What is the best inverter welding machine to choose for a summer residence and at home?

Before buying any equipment, you need to decide what tasks it will perform and what requirements it will meet. What is the best inverter welding machine for use at home or for household work in the country? What is important to know and what to be guided by when choosing a unit?

The content of the article

- 1 Device and basic characteristics of inverters

- 2 How to choose a 220 V welding machine for home and garden

- 3 Which inverter welding machine is best suited for household purposes

- 4 Characteristics of devices by manufacturers and prices

- 5 Recommendations for the operation of household inverters

- 6 Choosing a home master

- 7 Video: how to choose a welding machine

Device and basic characteristics of inverters

The main advantage of devices of this type is their small size and low weight. They are confidently pushing out bulky transformers from the market, which weigh up to 20-25 kilograms. To understand how to choose a welding inverter for home and summer cottages, it is important to have a basic understanding of its structure and principles of operation.

Device device

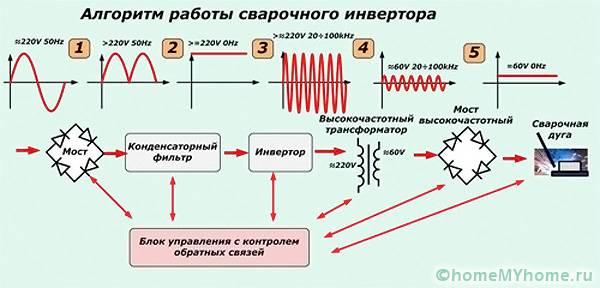

Welding inverter models have distinctive features, but all are based on the use of pulse converters. Any instrument has in its circuit:

- inverter;

- low-frequency and high-frequency rectifiers;

- transformer;

- working shunt;

- electronic control unit.

Inverter welding machine:

- powered by a 220 Volt network;

- converts direct currents into high-frequency alternating currents;

- lowers high frequency voltage;

- at the output rectifies the reduced currents.

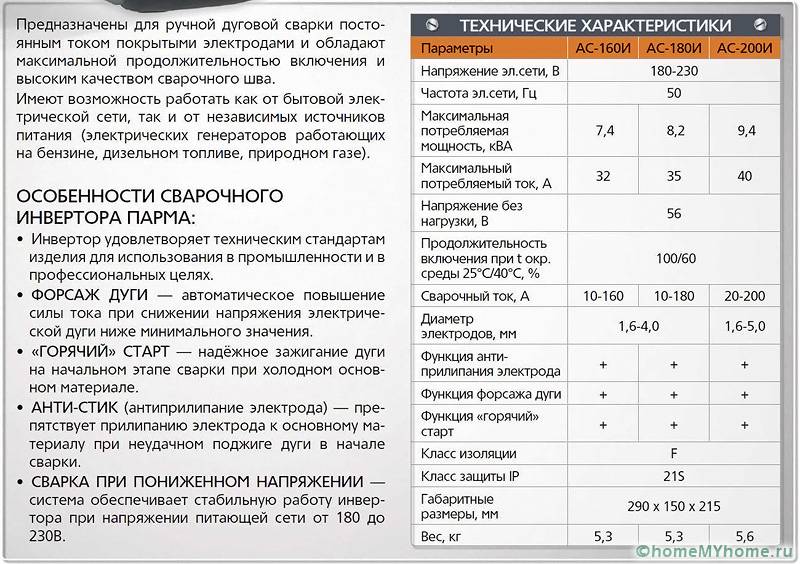

Technical parameters of devices

- Power - indicated in the passport of the device. The nominal welding current is indicated, at which the unit will not overheat during operation and shut down. If you need 120 A of rated current, it is better to choose a tool with an indicator of 180 A. This will help to use electric cables more than five meters long and work with unstable voltage in the network.

- PN - duration of the load.Shows in which time mode the tool can be used.

- DPN - supply voltage range. Especially important for work in unstable voltage conditions with surges of 20-30 percent. Such conditions are typical for rural areas and dacha cooperatives.

- Additional characteristics - provide comfort in using the tool. Additional characteristics include: electrode anti-sticking (AP), hot start (HS), arc stabilization (afterburner) (FD).

Basic principles of work

The basic principle of operation of the welding unit is the formation of a high-temperature electric arc using high voltage current. This arc occurs between the electrode and the metal surface. The high temperature melts the metal and fills the gaps between the parts. After welding, the metal cools quickly and forms a suture material characterized by increased strength. For a soft start of the unit, stabilizing devices are installed in it.

Pros and cons of inverter welding

Advantages of inverter units:

- The small weight of the unit is from 5 to 12 kilograms, such a device can be taken on a trip to the country in a regular bag;

- the efficiency of the device is 90 percent. The device does not require excess energy for heating and uses electricity economically;

- the welding tool has an adjustable amperage and is suitable for working with different materials (including copper);

- the inverter is great for novice welders, the anti-stick function makes welding easier;

- operation of the device does not depend on the stability of the voltage in the network;

- any types of electrodes are suitable for the instrument;

- in the settings of most inverters it is possible to program the welding mode.

Disadvantages:

- high cost of repair, replacement of the inverter unit will cost half the cost of the device;

- the relatively high cost of the unit itself in comparison with the transformer (the difference is several times);

- sensitivity of the device to dampness, low temperature and dustiness.

How to choose a 220 V welding machine for home and garden

Welding quality does not depend on the type and type of inverter unit. Which welding machine is best for home and work in the summer cottage? Household, of course, unless its owner is going to have additional income for welding in the future.

Inverter classification

Welding devices are classified into three categories:

- for household purposes;

- professional;

- industrial.

All their differences lie in the duration of the working cycle and the cost of the device itself. If the quality of welding does not depend on the "sophistication" of the apparatus, why spend money on expensive professional equipment?

