Making a beautiful ax from a simple ax-step by step instructions

An old Soviet conventional ax can be easily converted into a new and stylish one. This will be correct, since the steel of the blade in them is excellent, and a new one will be very expensive. How to make an ax with your own hands from an old one - read in our article.

The content of the article

What are the axes

First, let's look at the types of axes. It may seem that they are all the same, but no. The location of the center of gravity and sharpening depend on the shape. Some types are better for chopping wood, while others are better for chopping wood. Therefore, we will consider them separately.

Lumberjack

Good for felling trees. Its center of gravity is strongly shifted towards the blade, so the main blow is concentrated at the beginning. For this reason, hold it with both hands. The ax is relatively long in order to increase the reach and power of the blow.

Cleaver

It has a wide, short and narrow blade. From the name it is clear that it is intended for chopping wood. The butt of the ax is thick in order to more efficiently go into the fire. Medium length handle. A photo of the ax can be viewed below.

Plotnitsky

The carpenter's ax has a relatively short handle so that it is convenient to work with it with one hand. On the contrary, the blade is wide. Indispensable for preparing logs for building a house.

Srednerus

Also called the taiga ax. Refers to a universal instrument, as it was often taken with you on expeditions. They can chop wood and cut the carcass of an animal.

Combat

These include Viking axes, axes and other melee weapons. It should be noted that the production and sale of such products is controlled by government agencies, so it is not worth doing it. Or have to register with expertise.

Sturdy

A beautiful ax with a short handle and a large blade. It makes no sense to buy it for your home, as it is inconvenient, but indispensable for hiking. It weighs almost nothing, compact, but not very suitable for regular splitting of firewood and felling of wood. For hiking, such an ax is often made from reinforcement.

Work process

Materials and tools for work

Handmade axes require at least basic locksmith and carpentry skills.We will make a do-it-yourself viking ax from a simple ax that can still chop wood. For this we need:

- Block of wood. No, ordinary pine or spruce will not work. Below is a list of acceptable breeds. All of them are given 1 requirement - there should be longitudinal fibers, not transverse ones.

- Sketch paper with pencil.

- Wedges.

- Varnish or oil (linseed, tung, teak).

- A small piece of leather or leather substitute.

- Ax blade. Anyone will do, even corroded.

From tools:

- Angle grinder.

- Welding machine. Normal MMA welding is sufficient.

- Grinding machine.

- Drill.

Separately, you need to talk about the tree. We need a little - a bar 40x40. But what breed? There is a choice here:

- Beech. Basically, inexpensive and beautiful material. It is the cheapest of all hard rocks. The only thing to consider is the rate of moisture absorption. It needs to be covered with a thick layer of oil.

- Oak. Probably the best grip material. Strong, durable, reliable.

- Maple. Its plus is elasticity. Where the oak cracks from the load, the maple will remain intact. By the way, one of the most beautiful wood species.

- Ash. The hardest breed of the listed, at the same time inexpensive.

Now we can make a Viking ax with our own hands.

We clean the corrosion

It also needs to be broken down into several stages. And the first one is cleaning:

- Before making an ax handle for an ax with your own hands, you need to remove the old one. The easiest way is to knock out. We cut it straight along the beard of the blade and knock it out with a chisel or punch.

- Now let's move on to processing the blade. It is necessary to remove the rust from it with a grinder. An ordinary petal circle is sufficient for this. We will deal with polishing later.

- Now we are looking for cracks and gouges on the blade. If they are, we just brew them and clean them with a grinder. There is nothing complicated here.

