Do-it-yourself metal braziers. Dimensions, photos and instructions

During rest, barbecues are in constant demand. Even inveterate inhabitants of megalopolises grill barbecue at least once a year. Do-it-yourself metal braziers remain a budget option for home and a convenient way for a country trip. The sizes, photos and instructions below will help you make any type of hearth with a minimum budget. All this in more detail in our today's review.

The content of the article

Video: do-it-yourself multifunctional grill

Varieties of braziers, materials, characteristics

A metal hearth is built faster than a brick barbecue oven, does not require the delivery of building materials, special skills. There are various do-it-yourself metal braziers. Dimensions, photos and designs may vary significantly. Since equipment for the preparation of hot meals is hastily constructed for long-term operation, one should seriously consider the choice of materials, dimensions of a stationary or mobile hearth.

Classification

Steel braziers are traditionally distinguished according to several criteria, the main ones of which are:

- mobility - stationary, mobile or portable hearth;

- configuration - barrel, classic rectangular box, complex shape;

- dimensions - for a large company, family gatherings;

- functional - covers to protect the coals, compartment for firewood on the side, folding roof.

Decorative elements are usually found in mobile or stationary modifications. The service life of the hearth depends on the thickness of the body. Portable barbecues are divided into collapsible and transformable ("suitcase").

Related article:

Gazebos with barbecue and stove. From this publication you will learn about the most beautiful and affordable options for arranging gazebos with a cooking place and a large company.

What can be made of?

The budget option is constructions from used products manufactured in an industrial way. For example, a propane tank or a 20L barrel are practically finished bodies, to which you just need to weld the legs.

Old coffee tables, sewing machines, on the contrary, provide the craftsmen with cast legs of the original shape, you just need to supplement the structure with side walls. Classic barbecues are constructed from sheet steel, rolled metal (corner or shaped pipe).

Barbecue dimensions

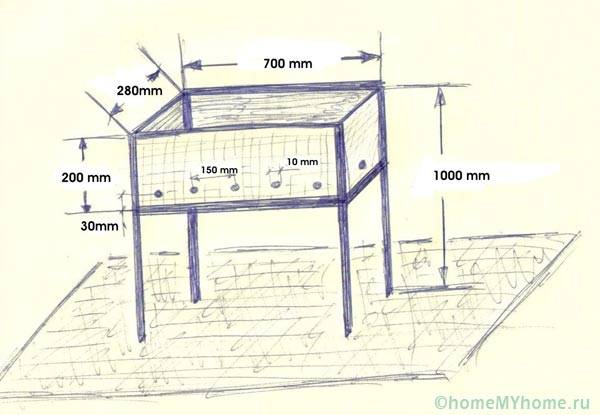

The main recommendations for a home craftsman who has decided to improve the comfort of family and guests are:

- the length of a standard skewer with 6 pieces of meat is 25 cm, so the width of the barbecue should be increased to 30 cm;

- The simplest version without a side compartment for coals has a length of 0.7 - 1 m for a family, receiving guests, respectively, based on the fact that for normal roasting of a skewer, the distance should be 10 cm;

- a depth of 20 - 25 cm allows you to cook meat faster, but there is a risk of burning, so 30 cm from the skewer to the coals is recommended;

- depending on the height of the chef, 0.5 - 0.7 m legs are more convenient for mobile hearths, 0.8 - 1.2 m for stationary structures.

Helpful information! If the brazier is made from a barrel, the coals are unevenly located inside it, the structure is complemented by a hearth - a steel sheet at a specified depth.

Do-it-yourself brazier, instructions for making, drawings, photos

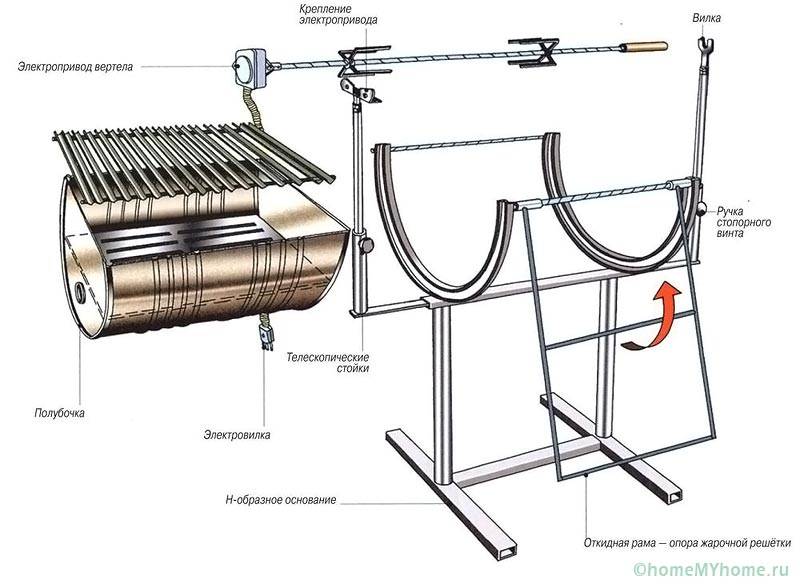

The easiest way is to choose a thick-walled (2 mm minimum) barrel or a large propane cylinder for a barbecue made of metal with your own hands. Dimensions, photos explain the process of constructing a stationary hearth. It is important to take into account the height of the hearth when making legs / stand, add a pipe to the side of the structure.

Cut materials

The barrel (balloon) can be cut in two ways:

- cut a hatch to provide access to the interior of the firebox;

- cut off the top completely (1/3 - 1/2 cylinder).

You will need hinges anyway to cover the top for quick cooking or in bad weather. The barrel can lean on cross-welded racks, ordinary legs from a profile pipe, a corner or a special frame, inside which a brazier is placed.

