Bath interior decoration: photos, stages of installation work and choice of materials

After the construction of the bath, the turn of finishing work begins. Internal cladding serves an aesthetic function and is also used to protect wall, ceiling and floor surfaces. The use of furniture in this room will allow you to give the interior your own style and certain completeness. The interior decoration of the bath, a photo of which can be viewed on the website, can be done by hand. To do this, you will need to prepare certain materials and familiarize yourself with the technology for carrying out installation work.

The content of the article

The choice of finishing materials for the interior of the bath

It is important to select quality materials before finishing the bath inside. Photo of interiors allows you to choose the appropriate option.

The materials should have the following advantages:

- resistance to moisture and vapors;

- hygiene and environmental friendliness;

- durability and strength;

- aesthetic qualities.

One of the popular finishing materials lining is considered. It is characterized by safety and attractive appearance. This material is made from larch or cedar.

Helpful information! Create a original interior a successful combination of different woods will allow.

Bath interior decoration: photos and stages of work

With the help of the lining, the external cladding and decoration of the bathhouse are made inside. Photos of the best options can be viewed on the website. Clapboard wall cladding looks very attractive. In this case, the boards allow you to level the surface.

The installation technology is characterized by simplicity. The lining is placed in the steam room to adapt to the internal microclimate. The uneven surfaces are then leveled with battens.

Slots and joints should be well caulked. The lathing is made of special strips. They are mounted at a distance of half a meter from the surface. If the walls are even, then the crate does not need to be mounted.

Features of flooring

Most often, finishing work begins with the flooring. Finishing the floor of the bath inside, the photo of which can be viewed on the site, must be protected from unnecessary drafts. Can be used as a coating tile or edged board.

Rough flooring is done with clay or concrete. At the same time, it is important to think over the system for removing water from the room.

The flooring can be made from cork, boardwalk or fiber mat.

The wood laying process is simple. Logs are mounted, and then boards are laid. For covering, a tongue-and-groove board option is used. In this case, the thickness of the wood should be about 30 cm. The wood is preliminarily treated with antiseptic agents and agents against the growth of fungus.

Tiles are considered another popular finish. For this, a floor screed is made. The tiles are mounted on special glue. A moisture resistant grout is used to process the seams. To prevent slipping on wet surfaces, wooden gratings should be installed.

In the steam room, the floors can be made of non-slip tiles, and in the relaxation room, you can use a regular floorboard

It is important to properly finish the floors in the sink. They should have two tiers. The bottom one is made of concrete, which will withstand water flows. This produces a special surface slope and drain. The tier on top should be made with a crate. To create it, conifers are taken. Gaps are left between the boards through which water must pass.

Helpful information! To ensure the best drainage of water, you need to make the floors with a slight slope.

Related article:

Sauna projects with a relaxation room and a terrace. In a separate publication, you will learn about the most successful layouts of baths with an extension in the form verandas or terraces.

Bath interior decoration: lining fixing video

They will help control the process of finishing the bath inside the photo with the sequence of stages of installation work.

The interior cladding does not use standard nails, which corrode and rust stains.

The lining is cut taking into account the height of the bath, and then mounted to the prepared lattice. For finishing, specially treated wood is used, which is resistant to strong moisture and temperature fluctuations.

When installing, it is worth using level... Antiseptics are processed frame system and lining. The material is installed from the corner. For fixing, staples and special nails are used. The lining can also be used to decorate the ceiling. In this case, the material should have a small amount of resins. Otherwise, the hot drops can burn the skin. The area around the stove is finished with materials that are not prone to burning. It could be tile or brick.

The inside cladding must not be varnished or painted, as such coatings will not let steam through. A space of 20-30 mm should remain between the facing material and the frame. In some cases, ceramic can be used.This material does not absorb moisture and does not crack. Since this flooring is cold, wood flooring can be laid on top.

Useful advice! It is better to use linden lining. Pine or spruce is not suitable for this room.

How to insulate and insulate walls?

