Projects of frame houses: photos and prices, types of technologies

Projects of frame houses are very popular, photos and prices for which differ in variety. The main advantage of such structures is their low cost, as well as the ease of construction and the shortest installation time. Frame structures have excellent thermal insulation properties, thanks to the use of the latest materials and modern technologies. Building projects can be one-story, with a garage, with a basement, several floors or attic... The affordability of such housing is pushing many people who want to get their own home.

The content of the article

House projects and their arrangement

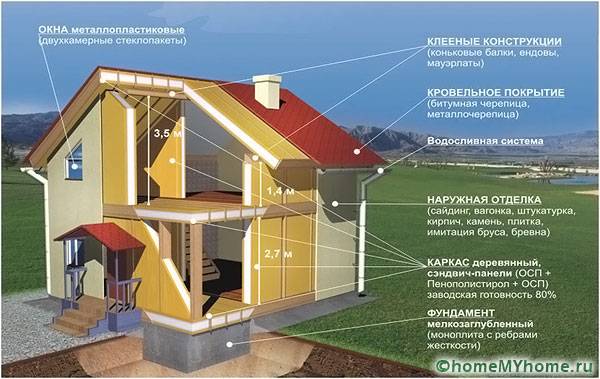

Sandwich-type frame houses are built mainly from wood. They warm up quickly, which helps reduce heating costs. Considering the projects of frame houses, as well as their photos and prices, you can choose a comfortable housing for your needs. The classic options include one-story buildings with a gable roof or two-story. An interesting solution is considered projects with attic, balcony, porch, as well as an option with a broken roof.

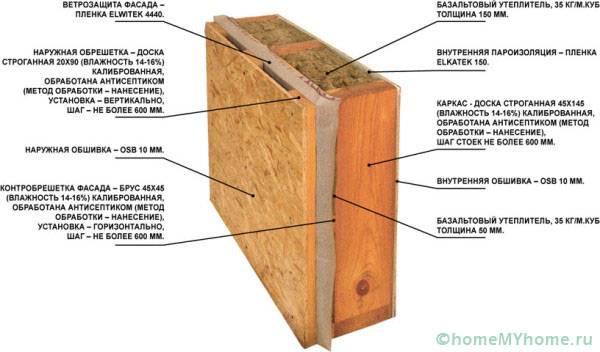

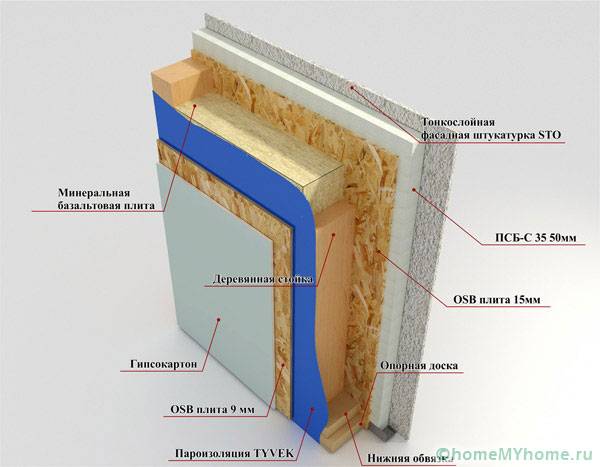

A frame structure is a structure based on a frame made of wooden beams and floors. A mineral bath or expanded polystyrene is embedded in the space between the plates. The cladding of frame structures is made of any materials.

The construction scheme of such a building is considered more complex than a brick one. Therefore, the assembly of the structure requires skill and knowledge of the nuances of technology. When planning construction, load calculations are carried out and technical characteristics of materials are taken into account.

When choosing frame houses, projects, photos and prices, it should be borne in mind that their construction consists of the following stages:

- A convenient place for construction is selected, taking into account the location of groundwater, climatic features and communication systems.

- Marking and laying of the foundation is in progress.

- When installing a timber frame, crowns of processed timber are placed in the foundation, on which the frame is installed.

- Installation of the frame and cladding outside.

- When cladding is performed, doors and windows are mounted.

- Insulation of the structure is in progress.

- Mounted internal partitions, communications are carried out and ceilings are equipped.

Finally mounted roof, and finishing work is in progress.

Related article:

Projects of country houses for 6 acres. Photo examples of beautiful and compact country houses with recommendations for choosing a layout in a separate publication of our portal.

Construction technology

During construction work, there are two ways: doing the house on your own or hiring specialists. The box is made of ready-made panels, which are made at the factory as sandwich panels. At the same time, thermal insulation materials are laid between the two layers and vapor barrier... To assemble the structure, lifting equipment and a prepared foundation are required.

There are several popular construction technologies.

Helpful information! When erecting the frame, it is forbidden to use materials with a defect: mechanical damage or fungal plaque. The fungus will cause wood to rot.

Variety of technologies

The most common options are:

- Canadian technology is carried out according to the "Platform" or Sip system.

- The German technology involves the installation of a factory-assembled panel structure.

- Frame - frame structures.

The platform system involves the installation of boards on platforms from the log. Panel sheets are mounted using the upper strapping. During installation, a seal is inserted between the walls. Using SIP technology, high-quality frame panel houses are assembled: projects, photos and prices for which differ. At the same time, shields with small dimensions are attached, which are made in the factory. Such shields are made of polystyrene sheets.

A distinctive feature of German technology is that the structure is built from wall panels, which are assembled at the factory. IN panels insulating material and communications are laid.

Frame-frame structures are more reliable. The frame is made of large section glued beams. Then the resulting frame is sheathed with boards or slabs made of moisture-resistant materials. The structure is filled insulation.

