Do-it-yourself staircase to the second floor with a turn of 90: correct calculation and installation work

ABOUTA solid wooden staircase is a great decoration of the country house. This design is made of various materials. A country house in several tiers is necessarily equipped with a similar element. Staircase to the second floor do it yourself from a tree with a turn of 90 degrees should ensure comfortable movement along it. The most important points in the manufacture of such a structure are accurate calculations and correct installation. The safe movement of residents depends on the quality of installation work.

The content of the article

- 1 Types of ladder structures

- 2 Pivot Staircase Options

- 3 Do-it-yourself stairs to the second floor made of wood with a turn of 90: we mount it ourselves

- 3.1 The most popular wood for production

- 3.2 Features of calculations

- 3.3 How to calculate a stair with a turn: drawings and diagrams

- 3.4 Video: the easiest way to calculate yourself

- 3.5 Installation of the supporting structure

- 3.6 Installation of steps and assembly of the structure

- 3.7 Installation of handrails and balusters

- 4 Useful Tips

- 5 Video: installation of a wooden staircase in the house

Types of ladder structures

There are several types of such stairs to the second floor:

- Marching structures are simple systems that can contain one or more flights. Basically, these are straight parts with steps. One march should not have more than 16 steps.

- Screw varieties are suitable for small spaces. They are structures around which steps rise in a spiral. A similar structure can be erected anywhere in the room, even in the central part.

- Combined systems look like an arched and curved structure. They combine elements of screw and marching structures.

- Bolt-on structures are frameless systems. In this case, the steps are installed against the wall, and are connected to each other by bolts.

Even at the time of design, it is worth considering what type of construction will be and from what material.

Helpful information! Rotary cruise systems are used in confined spaces.Wood products are especially popular in individual cottages.

Pivot Staircase Options

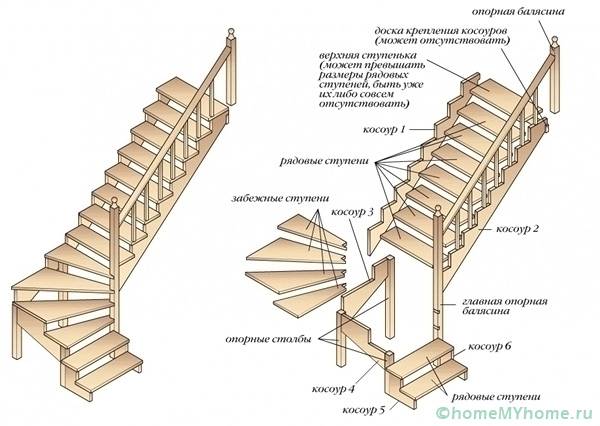

Marching stairs to the second floor, made of wood with their own hands, with a turn of 90, may differ in the placement of parts and the general appearance. The lifting mechanism is mounted on stringers or bowstrings. The device can be open or closed. The lift march is made straight or pivotal.

Rotary structures are divided into varieties:

- L-shaped has a scheme when two spans are placed at 90 degrees to each other.

- U-shaped is characterized by a 180-degree rotation The spans are placed parallel to each other. The distance connecting them is a platform and has access to a floor or between tiers.

Note! In some cases, several basic designs are used in one model. Such products are called combined.

Related article:

Stairs to the second floor in a private house. A detailed overview of existing types of stairs and a practical guide to installation in a separate material.

Do-it-yourself stairs to the second floor made of wood with a turn of 90: we mount it ourselves

A high-quality and comfortable staircase to the second floor with your own hands made of wood with a turn of 90 degrees can be assembled with your own hands or you can buy ready-made elements of such systems. In both cases, a preliminary design is developed, and the necessary measurements of the structure, as well as the span height, are made.

The most popular wood for production

It is necessary to take a responsible approach to the selection of quality materials for the construction of the product. Wood is considered the best option. It is easy to fit and also comes in budgetary ways.

To create convenient systems, the following options should be considered:

- Maple is characterized by stability and bending strength. But cracks can appear in such wood.

- Beech can be used in rooms where there is no high humidity.

- Oak is one of the best building materials. It is hard and durable.

- Larch is resistant to decay and is considered to be a strong and tough material.

- You can choose the budget option pine.

For installation work, you will need a jigsaw, screwdriver, hacksaw, chisel, square and level. Material is selected from edged boards, support and auxiliary beams, as well as fasteners.

