DIY gazebo: drawings and dimensions, step-by-step instructions for a home craftsman

ABOUTimprovement of the territory is, as a rule, the construction of related objects for recreation and the creation of the integrity of the landscape ensemble with the house. We are talking about such a structure as a do-it-yourself gazebo, the drawings and dimensions of which are individual for the site. The object is multifunctional and easy for independent work. What and how to make - two questions requiring detailed investigation. What will we do!

The content of the article

Types of gazebos from various materials - the advantages and disadvantages of each

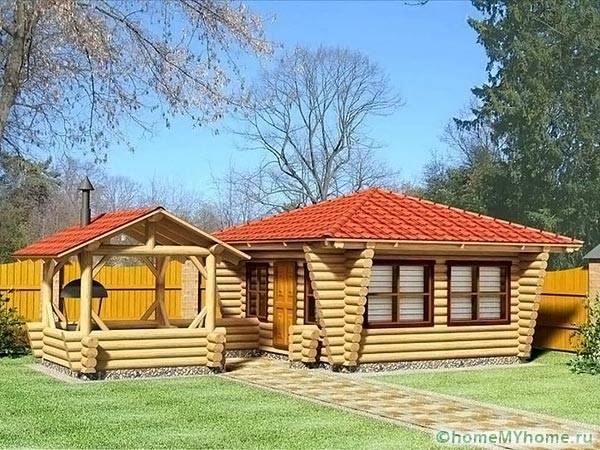

Traditionally, the construction of the gazebo is carried out from the same material that was determined for the construction of the house. Wooden lumber or log platforms will create a single picture with it, the stone is in harmony with brick, forged or profile resting corners are acceptable in any case.

Nevertheless, each building raw material has advantages and disadvantages and it is important to consider them in detail before starting work:

Wood

When choosing such a material for construction, it should be remembered that it is the most short-lived - wood is capricious, prone to shrinkage, decay, and cracks. It is a treat for rodents and parasites.

But, at the same time, it is cheap and has a unique beauty of the pattern, in contrast to factory products. Make sure:

In addition, it is better for novice craftsmen to choose it for work, since the material is malleable for processing and requires minimal handling skills.

Related article:

Do-it-yourself gazebo made of wood. Step-by-step instructions and practical advice on the construction of a wooden gazebo in a separate publication of our portal.

Metal

The indisputable advantage of a gazebo made of steel - forged or shaped pipes - is its strength and durability. Such objects are mobile - they are transferred to any convenient place.

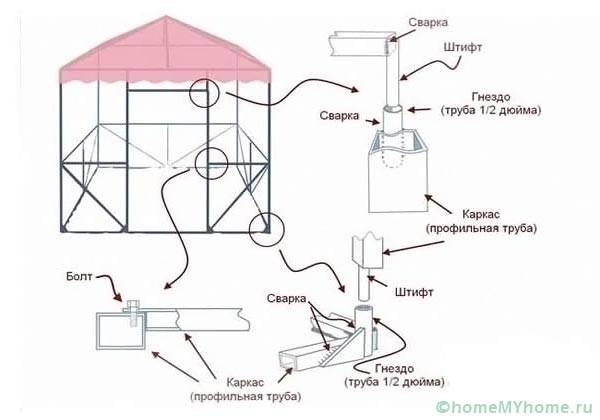

Admire - wrought iron gazebo do-it-yourself rectangular drawings and dimensions of profile pipes which are individual:

However, there are also disadvantages:

- Even to assemble a gazebo with your own hands, the drawings and dimensions of the diagram of which are simple, you need the skill of welding. The bolt connection is not very presentable;

- The metal, although less capricious, is prone to corrosion, therefore, regular prevention in the form of coating with protective compounds is necessary for it;

- Forged products are expensive.

The abundance of welded and bolted joints makes a metal gazebo one of the most difficult to manufacture

Often, such products are prepared to order for specific drawings. In this case, the land owners receive an exclusive model that emphasizes the taste of the owners.

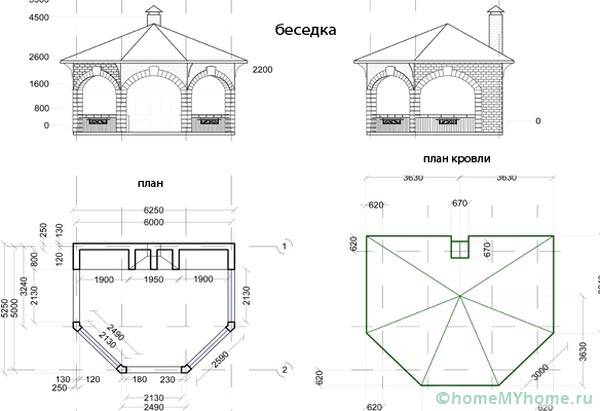

Brick

There is no doubt about the solidity of the object. Often, gazebos become an extension of the house: annex to veranda, place rest by the bath.

Advantages:

- Non-flammable material allows installation inside barbecue or oven;

- The insensitivity to weather factors makes the gazebo almost eternal;

- The closed version is operated all year round.