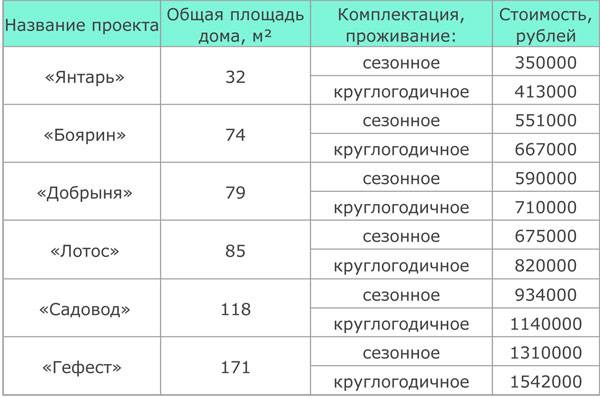

Average prices for various house projects

Related article:

DIY frame house. Step-by-step instructions for the construction of a frame house with useful recommendations in a special publication of our portal.

How to choose a material for frame structures

Whatever projects of frame houses: photos and prices you choose, most of the costs are for materials. The following materials are used to install the walls and frame:

- Sliced non-profiled timber of various shapes. A board is used to tie the structure.

- The best option is a profiled beam. It has grooves on one side, and spikes are located on the other. Other surfaces are planed. The use of this material allows you to save on supporting structures, since it is also a material for walls.

- Glued laminated timber is easy to install.It is created from scraps of bars that are glued together with special compounds.

- For cladding the frame is used waterproof plywood... The material is made from coniferous or birch veneer.

- An excellent option for interior and exterior cladding is oriented strand OSB board... It is made from thin chips that are glued together vertically on the surface layers.

- SIP panels manufactured in the factory.

Related article:

Projects of houses from a bar for permanent residence. Interesting layouts and advantages of glued and profiled timber in a separate publication of our portal.

The frame can also be made of metal or reinforced concrete. In this case, the structure merges with the foundation. Such a frame consists of two chords, which are connected by steel rods and pipes.

Helpful information! Lightweight thin-walled steel structures allow you to create frame country houses: projects, photos and prices of which can vary significantly, in three floors. The frame is made using thermal profiles, which are equipped with perforated grooves.

Advantages and disadvantages of houses: what residents say

When choosing a project, many factors are taken into account. The owners want the building to be inexpensive and last for many years.

As evidenced by numerous reviews, frame construction has the following advantages:

- frame technology is considered the most budgetary option;

- the low weight of the building does not require the installation of expensive foundations;

- quick installation;

- frame buildings have excellent energy saving properties, which saves heating costs;

- houses have good thermal protection, resistance to damage and are characterized by increased rigidity;

- the surface of the cladding materials can be applied without additional treatment.

Skeleton technologies also have drawbacks worth knowing about:

- to install the structure, craftsmen are required who will follow the technology and use a special tool;

- similar construction is used for buildings of no more than three floors;

- for a wooden frame, a special impregnation and treatment with an antiseptic composition is recommended.

Popular myths about frame buildings

There is a lot of controversy about the quality of frame buildings. Practice shows that this technology fully complies with all the standards necessary for living even in severe frosts. Projects of frame houses, as well as their photos and prices, are overgrown with many myths.

Myth 1: Fire hazard of frame buildings

This myth arose because frame structures are often constructed from wood, which is considered a combustible material. Despite this, many houses have been built from timber over the years. And modern materials are treated with protective solutions and various impregnations that prevent fire.

Myth 2: The fragility of this type of structure

Various types of such structures serve for 30-100 years. This indicator depends on the material of the frame, its quality and insulation. Worth paying attention high-quality insulation... Building with polystyrene foam insulation can last at least 30 years. The use of durable mineral wool raw materials will extend the service life up to 60 years. The use of raw wood can reduce the durability of the building.

Myth 3: A frame house will not survive frost

In fact, one of the advantages of the frame structure is the energy-saving properties of the walls. They are provided by a high-quality layer of insulation, which is located between the posts. Additional insulation is also performed on the outside.

On a note! The author of the idea of the frame structure was the builder and businessman Bill Levit. Thanks to this man, after the 40s, thousands of American families who could afford cheaper housing moved to the suburbs to live. Many of those houses still stand today.

Myth 4: Frame house is not environmentally friendly

Many of these buildings are environmentally friendly. Many buildings have European level certificates. The most environmentally friendly materials include wood and metal. If the house is too cheap, then there is a danger of using substandard materials.

Important! As part of a high-quality frame building, materials that are harmful to health should not be used.

Helpful hints and tips

Frame houses are offered by various manufacturers, but not all of them are responsible for their work. It is important to know how to choose the right frame. It is profitable and safe to cooperate with a company that has its own production. Better yet, order an individual project. For example, one-story frame houses: projects, photos and prices of which are available to many and are made of high-quality materials.

You need to pay attention to the quality of materials for home production. There are manufacturers who offer cheap insulation instead of safe thermal insulation. And it may contain phenol-formaldehyde resins hazardous to health.

Also, sellers can save on the frame and offer thin and unreliable material. It is worth checking the following parameters:

- The thickness of the material for the frame is not less than 40 mm.

- The timber must be treated with protective compounds.

- The dimensions of the strapping must be at least 100-150 mm, the joists for installing the floor must be at least 50-150 mm.

- The width of the board for the subfloor is chosen at least 20 mm.

In order for the selected frame structure to last a long time and satisfy all needs, the work should be entrusted to professionals.

In conclusion, it is worth highlighting the important points of such a design:

- The frame structure is the optimal design for a variety of geological and climatic conditions.

- The house created using this technology does not overload the foundation. And there is no need to build expensive foundations.

- The frame technology provides comfort and warmth in the room, lowers energy costs and creates a favorable atmosphere of coziness and ecological environment.

Video: gross mistakes in the construction of a frame house