The machine for sharpening chainsaws is an indispensable assistant to the villager

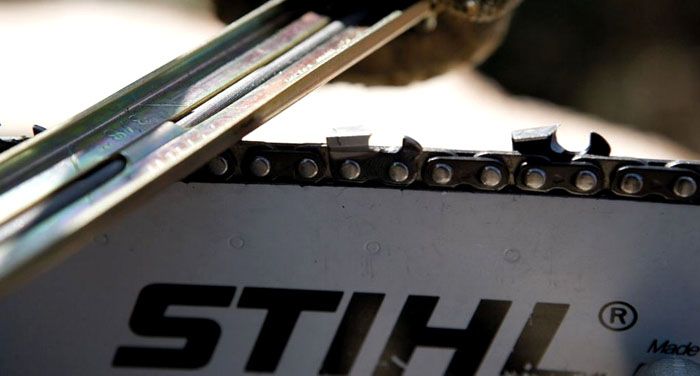

Although the 21st century is already in the yard, but, nevertheless, in rural areas, firewood is almost the main type of fuel used for heating houses and cooking, especially in the Northern regions of our country, Siberia and the Far East. When harvesting firewood and commercial wood (on a non-industrial scale), chainsaws of various brands and manufacturers are used. Cutting tools chainsaw is a saw chain, the quality of sharpening of which depends on the productivity and safety of the work performed. Chainsaw chain sharpening machine - the principle of the tool, the advantages and disadvantages of manual and automatic models, a review of prices for the most popular devices of this type today in a detailed review of the homemaster.techinfolux.com/en/ editorial office.

The content of the article

- 1 The device and technical characteristics of the tool for sharpening chainsaw chains

- 2 Types and principle of operation of sharpening devices for chainsaws

- 3 Advantages and disadvantages of manual and automatic models

- 4 How to choose the right sharpening device

- 5 Popular models of equipment for sharpening saw chains

- 6 At what price to buy a sharpening machine for sharpening chainsaws

- 7 Video: sharpening the chainsaw chain

The device and technical characteristics of the tool for sharpening chainsaw chains

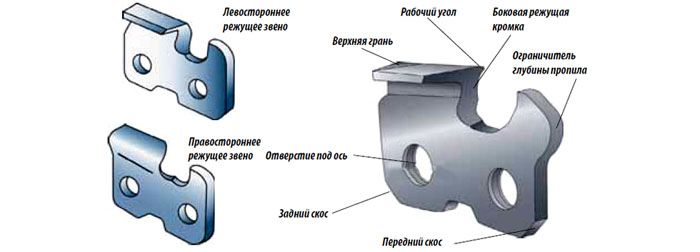

The saw chain tooth has a complex geometric shape and is equipped with two cutting edges, one of which is responsible for making an incision on a wooden surface, and the other removes chips from the sawing site and ensures its width.

The edges are located relative to each other in perpendicular planes.

For sharpening cutting edges (cutters), various tools can be used, differing in the degree of process automation, these are:

- file - the simplest tool for performing such work;

- mobile manual machine - is installed on the tire, and sharpening is performed without removing the chain from the saw using a file;

- mobile manual electric machine - it is used, like a manual analogue, the only difference is that the abrasive is driven by an electric drive;

- stationary manual electric machine - it is installed on a flat and hard surface; for sharpening, the chain must be removed from the guide bar and installed on the machine;

- automatic machine - is a functional device, but due to its high cost in a domestic environment, it is used extremely rarely.

If with the device of the simplest chain sharpener - a file, everything is clear, tk. every user is familiar with it since school, then not everyone knows about the device of other types of instrument.

Using a file, you can sharpen the chain without the use of other devices or with their use to facilitate this process.As additional devices that provide the required angle of sharpening of the cutting edges, hand-held mobile machines that are not equipped with an electric drive are used.Files used for manual sharpening of chainsaw chains are sold in special sets designed for this purpose.

The main element of any household appliance, including chain sharpening machines, is an electric motor that rotates the abrasive tool, which ensures the processing of the saw chain cutters.

Usually, an abrasive wheel is used as a sharpening element, through which chainsaw chains are sharpened.

The main technical characteristics of the tool used for sharpening saw chains are the following indicators, such as:

- for files - diameter and degree of notch;

- for hand-held mobile machines - the geometric dimensions of the file used;

- for electric mobile and stationary machines - electrical power, voltage class and dimensions of the abrasive disc (seat and outer diameter).

Types and principle of operation of sharpening devices for chainsaws

Sharpeners are classified according to:

- type of grinding surface drive - manual and electric;

- type of use - mobile and stationary;

- voltage class - 220 and 12 Volts;

- type of work - manual and automatic.

