If the roof is already covered: insulation of the attic from the inside according to all the rules

Whether you are building a new structure or remodeling a roof for additional rooms, you need to take care of how to make high-quality insulation attic... If the roof is already covered, from the inside all work is carried out taking into account the geometry of the roof and the climatic characteristics of the region. In this material, we have collected all the necessary information about possible methods of insulation and will provide you with practical recommendations from professionals.

The content of the article

- 1 Useful information and video on how to insulate an attic for winter living

- 2 Preparation of the roof space for insulation

- 3 A little about the choice of tools

- 4 Choosing insulation for the attic roof

- 5 Advantages and disadvantages of different types of insulation

- 6 Geometry features: insulation of the attic from the inside, if the roof is already covered

- 7 The need for waterproofing work

- 8 How to properly insulate the attic from the inside: tips and video instructions

- 9 Basic mistakes in attic insulation

Useful information and video on how to insulate an attic for winter living

A lot depends on the high-quality insulation of the attic roof. If you plan to use this room during the winter, you need to carefully think about what materials to use for thermal insulation. Another important aspect is the roof structure.

If the geometry of the roof is very complex, you may have to sacrifice part of the area to keep warm

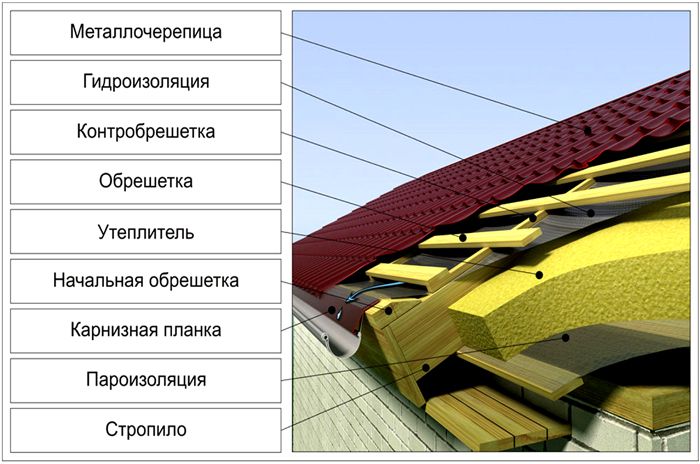

The peculiarity of the under-roof space is not only in geometry, in winter it is colder here than in other rooms, and in summer it is hotter. To maintain the optimum temperature, roofers recommend forming a multi-layer "cake" of waterproofing under the roofing, vapor barrier and insulation.

An important point! With a large heat loss through the roof in winter, the snow on it begins to melt and forms an ice crust. And water, as you know, looks for any, even the smallest loophole.So an ice roof is bad, there is a good chance that you will get a leak.

High-quality thermal insulation will prevent heating of the roofing material and the formation of ice

And now a small video material to get a general idea of the attic insulation:

Preparation of the roof space for insulation

You should know that, according to GOST standards, the ceiling height in the attic cannot be less than 2.5 meters. But this does not apply to the entire attic area, but only half of it, that is, on the remaining 50 percent, the height of the room may be slightly less.

What factors affect the heat loss of the attic floor:

- the type of the main building material of the house;

- the presence of common communications with other areas of the house;

- features of the geometry of the roof, the number and shape of the slopes;

- type of load-bearing roof materials;

- placement of the attic relative to the main structure (with going beyond it or not).

All these factors must be considered before proceeding with roof insulation from the inside with your own hands. Building rules dictate that the house should be insulated outside so that the freezing point moves to its outer part. But this rule does not apply to attic floors. Here, the specifics of construction requires precisely internal insulation, since roofing material must be placed outside.

In terms of preparation for insulation work, you need to carefully study the options for the thermal insulation coating and select a high-quality waterproofing film.

A little about the choice of tools

If you ask an experienced roofer what tools are needed to insulate the attic roof of a private house, he will shrug his shoulders and say: hammer, knife, head and hands. For the most part, this is true, but there are professional secrets that not everyone wants to share.

The most important trick is choosing a knife. If you take a simple construction and assembly knife, then throughout the entire process you will suffer, unevenly shredding the insulation. The blade of such a tool is too short, it does not cut through the thick layer of insulation material. In addition, the assembly knife will quickly become blunt on mineral wool or foam.

You can get by with an improvised cutting tool (a hacksaw for wood) or use a wide kitchen knife for cutting bread with a toothed sharpening for work.

The professional cutting tool is a wide long carbon steel knife. Blade length - 35 centimeters, durable plastic handle is very comfortable to work

In addition to a good knife, you really need a hammer, as well as screws and screwdriver, strong cord, protective clothing, respirator and goggles.

