Choosing penoplex: technical characteristics, features, types and cost

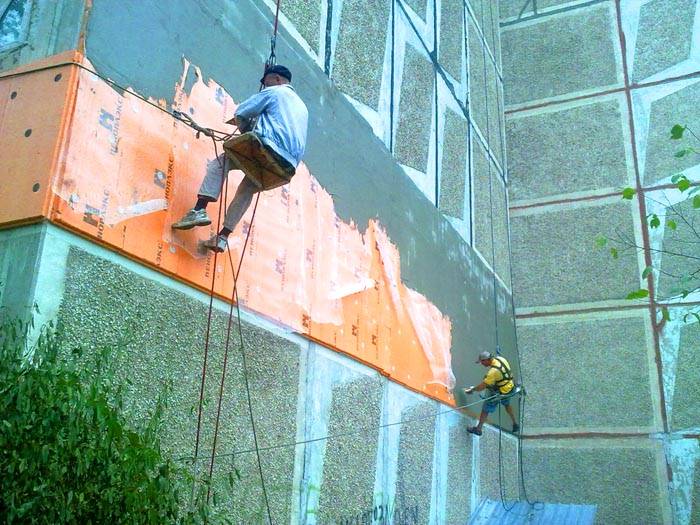

When performing thermal insulation works, various heaters... These materials can significantly reduce heat dissipation into the surrounding space. Penoplex is especially popular, the technical characteristics of which make it possible to use it in various regions. By choosing slabs of suitable thickness, you can ensure a sufficient level of thermal insulation of the walls, floor, ceiling. Let's talk about this insulation in more detail.

The content of the article

What is Penoplex: features, benefits, types

Penoplex - extruded polystyrene foam, which got its name from the trademark of the same name. It belongs to the category of the most popular thermal insulation materials due to its unique technical characteristics and reasonable cost. It is actively used to insulate various surfaces in the construction and reconstruction of residential buildings and public buildings.

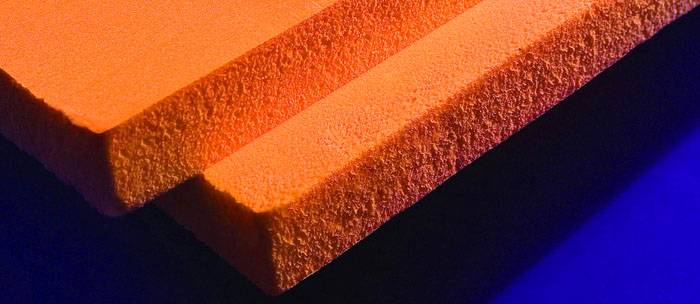

During the production process, polystyrene granules are foamed under high pressure and temperature conditions. The process is catalyzed by carbon dioxide and light freon. The finished mass, similar to cream whipped with a mixer, is blown out through special nozzles of the extrusion unit. Here freon evaporates, and the resulting voids are filled with air.

