How to choose drywall: sheet dimensions, thickness and price

Many parameters are evaluated by experienced specialists in order to choose the right one drywall... Sheet dimensions, thickness and price are of no less importance than the scope and conditions of future use. For a correct analysis, all significant factors should be taken into account in the aggregate.

The content of the article

Types and characteristics of gypsum board

Building material parameters can be found in the relevant official standards. They contain the most accurate information. Plasterboard sheets, or "GKL", "drywall" are described in GOST No. 6266-97. This is an interstate document that has been developed in Russia and has been in effect since April 1, 1999. It has been approved by the executive authorities in Belarus, Kazakhstan, Moldova and Armenia.

Helpful information! On the territory of the Russian Federation, the sale of building materials made according to other standards is not prohibited. The only significant limitation is harmlessness. If the accompanying documentation contains a link to the aforementioned GOST, then the information from this article can be used for verification and comparison.

What and how these products are made

The composition is clear from the name. Cardboard is fixed on the outer sides of the sheet. For its manufacture, wood pulp is used, which explains the impeccable environmental characteristics. Under pressure press a density of 0.17 - 0.22 kg per square meter is created. This range is normalized by another standard (No. 8740-85). Compliance with these rules ensures sufficient strength and rigidity of the structure, resistance to mechanical stress. To improve resistance to high temperatures, the cardboard is impregnated with flame retardants.

Gypsum is a naturally occurring salt. It is formed naturally from sea water. The deposits of these substances are developed industrially.The raw materials are fired at a relatively low temperature (180-190 ° C) and crushed. To create products of the desired shape, a solution is created with water. Fiberglass is added to it to increase fire resistance. The same component helps to maintain the integrity of the product during deformations.

Physical and mechanical characteristics

These sheets are used in building structures, therefore load resistance is one of the most important criteria. The following standards have been established for maximum non-destructive effects with a permissible deviation of less than 10% in both directions:

| GKL thickness in mm | Longitudinal load in kgf | Shear load in kgf |

|---|---|---|

| 6,5 | 12,5 | 5,4 |

| 12,5 | 32,2 | 10,5 |

| 18 | 44 | 13 |

| 24 | 49 | 13,6 |

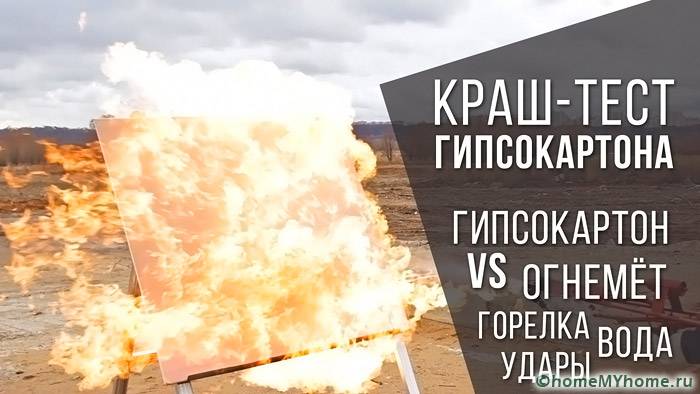

For verification, tests are carried out with reference lines set at a distance of 35 cm. Water absorption is limited to 10%. When exposed to an open flame, the integrity of the structure must be maintained for at least 20 minutes. The latter requirements apply to protected modifications.

Purpose

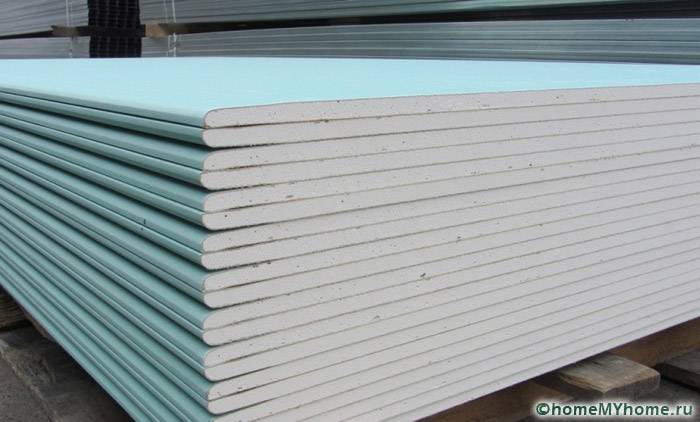

From the above data, it is clear that the use of special additives allows you to change the initial parameters of drywall. Therefore, sheet dimensions, thickness and price should be taken into account together with the intended purpose of the product:

- For decoration of walls and ceilings in residential and office premises, basic types of products, "GKL", are used.

