How to make a wood splitter with your own hands: drawings, photos, instructions

Chopping wood with an ax is very hard work, so many owners of country houses who heat the stove with wood try to buy or make a wood splitter on their own. These devices allow you to avoid the tedious waving of a cleaver, thanks to which you can chop much more firewood in one day, because you do not have to rest every now and then. From the article you will learn how to make a wood splitter with your own hands: drawings, photos, instructions will help you in making it.

The content of the article

Types of wood splitters

There are three main types of wood splitter, which differ in the source of energy for influencing the log:

- hydraulic;

- electrical;

- kinetic (manual).

Hydraulic wood splitters

This device works according to the principle hydraulic press... A hydraulic cylinder pushes the log onto a sharpened wedge, which splits the wood. These wood splitters are driven by an oil pump powered by a gasoline or diesel engine. Their main disadvantage is the high cost of high-quality hydraulic cylinders, control units and pumps.

Electric wood splitter

Electric (rack and pinion) wood splitters work on the same principle as hydraulic ones. Their basis is a rack and pinion gear, which pushes the log onto a sharp wedge. Their advantage is the availability of parts and their low price. Such gearboxes are installed on sliding gates and other similar techniques. Electric (cone) wood splitters work on the principle of a self-tapping screw. The steel cone is threaded, so it twists into the log and breaks it.

Manual (inertial) wood splitter

The basis of this wood splitter is a metal pipe (crane), which is hinged on a metal support. The pipe is fitted with a wood splitter blade and various steel reinforcements.A counterweight is sometimes used to make it easier to lift the pipe. To split the log, the pipe is sharply lowered. The blade splits the log under the action of the inertia of the pipe and reinforcing elements. The advantage of such a device is that it can be made of any steel pipes, which an employee of the nearest ferrous metal collection point will sell for several hundred rubles. The disadvantage of this wood splitter is that it uses muscle strength to work, so a person gets tired quickly.

Video: wood splitter with washing machine engine

Homemade wood splitter - what and how to do

If you have the necessary materials, then it is not difficult to make a wood splitter with your own hands: drawings, photos, instructions are freely available on the Internet. To do this, you need:

- various metal scraps;

- Bulgarian;

- welding inverter;

- the ability to cook;

- the ability to draw up and calculate schemes;

- creative savvy.

Useful advice!The scheme of each wood splitter must be developed individually, for the available parts.

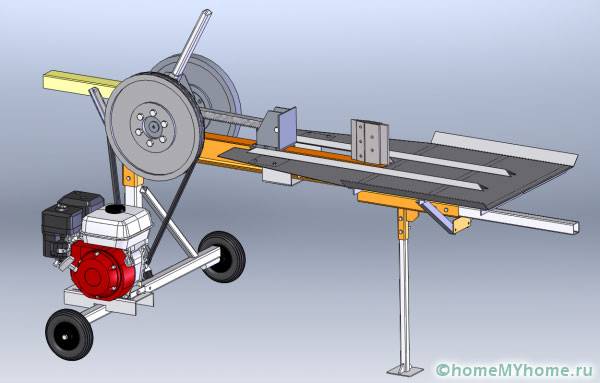

Rack wood splitter - scheme and manufacturing

The easiest way is to make a rack and pinion wood splitter with your own hands: drawings, photos, instructions for which are posted on the Internet. Its basis is a powerful steel frame, to which a wedge, a motor and a gearbox are attached. To make it, take an electric motor with a power of at least 2 kW and two pulleys with a diameter ratio of at least 1: 4. You can also use gearboxes from various mechanisms with a gear ratio greater than 8: 1. If you do not have an electric motor, but have a gasoline engine from a saw or trimmer, you can connect it. In this case, it will be necessary to further increase the gear ratio of the gearbox due to the too high speed of such a motor. Make a knife for a wood splitter from sheet steel at least 1 cm thick, sharpening it at an angle of 90 degrees. To work with thick logs, it is necessary to make a compound knife so that its thickness is at least 5 cm, and inside it, reinforce it with a steel blank of a suitable shape.

