Stainless steel railings: useful information for the correct selection and operation

Quality stainless steel railings serve many useful functions. They are used to enclose space, create supports and decorations. With the help of the editorial recommendations of homemaster.techinfolux.com/en/. it is much easier to choose the right design for a specific task. This publication contains information about the technical requirements, production features and the correct execution of installation operations.

Elegant stainless steel railings decorate the interior, provide safety and convenience during operation

The content of the article

- 1 The main parameters of the enclosing structures and stainless steel railings

- 2 Features of different stainless steel designs

- 3 Technical Requirements for Stainless Steel Railings and Railings

- 4 Main components for stainless steel railings

- 5 Specialized fittings for stainless steel railings

- 6 Stainless steel railing technology

- 7 How is stainless steel railings installed?

- 8 Maintenance of stainless steel railings for stairs

- 9 How much are stainless steel railings: price per meter of structures and payment for services

- 10 Video: the process of assembling stainless steel railings by profile specialists

The main parameters of the enclosing structures and stainless steel railings

The correct formulation of product requirements makes it easy to find suitable options. You can make your own list taking into account the following factors:

- A flawless appearance is required. Stainless steel railings are often installed in a conspicuous place. They have a noticeable impact on the design impression.

- Such products must be reliable so that the supports remain stable under the maximum design loads.

- Resistance to temperature extremes, high humidity and other adverse influences will come in handy. In this case, you can count on a long service life, ease of maintenance.

For an objective analysis of stainless steel handrails, it is necessary to compare with analogs created from other materials.

To restore the aesthetic parameters, it is necessary to frequently renew the paint layer. Quite often, restoration work is performed outdoors. Corrosion destroys welded seams, which is unsafe in the elements of bridges, staircases and other fences.

Overweight is a significant limitation in some situations. Given the large size, it is difficult to imagine such a detail in an ultra-modern high-tech interior.

However, in more massive structures, it is better to use reliable steel. Study the photo carefully. You will find metal fasteners that are installed specifically to further strengthen the frame. Another disadvantage wooden products is a fire hazard.

Taking into account the noted nuances, it is easy to list the advantages of fences and railings made of stainless steel:

- Excellent aesthetic properties without special decorative coatings.

- High protection against various external influences.

- Multiple safety factor for typical loads.

- Durability, no unnecessary costs during long-term operation.

Related article:

Stairs to the second floor in a private house. A detailed overview of existing types of stairs and a practical guide to installation in a separate material.

Features of different stainless steel designs

It is convenient to consider the above-mentioned advantages and important nuances using specific examples. This section contains typical and non-standard engineering solutions. Comments on illustrations will help you better understand the ideas of the developers.

Simple and complex stainless steel stair railings

The total cost of these products largely depends on the complexity of the design.

Such solutions are classified as inexpensive options. Individual parts are assembled from straight parts. It is not difficult to create reliable fasteners based on reinforced concrete steps, brick main walls.

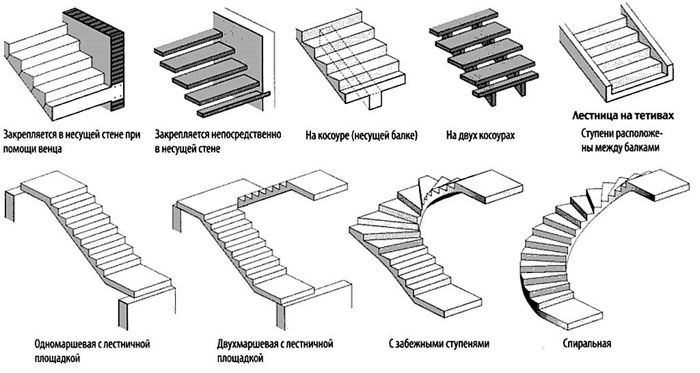

With a high height between floors, several straight sections with a turn or an intermediate platform are used

The photo shows an example with the support of the steps on the supporting lateral parts of the characteristic shape (stringers).

One support in the central part of the steps saves building materials. But this option increases the load on the stainless steel railings. They perform part of the functions of the load-bearing frame, so the choice of material is justified taking into account the targeted increase in overall strength.