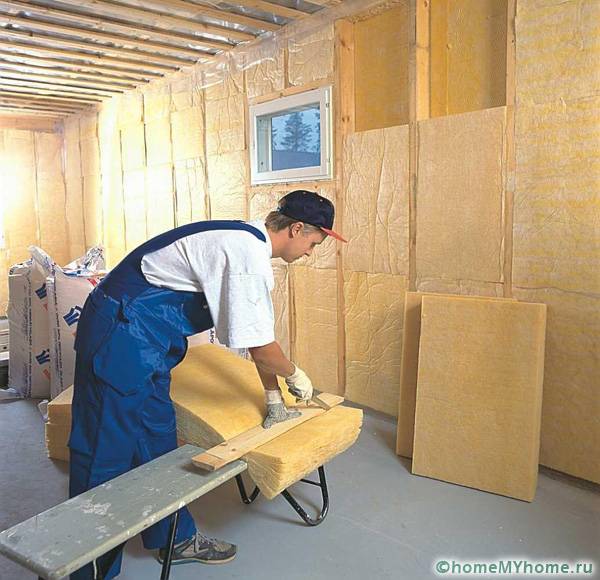

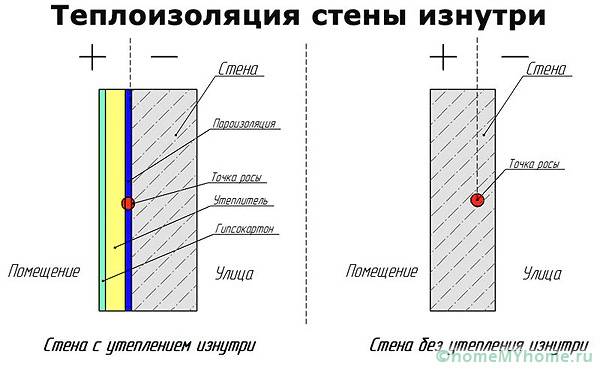

Allows you to see the features of finishing the bath inside the photo. The steam room must first be insulated. In some cases, mineral wool is used, which is laid on the crate. If the bath is built of stone or concrete, then you can do without insulation... It is important to perform the correct waterproofing constructions. Aluminum foil is best suited for such purposes, or even vapor barrier film.

Wall insulation is carried out taking into account certain recommendations:

- when cutting insulation, allowances of 5 mm must be left. This will ensure high-quality fixation of the material;

- when installing a vapor barrier material, it is necessary to maintain the integrity of the membrane and overlap it. In this case, the joints are fastened with mounting tape;

- when working in small rooms, thermal insulation boards can be used, which are convenient to install even for one person.

If bath made of brick, then the thickness of the insulation can be about 10 cm. If the wall is made of timber more than 20 cm, then they can not be insulated. After finishing, you need equip the room with furniture and original decor items.

Useful tips: the nuances of finishing work for a bath

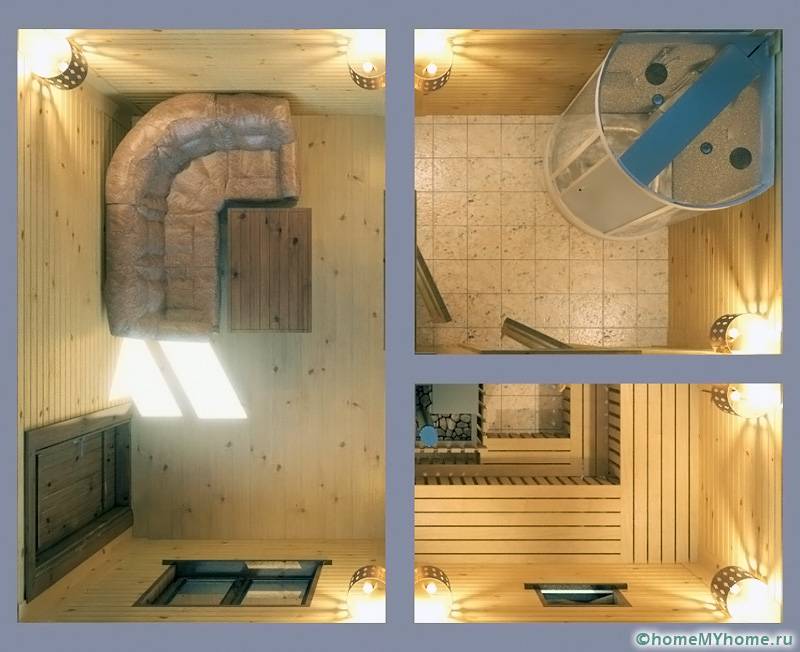

Particularly noteworthy is the decoration of the sauna rest room inside. Photos of interesting solutions can be found on the Internet.

Knowledge of some of the intricacies of installation will help to carry out the finishing work qualitatively:

- in the steam room, it is necessary to raise the floor level by 16-25 cm above the washing room. This will prevent excess moisture from entering the steam room;

- you should prefer edged board or grooved board. Both options must be moisture resistant;

- before performing the facing, you need to carry out all the necessary communications;

- when installing benches and shelves, you should make sure that their edges are rounded;

- no gaps are left between the boards.

Natural wood is used for interior decoration. Walls can be sheathed with clapboard, especially from cedar. An original interior can be created using a block house. These are processed boards that imitate real timber.

Windows and doors should be kept small to reduce heat loss. Doors must be strong and thick. For internal cladding, boards without knots are selected.

You can do a beautiful finish in the bath with your own hands. If you choose high-quality material and follow all installation technologies, you can create a functional and original cladding.

Video: ideas for decorating steam rooms and saunas