How to make the right pipe bender for a profile pipe with your own hands

In some cases, it becomes necessary to bend profile pipes into an arc shape. This will require special skills and some tool. Special devices will help you create a pipe bender for a profile pipe with your own hands. For such products, you will not need to purchase expensive materials and equipment. More details in the material below.

The content of the article

Features of pipe benders

Before you start the production of a pipe bender for a profile pipe with your own hands, you need to find out why such equipment is required. A pipe bender is a device that helps to bend a selected part from different materials with the required radius.

The element can be made of steel, plastic or aluminum, as well as shaped. The bend angle ranges from 0 to 180 degrees.

Helpful information! The devices made are of different types, so before making them it is worth choosing the most optimal option.

Varieties of pipe benders

Gadgets industrial applications can be classified by bending method or drive type.

Device classification by drive type

On a production scale, various types of machines... They will help to make suitable types of do-it-yourself pipe benders for a profile pipe - drawings and professional diagrams.

The following types of devices are distinguished:

- Hydraulic machines are stationary or manual. They allow you to bend 3-inch parts. Similar devices are used in production. With their help, a huge amount of work is performed.

- Electromechanical type constructions are suitable for processing any lines. Electronic capabilities help you accurately calculate the bending angle and the required pressing force.

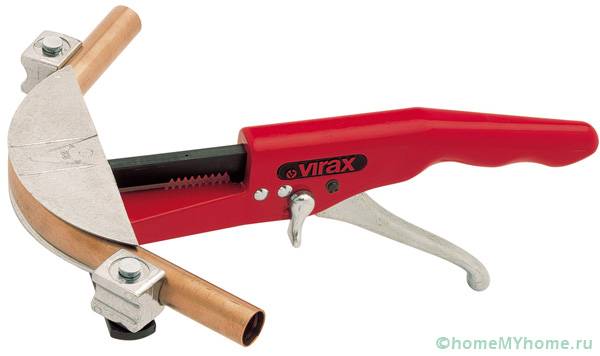

- Hand devices are used to bend products with a small diameter.

Helpful information! It is important to take into account that the thermal effect on the profile elements causes changes in the internal structure of the material. In this case, the strength properties may decrease. Multiple bending can lead to structural failure.

Device options for the method of bending pipes

The part can be bent in various ways. Benders are classified according to the bending method:

- Segmental ones are equipped with a special mechanism that allows you to pull the line and bend it at a certain angle.

- Crossbow devices are equipped with a special device, which is a bending element.

- Spring devices are equipped with special springs that help to bend plastic products.

Helpful information! The possible angle depends on the characteristics of the product. When doing independent work, it is worth adhering to the minimum value of the bend radius. If bent to a greater distance, then over time, such a line may deform.

Self-made device

There are many auxiliary materials that tell you how to make a pipe bender for a profile pipe with your own hands: drawings, videos and professional diagrams will help you create a high-quality design.

It is worth considering simple options for homemade equipment. You can construct a simple mechanism using a template and a custom radius. Similar technologies allow processing aluminum and steel lines. A template can be created from regular boards. In this case, parts are selected with a larger diameter than the pipes that need to be bent. The selected boards must be securely fastened so that the pipe cannot jump out of them. To create a rounded groove, the boards are cut under the required shape. The wooden product is attached to a solid base and a stop is mounted next to it for fixing the workpiece.

Hand-made products are able to bend even elements with thick walls. To do this, you need to use a winch. When using a profile line, bevels are not applied when processing boards. The product is fixed with special limiting devices.

It is also possible to create a rolling version of the pipe bender from wood, but this will require special polyurethane rollers or bearings. For products made from softer materials, wooden bending units can be made, and for more rigid lines, metal parts will be required.

Helpful information! When doing it yourself machine tool individual parts are made of metal. Before installation, it is worth calculating the strength of the processed parts and the quality of the material of manufacture, so that the structure can withstand their processing.

Do-it-yourself hydraulic pipe bender for a profile pipe: drawings and diagram features

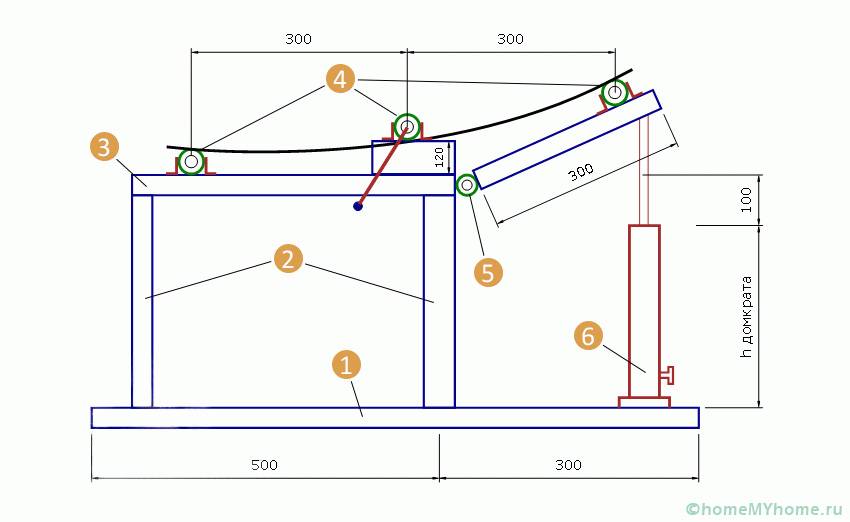

The creation of a hydraulic structure requires special attention. To perform such an installation, you will need a channel, a jack with a special drive, rollers and a shoe. It is necessary to select metal sheets with a thickness of more than 3 mm.