Rate option:

Before the construction of a gazebo from bricks, it is important to see the harmony and appropriateness of a heavy object next to the house - it can no longer be transferred. The price of brick buildings is high.

Related article:

Gazebos with barbecue and oven. All about the options for the device of the stove or barbecue in the gazebo and the features of use in a special publication of our portal.

Combining

Often, the owners, in an effort to save money, use the materials left over from the main construction to build the gazebo, combining iron, wood and brick. Interesting options turn out:

Video: options and types of gazebos for summer cottages

Step-by-step instructions for making a wooden gazebo

Project

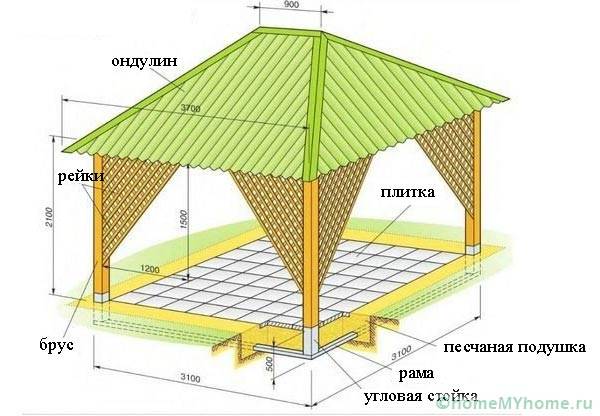

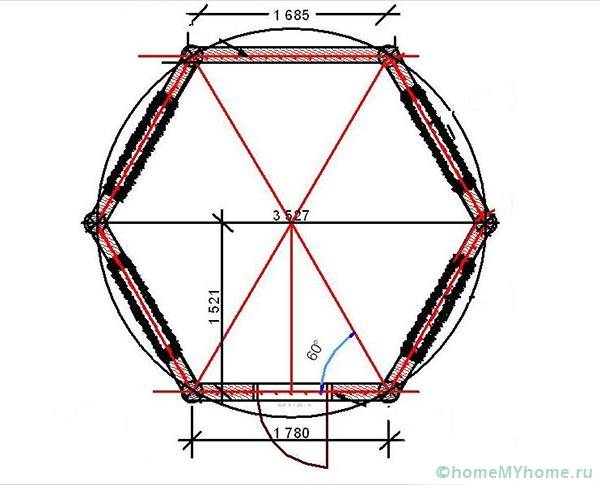

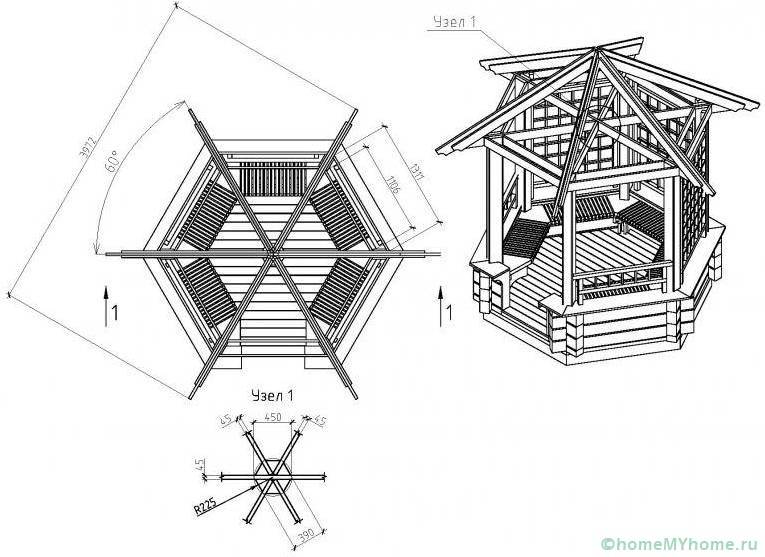

Analyzing the above, we can confidently conclude that a do-it-yourself wooden gazebo is suitable for self-production without special skills. The drawings and dimensions of the roof dome are as follows:

The position of the frame struts is oriented along its extreme points. The advantage of the hexagonal dome is its interesting appearance, better wind and snow resistance.

Materials

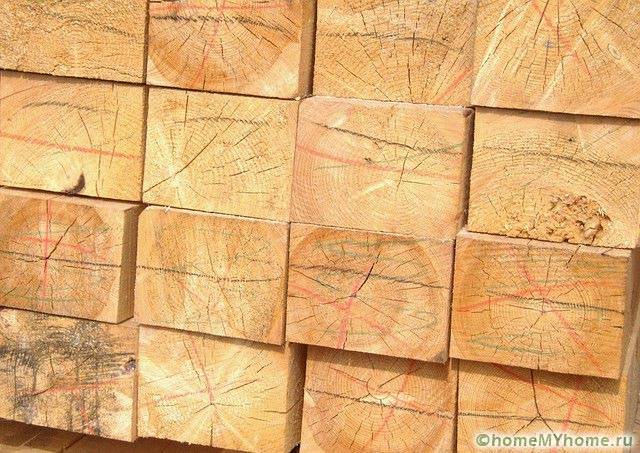

To manufacture a budget option, you will need:

- Rack bar 150 * 150 mm - 6 pcs, 2 m each;

- Tying and rafter beams for roof elements - 100 mm and 40 mm for lathing;

- Roofing iron or shingles;

- Carved shields;

- Edged board;

- Fasteners - screws, bolts;

- Impregnating and decorative compounds - varnish, stain and others.

