What can be the size of red brick, as well as its varieties

Often land owners are faced with a construction problem. And the right choice of building material plays an important role in this matter. The most common in this sense is red brick, which is suitable for the construction of most different structures. What do you need to know to correctly calculate the amount of building material? Of course, these are the dimensions of red brick, as well as the purpose of its various types. This is exactly what we will understand now. And for a start, it is worth clarifying general information on such material.

The content of the article

- 1 Varieties of bricks and areas of application

- 2 Red brick - dimensions and markings of this building material

- 3 Masonry calculator online

- 4 How much does a red brick weigh, depending on the purpose

- 5 How many bricks in the pallet - red facing bricks, solid and stove bricks

- 6 Various red bricks: price per piece of a particular brand and type

- 7 In custody

- 8 Video: how bricks are made

Varieties of bricks and areas of application

There are several types of this building material, depending on the area of its application. He can be:

- Plain full-bodied;

- Facing;

- Stove;

- For the foundation.

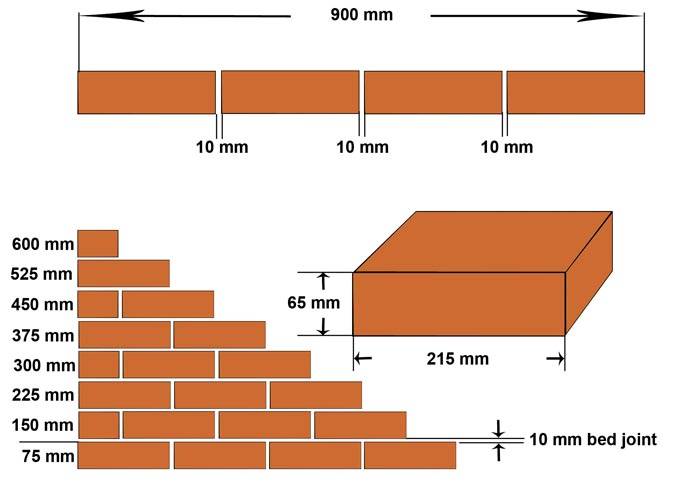

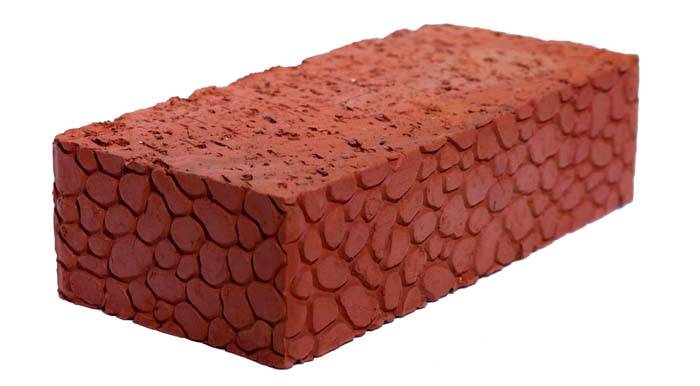

If we talk about the methods and materials used in its manufacture, then they are fundamentally different. But still there are similarities. For example, red solid brick, like all others, is ceramic, while white is silicate. The standard dimensions of ordinary bricks are 250 × 120 × 65 mm. As for the rest of the varieties, we'll talk about them below.

Someone may say that the information about the sizes is superfluous, but this would be a big mistake. Indeed, during construction, these data are necessary to accurately calculate the consumption of material for a particular structure.

First, you should understand that this building material, like any other product, must be checked upon purchase. Indeed, not only the beauty and aesthetics of the structure depend on its quality, but also the safety of those living in it or using it. In addition, both the convenience of work and the quality of the final result depend on the choice of the size and shape of the product. We will now talk about the types of these materials.

Red brick - dimensions and markings of this building material

In this section, we will consider in detail the sizes of certain types, and also try to understand which of them is applicable for what and whether it is possible to interchange one type with another. We have already mentioned the sizes of ordinary red bricks, but only superficially. Based on its popularity, it makes sense to dwell on this issue in more detail.