Helpful information! Before use, the wood material is dried and covered with protective water-repellent solutions.

Features of calculations

Before proceeding with the installation of the stairs to the second floor with your own hands from wood with a turn of 90, you need to develop a drawing. In the process, special formulas are applied.

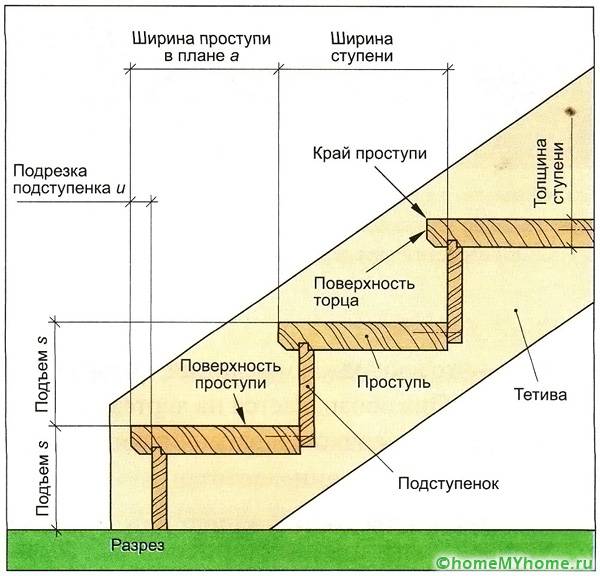

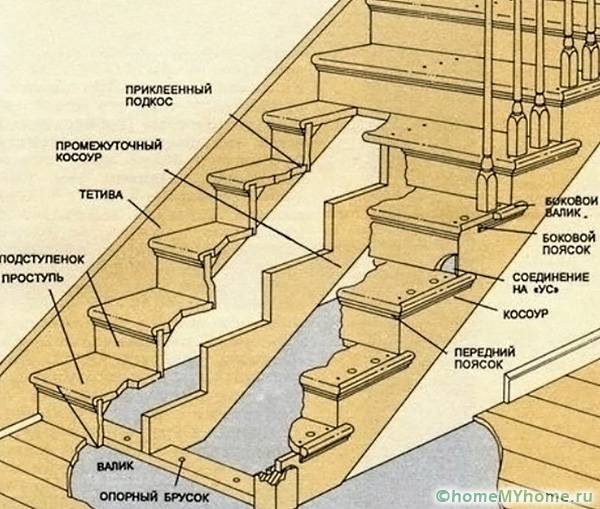

Drawing up a project requires knowledge of the main structural elements:

- The steps are divided into swivel, rotary structures, and straight.

- Bearing supports can be bowstring or stringer.

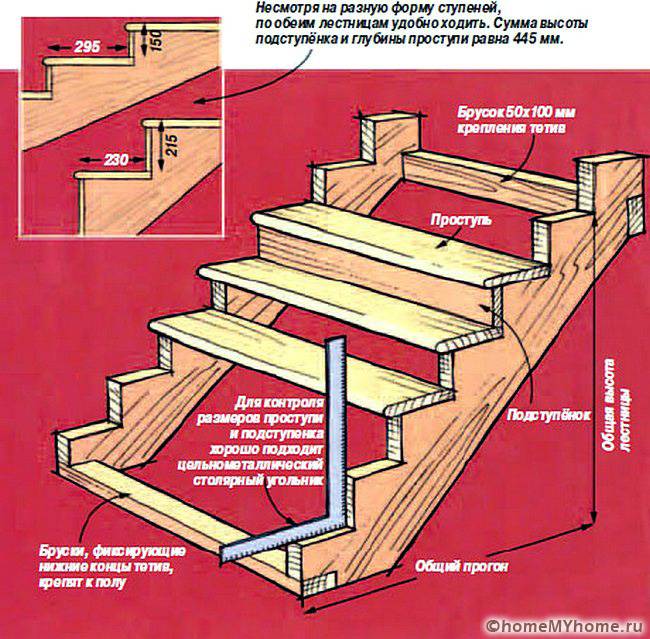

To make an ideal design, you need to know the following parameters:

- The distance of the opening from the uppermost riser to the corner of the runner.

- The width of the steps. Required minimum 120 mm.