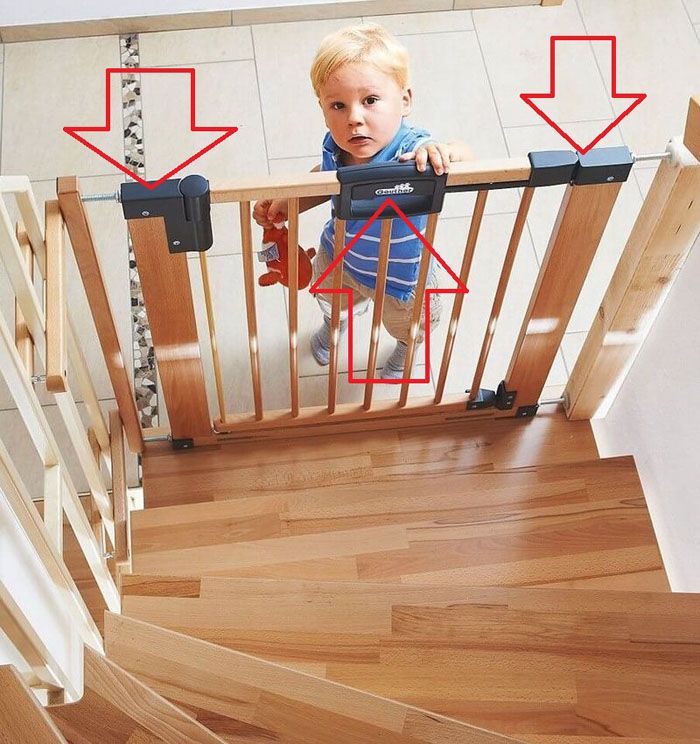

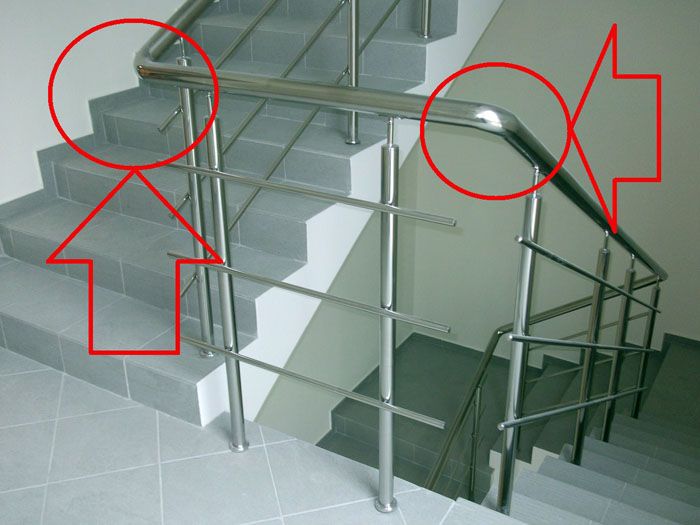

Such structures look easy. For a high-quality repetition of the project, an accurate design calculation is needed. The steps are attached to the wall using long anchors. Additional reinforcement is provided by the bolts marked with arrows together with the railing elements.

Here, special connections to the ceiling and floor are made of stainless steel. They perform the functions of a load-bearing frame and a fence.

Such complex structures are created from a variety of elements. As a rule, products are designed and manufactured to order. They take into account the size of the premises, design requirements, operational loads.

Note! The installation of stainless steel railings together with other parts of the spiral staircase is best left to the manufacturer's assembly team. In this case, you can get comprehensive written guarantees for products and work performed.

Related article:

The most reliable option is considered stairs to the second floor on a metal frame... What schemes are available and how to implement them in practice to create a reliable design, we will tell in the publication.

Reliable and durable stainless steel handrails

As can be seen from the examples, these parts of the structure perform not only supporting, but also bearing functions. Other important nuances are noted below.

Turns 90 ° and other angles create smooth, potentially dangerous sharp edges. The seams are ground until a continuous, even surface is formed.

Other types of stainless steel fences

Here are other products made from durable stainless steel.