Using welding units a system in the form of a rectangle is made from a durable channel element. Its height should be the same as that of the jack.This element should act as a pusher. It is important to select high-quality rollers to accurately grip the selected pipes.

This hydraulic unit has many advantages. This is ease of manufacture and low cost of auxiliary models. With this installation, you can bend any pipe, even in a cold state. Shows in detail how to make a pipe bender with your own hands for a profile pipe, the video below.

Helpful information! A shaped pipe with a square section will be easier to bend near the ends of the line.

Video: an example of a self-made hydraulic pipe bender

DIY rolling manual pipe bender for a profile pipe: videos and diagrams

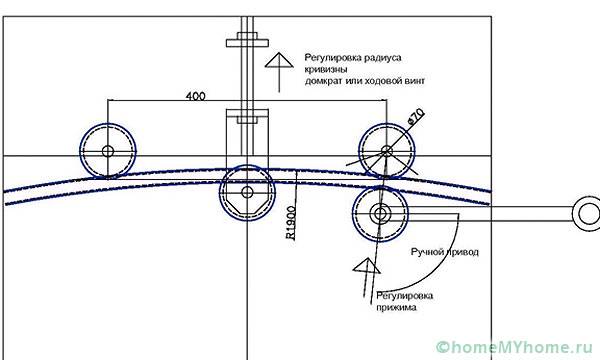

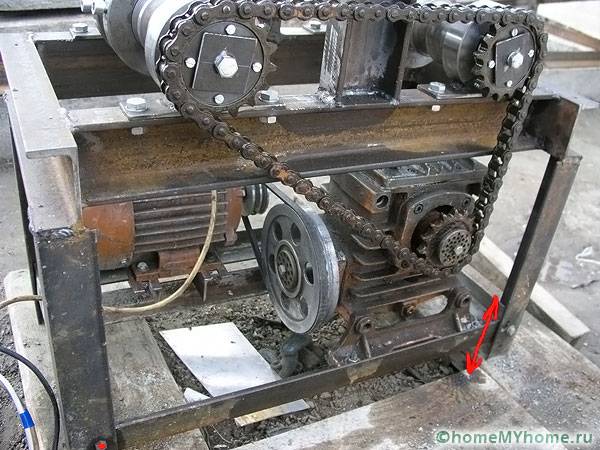

The selected element is processed on a rolling mill in a certain way. The part is installed on rollers and fixed in the desired position. When the handle moves, the chain moves and moves the shafts. As a result, the profile tube bends in a given and desired direction.

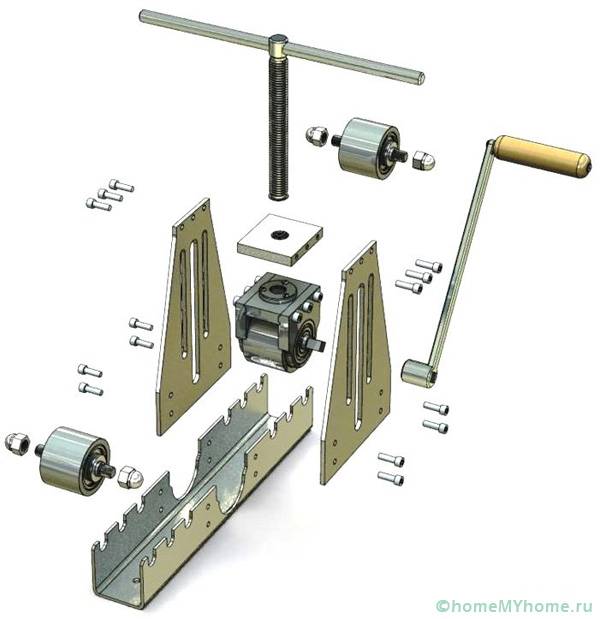

To create a rolling unit, you will need to do the following:

- Cages and special rollers for the bearing mechanism are turned. If there are drawings, then you can order a similar work from a specialist.

- The unit has three shafts.

- The construction of the screw mechanism is being manufactured. A shelf is made from the channel. Holes are made in it for fastening the shafts, and a thread is also cut to adjust the pressure shaft.

- All elements are assembled using a welding machine.

- The pressure shaft design is mounted on special springs. The side shafts are attached with a chain. The handle is also welded, which is responsible for rotation.

- A jack is installed that allows you to control the downforce.

Helpful information! To create a rolling structure with your own hands, special calculations are required, as well as detailed drawings. You should not create a unit without special documentation.

Profile tube benders can be created in-house. For simple work, fittings made of wood are suitable. If pipe bending is the main activity, then a more powerful machine.

Video: tips for making a manual unit