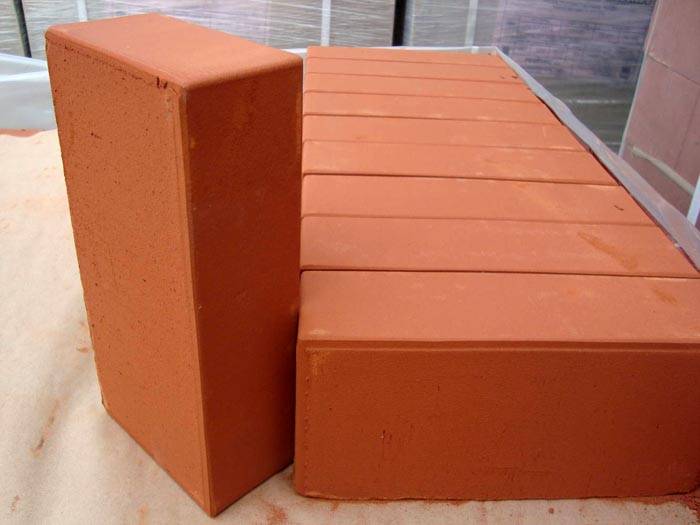

There are two methods of making such products - this is the method of semi-dry and plastic formation. Let's try to consider each of them.

Plastic forming method is as follows. Clay is prepared, stones are removed from it, after which it is steamed to the state of plasticine. Further, with the help of a special machine, it is cut into blanks, which are slightly larger in size than red brick, because during the drying process, the material shrinks slightly. After that, the blanks are dried. At the same time, it is important to observe the technology, otherwise the product will crack and be unsuitable for construction. The last stage is firing at high temperatures.

With semi-dry formation the moistened clay is ground into powder and rammed into molds, which are immediately sent to the kiln for firing. This eliminates the drying process.

Important information! When purchasing such a building material, you should pay attention to the absence or presence of cracks. If there are a lot of them, then the manufacturing technology was not followed. Color is also important. If it is too light, the product was not burnt, and if it has a black tint, then it was burnt. Both are unacceptable and it is not worth purchasing such building material.

The marking is also of great importance, which is designated as M-100, M-125, M-150, M-200, M-250 or M-500. To make it clearer, you need to clarify. The number after the letter "M" indicates the maximum pressure in kg / cm2that the building material can withstand. This means that the M-250, for example, can withstand a pressure of 250 kg / cm2.