Low fences (bumpers) are used to protect the decorative wall covering with carts in commercial enterprises

Welded and prefabricated stainless steel railings with sample photo

The choice of a suitable option must be made taking into account all important factors. Prefabricated sets are more convenient to transport, move in the process of performing work operations. Installation is carried out using the simplest tools. Welded structures are distinguished by the best anti-vandal characteristics.

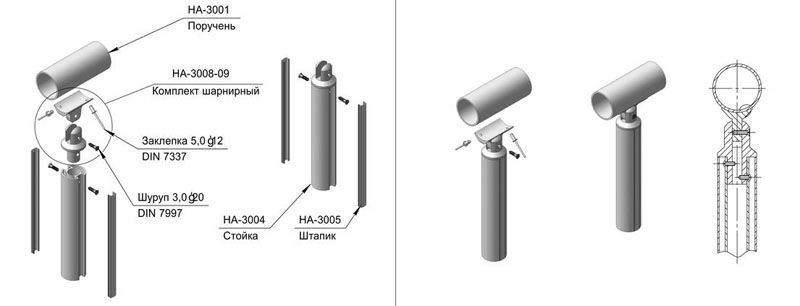

Combined design. The crossbars are inserted into special holders. Parts of the handrails are fixed not with welding, but with metal glue

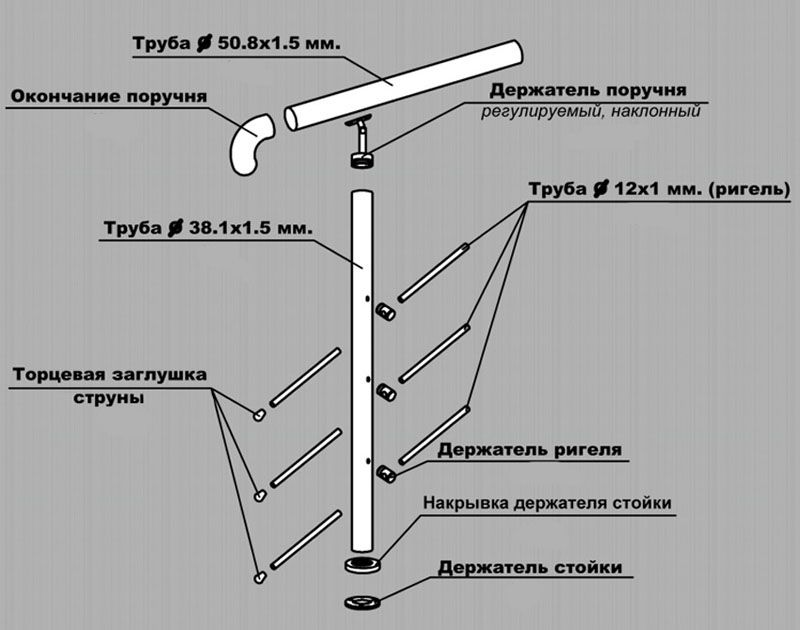

A complete set of stainless steel handrails for the stairs for assembly includes fasteners, decorative elements, supports and other necessary parts

Technical Requirements for Stainless Steel Railings and Railings

| Products, services | Limitations | Normative document |

|---|---|---|

| Fencing with vertical filling between the posts | The distance between the elements is up to 10 cm. | GOST 25772-83 |

| Design and production of enclosing structures | No sharp protrusions, dangerous edges. | GOST 23120-78 |

| Railings in residential / public real estate | Permissible load without destruction - not less than 0.3 kN / m. | SNiP 2.01.07 |

| Metal enclosing structures | Reliable protection against corrosion. | SNiP 2.03.11-85 and 3.04.03-85 |

| Railing for children | The height of the handrails is no more than 50 cm. Horizontal crossbars are not installed. | SNiP 2.08.02-89 |

| Disabled ramps | Rounded parts of handrails (start / end). Installation heights - 70 and 90 cm. | GOST R 51261-99 |

The table contains part of the current regulations. For detailed information, you can refer to the original source. If you are going to order a stainless steel railing for a balcony in buildings no more than 30 m high, use the following dimensions in cm (GOST 25772-83):

- railing mounting height - 90;

- total height of the enclosing structure - 100;

- distance between vertical elements in lattice / screen and combined fences - 100/300.

