How to make sandblasting with your own hands: video tutorials and some tricks

Often, in order to remove rust from a car body or to clean any part, motorists turn to specialists for help and pay them a lot of money. Even an ordinary metal fence cannot be painted without cleaning it from rust. In fact, you just need to understand how to make sandblasting with your own hands (the video will be presented in today's article), and these problems will be solved. The work will not require large expenses, and the home craftsman will have his own personal apparatus capable of performing such dirty work.

The content of the article

- 1 How the sandblaster works: general information

- 2 What is the principle of operation of a sandblaster: video and photo examples

- 3 What types of sandblasting machines are distinguished

- 4 Sand for sandblasting: which is better to use

- 5 How to choose a sandblaster: tips from the editors homemaster.techinfolux.com/en/

- 6 What tool is required to make a sandblasting machine

- 7 What can you make a sandblaster with your own hands?

- 7.1 Do-it-yourself sandblasting from a gas cylinder: step by step instructions

- 7.2 Is it difficult to make sandblasting with your own hands from a fire extinguisher

- 7.3 How to make a do-it-yourself sandblasting nozzle: editorial advice homemaster.techinfolux.com/en/

- 7.4 Making a sandblasting gun with your own hands: how difficult it is

- 7.5 How to make sandblasting with your own hands: video tutorials on making various units

- 8 Pros and cons of homemade units

- 9 Sandblasting machine operating instructions: take care of your life and health

- 10 The cost of factory-made sandblasting machines in the Russian market

- 11 Finally

- 12 Video: ZIL compressor and do it yourself sandblasting

How the sandblaster works: general information

Such a unit consists of several main components:

- a compressor that creates the pressure required for the sandblaster;

- cables through which voltage is supplied to the compressor;

- hoses;

- fittings;

- taps for pressure regulation;

- dispensers;

- moisture separator.

However, one of the most important parts of the device is the nozzle through which the abrasive passes under air pressure.In industrial production, the steel nozzle is coated with boron or tungsten compounds. Such parts are durable, but it is impossible to make them at home when making a sandblasting unit with your own hands. Although here the load on the nozzle will be small, incomparable with the industrial scale.

Helpful information! For homemade installation, you can use ordinary steel. An old car candle from which the electrode is pulled out is not bad. Of course, the service life of such a nozzle is minimal, but also the cost is zero.

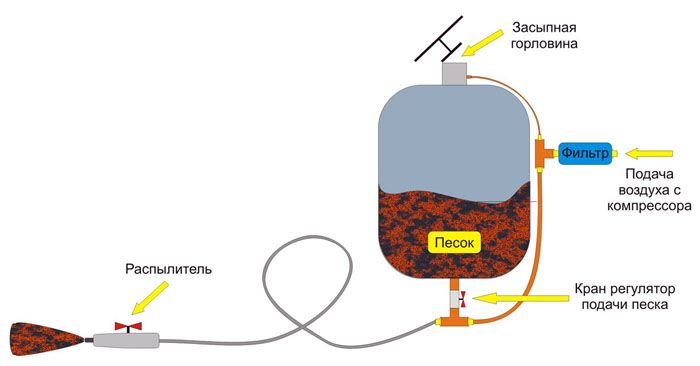

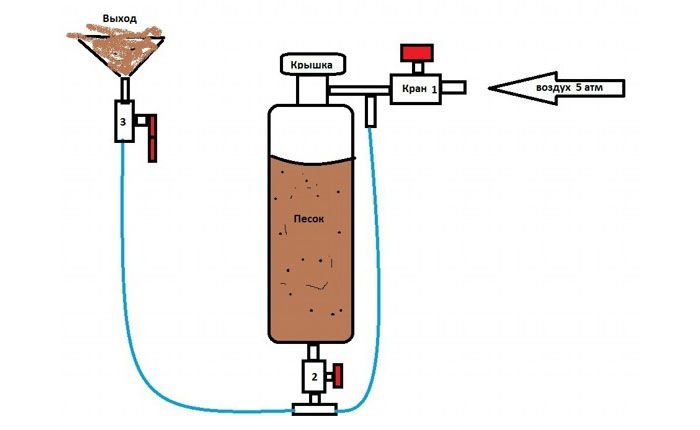

Sandblasting machine diagram: some subtleties

In order to make it easier for the respected reader to navigate in the device of the unit, we suggest looking at the schematic image of the sandblasting. You will make sure that there is nothing complicated in its device. The main thing is to understand the principle of its operation, which we will now deal with.