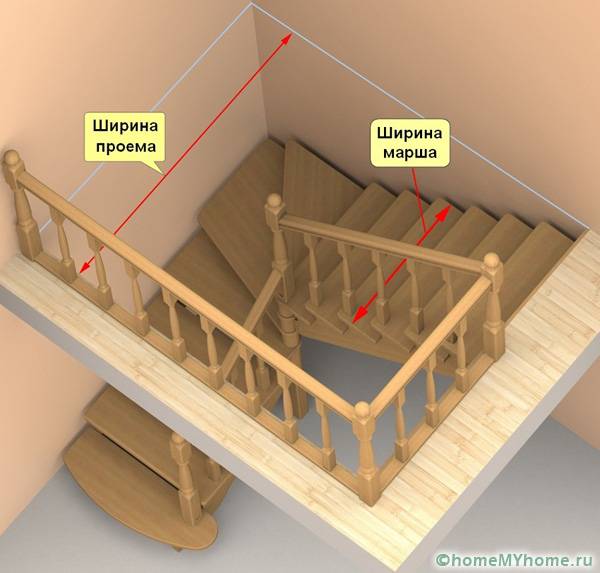

- The span (march) width is not less than 80 cm.

- The largest step height is 220 mm.

Helpful information! The most practical designs are the models with a stand in the middle. They are easy to assemble and have good performance characteristics.

