GKL - what is it. GVL, GKLV and other types with comparative characteristics

"Dry" construction has been actively used in our country for only a few decades. This term hides a way of erecting certain structures without using special solutions and mixtures designed to align the geometry of the surface being trimmed. Instead, special materials are used that initially have a perfectly flat surface. Those who are not associated with the implementation of construction work will immediately decide to clarify the GCR - what it is. GVL, GKLV - will also be little-known terms. We offer you to understand the features of each material and their possible field of application.

The content of the article

- 1 GVL, GKLV, GKL - what is it and their distinctive features

- 2 Comparative technical characteristics of GKL and GVL: parameters that are relevant when choosing a material

- 3 Scope of GKL and GVL: ideas for subsequent implementation

- 4 GKL and GVL by "KNAUF": distinctive features of the material

- 5 Conclusion

- 6 Video: what is GVL and how it differs from drywall

GVL, GKLV, GKL - what is it and their distinctive features

Before proceeding with the purchase of building material, it is worth understanding the distinctive features of GVL and gypsum board. Each material has its own recommended area of use. Having familiarized yourself with the characteristics of a particular type, it will be easier to choose the appropriate option for the structure being built.

What is gypsum board in construction. Main types of material

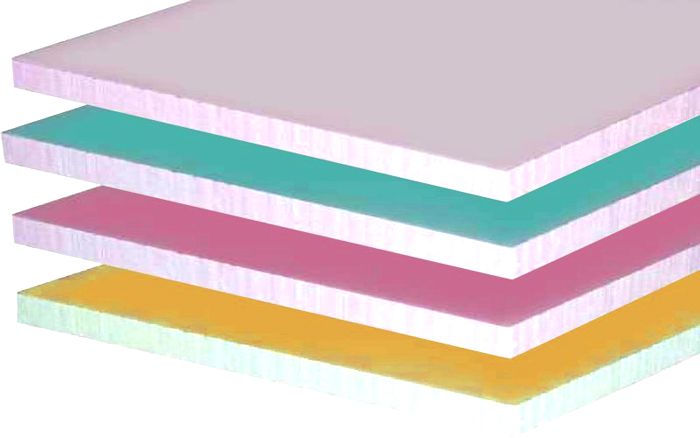

Drywall sheets are laminated material, in the middle of which there is gypsum, and along edges - thick cardboard. They are widely used for leveling walls, erecting partitions and multi-level structures, including ceiling ones. Manufacturers offer four main types of drywall:

- Plain gypsum board. The sheets are gray with a distinctive blue marking. They can be used for finishing residential and public premises where the humidity level does not exceed 70%. The most common and cheapest type;

- Moisture resistant gypsum plasterboard. What it is? These are multilayer sheets, inside of which there is gypsum, and along the edges of a cardboard of a characteristic green color, processed with special components that increase the resistance of the material in conditions of high humidity;

- Refractory GKLO. Such material is able to withstand the direct effect of fire for at least 20 minutes, achieved by introducing special reinforcing elements made of glass fabric into the composition. Their distinctive feature is the characteristic red color of the cardboard located on both sides of the plaster;

- Universal GKLVO, which can be used for finishing industrial premises due to its good moisture-resistant fire resistance properties. During the production process, the fire-resistant base is glued on the outside with moisture-resistant cardboard.

Related article:

Drywall: sheet dimensions, thickness and price. From a separate publication you will learn about the types and production of gypsum boards, technical characteristics, prices and manufacturers.