Sizes of standard red bricks and difference in dimensions

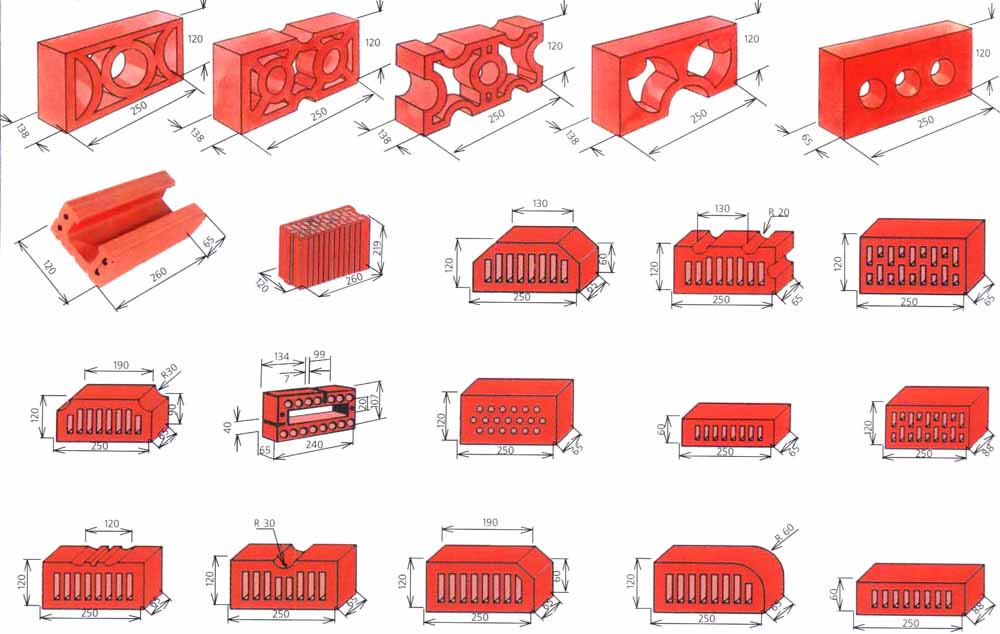

It should be noted here that the manufacturer offers three subspecies of such material, both corpulent and hollow. It:

- Single, with a size of 250 × 120 × 65 mm;

- One and a half. Slightly wider than the previous version. Its dimensions are 250 × 120 × 88 mm;

- Double - the width of this brick is even greater, and is 250 × 120 × 138 mm.

There are other varieties, but in our country they are less in demand. This does not apply to curly veneers, which may not have a specific shape at all. The height of a red brick is always the same. This is done for the convenience of combining its types during construction, as well as cladding.

Important advice! Despite the similar dimensions of a solid red brick and its hollow appearance, load-bearing walls should never be erected from the second, on which the load will be carried out, because it has less strength and is not designed for the same.

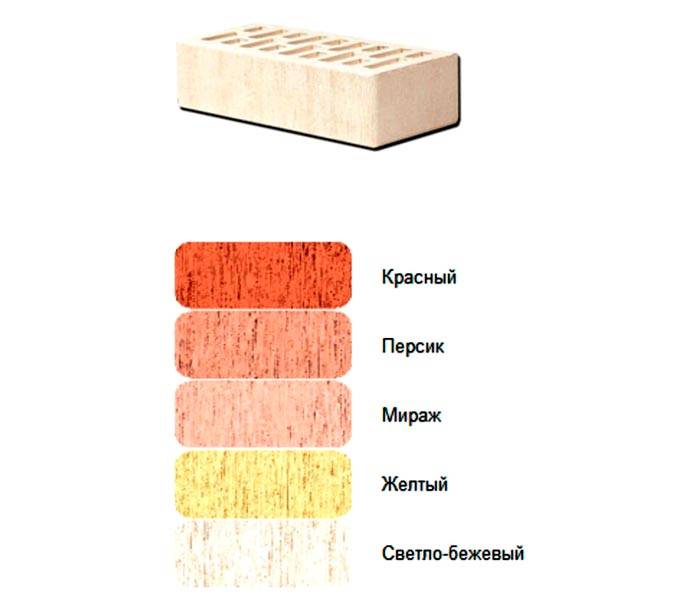

Red facing brick - sizes, varieties and features

Here you should already pay attention to the smoother, sometimes even glazed walls (edges). Moreover, such material will not necessarily have the shape of a rectangle - it can also be curly. Although there is a variety of facing bricks and with "broken", as if torn edges.

The peculiarity of such a material is in a structure more resistant to temperature extremes and weather phenomena. But it should be noted that this stability is inherent only in the outer edges. Its working surfaces (those on which the solution is applied) are not protected from this. That is why refining and grouting with mortar at the end of work is of great importance.

Important information! If you buy cheap and poor quality facing material, there is a possibility of its chipping already in the second year of operation. That is why you should be especially careful when choosing it.

The dimensions of facing bricks differ from solid ones. They can be either single or half. Also on the building materials market, there are products with a width of ¾. The rest of the dimensions of single facing bricks or other types are the same with the full-bodied version.

Dimensions of oven red brick and its features

A feature of this building material is its resistance to high temperatures. It also differs in low thermal conductivity, which determines its characteristics, which are ideal for stoves and fireplaces.

As for the price of stove red brick, its range is wide enough and ranges from 20 to 1000 rubles. for 1 pc. but we will talk about comparing the cost of one type or another a little later. Now it is important to understand which material is best to choose for a home stove or fireplace. Particular attention should be paid to the brand - it should be designated as M-250 or even M-500.

