes for a water-heated floor and what is their cost in the Russian market

Prices for pipes for a water-heated floor differ, depending on the material of manufacture and the region of sale. Affects the cost and brand of the product - well-known brands will cost more. When purchasing such a product, you should not choose something that is much cheaper than analogues - there is a risk of throwing money away.

For example, consider the prices of pipes for a warm water floor "Rehau" - one of the well-known manufacturers.

| Photo | Product length in the bay, m | Size, mm | Cost, rub / rm |

|---|---|---|---|

| 240 | 10.1x1.1 | 60 |

| 140 | 14x1.5 | 70 | |

| 240 | 14x1.5 | 70 | |

| 500 | 14x1.5 | 65 | |

| 120 | 17x2 | 75 | |

| 240 | 17x2 | 75 | |

| 500 | 17x2 | 70 |

This information has been provided for a general concept of pricing. Now let's consider the cost of pipes for a water floor made of various materials.

| Photo | Manufacturing material | Size, mm | Cost, rub / rm |

|---|---|---|---|

| Metalloplast | 16x2 | 60 |

| XLPE | 16x2 | 50 |

| Corrugated stainless steel | 12x2 | 140 |

| Corrugated stainless steel | 15x2 | 300 |

Selling copper pipes for underfloor heating is done differently. Regardless of the size, the buyer pays a fixed amount by weight. In Russia today it is from 550 to 800 rubles / kg.

Finally

Sometimes warm floor is necessary. And although it is more difficult to install a water one than an electric one, it is more practical, more durable and more economical. The main thing is to correctly calculate and purchase quality material. Then the system will delight you and your loved ones with warmth for many years to come.

We hope that the information presented today was useful to our reader. If you have any questions, we will be happy to answer them in the discussion below. Write, ask, share your experience.

And finally, a short video on the topic:

Video: which pipe for a warm floor is better and stronger