GVL: what is it and the main types

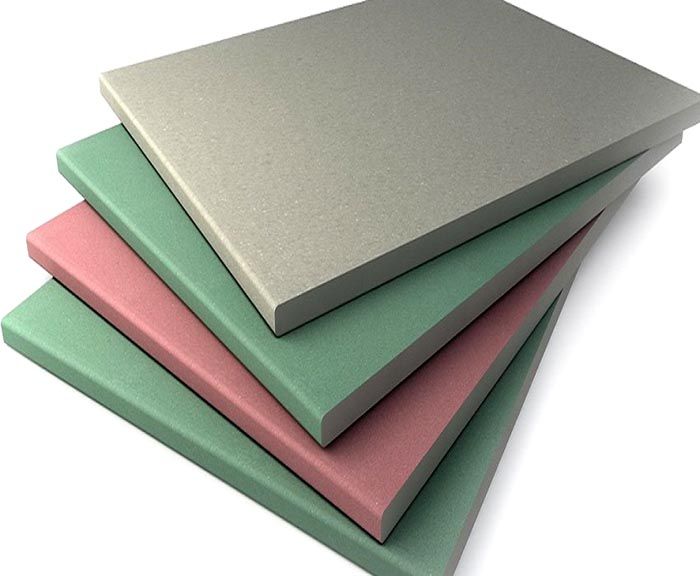

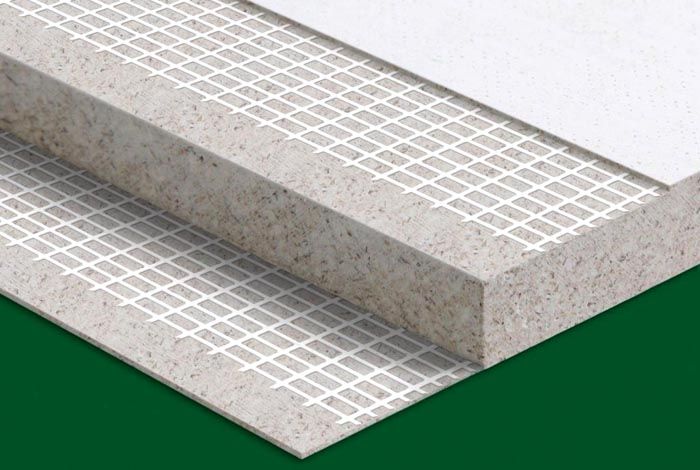

Now it's worth figuring out what GVLV and GVL are. Thus, gypsum fiber sheets are designated, for the manufacture of which gypsum reinforced with cellulose fiber is used. The presence of the last letter "B" in the designation indicates that the material is moisture resistant and can be used for finishing rooms operated in conditions of high humidity.

Is there a difference between GVL and GCR: a comparative analysis

When choosing a finishing material for wall decoration, it is important to know the differences between gypsum board and gypsum plasterboard and the distinctive characteristics of each material. The possibility of using sheets in specific conditions and their service life depends on this. So, if you have to align the walls in a production, office or public space, you should give preference to gypsum fiber sheets. To form a niche, column or arch, it is worth purchasing drywall.

We suggest that you familiarize yourself with the main differences between GVL and GCR:

| Indicators | GKL | GVL |

|---|---|---|

| Strength | Small. In the presence of shock loading, drywall sheets may crack | High. The material is able to withstand impact and increased stress. |

| Installation procedure | Good machinability. Sheets are easy to attach. Ease of mounting material of various thicknesses. | Difficulty cutting due to hardness. Increased requirements for supporting structures due to the significant weight of gypsum fiber. |

| Isolation level | Average. With increasing humidity, the insulation performance decreases. | Tall. The cellulose fibers included in the material provide good sound and heat insulation characteristics of the material. |

Of the general characteristics, it should be noted the absence of a characteristic odor and the presence of toxic substances in the composition, which makes it possible to use sheets for decorating residential premises. Good dielectric properties.

What is better GKL or GVL: which material to choose

Both materials are functional and well-deserved. It is often difficult to choose the material for the walls. Drywall or gypsum plasterboard? The decision is made with great difficulty.Each material has its own distinctive features, and therefore, when choosing, you should focus on the operating conditions.

To decide what is the best gypsum board or gypsum fiber for specific operating conditions, we suggest that you familiarize yourself with the technical characteristics of both types of materials. In this case, it will be possible to ensure a sufficient service life of the mounted structure.

Comparative technical characteristics of GKL and GVL: parameters that are relevant when choosing a material

To make the final choice in favor of a particular material, it is worth comparing in advance the technical characteristics of GCR and GVL. If according to some indicators the plates differ slightly, then according to others the difference is very significant. We suggest that you familiarize yourself with the numerical values of the most relevant parameters.

Geometric parameters of gypsum board and gypsum plasterboard: is there a difference

The dimensions of the sheet largely determine its possible area of use. The geometric parameters of the material are standardized, however, if you wish, you can contact the manufacturer directly and order sheets of a certain size in order to reduce the amount of waste.