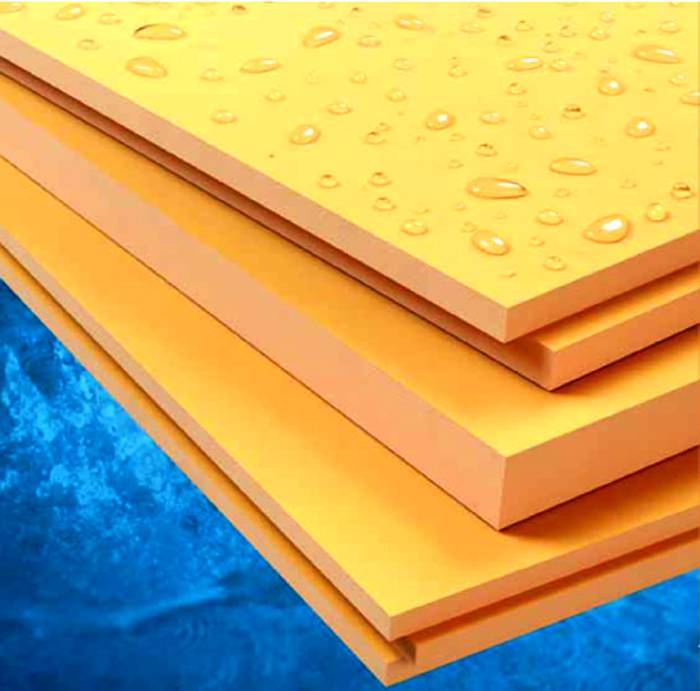

This production technology makes it possible to obtain a fine-porous material, inside which adjacent cells with air are isolated from each other. The diameter of the air pockets does not exceed 0.1-0.2 mm. Due to the uniform distribution throughout the volume of the material, the manufacturer provides the required level of properties.The material is highly durable and exhibits excellent thermal insulation properties. By selecting a material of sufficient thickness, the desired effect can be achieved.

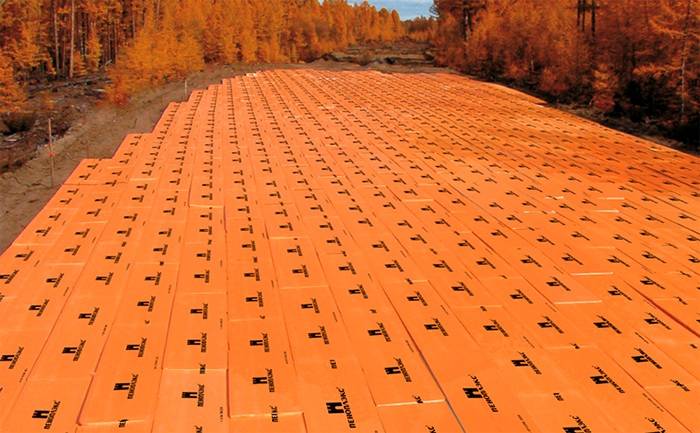

Note! Penoplex 50 mm is used for insulating buildings, roads, runways.

The manufacturer offers various types of thermal insulation material:

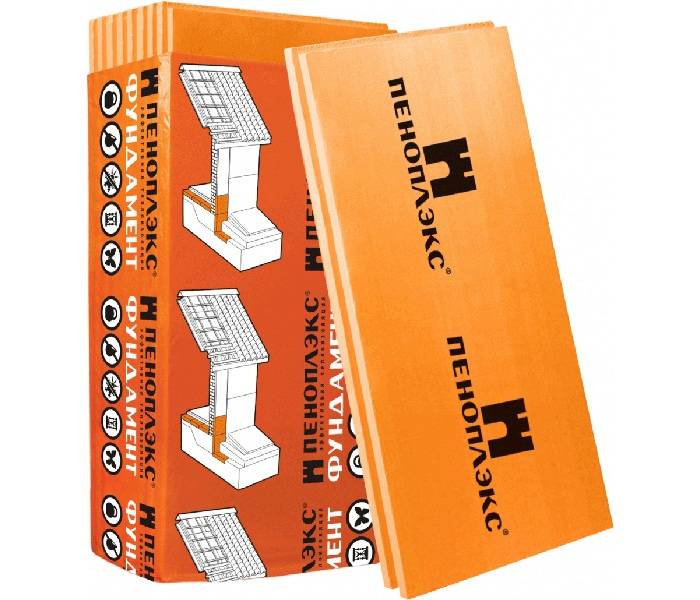

- Foundationcapable of withstanding significant loads during operation. The minimum board thickness is 50 mm. If necessary, you can order a thicker heat insulator if the operation of the building will be carried out in the northern regions;

- Roofwith a special shape that facilitates the process of laying the plates. With the help of this type of thermal insulation material, it can provide high-quality protection of the roof from external cold. In this case, it becomes possible to use attic as a living space;

- Comfort... Penoplex thickness of 30 mm, as a rule, is enough for high-quality thermal insulation of the walls of a residential building or loggia;

- Wall... A suitable option for wall insulation inside and outside the assignment. The thickness of the material can be 20-50 mm. If the work will be done from the inside, it is better to choose a thinner material. For the facade, it is worth ordering thicker slabs.