Helpful information! For domestic purposes, a working cycle of 20 minutes is sufficient, after which the device cools down for half an hour.

Types of inverters

Household inverters in the documents are designated by the letters MMA. Following the abbreviation are numbers that indicate the value of operating currents - 200 or 250. A professional device has the ability to operate in a wide temperature range, from 150 to plus 150 degrees. A modest home unit has a range from zero to plus thirty, and that's quite enough. Another difference between a household appliance and a professional and industrial one is the duration of the working cycle. A professional inverter will work for eight hours with breaks of several minutes, an industrial one - a day with a rest of half an hour.A good household appliance can cook continuously for up to half an hour with a cooling interval of 60 minutes.

The voltage range of the home appliance is 220-230 volts. There are devices in the documents of which a wider range is indicated - from 170 volts, but in practice the performance at this voltage is very low.

By the type of welding mode, inverters are divided into the following types:

- plasma cutting;

- argon welding;

- semiautomatic device;

- manual welding.

Additional functions in inverters

Devices from modern manufacturers are equipped with overheating protection. Thermal sensors turn off the power if they detect a high temperature on one of the device nodes. Such systems are found on all devices - expensive and budget. Therefore, when deciding which welding inverters are better to purchase, for the presence of these additional. functions are not worth paying special attention to.

In addition to temperature sensors, the devices are equipped with moisture and dust protection systems. They are also provided on all devices and differ in the degree of protection or in the way of replacing and cleaning the filters.

The additional function "Anti-adhesion" is especially in demand among novice craftsmen. If the electrode is attached to the part, the device drops the voltage and waits for the circuit to open. As soon as the working process is restored, the device starts to supply current again.

Note! When the device is switched on in standby mode, the voltage on the electrode is automatically reduced to a level that is safe for humans. This mode eliminates accidental electric shock.

Which inverter welding machine is best suited for household purposes

The home craftsman is most often faced with the need to repair small metal structures or appliances. For these purposes, a sufficient household tool designed for a small current. It is worth considering that such a device will not master thick material.

Determining the type of inverter according to the possible load:

- Light load: welding metal up to three millimeters thick. For work, 3 mm electrodes are used. Useful for a home workshop, urgent repairs in an apartment or at a summer cottage.

- Average load: the device is able to cope with bulk metal, has an operating range within 200 amperes. Such a device is able to work for a long time and weld various metals.

- Huge pressure: the device operates with a three-phase voltage of 380 volts. Its functionality is suitable for professional builders and craftsmen who require high precision welding.

Characteristics of devices by manufacturers and prices

Many buyers are worried: how to choose a 220 V welding machine for home and summer cottages from the extensive range exhibited in retail chains? It is worth considering the technical characteristics and prices of household appliances from the most famous manufacturers:

| Name | Rated current / Input voltage | Incl. at max current% | Add. functions | Working temperatures | price, rub. |

|---|---|---|---|---|---|

| ISA-160 / 7.1 Interskol | 20-160A 170-242V | 100 | AP, GS, FD | From -50C to + 400C | from 7356 |

| ZAS-190 Bison | 30-190A 180-250V | 60 | AP, GS, FD | From -50 C to +400 C | from 7167 |

| SAI-220 Resanta | 10-220A 140-260V | 70 | AP, GS | From -50C to + 350C | from 7200 |

| EASY ARC 160 (Z213) Svarog | 20-160A 175-240V | 40 | HS | From -50C to + 350C | from 11160 |

| FUBAG IN 163 | 10-160A 198-240V | 60 | AP, GS, FD | From -100C to + 400C | from 11235 |

| FUBAG IR 200 | 5-200A 150-240V | 40 | AP, GS, FD | From -100C to + 400C | from 10220 |

| REDBO BLACK-204 | 20-200A 190-240V | 40 | AP, GS, FD | From -100C to + 400C | from 12410 |

| Smart WI-160 Craton | 10-160A 198-242V | 60 | AP, GS, FD | From -100C to + 400C | from 10186 |

| IC 220 Elitech | 10-200A 154-253V | 80 | AP, GS, FD | From -100C to + 400C | from 7956 |

| SAI-250K Resanta | 10-250A 198-242V | 70 | AP, GS, FD | From -100C to + 400C | from 9680 |

Separately, I would like to note one of the most powerful and functional inverters KRÜGER WIK-300A - a tool from a German manufacturer with an optimal ratio of quality and price. The price of the Kruger welding machine is from 5990 rubles. With the help of the Kruger inverter, you can process metal with high quality by manual arc welding. The current in the Kruger welding machine is regulated by means of a digital display - there will be no problems with setting parameters.

Welding Kruger absorbs voltage surges, it provides overheating protection, powerful ventilation. The package includes a chameleon mask that protects against harmful radiation and metal splashes.

Based on these parameters, it is easy for yourself to decide which inverter welding machine is better to choose so that it is affordable and suitable for use in everyday life.

Recommendations for the operation of household inverters

When starting work with a home appliance, you should adhere to the basic rules and recommendations:

- The size of the consumed electricity depends on the diameter of the electrode. It is important to take this fact into account in order not to burn electrical appliances in the area.

- Each electrode corresponds to a certain minimum current strength. Attempts to reduce the amperage will result in welding failure.

- For welding work, it is important to have protective clothing: tarpaulin gloves, a coarse fabric jacket, a helmet.

Choosing a home master

When deciding which inverter welding machine is best suited for home use, you should pay attention to the main characteristics:

- the duration of the working cycle;

- range of load characteristics;

- voltage range;

- availability of additional functions to facilitate the welding process.

The purchase should be made from the manufacturer who offers service for the unit. The optimal choice depends not so much on the cost and promotion of the brand, but on the compliance of the device with the operating conditions and the requirements.