Making the shape

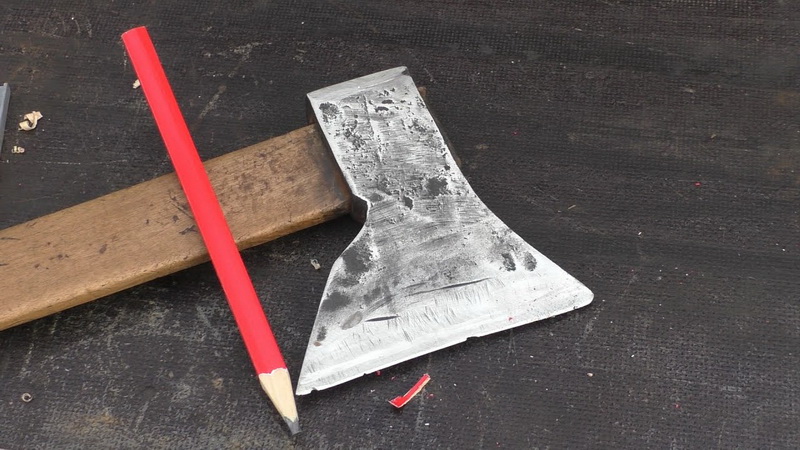

Now we must give the desired shape, also according to the instructions:

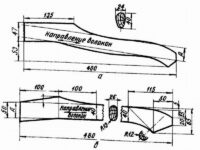

- Draw a contour on the blade using this template. If there is no printer and there is no way to transfer the form, then you will have to work according to the calculations. We retreat a centimeter from the top of the butt and put a point. Now we draw a straight line from the selected place to the toe. We also retreat a centimeter from the heel and make a note. We apply any round object so that it simultaneously touches both the selected point and the beard. We circle.

- How to make the Viking ax straight? Is it not so easy to cut a circle by hand? Draw rays along the inner circle and cut along them. Now we cut out a circle.

- It remains only to polish. We take special grinding attachments for the grinder and polishing pastes. From cheap, GOI or diamond pastes are suitable.

Hardening

A handmade ax must be hardened and it is best done using technology. The metal can be burned, making it brittle due to carbon burnout. In general, everything consists of 3 stages:

- Annealing. It is necessary to remove the stress from the steel, which is there anyway. It's easy to do - heat it up to 760-800 degrees. The metal will be red and burgundy. Then we put it on the brick and let it cool. Then we remove the scale.

- Hardening. Much more complicated process. Initially, we prepare 2 buckets of water. In one water - in the other oil. Anyone will do, including working off. We heat the blade to 830 degrees and lower it 4 centimeters into the water for 5 seconds. Then completely dipped in oil. Unforgettable to make circular movements to knock down air bubbles.

- Vacation. After hardening, the steel is hard but brittle like glass. If it falls, it will simply crack and must be released. You need to heat it up to 200 degrees and let it cool slowly with the oven for an hour. Even a regular oven will do.

By the way, in the same way you can harden an ax from rails or reinforcement.

The blade can now be sharpened. There is no point in doing this in advance, since heat treatment will remove the cut anyway. Moreover, the blade can also lead.

Sharpening an ax is a simple matter.We take a grinder with an abrasive disc and try to maintain an angle of 20 degrees.

Making an ax

How to make an ax with your own hands? Quite simply, you only need a block, a marker or pencil, a bow saw, chisels and sandpaper.

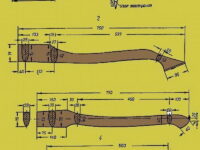

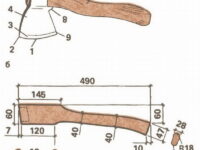

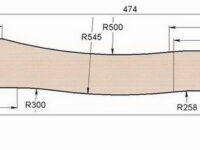

We take a sketch of the hatchet and apply it to the bar. Cut the handle along the contour. Remove sharp corners with chisels and round off with sandpaper.

Now you can decorate it. We put a drawing on the ax and cut it out in any convenient way. It can be wood carving or engraving.

Fitting the ax to the blade

There is only one thing left - to connect the handle and the blade. How to put an ax on a hatchet correctly? According to the instructions:

- The head of the ax is adjusted to the size of the hole in the blade. To do this, you need a saw and sandpaper. There is nothing difficult in this.

- After fitting, if it melts correctly, it's time to wedge. If we make an ax from reinforcement, the hole is made of our own free will.

- At the end of the landing, we make cuts. Simple option: 1 rip cut and 1 wedge. But this is not as effective. The optimum is the cross. 1 rip and 1 cross cut. Wedges of size melt into them and are hammered into them. Professionals say that wedges are best made from the same wood.

- We cut off the excess with a saw.

Making a storage case

A DIY ax case is needed for safe transportation. Moreover, you cannot do without it on a hike.

Detailed instructions for PVC bags in the video.