Metal lathe for garage: which one to choose?

In conditions of limited space for a home craftsman, the best option becomes lathe for metal for a garage in the basic or extended configuration. There are a lot of manufacturers and modifications of equipment on the modern market. Therefore, below are the recommendations of specialists on choosing a mini-machine for metal turning.

The content of the article

Video: how to choose a desktop lathe

Selection criteria, types

A metal lathe for a garage can save both the budget for operating a car, a backyard, and time. The search for small things that are necessary for repair, construction, often take several days. If you have the equipment, all this can be made on your own. The main selection criteria are:

- purchase budget - most often the basic equipment is purchased, additional functionality is purchased later, as needed, with sufficient funds it is better to choose a multifunctional (universal) machine immediately;

- dimensions - about the same for most manufacturers;

- quality - it is not recommended to buy such equipment on order, better than a visual inspection, a trial run of purchase methods has not been invented;

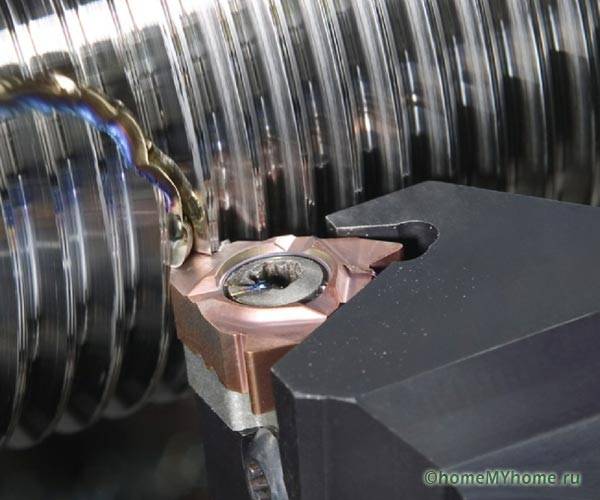

On small machines, small workpieces are processed by default, so the accuracy must be appropriate. Spindle runout, lack of centering, cutter feed scale are not allowed.

For use in a garage, there are several machine options:

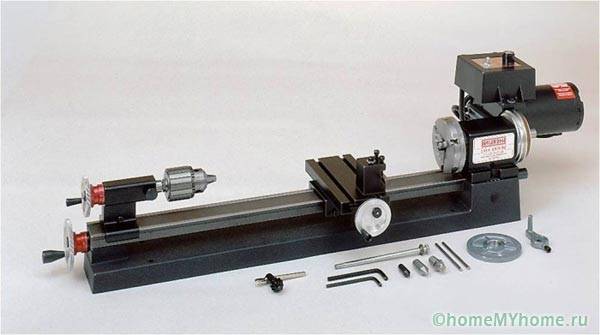

- desktop - minimal functionality, some models do not include a tailstock;

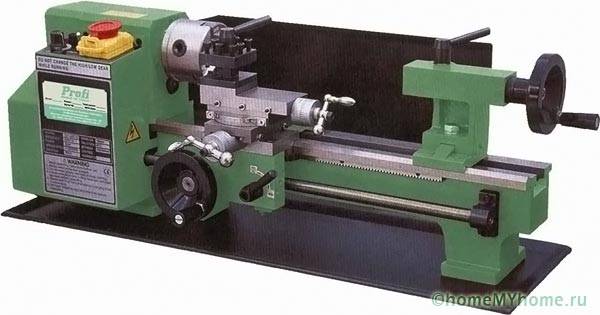

- universal - milling adaptation included in the kit;

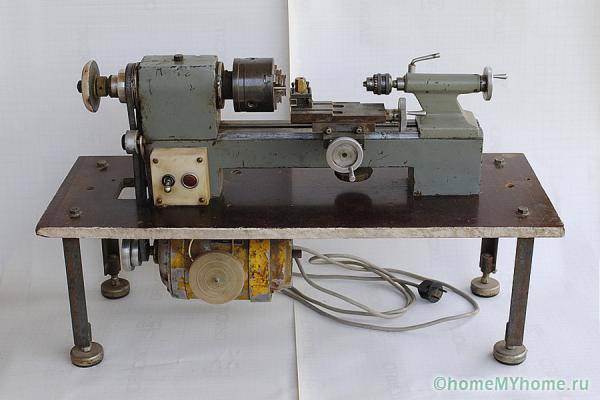

- school - various equipment, 2 step speeds with smooth adjustments inside each of them, reverse, weight within 200 kg;

- screw-cutting lathe - minimal runout of the spindle, high price;

It is very difficult to focus on the size of the workpieces that can be clamped in the chuck's jaws, placed between the centers of the headstock. The needs of each master are different, from time to time it is required to process large-sized parts or perform jewelry operations.