- In the abbreviation of moisture-resistant sheets add the corresponding letter - "GKLV".

- Modifications resistant to open fire are labeled as "GKLO".

- For maximum protection against potential adverse effects, install "GKLVO". These sheets do not absorb moisture and retain their integrity for a long time at high temperatures.

Dimensions, thickness, weight of a drywall sheet

This material lends itself well to processing. Therefore, it will not be difficult to cut workpieces with the required geometric parameters. The following list shows the norms from the standard:

- The standard size of a drywall sheet (length) is created from 200 to 400 cm in 5 cm increments.

- There are only two widths, 60 and 120 cm.

- Builders use different sizes of plasterboard. But the thickness is often chosen to be 6.5 or 12.5 mm. In addition to these, the following permissible values are given in GOST (in mm): 8; 9.5; 14; 16; 18; twenty; 24.

- The ends of the sheets are created: straight, rounded, smoothly or evenly thinned on one side.

Related article:

Do you have to trim the drywall edge? From a separate publication, you will learn about the types of gypsum board edges, methods of cutting and joining sheets, as well as the tools used.

Weight of one square meter normalized as follows:

| Picture | Sheet type | Coefficient |

|---|---|---|

| GKL | 1 |

| GKLV | 1 |

| GKLO | 0.8 to 1.06 |

| GKLVO | 0.8 to 1.06 |

For the calculation, the thickness of the product is multiplied by the coefficient from the table.

Installed two groups of products "A" and "B". They differ in the precision tolerances that are applied during the manufacturing process. The following table shows data on permitted deviations:

| Options | For gypsum boards with a thickness of not more than 16 mm | For products with greater thickness | ||

|---|---|---|---|---|

| Group "A" | Group "B" | "A" | "B" | |

| Length | 0 | ±8 | -5 | - |

| Width | 0 | 0 | -5 | -5 |

| Thickness (±) | 0,5 | 0,5 | 0,9 | 0,9 |

It is not forbidden to manufacture products on an individual order. In this case, it is necessary to draw up a technical task in advance and coordinate it with the capabilities of the manufacturing enterprise.

Market offer overview

Below in one table are collected prices for different types of gypsum board. These data will not help you find out exactly how much moisture-resistant drywall currently costs. The price and size of the sheet must be clarified immediately before purchasing the product, based on a specific project. But the information is useful for comparative analysis of modifications, manufacturer's name:

How to purchase a suitable drywall: sheet dimensions, thickness and price, other important criteria

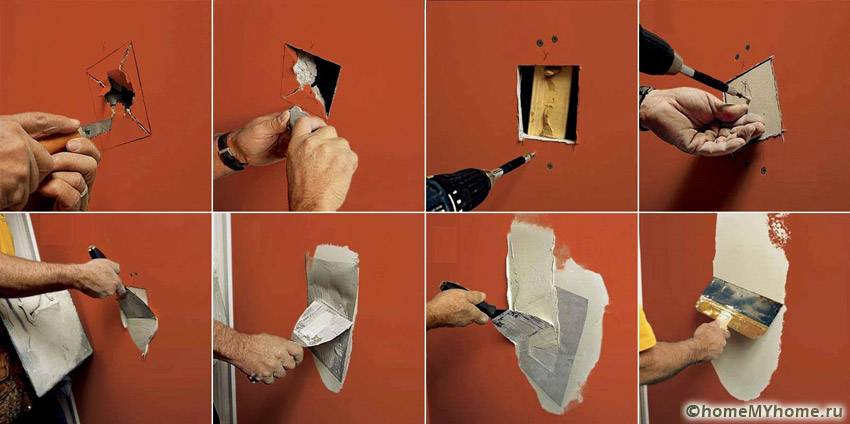

The above grouping allows you to identify possible shortcomings and other features by name. So, for example, in GKL "A", according to the standard, there should be no chips or other damage to the edges, corner parts. Such products can be installed in visible places. In sheets "B" such defects are allowed in an amount of no more than 2 per item. They can be removed with putty before finishing, along with other cracks and irregularities.