Advice! Calculate the amount of material needed and cut to maximize material utilization and reduce costs.

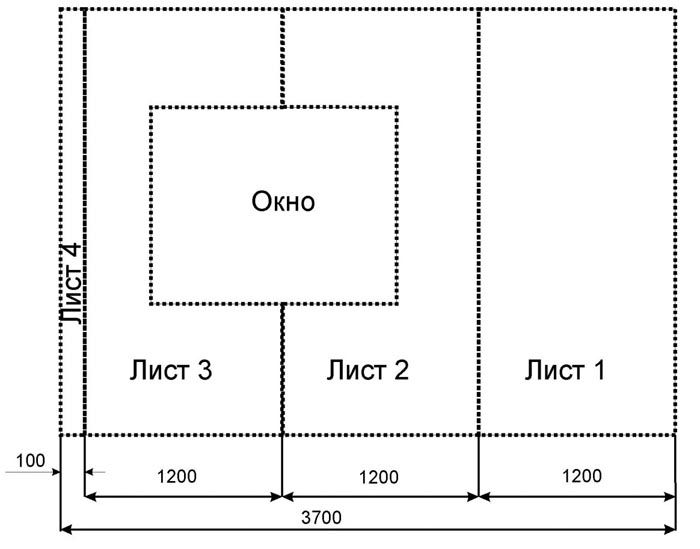

Manufacturers offer drywall of various lengths: from 1.5 to 3.6 m. The dimensions of 2, 2.5 and 3 m are considered standard.When choosing a suitable length, it is worth focusing not only on the parameters of the surface to be finished, but also on the conditions for delivering the material to the place of execution work. If the height and width of the openings are relatively small, buying sheets longer than 2.5 meters may be impractical.

The standard width of drywall is 1.2 m. However, the given dimensions of the gypsum board may differ. In the catalogs of some manufacturers, you can find material with a width of 0.6 m, which is convenient to transport in a car. This is a suitable option for facing a small surface area, since otherwise the number of seams formed will be significant, which will increase the cost of finishing work.

The thickness of standard sheets is 6, 9 and 12.5 mm. In the catalogs of some manufacturers, material with a thickness of 6.5 and 9.5 mm is presented. For reinforced and fire-resistant boards, the transverse dimensions reach 15, 18 and 25 mm. When choosing a material, you should focus on the type of work to be performed. Thickness of plasterboard for walls 12.5 mm. For the formation of arches, it is better to choose thinner sheets - 0.5 mm.

The gypsum fiber sheets are of similar dimensions. Most manufacturers offer material with a size of 1.2 by 2.5 m. You can find sheets with other parameters, among which the most popular is the size 1.2 by 1.5 m. The length of the sheets can exceed 2.5 m. a sufficiently high ceiling, it is worth giving preference to 2.7 or 3 m.

Attention! In the catalogs of manufacturers, material is presented in widths of 0.5 and 1 m.

The standard thickness of sheets is 1 - 2 cm. The area of use of a particular material largely depends on this dimension. The dimensions of a sheet of GVL for walls may differ, but the thickness will be 1 cm. For the floor, choose a thicker material - 2 mm.

Attention! If the cost of gypsum fiber sheets turns out to be "unaffordable" for the family budget, it is worth giving preference to a moisture-resistant gypsum board measuring 2.5 by 1.2 m.

GKL and GVL weight: compare parameters

When calculating the strength characteristics of supporting structures, he pays special attention to the materials that are planned to be used at the finishing stage. If their weight turns out to be significant, additional measures will have to be taken to increase the bearing capacity of the structure being erected.

The weight of the gypsum board sheet depends on its thickness and linear dimensions. The greater the geometric parameters of the material, the greater its mass. When calculating, it is imperative to take into account the weight of 1m2 of plasterboard. This indicator depends solely on the transverse dimensions of the sheet. How to change the weight of a sheet of the same size with an increase in its transverse dimensions can be found in the table:

| Linear dimensions, m | Weight of a drywall sheet in kg, if the thickness is equal, mm: | ||

|---|---|---|---|

| 6 | 9,5 | 12,5 | |

| 1.2 by 2.5 | 15 | 22 | 26 |

Attention! The weight of the moisture resistant gypsum board is more than the standard one. A sheet with dimensions of 1.2 by 2.5 m and a thickness of 12.5 mm weighs 29 kg.