Specifications

A desktop-type garage metal lathe most often has the following operational characteristics:

- power button - may be absent (for example, for the Corvette-2 model), rotation is activated by a rheostat that regulates the speed

- dimensions - length 1.2 - 1.7 m, width 0.5 - 0.6 m

- weight - within 120 - 200 kg

- workpiece diameter - 10 - 20 cm above the bed or 5 - 15 cm above the slide

- center-to-center size of RMTs - 20 - 50 cm

- drive power - 0.15 - 0.6 kW

For lathe machine tool for metal for the garage, asynchronous or collector motors of 220 V are used. The designs of the speed control systems, the transmission of torque to the screw shafts of the support differ significantly from different firms. In some modifications, the reverse is switched with a lever, in others, to obtain reverse rotation, you have to throw the transmission belt.

Most lathes only cut metric and inch threads in one direction. Among domestic producers, the most popular are Domashny Master, Handyman, Caliber. All other products, regardless of the brand's homeland, are manufactured in China - Optimum, Corvette, JET, Proma, DIY.

For example, the company "Enkor" produces turning and milling modifications of the Corvette 407, lathes Corvette 401 - 403. Automatic feed of the caliper is used only for threading, processing, roughing is carried out manually. The chuck is equipped with straight, reverse jaws, parts can be clamped without chuck in the centers. The smallest of them (Corvette 401) is equipped with a 0.5 kW electric drive, a speed of 2,500 rpm, an electronic system that allows maintaining the same speed under any load. The through hole in the spindle allows you to machine 20 cm of workpieces.

The machines of the Optimum company are equipped with motors of 0.5 - 1.5 kW, the RMC reaches 40 - 70 cm, the height of the centers is 7 - 14 cm. The homeland of the brand is Germany, 95% of production is concentrated in China. A feature of the equipment is an error of 0.025 mm and 0.01 mm (displacement, spindle runout, respectively).

Weiss table lathes have the lowest possible vibration and sound pressure. The spindle rotates in roller bearings, after stopping the rotation, it is possible to automatically reverse to move the caliper. The tailstock has a longitudinal movement with fixing the position in space.

Related article:

Homemade metal lathe with your own hands... In the publication we will consider step-by-step instructions for making a machine tool with photos and videos, an overview of finished models, safety precautions when working on a machine.

Recommendations

When purchasing a metal lathe for a garage, you should pay attention to the following points:

- manufacturer - the products of domestic firms are easier to operate, since there are more service centers, spare parts, consumables in the Russian Federation;

- transmission type - belt or gear (the input shaft is always driven by a V-belt);

- gear material - caprolon is preferable, which, unlike conventional plastics, does not crumble, but self-strengthens;

- the presence of roller bearings on the spindle - provides high-precision machining;

- type of guides - the resource of hardened machine elements is an order of magnitude higher, as well as the quality of processing;

- rpm - usually 0 - 1500 in 1st gear, 0 - 2500 in 2nd gear;

- the presence of several speeds - usually 1 or 2;

- protective devices - some models are equipped with plexiglass casings, which fade over time, crack, reducing the view of the workpiece;

- headstock - preferable options with a through hole, allowing you to grind, cut threads on long parts.

For an entry-level user, the budget for the purchase and operation is much more important. Therefore, Chinese metalworking machines with average characteristics are more often chosen.

conclusions

Thus, the range of metal lathes that can be placed in the garage is quite diverse. A home craftsman can focus on functionality, budget, dimensions of workpieces, processing accuracy, and other parameters. There are currently no unambiguous leaders in this niche.

Video: how to set the head and tailstock of the machine