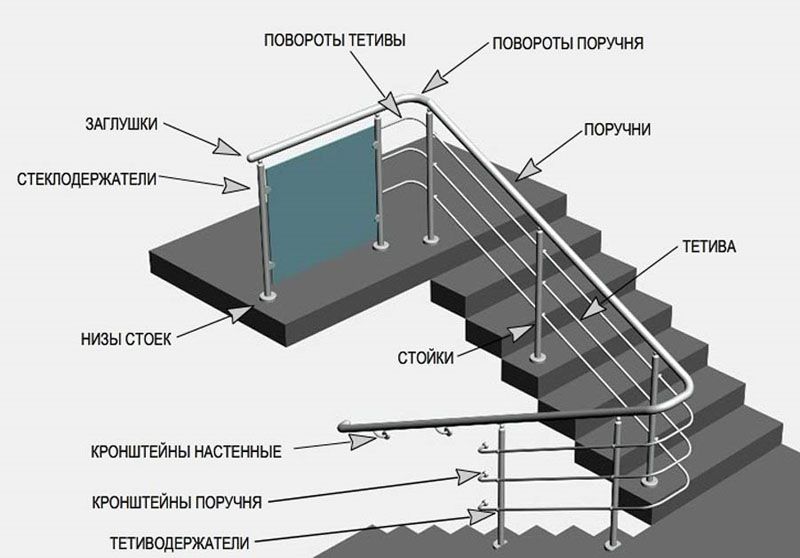

Main components for stainless steel railings

The final cost and set of services, as well as components, are formed taking into account the terms of reference for a specific project. Below are the products that are used to solve typical tasks.

Specialized fittings for stainless steel railings

This section provides details that are used to change functional and decorative parameters.Certain elements need to be installed to ensure compliance with applicable standards.

In a wide range of specialized manufacturers, you can find fittings for the successful implementation of complex projects

Stainless steel railing technology

It is not always possible to create stainless steel railings for stairs from standard products. The customization price will be higher. However, in this case, you can take into account the special requirements, architectural parameters of a particular property.

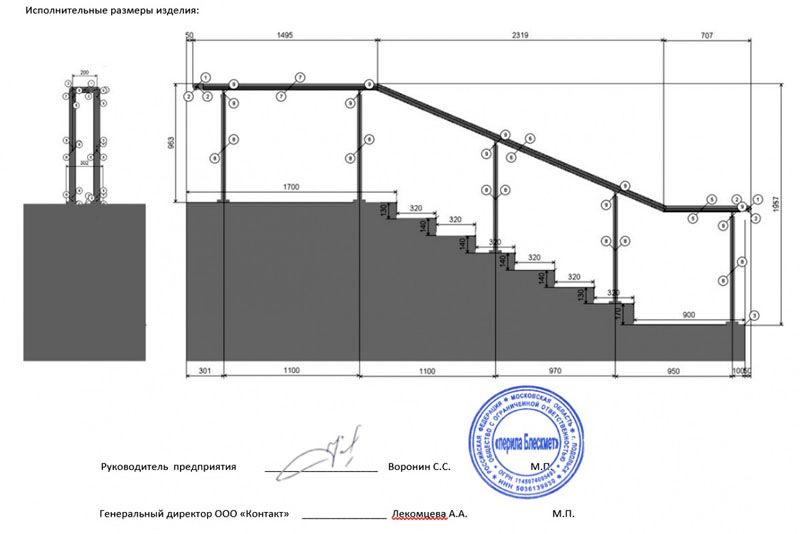

Measurement and design

The foreman who arrives on call will check the general characteristics, the condition of the stairs and walls. Particular attention is paid to reliable fastening. If necessary, determine the places of additional reinforcement. The measurements are carried out by a specialist, so errors are practically excluded. With the correct execution of obligations, deficiencies will be corrected at the expense of the contractor.

The project, drawn up in a specialized organization, will comply with the current GOST and SNiPs. Corrosion resistance is determined by the choice and percentage of alloying additions. For indoor use, for example, AISI grade 304 steel is suitable.