GVL also weighs more than standard drywall sheets. The mass of the slabs depends on their transverse dimensions. With standard dimensions of 1.2 by 2.5 m, a 10 mm thick sheet will weigh 36 kg, and with a thickness of 12.5 mm - 42 kg. The average weight of one square of material in the first case will be 12 kg, and in the second - 14 kg. This should be taken into account when planning finishing work in a particular room.

Main technical characteristics of GKL and GVL

When choosing a suitable option, you should focus on the technical characteristics of the material offered by manufacturers. This largely determines the possible area of use of specific sheets, the conditions of their transportation and installation.

Strength

Due to the reinforcement with cellulose fiber, gypsum fiber sheets have a sufficiently high strength. Its tensile strength for material with standard parameters is at least 5.5 MPa.

Drywall is fragile, which must be taken into account already at the stage of transportation. There is a high probability of sheet splitting or other mechanical damage. If in the course of subsequent operation it is planned to increase the load on the surface being trimmed, a material of greater thickness should be chosen initially. For example, to decorate walls on which some heavy equipment will hang, it is worth choosing sheets thicker than 12.5 mm.

Flammability

Standard drywall sheets have a low level of flammability. In case of fire, the outer layer of the cardboard can burn out, and the gypsum layer can crumble. If the room has increased requirements for fire resistance, you should choose GKLO. Thanks to the introduction of special reinforcing additives into the composition of the gypsum filler, manufacturers have managed to increase its strength characteristics. As a result, GKLO sheets are able to maintain their structure in conditions when ordinary drywall loses its shape. In terms of flammability, GCR corresponds to class B2, flammability - G1 and self-formation - D1.

Gypsum fiber has a high level of fire resistance. Sheets are used for decoration of premises corresponding to F1 and CO hazard classes. They are often used in wooden structures to protect structures made of wood from possible fires.

Frost resistance

Drywall can be used little for decoration of premises that are used exclusively in the summer. Such material is able to withstand temperature fluctuations without loss of strength characteristics (up to 4 freeze / thaw cycles). After warming up the room to room temperature, the mechanical properties of the sheets are fully restored.

HS sheets also have a high level of frost resistance. They are able to withstand up to 15 freeze / thaw cycles without losing their basic characteristics. They are often used to decorate buildings in which there are interruptions in heating during the winter.

Water absorption

Drywall is sensitive to moisture. Standard GKL sheets can be used for decoration of residential and office premises.If the bathroom is to be cladding, it is worth ordering waterproof plasterboard, which, thanks to special processing, is able to withstand high humidity.

Moisture resistant gypsum board is able to absorb no more than 10% moisture. For standard material, this parameter is much lower.

Attention! After getting wet, standard drywall sheets lose strength.

GKLV can be operated in a room with a high level of humidity, provided there is good ventilation and additional treatment with protective compounds. Otherwise, there is a high probability of excessive penetration of moisture into the material.

Gypsum fiber has a low level of water absorption, which makes it possible to install them in a room with high humidity. Due to the special production technology, the moisture content of the gypsum fiber board does not exceed 1%

Thermal conductivity

Drywall has a fairly high low thermal conductivity (0.15 W / (m * K)). It is able to retain heat indoors better than most natural materials. A similar indicator is typical for gypsum fiber (0.22 - 0.35 W / (m * K)). In terms of thermal conductivity, sheets are close to natural materials. So, for oak, the same indicator is 0.23W / (m * K).

Ability to load

To determine this characteristic, a standard technique is used, which involves the use of a sheet of drywall 0.4 m wide, laid on supports, the distance between which is equal to forty times the thickness of the material. So for sheets with a thickness of 10 mm, this parameter is 15 kg. With an increase in the cross section to 11 - 18 mm, the possible load increases to 18 kg.

Due to the presence of reinforcing fibers, GVL is able to withstand a heavy load.

Scope of GKL and GVL: ideas for subsequent implementation

GVL and GKL are used to design various surfaces. With their help, you can not only level the walls, but also create unique and functional partitions. We offer you to get acquainted with ready-made solutions to make it easier to develop a project for your home.