Attention! The thickness of 10 mm foam is not enough for high-quality insulation of the walls of the building, which is operated in winter. Thicker slabs should be chosen, for example 70 mm.

Related article:

In our article you will find out what types of penoplex are, how it happens insulation of the facade with penoplex (technology), as well as the pros and cons of this facing material.

The main technical characteristics of foam for the foundation

According to its technical characteristics, GEO penoplex corresponds to the old type of Penoplex 35, the production of which was carried out without a flame retardant. It is used for thermal insulation of surfaces, the fire resistance of which is not subject to increased requirements. The material belongs to the G4 group.

The main area of application of the heat insulator is the insulation of loaded structures with the subsequent application of a protective layer. The material is in demand for the device cement-sand screed, thermal insulation of the foundation, floor, basement of the building or garden paths. Plates become reliable protection for waterproofing layerensuring drainage of groundwater and reducing its impact on the underground structures of buildings.

Note! Biostable durable insulation is in demand when building a shallow foundation on heaving soils.

The minimum thickness of the Penoplex Foundation is 50 mm. If necessary, you can also purchase boards with a thickness of 80 mm. Plates are capable of withstanding significant loads throughout their entire service life. Their strength at linear deformation of 10% is 0.25 MPa. Water absorption by volume for 4 weeks does not exceed 0.5%. The insulation is able to serve for more than half a century, including when used in the harsh climate of the northern regions.

Basic technical characteristics of Comfort Penoplex

This type is universal. Technical characteristics of Penoplex Comfort 50 mm allow for thermal insulation of many surfaces. With its help, the roof, basement, walls, floor and foundation of the building are simultaneously insulated. Low water absorption, not exceeding 0.5% for 4 weeks, makes it possible to use Comfort when insulating saunas, pool or baths. Thermal insulation of other objects is possible, the operation of which is carried out in conditions of high humidity.

Tight joining of elements with each other contributes to increasing the stability of the enclosing structures. Not biodegradable. There is no need to fear that insects will appear inside the insulating material, which will destroy the structure of the plates from the inside. Able to serve for more than 50 years, while maintaining its technical characteristics. It can be operated in various regions, including the northern ones.

The material is quite dense, and therefore does not sag when attached to a vertical structure. It is necessary to correctly perform the installation and reliably protect all the plates. The density of the Comfort foam is regulated by TU 5767-006-54349294-2014. When cut, it does not crack or crumble. Compressive strength depends on the thickness of the slabs: if less than 60 mm - 0.12 MPa, more than 70 mm - 0.18 MPa.

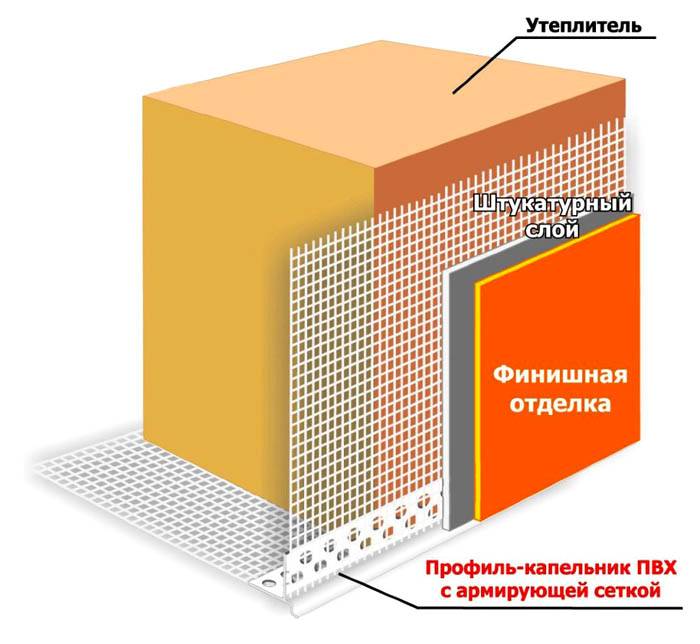

Attention! Finishing should be done on the insulated surface.

The application of the finishing layer allows:

- Give the penoplex an aesthetically pleasing appearance. The material itself does not allow to form a beautiful surface that could be exploited without additional processing;

- Prevent plate color changes;

- Avoid material destruction.