How manual chain sharpeners work

The work of hand tools used for sharpening saws is based on the physical impact of a person on the surface to be treated. Thus, work is performed both with the use of a file without a hand-held mobile machine, and with its use.

When using manual electric machine tools work is carried out as follows:

- Stationary models:

- the chain is removed from the saw and fastened between the rotary vise located on the body of the device;

- the required sharpening angle is set;

- the electric motor turns on and the abrasive disc is mated with a link in the saw chain;

- sharpening of a specific link is performed, after which the disc is retracted;

- the chain is shifted by one tooth, after which the sharpening operation is repeated for all chain links.

- Mobile models:

- the machine is attached to the chain directly on the surface of the saw bar:

- the required angle of inclination of the saw blade is set and a particular chain tooth is sharpened;

- the fastening of the machine is loosened and the chain is shifted by one tooth;

- the sharpening operation is repeated on each of the teeth along the entire length of the chain.

When using mobile hand-held machines using a file, the work is carried out in the same way, the only difference is that sharpening is done manually.

Sharpening with a file requires experience and knowledge of the construction of chains of various types and purposes.

The principle of operation of automatic machines

Working with automatic machines is similar to the principle of operation of stationary models, with the only difference that after fixing the chain on a rotary vise and starting the machine, you do not need to manually move the chain, this operation is performed automatically.

In addition, using the settings, you can adjust the amount of cutting off the edge of the tooth and the depth of the cavity, as well as set the parameters for sharpening the front cutting corner of the tooth.

Features of sharpening on mobile and stationary machines

Using electrically driven machines, you need to know that in this case there are some features of sharpening, in comparison with devices working on the physical strength of a person, these are:

- overheating of the treated surface must not be allowed, because this will lead to a decrease in the strength of the metal;

- the abrasive disc must have a flat surface, otherwise it is impossible to achieve high-quality sharpening of the cutting surface;

- water must not be used to cool the links;

- when using coarse-grained discs, it is necessary to additionally grind the cutting edges using fine-grained abrasive materials.

Advantages and disadvantages of manual and automatic models

Any device, technical device and tool has certain advantages and disadvantages, and this fully applies to machines for sharpening chainsaw chains.

The advantages inherent in all types of sharpening devices include:

- the sharpening process is faster than without using them;

- the quality of sharpening is higher, which is due to the rigid fixation of the required angle of processing of the cutting edges;

- the ability to perform high-quality processing on their own in various operating conditions (forest, garage, etc.);

- versatility of use, expressed in the possibility of using when sharpening other tools and equipment.

If we consider individual groups of sharpening machines, then additionally the advantages of each of them will be the following indicators:

- for manual models:

- low cost;

- the ability to use in "field" conditions;

- the ability to perform high quality sharpening.

- for automatic devices:

- performing operations without using human physical strength;

- high performance and functionality.

The disadvantages of certain groups of sharpening equipment include:

- Dli hand models:

- low labor productivity with their use;

- the need for knowledge of the chain design, the angles of sharpening of cutting edges, as well as the abrasive tool used.

- For automatic devices:

- high price;

- dependence of use on the availability of a power supply system;

- when sharpening cutting edges, their rapid wear occurs, and therefore, after several operations, the chain becomes unusable.

How to choose the right sharpening device

When choosing a grinding machine for chainsaw chains, the criteria that determine the choice of a particular model will be the following indicators:

- The nature and place of use - this indicator determines the type of device: mobile or stationary, manual or automatic.

- Cost - with periodic use, it makes no sense to buy an expensive automatic model.

- For models equipped with an electric drive, their technical characteristics, such as:

- electrical power - determines the possibilities of using the equipment, both in terms of frequency of use and tool mobility;

- speed - determines the speed of sharpening and its quality;

- grinding wheel diameter - determines the overall dimensions of the machine and the scope of its application;

- availability of additional functions and options.

The electric power of the grinding machines is usually 0.2-0.5 kW, but the models for professional use are equipped with more powerful electric motors.

The speed of the sharpening equipment used for sharpening chainsaw chains is 3000 - 7500 rpm, while the more revving ones are business models.

Circles of large diameter (250-400 mm) are equipped with permanently installed models, and with sizes up to 250 mm - both stationary and mobile devices.

Sharpening the saw chain with an automatic machine does not require the use of human physical strength

Additional functions that can be equipped with machines for sharpening chainsaw chains include the following features and settings, these are:

- the ability to rotate the grinding head and clamping block;

- performing wet sanding;

- the presence of a protective screen and casing;

- tension adjustment of the processed chain;

- the presence of a cooling system;

- other functions inherent in a particular model.