Partitions and walls: ideas for space zoning and room decoration

GVL for walls is rarely used due to the large weight of the sheets. Most often, wall surfaces are leveled with drywall. When starting to sheathing gypsum boards, it is worth choosing a material with suitable characteristics. If standard drywall is suitable for residential premises, then a moisture resistant one should be purchased for the bathroom.

If you plan to install partitions from gypsum plasterboard, you should immediately think about their sizes, shapes and the presence of niches. In the latter case, dividing the space into separate zones, the partition can act as a shelf for storing beautiful products.

When starting to install the gypsum board on the wall, you should choose the method of fixing the sheets. Most often, a metal frame is pre-mounted for this purpose, to which the sheets are subsequently attached. In this case, strict requirements are not imposed on the base surface.

However, if the wall surfaces are initially flat enough, you can fix the sheets directly to the wall.

Related article:

Do-it-yourself GKL partitions. A separate material provides detailed information on the construction of partitions on your own with explanations and photos.

Ceiling: lighting placement option is selected individually

The device of the gypsum plasterboard suspended ceiling has become widespread.Due to the sufficient rigidity of the material, it is possible to form a ceiling system of any size and shape.

If you have to design a bathroom, then the best solution would be a ceiling made of gypsum fiber board. Such a design will not be afraid of moisture and will be able to serve for a long time.

The technology for mounting the gypsum board on the ceiling involves the preliminary fastening of a metal frame designed to fix the gypsum board.

Other ideas you should definitely get acquainted with

Drywall and gypsum plasterboard is used in the design of many surfaces. The device from the GKL slopes of windows and doors is especially popular. In this case, form a smooth and even surface without significant effort.

Laying gypsum fiber on the floor allows not only to level the surface, but also to significantly reduce the time of work.

An entire article can be devoted to the formation of arched openings from gypsum board. The choice of design will depend on the width of the opening and the style of the room.

Related article:

Do-it-yourself drywall arches. A separate material contains photo examples of arches for different rooms, as well as instructions on how to make them yourself.

GKL and GVL by "KNAUF": distinctive features of the material

The material manufactured under a well-known trademark traditionally has high performance characteristics. If there is a certificate of conformity, Knauf GCR will have better technical characteristics and a longer service life than its counterparts offered by other manufacturers. We invite you to get acquainted with the distinctive features of the material offered by well-known manufacturers.

Characteristics and dimensions of GKL and GVL "Knauf"

Dimensions of sheets of gypsum board "Knauf" - one of the important characteristics. Manufacturers offer material in standard widths of 1.2 m with lengths of 2, 2.5, 2.7 and 3 m.

Knauf gypsum fiber is relevant for the construction of interior partitions, installation of suspended ceiling structures, wall cladding or floor screed. Manufacturers offer sheets with straight and folded edges.

When choosing a material for finishing a room with a high level of humidity, you should give preference to moisture-resistant GVL. For Knauf flooring, superpol 1200x600x20mm will be the best choice. Sheets of this size are conveniently fastened, performing installation work alone. If you have an assistant, you can safely purchase material measuring 1.2 by 2, 2.5 or 3 m.

GKL "Knauf" with special characteristics

In addition to material with standard characteristics typical for drywall of most manufacturers, Knauf offers to purchase gypsum plasterboard with special properties. Such sheets can be used for decoration of premises operated in special conditions due to their high performance.

Acoustic GCR "Knauf" is characterized by the following properties:

- Ability to improve the perception of sounds;

- Reduced boominess;

- Reducing background noise.

It is used to decorate cinemas, classrooms, recording studios, conference rooms. They also resort to his help when decorating residential premises located near a busy highway or an apartment building.

The moisture resistant gypsum board "Knauf" also has quite high performance characteristics. It is in demand when decorating rooms operated in high humidity conditions: kitchen, bathroom, toilet.

Conclusion

Thus, drywall and gypsum fiber are modern materials that allow you to quickly and efficiently level the walls in the house or create an original structure. Comparing the technical characteristics of GKL and GVL, you will definitely be able to choose the appropriate option for specific operating conditions.

Video: what is GVL and how it differs from drywall