Stainless steel handrail manufacturing process

Argon technology is preferred to create welded joints. It implies the creation of a neutral working environment, the exclusion of impurities. After the temperature drops below + 400 ° C, oxidative reactions stop.

Surface leveling is performed in several stages. As a rule, 3-4 types of abrasive materials are used with a gradual decrease in the grain size. At the finishing stage, a felt circle with special pastes is used.

A complex order with delivery and installation operations is carried out within the agreed time frame. If you have any problems, you can use the official warranty. Of course, for this it is necessary to observe the operating rules determined by the manufacturer.

How is stainless steel railings installed?

Independent performance of work operations allows you to choose the right time without significant restrictions. Saving on the services of contractors will help reduce the total cost of stainless steel railings. For high-quality reproduction, it is better to use a relatively simple assembly using adhesive joints. Welding technology is much more complicated.

What tool is needed for work

You should prepare in advance:

- tape measure, marker, square;

- a grinder with discs for metal (alternatives are a hand saw, a band saw);

- sanding paste, soft cotton cloth;

- drill with electric drive, durable drills for stainless steel;

- clamps with plastic pads;

- special tool for mounting rivets (if necessary);

- screwdriver, specialized attachments for electric drills;

- vacuum cleaner.

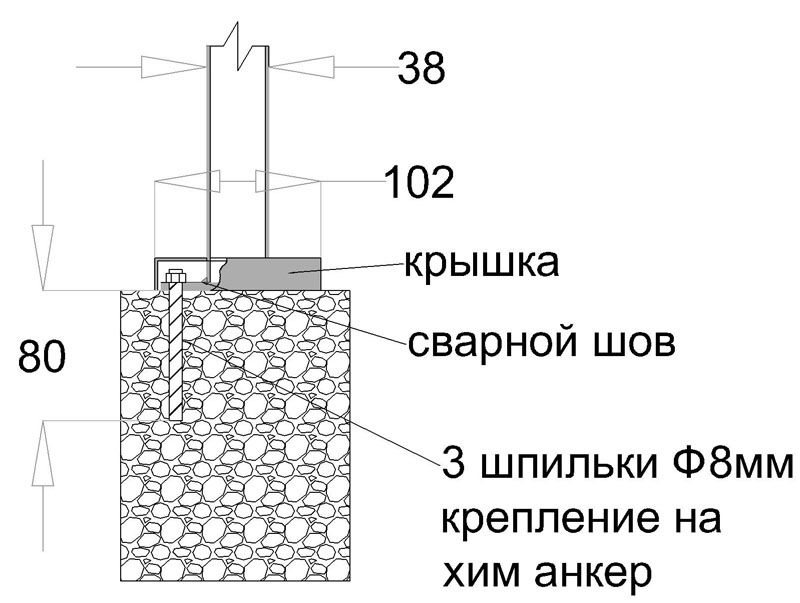

Installing stainless steel railings step by step

Let's consider in more detail the technology of installing handrails. For this we have prepared a special photo instruction.

Maintenance of stainless steel railings for stairs

To extend the life of your products, use the following guidelines:

- Do not use compounds with abrasive components.

- Simple greasy stains are removed with acetone or alcohol.

- Stubborn dirt is removed using ammonia (1% solution).

- Transport and advertising stickers are removed with preliminary oiling.

How much are stainless steel railings: price per meter of structures and payment for services

| Structural elements | Cost (as of June 2018), RUB for 1 r.m. | ||

|---|---|---|---|

| Type of fixing the handrail to the rack | Cup-shaped | Welded | Ball |

| Number of horizontal transoms | 2 | 3 | 4 |

| Type of fastening of horizontal transoms | Welded | "Ring" | "Barrel" |

| 3450 | 4600 | 5500 | |

In this example, we have indicated the cost of work, taking into account the professional assembly. On the official websites, sellers offer special calculators to quickly check the cost of different solutions. As noted above, stainless steel handrails can be purchased as a set. For a correct comparison, all real costs should be taken into account, which include general construction and finishing work.

Ask questions and post your own comments, tips and thoughts in the comments. In this video you can watch the process of assembling stainless steel railings by specialized specialists.