Tips for cutting insulation:

- the room in which you will cut the mineral wool should be well ventilated;

- hands, head and especially eyes and respiratory tract must be protected from the penetration of volatile fibers;

- after working with insulation, you need to take a shower, wash your hands and face thoroughly;

- the material must be cut across the fiber - this way there will be less flying dust;

- in order not to make a mistake in the size of the pieces, you should carefully measure their locations.

Choosing insulation for the attic roof

Take your time to buy the first one you see insulationthat you liked because it looks thick or has bright packaging. A suitable material must meet strict requirements, we will consider them in more detail:

| Demand | Explanations |

|---|---|

| Low thermal conductivity | This is the most understandable condition. The insulation should retain heat as much as possible, while keeping its shape well and withstanding high temperatures. |

| Noise isolation | Can you imagine how difficult it will be for you to fall asleep if the rain starts drumming on the metal slopes and the roof insulation does not absorb the noise? If the roof is iron, you cannot do without sound insulation. |

| Moisture resistance | The insulation should not absorb moisture. We are talking not only about possible leaks, but also about atmospheric moisture. If the thermal insulation layer absorbs water like a sponge, it will soon deform and lose its properties. |

| Fire safety | Timber roof framing is a potentially attractive fire material. It is better if the insulation will not support combustion. |

| Service life | The insulation must be resistant to the development of fungus and mold. It is undesirable for it to attract insects and rodents. |

| Human safety | Roof insulation material must be safe for humans. It should not contain toxic substances released when heated. |

| Profitability | An important factor for those who are prudent in their construction costs. |

| Easy to install | If you decide to take on the insulation of the attic walls from the inside with your own hands, it is important that the material is lightweight and easy to install. |

And now let's talk specifically about each of the possible types of insulation.

Styrofoam

Foam is a foamed polymer material. It is very light, as its main contents are air bubbles. It is they who act as a heat insulator. Polyfoam can be pressed and unpressed. It's easy to figure out what kind of material is in front of you - unpressed foam is similar to a honeycomb, it crumbles effortlessly. This material is mainly used for the manufacture of shockproof packaging. Press foam is more dense - it cuts well, does not crumble into crumbs.

For insulation, you can use both types. The foam boards are easily attached to the rafters with self-tapping screws or glue. The surface of the boards can be plastered. For the attic, slabs with a thickness of 7 centimeters are used.

Extruded polystyrene foam

Extruded polystyrene foam is better known to modern builders as penoplex... It was invented in the middle of the last century and since then has been successfully used to insulate roofs, walls and floors in residential premises. Its production is somewhat similar to the production of polystyrene, but it is distinguished by a high-temperature effect on raw materials. The resulting material has a high density and corresponding strength. An excellent indicator of strength - Styrex is used for thermal insulation of runways at airports.

Penoplex sheets are made with a chamfer along the edge, this allows you to insulate surfaces without joints and gaps

Mineral wool

Mineral wool is one of the most popular heat and sound insulation materials. It is successfully used for insulation of roofs and attic, floors and walls. This insulation can be used inside and outside the building. It can withstand temperatures up to plus 690 degrees and can be used to protect hot pipelines.

The term "mineral wool" can mean stone wool, glass wool and slag wool. Mineral wool comes in different densities, depending on the brand and manufacturer. For thermal insulation of the attic, it is better to select mineral wool with vertically arranged fibers.

There are types of lukewarm with chaotically arranged fibers, this option is characterized by increased strength

Glass wool

One of the varieties of mineral wool, glass wool, has long and successfully been used as insulation for the roof. It is produced from broken glass containers and other crystalline production waste.

Fiberglass insulation has proven itself well in insulating a broken roof from the inside. Due to its strong structure, glass wool compares favorably with other types of mineral wool.Its fibers are almost three times longer than ordinary mineral wool fibers.

Glass wool is easy to fit and cut, is relatively inexpensive and can be used for indoor and outdoor insulation

It is necessary to work with this material very carefully, using personal protective equipment. The thinnest fibers in contact with the skin and mucous membranes cause severe irritation.

Stone wool

Stone, or basalt, wool is a heat insulator based on natural rock material. This insulation does not belong to the category of cheap ones, but compares favorably with others in its long service life and excellent performance characteristics.

Basalt wool production process involves high-temperature exposure up to 1500 thousand degrees. Modern production uses phenol-formaldehyde-based composite compounds to bind particles.

Ecowool

This is a relatively new type of insulation that has not yet gained such popularity as polystyrene or mineral wool. It differs from other thermal insulation products in that it is not produced in layers or rolls. Ecowool is a free-flowing substance, the fibers in which adhere only due to electrostatics.

Ecowool consists of cellulose and is produced from waste. Its advantage lies in the fact that the free-flowing composition fills well all the cracks and holes. At the same time, its thermal insulation qualities are the same as that of mineral wool.