Depending on the complexity of the design, a reinforcing beam, steel corners, and logs are additionally required. Next, we will consider the algorithm for erecting a hexagonal gazebo with our own hands according to individual sizes and drawings.

Site marking and preparation

Sod is removed from the surface of the soil and leveled. The markings for the racks are carried out using stakes and a cord. In a hexagonal shape, the triangles formed by the string are equal - see the drawing of the dome. After making sure of the correct position, proceed to the next stage.

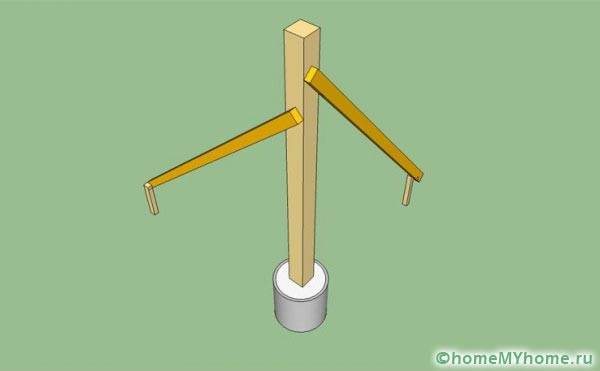

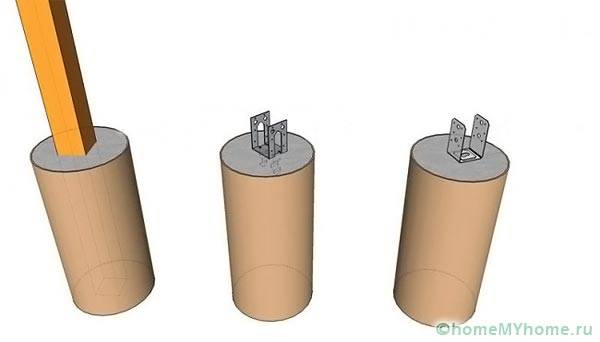

Foundation and installation of racks

For recesses under the rack frame, use a hand drill.By rotating it to a depth of 0.7 m, 6 identical holes are obtained. The ends of the prepared racks are coated with liquid bitumen or wrapped with roofing material to prevent decay. The installed timber is poured with a liquid cement mortar and left to set for about 1 week.

Installation of a strapping bar

Using the punching method, the upper strapping bar is attached to the paw, and then the lower one to install the sex lags. The nodes are reinforced with steel corners. If you use self-tapping screws, then holes of a smaller diameter are pre-drilled, and then the fasteners are screwed in, otherwise the bar will crack.

For reliability, a hexagonal gazebo with your own hands, the drawings and dimensions of which are indicated on its own plan, should have an average strapping bar installed at half the height of the object. It will be a guide for the installation of carved shields.

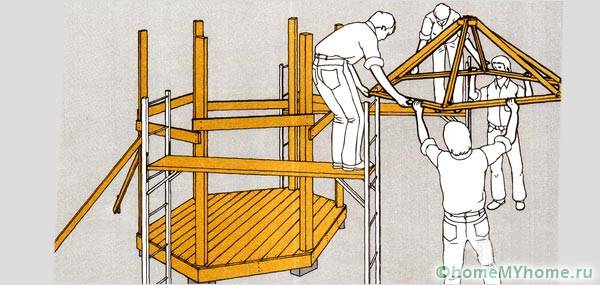

Assembly of the dome

The roof is assembled at the bottom and installed completely at once. To do this, the rafter is cut at the desired angle and connected with the ends at one point. The other ends fit into the grooves on the racks, with the remainder outside the gazebo by 30–40 cm to protect against dripping moisture at the time of rains. They are reinforced with bolts - the roof requires reliability. Between themselves, the rafters are reinforced with their own strapping. It remains to fill the crate on the sectors and cover the roof with tiles or ondulin.

Floor and fittings installation

To the lower strapping bar, floor logs are reinforced in the grooves cut in advance. They should not closely interact with the ground to avoid dampness. Next, the floorboard is laid. From the outside, wooden carved shields are strengthened, and inside, along the walls of the gazebo, they are mounted benches, Unless Otherwise Posted.

Useful advice!When laying the floorboard, leave a gap between adjacent boards. With high humidity, the wood swells and the floor can swell.

Protection and decor

The finished gazebo is cleaned with a grinding wheel or paper, then impregnated with compounds to prevent moisture penetration and prevent mold and decay. It remains to decorate your own brainchild. It's a matter of taste - the woody pattern itself is good. However, if secondary materials were used for the gazebo, then it makes sense to varnish the cleaned wood or to reveal the pattern with the help of a stain. In extreme cases, paint in dark noble colors.

Complex variants are made on the basis of simple ones. For clarity, a detailed video instruction for assembling a summer cottage is offered to the home master to help.

Video: how to build a gazebo with your own hands