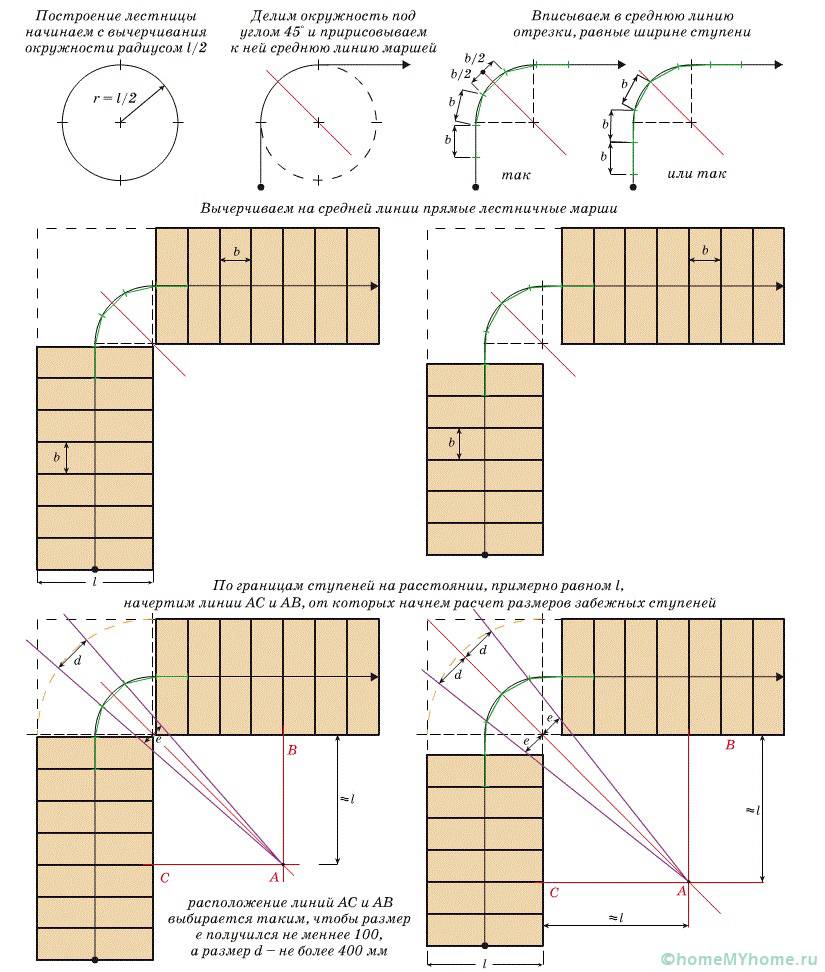

How to calculate a stair with a turn: drawings and diagrams

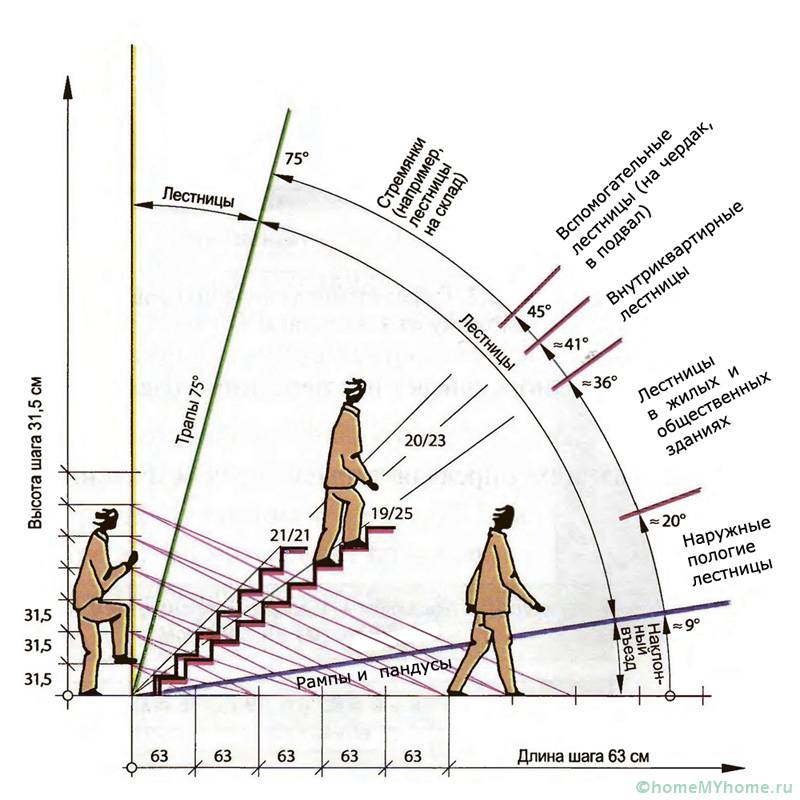

When designing yourself, you need to provide for the following points:

- Width and height of steps.Since the size of the average step is 60 cm, the width and height of one step is calculated using the following formula: 2b + c = 60. In this case, c and b represent the dimensions of the steps.

- The angle of inclination of the steps is calculated. For the sake of saving space, you should not make a too steep design. The optimum tilt angle ranges from 25 to 35 degrees.

- When calculating the turning steps, it must be taken into account that the size of the smaller side should be about 100 mm. And the overlap of the swivel unit over the previous one is about 50 mm.

The calculation of the stairs depends on the width of the opening in the ceiling and the height of the room

Video: the easiest way to calculate yourself

Installation of the supporting structure

A staircase to the second floor with your own hands made of wood with a turn of 90 is performed with the installation of supporting structures. In this case, the following actions are performed:

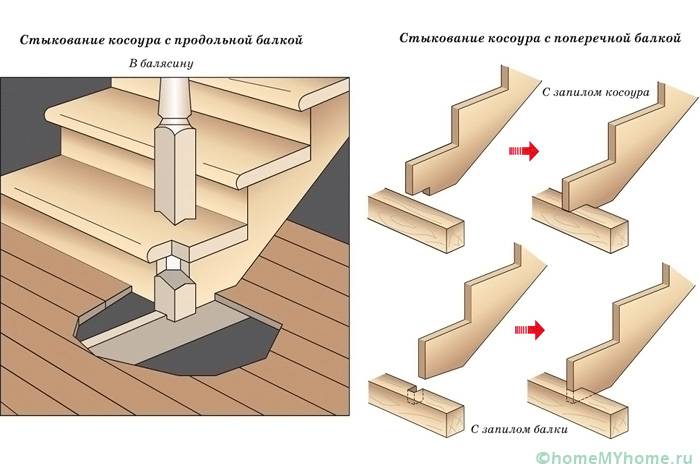

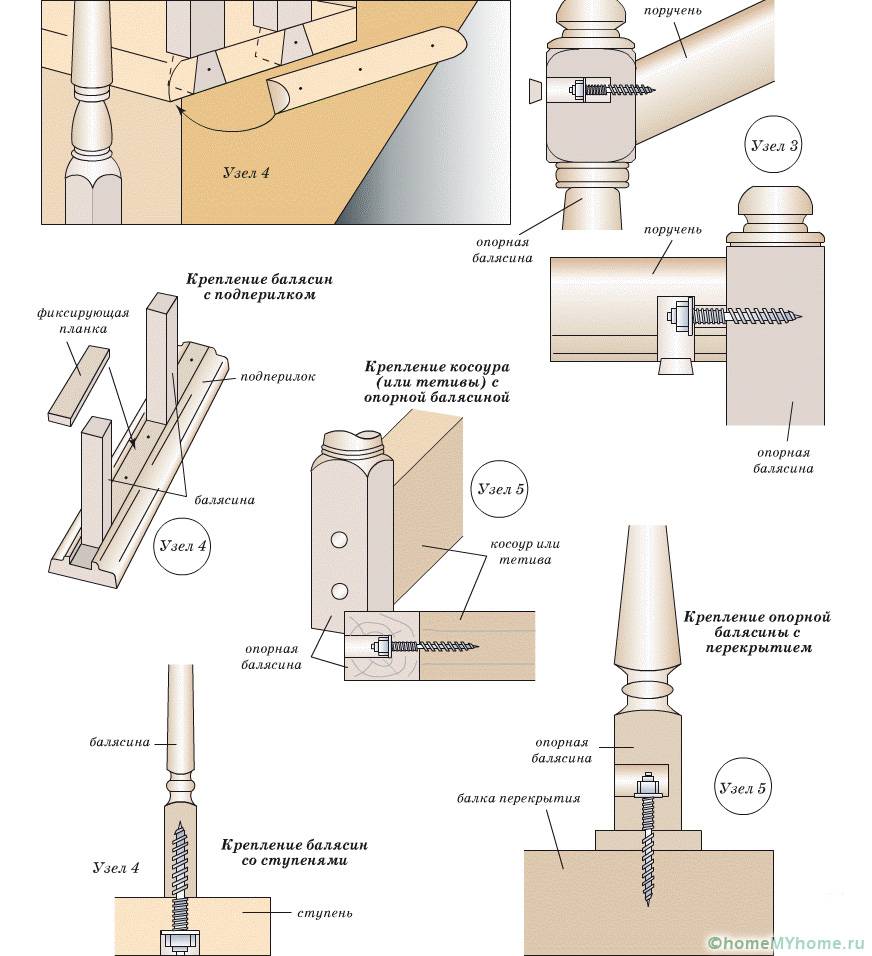

- Cutting of stringers is performed. First, a template is made in the form of a triangle with a right angle and marked dimensions of the height of the step and the depth of the step. Marking and cutting out the elements. The end parts are well polished.

- For fastening the kosour, the posts are mounted with supports. The timber is fixed with special fasteners. It can also be concreted into the floor.

- The stringers are mounted to the details of the overlap with self-tapping screws and bolts. The part at the bottom is inserted into the support bar. In this case, a groove is machined. For better fasteners, a mixture of glue and sawdust is prepared.

- The wall piece is mounted in the same way at the top. At the bottom, it is fixed with a metal corner. A level is used at all stages of production.

Installation of steps and assembly of the structure

The staircase to the second floor is made by hand from wood with a turn of 90 from the same steps, which are cut according to a template.

Run-in steps are made from the site. They are cut according to the drawing. In this case, the lines should go out from one corner. After the production of all the elements, they are treated with varnish and a special protective compound.

A bowstring is being performed for the march, which is below. The grooves are cut into which the steps will be installed. The protruding parts of the outer string are masked by the ends of the winder steps.

Useful advice! You should not make blanks that fit tightly between the steps. To make the structure durable for many years, small gaps are made.

Installation of handrails and balusters

Decorating details - balusters and railings - play an important role in the interior arrangement. Dowels are used to secure the balusters to the steps. Additionally, processing with resin and glue is performed. To fasten the railing, a groove is made along the entire length, where the rail nailed to the balusters enters. The finished ladder needs to be processed with a sanding machine or sandpaper. Then staining or coating with a stain or varnish is performed.

Useful advice! It is better to place balusters at each step, which will provide greater structural strength.

Useful Tips

Wood stairs require special care. For this, the following measures are taken:

- Cleaning is done with a wet cloth without the use of detergents.

- Wipe the surface with a dry cloth with added wax.

- Do not allow the structure to dry out.

- It is necessary to eliminate all problems in time: creaks, pasting of joints and loosening of fasteners.

Helpful information! This system shrinks. Therefore, you should not immediately mount it tightly. It should sit for several weeks.

Self-assembly and proper care will create a durable and beautiful product that will last for many years.

Video: installation of a wooden staircase in the house