The natural composition of this insulation is a favorable environment for the development of microorganisms and mold, insects and rodents feel great in it. To give the insulation fire-fighting properties, cellulose is treated with fire retardants.

Polyurethane foam

Polyurethane foam is one of the types of plastic characterized by a foamy composition. The practice of using polyurethane foam was brought to us by the Germans. This insulator can be used to insulate concrete houses and bricks... It is applied by spraying and adheres firmly to any surface.

While it is difficult to say what is the maximum service life of this insulation, the history of its use is still very small. We have been using polyurethane foam sponges for a very long time, but as a heater - relatively recently.

It is known that this composition well insulates noise and is not inferior in its thermal insulation qualities to polystyrene.

Penofol

Penofol is a thin polymer heat insulator consisting of foam and aluminum foil. The reflectivity of this material is excellent - up to 97 percent. This heat insulator does not allow water and air to pass through, and reflects heat flows back into the room. The work of such a material is similar to that of a thermos. Coating thickness - from 3 millimeters to 4 centimeters.

Experts recommend combining penofol with other heat insulators, including using it for waterproofing

Advantages and disadvantages of different types of insulation

There are many types of thermal insulation materials and technologies for their application. How to choose the most suitable one? Of course, you need to consider all the disadvantages and advantages of materials, compare their characteristics:

Geometry features: insulation of the attic from the inside, if the roof is already covered

On the one hand, it seems like in deciding how to properly insulate the attic from the inside with your own hands, and there are no particular difficulties. But it was not there. The main difficulty can be hidden in the geometric shapes of the roof, especially if you tried to make it as attractive as possible. As a rule, the shape of the attic floor follows all the curves of the roof. Insulation is mounted directly on inclined walls. By the way, a heat insulator that is too elastic can sag, so it is important to think over a way to secure it.

But what if you provided the roof with a pointed cone or other architectural delights? In this case, you will have to slightly correct the geometry from the inside with the help of additional walls or even a ceiling.

An example of working with uneven ceilings in the attic in this video:

As you can see, it is quite possible to correct the geometry a little from the inside, if necessary. In this case, all work on insulation should be carried out on installed additional partitions.

The need for waterproofing work

All fibrous heat insulators absorb moisture in one way or another. It can form due to blemishes in the roofing or the formation of condensation inside the room due to temperature differences. Moisture trapped in the insulation adversely affects its condition. To prevent this is the task of the waterproofing layer.

Modern construction technologies involve the use of membrane materials. They prevent condensation from forming and at the same time do not allow external moisture to pass through.

How to properly insulate a roof with a waterproofing layer in the photo:

How to properly insulate the attic from the inside: tips and video instructions

And now from theory to practice: how to insulate the roof of a house from the inside with your own hands. There are several generally accepted methods, we will consider two of the simplest and most effective.

Video for insulating the attic with your own hands from the inside with mineral wool

Before starting work, all the necessary measurements should be taken. You will need to know the distance between the rafters. It is good if the rafter step corresponds to the standard size of mineral wool sheets - 60 centimeters. In this case, you do not have to deal with complex cutting. If the rafter step is 58 centimeters, then even additional fasteners are not required, the mineral wool will already be held securely due to the friction force.

Important! Insulation work is carried out only after laying the waterproofing layer.

If the rafter step is more or less than necessary, the insulation plates are cut with an allowance of 2 centimeters.

And now a simple sequential video instruction on how to insulate a mansard roof with mineral wool:

Recommendations for insulating the attic with foam

Foam plates, like mineral wool, must be tightly fitted to the gaps between rafters... Do not make too much allowance - the foam can collapse with excessive force. The gaps between the foam sheets and the rafters should be filled with construction foam, and the insulation itself is attached to the crate with special glue and additionally fixed with a wooden frame.

Video material on how to properly insulate a mansard roof with foam:

The technique of insulating the attic with polyurethane foam

Before performing insulation by spraying with polyurethane foam, it is necessary to carefully protect the already installed windows from the mixture. To do this, they are sealed with a film. If the foam gets on the glass, it is very difficult to remove it; the coating adheres firmly to any surface. In addition to windows, it is necessary to make protection on doors and other places that you do not plan to insulate.

Important! For good adhesion of polyurethane foam, you need to clean all surfaces from dust and debris.

Spraying procedure in the following video:

Basic mistakes in attic insulation

In conclusion, you should list the main mistakes in the insulation work in the attic. It is they who can negate all your efforts and expenses:

- improper selection of the thickness of the insulation can lead to the fact that you either waste extra money in vain, or do not achieve the desired result;

- lack of ventilation in the room will lead to the formation of condensation on the walls and damage to the coating;

- without hydro and vapor barrier, all moisture will be absorbed into the insulation, violating its properties.

If you have experience in insulating attic floors and there are points that we did not indicate in this material, share your opinion in the comments!