Dimensions of sheet metal for the roof: price, features of choice and installation work

Metal tile is a reliable and most demanded material for roofing. It is made of galvanized steel coated with a polymer solution. This produces thin but very durable sheets. Installation of flooring made of this material is simple. The main component in the selection of such a structure is the dimensions of the sheet of metal tiles for the roof, the price of which depends on the manufacturer, the configuration of the plates and their dimensions. You can choose the material not only in standard dimensions, but also in individual sizes.

The content of the article

Parameters to consider when choosing a sheet size for roof tiles

The roof made of metal has great advantages. In the photo you can see interesting options. The cost of this material is much higher than that of a tin covering or slate sheet. But at the same time, the coating has excellent properties.

The optimal size of the metal tile should include the size of the material for the overlaps. When choosing canvases, it is worth considering the useful area. It is also worth remembering that the plates are overlapped. This is necessary to prevent leaks and increase service life.

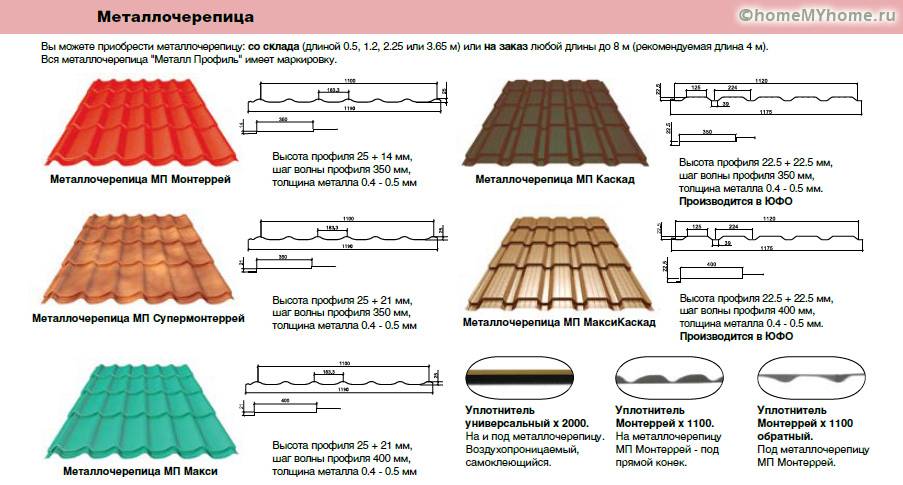

When selecting an insert, the following parameters are important:

- the plate thickness should be between 0.45 and 0.5 mm. It is recommended to check this value manually;

- wave step can be from 35 to 40 cm;

- profile height should be 1.8-2.5 cm.

The most popular is the metal tile of the optimal height - up to 50 mm. Such material is not as expensive as other types of profile and is easy to install.

Helpful information! The transverse overlap is about 7-9 cm, and the longitudinal one is 11-16 cm. These parameters depend on the brand of a particular coating.

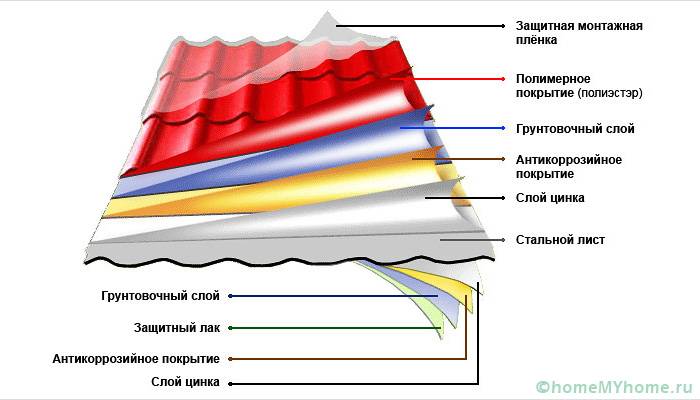

Material composition

When deciding which metal tile is better, it is worth considering that such a canvas includes several layers. Each layer has a specific purpose:

- the polymer layer gives the canvas a certain shade, and also protects the surface from various external influences;

- a zinc layer protects the canvases from corrosion, high humidity and various negative influences;

- a passivating layer does not allow static electricity to accumulate on the surface;

- the primer layer is the basis for the polymer coating.

The service life of this material is about 12-16 years. With proper installation and care, it can last for a longer time.

Sizes of a sheet of metal roofing: price and features of models and coatings

Sheets of metal tiles of a standard size have an upper part and a lower part, which are very different. When choosing products with a wave of complex shapes, it should be borne in mind that this will affect not only the cost, but also the complexity of installation.