Popular models of equipment for sharpening saw chains

In the woodworking equipment market in the category of professional tools, the most popular models are Oregon 519789 (USA) and "Stihl USG" (Germany).

In the group of machines for domestic use, the most popular models are "REZER EG85" (China), "SADKO SCS 85Pro" (Slovenia) and "CHAMPION C2000" (China).

Oregon 519789

The professional sharpening machine has a modern design and allows you to work in large volumes with high productivity in a workshop or workshop.With its use, you can sharpen chains for all types of chainsaws, with a thickness of 1.1 - 3.1 mm, in increments of 1/4 "- 3/4" and at three cutting angles.The machine is equipped with a self-centering mechanism, as well as illumination of the sharpening zone.

Main technical characteristics of "Oregon 519789":

- supply voltage - 220V / 50Hz;

- electric power - 0, 214 kW;

- disk dimensions - 145 × 22.3 mm;

- grinding wheel thickness - 3.2 / 4.7 / 6.0 mm;

- weight - 6.0 kg.

"Stihl USG"

Professional machine for universal use. It can be used to sharpen saw chains and discs for hedge trimmers and other cutting equipment. The presence of a rotary support extends the functionality and ease of use of the machine.

Main technical characteristics of "Stihl USG":

- supply voltage - 220V / 50Hz;

- electric power - 0.18 kW;

- disk dimensions - 140 × 22.3 mm;

- weight - 8.8kg.

"Rezer EG85"

The machine is intended for domestic use and has a high quality sharpening. The model is equipped with a protective screen and casing to protect the user and the electric motor respectively.

Main technical characteristics:

- supply voltage - 220V / 50Hz;

- electric power - 0.085 kW;

- disk dimensions - 108 × 22.2 mm;

- weight - 3.1 kg.

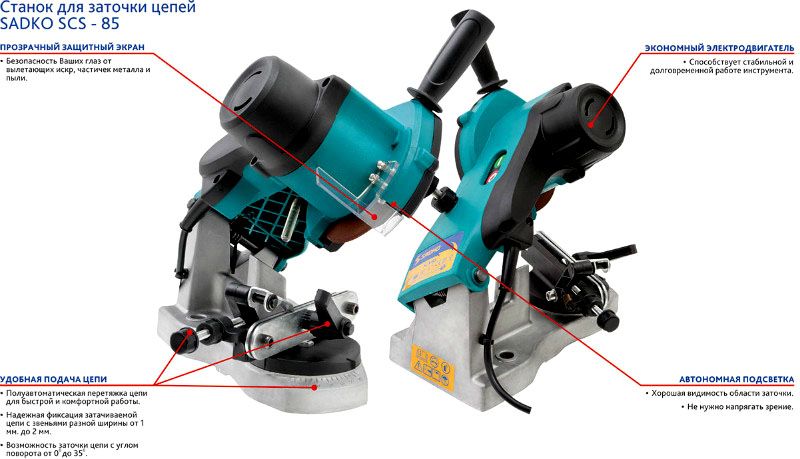

Sadko SCS 85Pro

The machine can be used for both domestic and professional use, the reason for this is the distinctive features of this model, which include: significant power and high productivity, accuracy of operations and ease of use. Main technical characteristics:

- supply voltage - 220V / 50Hz;

- electric power - 0.085 kW;

- disk dimensions - 104 × 22.0 mm;

- weight - 2.5 kg.

"Champion C2000"

The machine for home use is characterized by its compact size and ease of use, which is ensured by the presence of a rotary work table. A robust casing is provided to protect the user. Main technical characteristics:

- supply voltage - 220V / 50Hz;

- electrical power - 0.085 kW;

- disk dimensions - 105 × 23.0 mm;

- weight - 2.0 kg.

At what price to buy a sharpening machine for sharpening chainsaws

You can buy a machine for sharpening chainsaw chains in stores and retail chains that specialize in the sale of electric hand tools, in companies that sell equipment for woodworking and timber harvesting, as well as from dealers of companies that produce such equipment.

The following table shows the prices for the popular models of chainsaw sharpening machines considered in this article as of the end of the 1st quarter of 2018 when sold by dealers of manufacturers (professional models) and in trade organizations selling hand-held electric tools.

| Picture | Model | Average cost (as of April 2018), rubles |

|---|---|---|

| Oregon 519789 | 30000 |

| Stihl USG | 37000 |

| Rezer EG85 | 2200 |

| Sadko SCS 85 Pro | 2500 |

| Champion C2000 | 1900 |

Related article:

Chainsaw: which brand to choose. It is difficult to imagine life in a summer cottage without working with wood. In this case, a chainsaw is an important tool. So which model is right for you according to your goals and budget?