What is the principle of operation of a sandblaster: video and photo examples

The principle of operation of the device can be compared with a spray gun. Many people know that the high-pressure flow of compressed air captures the paint in small particles and carries it out through the nozzle. Here the principle is the same, only an abrasive (sand) acts instead of paint. And although the designs of sandblasting machines may differ, the principle of operation does not change from this. And to clarify the remaining incomprehensible points, we suggest watching a very informative video on this topic:

What types of sandblasting machines are distinguished

To answer the question of which sandblasting machine is better, you should clearly understand for what purpose it will be intended. Depending on the field of application, it is determined what type of apparatus is needed. There are three main types:

- Suction - such a unit is suitable if a small amount of work is required (light rust, slight oxidation). Air does a double job here - in addition to feeding the abrasive into the nozzle, it also picks up sand from the tank. Such a device is the easiest to manufacture.

- Vacuum sandblasting - an interesting solution, in which the abrasive is used repeatedly. Sand, thrown upward under pressure in such devices, is sucked back.

- Pneumatic sandblasting machines. They are designed to handle large areas. Their power is very high, which means that the pressure in the receiver must be high. For this reason, the editors at homemaster.techinfolux.com/en/ strongly discourage constructing this type of sandblasting by yourself.

Important! When large areas or difficult-to-clean elements are required, i.e. using pneumatic sandblasting, it is better not to spare money and hire professionals than risk your life. Remember that the receiver, bursting nearby, even at 4 atm, does not leave a chance for life.

Sand for sandblasting: which is better to use

Not only sand is recommended for sandblasting. It is often more profitable to use other abrasives. But for hand-made sandblasting machines, quartz sand is the best abrasive. Nobody will use them for too harsh dirt, and (for example) in order to remove rust on the fender or hood of a car before touching up this place, quartz sand is quite enough.

It's important to know! Quartz sand can also be heterogeneous. It should be understood that if polishing is required, fine, sifted fractions are used, and to clean the fence from rust before painting, it is better to use unsifted sand.

The size of the fractions for the areas of application is distributed as follows:

- 0.1−0.8 mm - glass matting is performed with even sifted sand;

- 0.3 mm - polishing copper, aluminum parts;

- 0.3-0.6 mm - paintwork;

- 0.6-0.16 mm - deep-seated rust.

In other cases, larger, harder abrasives are used.

How to choose a sandblaster: tips from the editors homemaster.techinfolux.com/en/

Having understood the area in which sandblasting will be applied, you should pay attention to the fact that such equipment differs in the following characteristics:

- volume of the bunker for abrasive - the convenience of the operator will depend on this. The larger the volume of the tank, the less often you have to stop during operation;

- unit operating pressure - for household use, devices with a pressure of 4-9 atm are used;

- performance - the optimal indicator is 15-30 m2/ h;

- sand consumption during operation - average value for simple sandblasting - 40 kg / h;

- equipment;

- number of operators involved in the work.

Pay particular attention to the nozzle. The performance will depend on it, and the frequency of its replacement will depend on the material of manufacture. Ceramic and cast iron nozzles are considered more acceptable - they work for a long time and are inexpensive.

The compressor must deliver at least 350 l / min, otherwise a large receiver will have to be installed, which will affect the mobility of the installation, which in itself is an important factor when choosing a device. Additional functions, the presence of which is desirable, include remote control of the abrasive feed. This allows less air, sand and more safety for the operator.

What tool is required to make a sandblasting machine

The first thing that should be purchased for the manufacture of sandblasting is a compressor; you will not be able to make it yourself. Next is a reservoir for sand (abrasive). A propane tank or an old fire extinguisher is a good choice for this purpose. Now the nozzle. Of course, you can grind it on a lathe, but then you need to be prepared that such a nozzle will quickly be erased. The way out will be the purchase of special ceramic caps that will protect the metal. Hydraulic hoses from construction equipment are perfect as air ducts and channels for sand with air under pressure. Do not forget about fittings, nozzles and taps - their number can be calculated according to the drawing, without which the manufacture of a sandblasting unit is impossible.