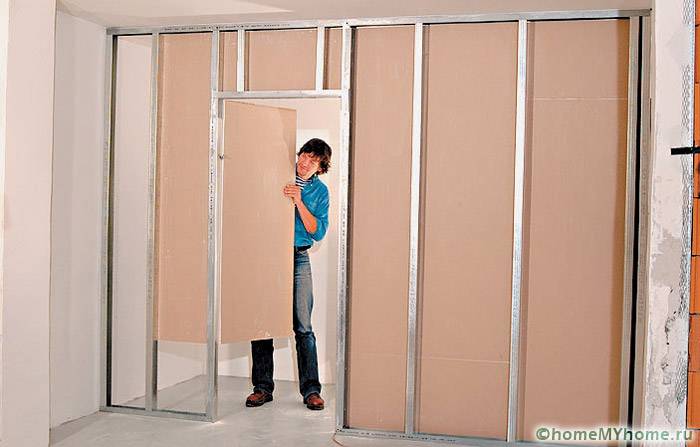

This example illustrates the importance of considering future work. When creating a false ceiling, the sheets are fixed with self-tapping screws on a special frame. Additional leveling of the surface will be required, so it would be wiser to purchase relatively cheap products of group "B".

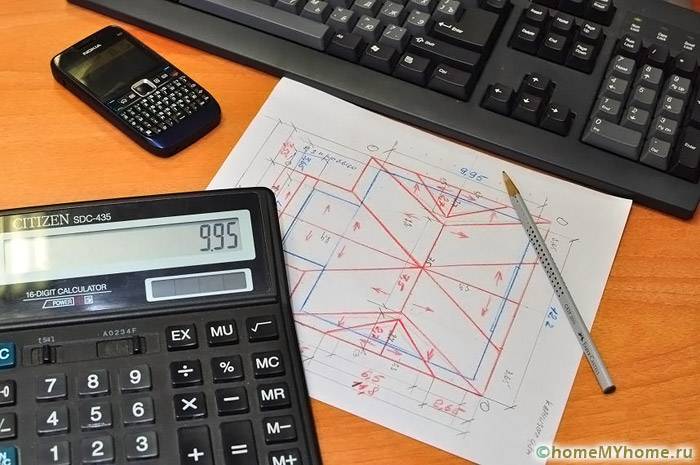

When calculating structural loads, you can use the manufacturer's reference data, or a simple formula. To find out the weight of a 12.5 mm drywall sheet with an area of 1 sq. M. the thickness must be multiplied by a constant factor of 1.35 (12.5 * 1.35 = 16.875).

When choosing drywall, sheet dimensions, thickness and price are checked together with thermal conductivity... In standard products, the value of this parameter is in the range from 0.2 to 0.36 W per m * K. The voids of the frame can be filled with mineral wool, expanded polystyrene. This design will significantly increase the insulation performance of the property. Such solutions are used to protect against noise and maintain a comfortable temperature in rooms.

General conclusions

If we summarize this information, the following important facts can be noted:

- To accurately complete the project, you must correctly prepare a list of suitable products. Take into account mechanical stress, humidity level during operation. Plain or additive-modified sheets are appropriately selected.

- The cost should be added to the GKL price profiles, guides and others structural elements, finishing materials, equipment. There will be additional costs for installation of insulation, installation inside the structure of electrical wiring, other engineering networks.

- Sellers often indicate different sizes of drywall, moisture resistant and other types. If the site does not have specialized tools, you should create a pivot table yourself. The data on products are entered there with the recalculation of the cost of one square meter.

Remember that careful preparation will make it easier to make the right decision when defining the parameters of the construction project.

Video: installation of profiles and installation of drywall