The rack and pinion gear should be 4–6 cm higher than the bed and be at a distance equal to twice the length of the log from the knife. In addition, it is necessary to make a carriage that will ride on the bed. The height of the carriage must match the installation height of the rack and pinion gear. On the front (facing the knife) side of the carriage, install a cross plate that will act as a pusher. For this, use sheet steel at least 7 mm thick. Install any hinge on the carriage that will raise and lower the rack, and attach a spring to lift the rack above the gear. Install and secure the return spring, which will move the carriage towards the gearbox. Install a lever on the bed that will press the rack against the gear. With this lever you will control the work of the wood splitter - when the lever is pressed, the rack comes into contact with the gear and moves forward. If necessary, cut the rail with a grinder - it should be slightly shorter than the distance from the feed plate to the knife.

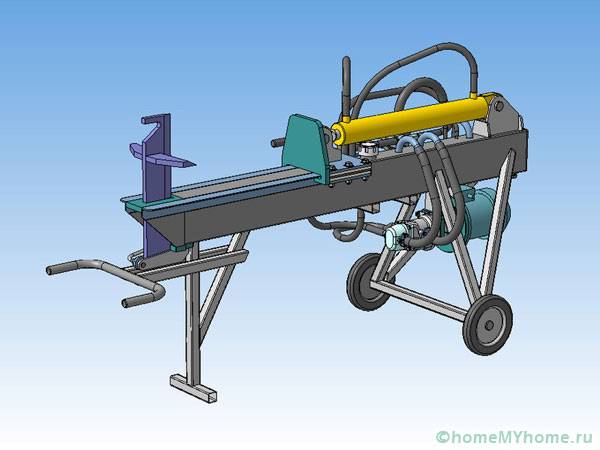

Hydraulic wood splitter - materials and drawings

To make a hydraulic wood splitter with your own hands: drawings, photos, instructions for which you will find below, you will need:

- electric or gasoline engine with a power over 2 kW;

- oil pump;

- oil tank;

- high pressure hydraulic hoses;

- control block;

- hydraulic cylinder;

- I-beam or U-shaped metal beam;

- metal corner with shelf size 30–40 mm;

- sheet metal 0.5–2 cm thick (it is advisable to stock up on pieces of different thickness).

Make a frame from an I-beam or U-beam. The wider the beam, the more load the frame will withstand and the more difficult it will be to transport the wood splitter.Therefore, the optimal beam width is 10–15 cm. Attach the hydraulic cylinder above the beam at a height of 5–7 cm and install a pusher made of sheet metal 7–10 mm thick at the end of the rod. Make a knife body so that it can be moved around the bed.

Useful advice! Changing the length to the knife will allow splitting long logs, but will make it difficult, if not impossible (due to enormous loads), splitting thick logs. Therefore, choose what is most important to you.

To lock the knife in different positions, do the following:

- drill holes with a diameter of 12 mm in 5 cm increments on the underside of the bed;

- drill 2 of the same holes with the same pitch in the knife body;

- insert 2 bolts with a diameter of 10 mm into the knife body from above and weld them;

- having adjusted the length of the working space, fix the knives with metal washers and nuts.

This way you can adapt the splitter to different log lengths. Invite a good hydraulics to connect the oil pump, oil tank, control unit and hydraulic cylinder in one chain.

How to make a wood splitter mobile

There are situations when the wood splitter needs to be delivered to another place. But the weight of the structure often exceeds 100 kilograms, so it is very difficult to carry it. Attach wheels to your device to increase mobility. To do this, you can use wheels from a garden or construction wheelbarrow. It is advisable to provide for some kind of wheel locking system so that the wood splitter does not roll while the engine is running. But you can get by and brickssupporting the wheels while the device is in operation.

Video: DIY hydraulic wood splitter