Important! Although the cost rises with the increase in the brand of the product, it is not worth saving on this. After all, if you buy a fairly cheap material of lower grades, then you can face a situation in which you have to move the furnace after a few years, and this process is many times more complicated than installing a new one.

The sizes of oven bricks can be of two types:

- 250×120×65 - standard, the same as full-bodied;

- 250×85×65 - somewhat already standard.

The size of the red brick for the foundation - the main differences

The dimensions of an ordinary red brick are the same as a full-bodied one, and in essence they are identical. The only thing that can be said about their differences is that solid bricks can be both oven and facing, while ordinary ones are used only for plinths, foundations and internal partitions in rooms. Also, its main difference is in strength and unpresentable appearance. That is why such masonry is subsequently closed with plaster, facing materials, etc.

The dimensions of the basement red brick rarely matter, but there is an approximation to the standards. The fact is that it can be quite uneven, which determines its low cost.

And yet, for any work, a preliminary calculation of the amount of material required is required. In this case, you can either calculate this parameter yourself or use the program.

Online calculator for calculating brickwork - an easier way to plan

Related article:

Aerated concrete blocks: sizes and prices per piece, features and advantages. In the material, we will consider what aerated concrete is, its scope, advantages and disadvantages, as well as dimensions and average cost.

How much does a red brick weigh, depending on the purpose

The weight of a red brick depends on many parameters. That is why it is worth organizing the data by combining them into a small table for a more convenient concept. For example, take the weight of a red solid brick 250 × 120 × 65 and compare it with other types of the same size.

Table 1. Types of bricks

| Brick type | Picture | Weight, kg |

|---|---|---|

| Corpulent |  | 3,3 |

| Hollow |  | 2,3 |

| Hollow cladding |  | 1,32 |

Thus, we can conclude that facing bricks weigh much less than others. Although, in comparison, this parameter is not very different, nevertheless, when building a wall, the load on the lower rows will be significantly different. After all, if you take into account how much a red solid brick weighs and multiply this value by the amount used in the construction of, for example, partitions, you can approximately estimate the pressure on the bottom row.

Important! When purchasing this material, you should pay special attention to the weight of the product. After all, if a solid red brick 250×120×65 weighs less than 3.3 kg, then its strength will be lower, which is unacceptable for the load-bearing parts of the structure.

Separately, you should pay attention to how much the oven brick weighs. The fact is that this material is the heaviest precisely due to special additives and the method of its manufacture. The average weight of a standard product is 4.2 kg. His choice also deserves special attention.

Specialist recommendations! When purchasing material for the oven, you should have a small hammer with you. With a sharp impact on the product, a ringing sound should be heard. If he is deaf, then such a furnace brick does not deserve attention. Also, there is always a battle of products. It is necessary to look at the rift. The composition should be uniform without foreign inclusions and stains.

How many bricks in the pallet - red facing bricks, solid and stove bricks

It is clear that the total mass of the pallet also depends on the weight of one red brick. But, as it turned out, the number of units that are stacked on a pallet also depends on the type of product. Let's try to summarize the information available on this topic, and then analyze it in more detail.

Table 2. Types of red bricks

| Brick type | Picture | Number of units per pallet | Total pallet weight, kg |

|---|---|---|---|

| Plain corpulent |  | 200-400 | 660-1440 |

| Plain hollow |  | 352-444 | 810-1100 |

| Hollow cladding |  | 480 | 634-662 |

| Furnace heat resistant |  | 330-360 | 1386-1512 |

So, having figured out how many pieces of red bricks are in a pallet, you can calculate how many pallets will need to be purchased for a particular building. All this can help in calculations in order not to overpay for extra material. But there is one more parameter that you need to know. This is how many red bricks are in 1 m3... The average data are as follows.

Table 3. The number of red bricks in 1 m3

| Brick size | Picture | Quantity when laying (considering mortar) | Quantity on a pallet (without solution) |

|---|---|---|---|

| Single |  | 394 | 512 |

| One and a half |  | 302 | 378 |

| Double |  | 200 | 242 |

Thus, knowing all these data, it is possible to accurately calculate not only how much a pallet of red brick weighs, but also to calculate the required amount for construction.