"Pod" is cut out of the sheet, taking into account the distance from it to the skewers of 30 cm. For reliable positioning of the brazier inside the barrel, two corners are welded along the ends of the cylinder.

Assembly

To assemble the brazier, it is enough to fasten the loops, put a brazier sheet inside the lower compartment. Side pipe chimney necessary for normal combustion of firewood when the hatch is closed in bad weather or windy weather. To prevent spontaneous closing of the cover by the wind, a latch is mounted.

The skewers are placed in the cuts made by angle grinders. Holes are drilled along the ends of the barrel below the brazier to provide traction. Operation with a closed hatch is also possible without a pipe - for this it is enough to add holes in the upper part (checkerboard pattern, diameter from 1 cm).

Helpful information! Decoration (painting) of external surfaces is carried out with Certa, Elcon paints or similar heat-resistant paints.

Related article:

Gazebo with barbecue: projects, photos. An overview of beautiful and functional gazebos with the organization of a barbecue area in different styles from different materials in a special publication of our online magazine.

DIY folding brazier, drawings, photos

There are do-it-yourself mobile barbecues made of metal, the size of the hearths and the design may differ significantly. For example, we will consider two leading modifications in the rating - a "suitcase" of a transformable type and a fully collapsible classic brazier.

Moreover, a home craftsman can use a dozen options for nodes in his design - hinged fastening of parts or their complete disassembly, removable, screw-in, folding legs at their discretion.

"Suitcase"

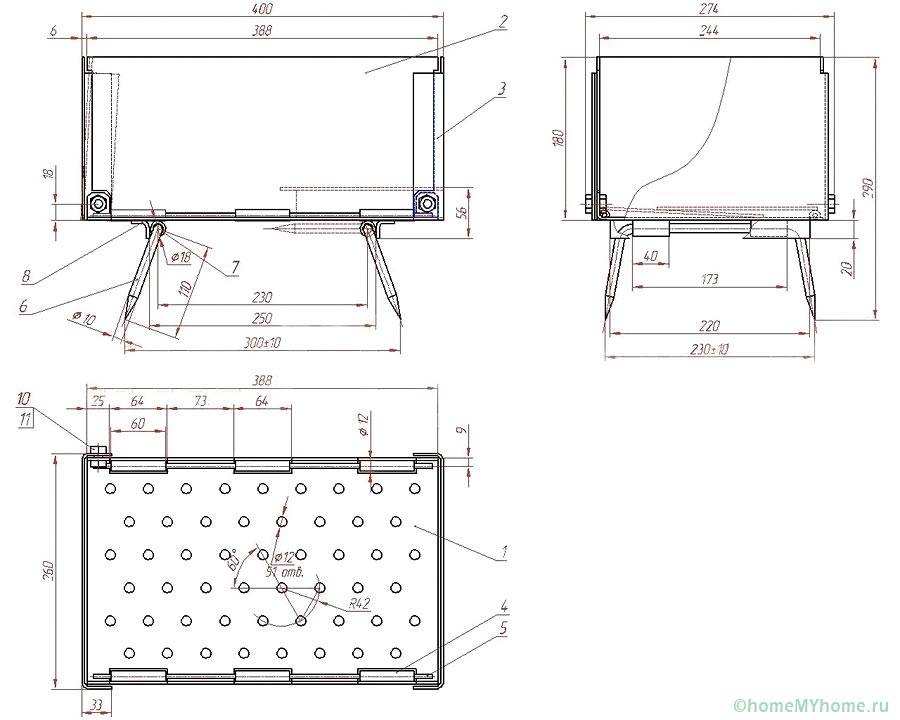

Do-it-yourself metal braziers transforming into a portable suitcase are constructed from blanks of the following configuration, size:

- bottom - 2 - 3 mm sheet 0.3 x 0.9 m;

- walls - lateral (long) 0.15 x 0.9 m, end (short) 0.15 x 0.3 m;

- racks - round or profile pipe 0.6 - 08 m;

- corner - 5 cm shelf, 2.2 m long.

A frame of 0.3 x 0.9 m is welded from the corner, the bottom is laid inside it, attached to tacks. The long side walls are pivotally fixed to the frame (2 loops on each side), have two rows of holes in the lower part for traction, slots at the top for skewers. They are folded at the time of transportation, reclined when cooking.

The end walls are removable, retracted inside the suitcase when carrying, put on the corner of the frame during the preparation of the barbecue. To do this, a bar is welded onto each of them, rigidly pinching them inside the structure.

The legs are either screwed into nuts welded to the corner at the corners, or inserted into square tubes 3 cm long.For carrying, a hinged handle from a bar is fixed on the side; to ensure the immobility of the long walls, a bolt can be passed through the suitcase into special holes, which is fixed from the back with a nut.

Collapsible brazier

The design of this portable hearth is somewhat different from the previous version:

- the rigid corner frame required for laying the brazier has been replaced with 2 cm shelves bent 90 degrees on long, short side walls;

- the legs are made of a bent lightweight corner.

To fix the elements of the barbecue relative to each other, a V-shaped perforation was created in the legs, side walls, bent outward (made with a chisel, bent with pliers). The side sheets are alternately inserted with perforated bent clamps into the brazier legs. The final rigidity of the structure is achieved only after the brazier has been laid.

Related article:

Do-it-yourself cold smoking smoke generator. Drawings, diagrams and step-by-step instructions for creating in a separate publication of our portal.

Conclusion

Thus, a home craftsman can build a stationary grill from scrap material. For the manufacture of mobile hearths, you will need sheet steel, rolled metal.

Video: do-it-yourself barbecue