Stairs to the second floor on a metal frame: what you need to know?

So you have built your own house, but there will be a lot of internal work, especially if the dwelling is two-story. One of the important points in its arrangement is the presence of a staircase to the second floor. There are many options for its installation and standard projects, but the most reliable option is considered stairs to the second floor on a metal frame. What schemes are available and how to implement them in practice to create a reliable design, we will tell.

The content of the article

Video: ladder on a metal frame

Why metal frame?

Stairs to the second floor on a metal frame have a lot of advantages, among them:

- Reliability;

- Strength;

- Ample opportunities for decoration, including large steps and other decor of any weight.

- Durability.

But it is not so easy to choose, and even more so to install such a staircase, and you need to have it provided with a variety of typical layouts and other important details.

Typical designs

Since stairs in houses have been used for a long time, there are a variety of their designs, these include:

- Marching - this metal support includes corners and a channel. The frame is welded from the latter, and steps from the corners are attached to them. If a single-flight staircase is planned, then the use of support logs is allowed, they are installed cone-shaped. When choosing this constructive solution, pay attention to the parallelism of the steps to the floor.

- On kosoura. Kosour is a support that is located under the steps, it can be in two versions - it is double and single. The first structure is placed on both sides of the staircase, and the step rests on two points: one stringer, channel or I-beam. It is located in the middle of the structure, metal plates are fixed on it, on which the steps are mounted.

- On bowstrings - that is, on a support that is located on the side of the steps.

- Spiral - these are used when it is not possible to install a full staircase.The role of the support is played by a metal pillar in the central part, around which paddle-shaped steps are mounted. This type of staircase will definitely not work if there are elderly people or small children in the house.

Related article:

Stairs to the second floor in a private house. A detailed overview of existing types of stairs and a practical guide to installation in a separate material.

Requirements

Manufacturing stairs to the second floor on a metal frame is laborious and requires certain rules to be followed. And this is not casual, because the safety of movement and the comfort of the passage from the first floor to the second will depend on its quality and convenience. These rules include:

- Staircase width - 90 cm;

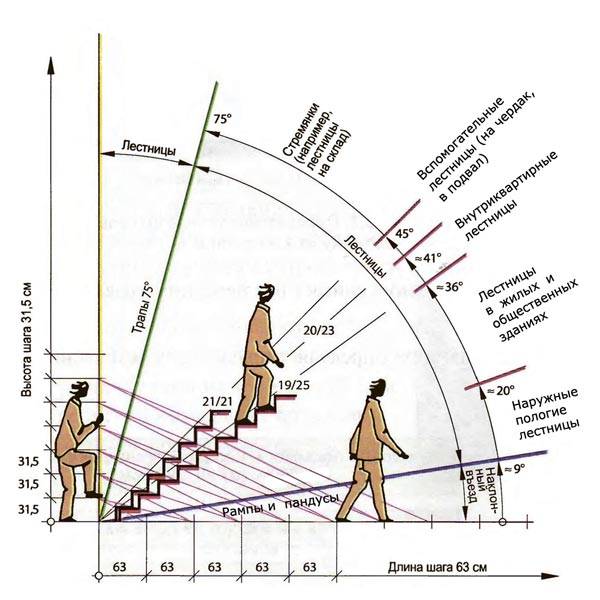

- The incline of the march must be constant, the values of the slope angles are presented in the table below;

- The most convenient step height is considered to be the interval from 14 to 18 cm;

- The depth of each is no more than 27 cm;

- If a fence is provided on the stairs, then it is necessary that it withstand a load of at least 100 kg;

- The distance between the posts is 15 cm, and this is the maximum.

| Width | Height | March slope |

| 40 cm | 10 cm | 14⁰ |

| 38 cm | 11 cm | 16⁰ |

| 36 cm | 12 cm | 18⁰ |

| 34 cm | 13 cm | 21⁰ |

| 30 cm | 15 cm | 26⁰ |

| 28 cm | 16 cm | 29⁰ |

| 26 cm | 17 cm | 33⁰ |

| 24 cm | 18 cm | 37⁰ |

| 22 cm | 19 cm | 40⁰ |

Frame calculation

Stairs to the second floor on a metal frame require careful calculations. The quality of the project is half the battle, and it needs to be given close attention. What is important to consider when designing is the structure of the frame, the method of fastening it and each of its elements, the size of the flights, the opening between the floors, the height of the steps and their width, the necessary materials.

We have already understood about the possible design variations, as for the opening, it is directly dependent on the height of the ceilings and the steepness of the stairs. The height of the steps can be different, the generally accepted one is from 14 to 18, but it will have to be calculated in kind, as well as their number. This can be done by dividing the length of the structure by the height of the steps.

When you have received all the data, you need to sketch the structure on a sheet of paper where you indicate all the dimensions and dimensions, this will help you when welding the frame and its components.

Preparation

Before starting work, you need to prepare all the necessary tools and equipment. Welding work should be carried out in special clothing and gloves to avoid injury. Of course, you need a manual inverter and electrodes, as well as a protective mask. You also need a grinder with cutting discs and for grinding, a drill and drills for metal. A reliable metal table, clamps, a vice, a tape measure, a square and a pencil will also have to be in place. First, you need to make all measurements and cut the materials into the necessary parts.

Support

At the very beginning, you need to make supports, depending on the type of construction chosen, they can be different:

- Metal stringers, which are cut from a dense sheet of metal - this will be the frame;

- Stepped bowstrings - metal channel bars are welded to one another, thus a stepped bowstring is obtained at the exit;

- Fillets - the basis is a channel, to which fillets for steps are welded;

- With central support. The best option is to use a metal pipe.

Process

Armed with the above tools, you need to weld structures in accordance with the project. Check the parallelism of the placement of the elements on which the steps (supports) will be mounted. It's good if you have an assistant with the appropriate equipment, since some elements are difficult to weld on your own. For example, stringers at right angles. The advantage of making a frame with your own hands is the ability to create any configuration and quickly change it.

Metal safety

Since the metal frame of the stairs to the second floor in the house can be negatively affected, it must be covered with a special anti-corrosion compound. First, it must be degreased and primed, then covered with a protective compound, after it dries with a special paint.

conclusions

The metal frame of the stairs is beautiful, reliable and durable, but only if it is correctly installed. Welding is not a business for beginners, and without having an idea of how to work, it is better not to take on such a task and trust the professionals.

Video: installing a ladder on a metal frame