Different manufacturers use the following types of materials for the production of the top layer of metal tiles:

- pural is made on the basis of polyurethane. With a small thickness, the material has a high level of resistance to temperature extremes, corrosion and mechanical stress. Such a metal tile is able to withstand significant temperature jumps;

- polyester is made of polyester gloss paint. It is distinguished by its rich and persistent color, the ability to mount in any conditions;

- matte polyester has a matte sheen and is thicker than the previous version;

- PVDF is a glossy plate that is composed of acrylic and polyvinyl fluoride. Material thickness 27 microns. The important advantages include resistance to ultraviolet light. Metal tiles with a similar structure have a metallic shade;

- Plastisol is considered the widest option, its thickness reaches 200 microns. The coating contains polyvinyl chloride. The canvases are highly resistant to mechanical and weather influences.

The table shows the cost of metal tiles from different manufacturers per square meter:

| Manufacturer and country | Product | Blade thickness, mm | Average price, rub / m2 |

|---|---|---|---|

| Lipetsk Metallurgical Plant (Russia) | Polyester | 0,4 | 190 |

| Akzonobel (Sweden) | Viking MP | 0,47-0,5 | 275 |

| Arsellor Mittal (Belgium) | Polyester GL (Grand Line) | 0,5 | 280 |

| Severstal (Russia) | Severstal T05 | 0,5 | 285 |

| Marsegaglia (Italy) | Purethane | 0,5 | 340 |

| Metal Profile (Russia) | Plastisol | 0,5 | 456 |

| Corus (England) | Agneta | 0,5 | 485 |

| ReutaRuuki (Finland) | Pural | 0,5 | 550 |

Varieties of roof slopes

When choosing the size of a sheet of metal for the roof, it is recommended to choose the right type of slope correctly. It is represented by the following options:

- a pitched roof is considered the simplest design option; it is characterized by a minimum set of parts. Such a roof structure does not have a ridge and ventilation passages;

- the gable roof is made of metal tiles of the usual size;

- a complex design is a hip, because of the shape a lot of material goes to waste.

Other types of stingrays are mansard, gabled or hipped.

Metal roof: photo and installation

When installing the roof structure, you need to pay attention to the dimensions of the sheet of metal for the roof. In this case, the price matters. Installation work is carried out in stages.

Preparing for installation

Before proceeding with the installation, you need to eliminate all the unevenness of the roof and all defects. After leveling the surface, you need to make all measurements of each slope and the entire roof. The dimensions of the material and its cost depend on this. The old roof covering must be removed. Before installing new canvases, all necessary chimney and ventilation passages should be carried out. Sheets of standard dimensions must be laid with an overlap of 9-11 cm.

Helpful information! The metal tile should be chosen if the roof slope is at least 14 degrees.

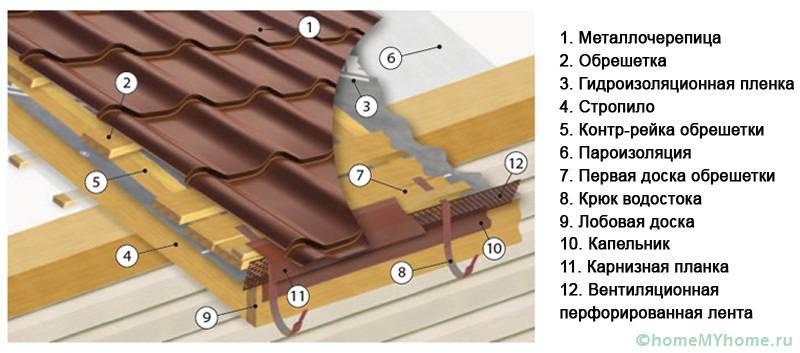

Arrangement of the lathing

Before laying the metal roofing, the lathing should be done. Installation is carried out taking into account certain recommendations:

- the pitch between the rafters should not be more than 90 cm. The boards should be 100 * 25 mm in size, and the rafters should be 150 * 50 mm;

- the first element should be installed along the edge, while it should not go beyond the eaves.

Self-tapping screws are selected depending on the thickness of the plate and the variety of polymer surfaces.

Installation of additional elements

It is also worth considering the installation of additional elements: eaves, gutters and ridge. The price of a ridge for metal tiles and other parts depends on the specific manufacturer and on average is 450-700 rubles. Their installation requires compliance with certain rules. On the sides of the ridge, you need to install additional panels lathing. To equip the drain, it is necessary to install the brackets to the bottom of the crate, on which the gutter will be installed.

Related article:

Installation of metal tiles: step by step instructions. A detailed step-by-step guide for the installation of metal tiles in a separate publication of our online magazine.

Cutting the sheet and laying the pan tile

The plates are cut using electric shears. Do not use a grinder that can deform the edges. Installation of canvases starts from the edge of the roof. Fasteners are made in the grooves between the waves. In the overlap areas, fasteners are made in each recess. The dimensions of the canvas must be taken into account.

Helpful information! When laying material on the roof complex configuration, you should hire a professional to cut the material, which minimizes the amount of waste.

You can build a high-quality roof if you choose the right size for the roof sheet. The price of the material can be adjusted to suit any budget. Good luck with your choice!

Video: dimensions and calculation of metal tiles