Important! Do not underestimate the weight to pallet ratio. After all, this is a direct indication of the quality of the products of this or that manufacturer. It should also be understood that, for example, the facing material is weather resistant only from the end sides. That is why its surplus, which has been in the open air for at least one winter, will be unusable. Such a product will begin to deteriorate very quickly, nullifying all efforts.

As for the cost of various types and brands, we will also provide a similar review now.

Various red bricks: price per piece of a particular brand and type

As for the cost of a red brick per piece, it also depends on the brand, type and quality of the product.

Table 4. Average cost of bricks

| Size and type | Picture | M-150, rub. | M-200, rub. | M-250, rub. |

|---|---|---|---|---|

| Private single |  | 15 | 16 | 18 |

| Private one and a half |  | 16 | 17 | 19 |

| Private double |  | 17 | 18 | 21 |

| Facing single |  | 16 | 21 | 43 |

| Facing half |  | 9 | 13 | 25 |

| Furnace standard |  | 59 | 67 | 107 |

| Stove reduced |  | 40 | 51 | 72 |

This is approximately how the cost of such products is distributed. Of course, the price of a red solid brick per piece may differ from those presented in the table, depending on the manufacturer and manufacturing technologies. However, it should be remembered that too low a cost may be the result of a disruption in the production process. This entails a decrease in frost resistance, strength and other parameters. Therefore, looking at how much a red brick costs, you can roughly determine its quality. But it makes sense to clarify that you still need to check the product.

For finishing work, you need to choose a material based on your preferences. At the same time, it is necessary to understand that how much a facing red brick costs will depend not only on its quality, but also on its shape. Such products today are quite diverse.

The front material can be used without rough masonry. For example, when building fence around the site, such a brick will look pretty good. Considering the absence of a heavy load on it, its use with slight nuances is quite acceptable. As you know, first, the columns of the fence are erected, and only after that the partitions are built. You need to understand that during construction, reinforcement with a metal mesh is necessary every 2-3 rows. Through the same distances, pieces of reinforcement must be driven into the column, with the help of which the partition will be fastened to the bearing part.

Related article:

Technical characteristics, sizes and prices of foam blocks. In the article, we will consider in detail the features of the building material, its advantages, scope, size and average cost.

In custody

Summing up, it makes sense to recall several important rules when choosing and purchasing such a building material for certain needs.Facing, as well as oven bricks should not have obvious irregularities, chips and cracks. At the same time, this rule does not apply to an ordinary foundation one. When choosing, you should pay attention to the shape. No flaws are allowed in the facing. The color should not be too light - this may mean that the brick is not "baked", and this fact speaks of its low quality. The same applies to dark spots on the surface or on a cut - a burned-out product also loses its strength.

You should not buy the front material in open markets and sites - the ingress of precipitation on its working surfaces destroys the structure. This happens due to the insecurity of these surfaces. After all, only its front parts are adapted to the weather.

The sound of any product when struck with a hammer should be sonorous - this indicates that there are no violations of manufacturing technology.Also, before purchasing, it makes sense to consult with those who have recently completed such construction. From their experience, you can understand what the disadvantages and advantages of the material of this or that manufacturer.

As for the oven brick, its choice is especially important. You should not buy cheap products of low brands. The most acceptable are M-250 and M-500. Such material will allow the stove or fireplace to last the longest, while providing normal heat exchange in the room - the stove will not cool down quickly.

Important! Pay attention to the weight of the product. It must meet the standards. If the material is too heavy, it means that it has not been completely dried. And such a marriage will greatly affect the strength and durability.

And the most important thing. Each type is designed for its own field of application. And therefore, no matter how convenient a hollow brick is in masonry and operation, it cannot be used on supporting structures. It may simply not be able to withstand the load. The result is the collapse of the wall.

If you have any questions on the topic of the article, you can ask them in the comments. Visitors to our resource will be happy to help you. Perhaps someone has additions or stories from personal experience. Share, ask, tell.