What can you make a sandblaster with your own hands?

The simplest is the manufacture of units from gas cylinders and fire extinguishers. At home, there is no better foundation. Now let's briefly consider the algorithm of actions that need to be performed.

Do-it-yourself sandblasting from a gas cylinder: step by step instructions

There are dozens and hundreds of variations of units made by hand from various scrap materials. Sandblasting can also be made from devices and parts that have lost their relevance.

Is it difficult to make sandblasting with your own hands from a fire extinguisher

If you understand in detail with our step-by-step instructions, then it will not be difficult to make a sandblasting unit from a fire extinguisher. Everything is done exactly the same here. The only difference will be the size of the sand reservoir.

How to make a do-it-yourself sandblasting nozzle: editorial advice homemaster.techinfolux.com/en/

The best option would be to manufacture a ceramic sandblasting nozzle from used automotive spark plugs. To do this, unscrew the central part, then cut off the candle from the side of the nut with a grinder. This should be done carefully so as not to damage the ceramics. After the work done, the ceramic glass is easily removed. Of course, such a nozzle will work no more than 2-3 hours, however, the beauty here is that it will not cost anything - you can find as many old spark plugs as you like. If you purchase a nozzle, it is best to buy a boron carbide product. It will last from 750 to 1000 hours of continuous operation. A cast iron nozzle lasts 6-8 hours, while a tungsten carbide product lasts about 300 hours.

Making a sandblasting gun with your own hands: how difficult it is

Making a gun for a sandblaster is a snap. To do this, you only need a pneumatic gun, with the help of which they blow through hard-to-reach places and a plastic bottle. We invite our dear reader to watch a short video that explains in detail the manufacturing process of a sandblasting gun for a compressor.

How to make sandblasting with your own hands: video tutorials on making various units

Such installations can be of different types. Now we will consider the processes of their manufacture. Let's start with an ordinary homemade do-it-yourself sandblaster. The video below will help our dear reader understand more fully how to make it.

Spark plugs often coke? Then a good solution would be to design and make a sandblast with your own hands to clean the spark plugs. How it looks and how it is used can be found in the video.

And from the following video you can understand how the sandblaster with water works. Quite an interesting solution that will not require large expenses from you, if you have a mini-sink of the Keercher type at hand.

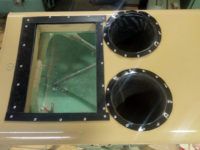

Well, if you decide to make a sandblasting chamber, the homemaster.techinfolux.com/en/ editorial office presents to your attention several homemade products made according to drawings.

Pros and cons of homemade units

If we talk about the positive aspects of self-assembled sandblasting machines, then they are on the surface - this is an opportunity to clean surfaces for a very modest amount that the master will spend on taps, fittings and pipes. And then, if this is not in his garage. This is where the pros end. And what about the cons. Here the question is more serious.Dustiness during work is understandable, but what about the risk of injury? Any oversight when welding parts will lead to a break in this place. In this case, death is also possible. Therefore, the editors of homemaster.techinfolux.com/en/ warns: weigh everything 1000 times and think if you can do this work with perfect quality. If not, then it is better to abandon the idea.

Sandblasting machine operating instructions: take care of your life and health

The main thing that is required when working with sandblasting is the mandatory use of personal protective equipment (respirator, gloves, goggles) and compliance with safety measures. It is probably clear that you cannot use faulty equipment, damaged hoses, etc. For the rest, each unit is controlled in its own way, which means that there can be no single operating instructions for them.

The cost of factory-made sandblasting machines in the Russian market

Consider several models of sandblasting machines popular among the Russian consumer with some technical characteristics and prices, as of May 2018.

Finally

A sandblaster in the garage or in a private backyard is a good thing. Moreover, you can make it practically at no cost. However, you shouldn't forget about safety either. After all, if you compare prices, then a small unit can be purchased relatively inexpensively. If the home craftsman is confident in his abilities and skills, then making homemade sandblasting is really more than justified.

We hope that the information presented by us today was useful to the dear reader. If you have any questions, we will be happy to answer them. Ask them in the discussions below. There you can share your experience in the manufacture or use of sandblasting machines - this will be useful for novice home craftsmen. Write, communicate, ask, share your experience. And finally, we suggest watching one very interesting video on today's topic.