The main technical characteristics of the roofing foam

Plates Penoplex Roofing are in demand in the construction industry. The material with a characteristic orange color is produced with a density of 35 kg / m3. It allows you to form a rigid and moisture-resistant heat-insulating layer with low weight. It can be used for various types of roofing, thermal insulation of building facades, floors and walls of erected and reconstructed buildings, basements, laying of utilities.

The material is classified as moderately flammable. During combustion, it emits a large amount of smoke. This feature should be taken into account when choosing a heater for a living space.

A special connection of the spike-groove elements allows to form a uniform layer without cold bridges. Due to the refusal to overlap adjacent elements during the installation process, it is possible to optimize the thickness of the thermal insulation layer to be arranged and more rationally dispose of the free space.

The water absorption by volume of the slabs does not exceed 0.5%, and therefore the heat-insulating layer practically does not absorb moisture. The high strength allows it to withstand the significant load that the heat-insulating material can be subjected to during the installation of plates and the subsequent operation of the insulated object.

If the facade of the building is to be insulated, a special type of heat insulator can be used instead of the roofing foam. Its characteristics were initially adapted for this type of work. The price of Penoplex insulation for walls outside the house is acceptable for many. It depends on the thickness of the slab. For balcony insulation, you can purchase material 20 mm thick, for a residential building - 50 mm.

Extruded polystyrene foam: technical characteristics and price of quality boards

This type of thermal insulation material became available to users more than half a century ago. Extruded polystyrene foam, which is sometimes referred to as extruded polystyrene foam, immediately became a universal insulator in demand when performing a variety of works. Manufacturers offer standard size sheets that can be transparent and colored. Due to its special structure and unique production technology, sheet plastic demonstrates high performance during operation.

Attention! Before buying, you should find out the required insulation characteristics. Penoplex must meet the requirements.

Technical characteristics of 50 mm penoplex may differ slightly depending on the type of material. However, in most cases, they vary within a fairly narrow range.

The technical characteristics of Penoplex 35 include:

- Low water absorption capacity. The main advantage of this insulation. The heat insulator absorbs water molecules only in the sections, since air cells are open in these zones;

- Low thermal conductivity. On average, this indicator is 0.03 W / m · C;

- Versatility. The manufacturer offers material of various thicknesses, making it possible to insulate many surfaces. It is used for thermal insulation of walls, foundations, loggias and balconies;

- Low vapor permeability coefficient;

- Long period of operation. Penoplex is able to withstand repeated freezing / thawing without loss of basic performance characteristics. On average, such material can last about 50 years;

- High strength. During operation, the insulation withstands significant load and pressure due to the presence of tiny air bubbles in the material, which prevent the compression of the material;

- Ease of installation. The material can be easily cut with a sharp knife, giving the elements the desired shape. The cut site does not crumble. Installation work can be performed all year round, since the heat insulator is not afraid of exposure to UV rays and high humidity. Plates can be fixed at any time of the year;

- Environmental safety. In the production process of insulation, freon is used, which does not have a negative effect on the atmosphere. During operation, the insulation does not emit substances that can have a negative effect on the human body;

- Fire safety. The material is resistant to combustion;

- Minimal chemical activity and biological inertness. When performing construction work, a large number of substances with increased surface activity are used. Only a few are able to interact with penoplex. The heat insulator does not rot or decompose.

Penoplex is not the only extruded polystyrene foam that can be purchased for home insulation. Similar technologies are used by other manufacturers, they offer high-quality insulation.

The technical characteristics of Technoplex are somewhat different from those of Penoplex. This is facilitated by a change in the composition of the raw materials used. Some graphite is added to the composition of the mass to be extruded. The result is a highly effective, water-resistant insulation material.

Technoplex absorbs noise well and has a long service life. At the same time, it is somewhat inferior in strength. It works well at fairly low temperatures typical of the far north and has a lower level of water absorption. Only 0.2%. However, when buying this type of thermal insulation material, you will have to pay more. Considering that a large amount of material is usually required for wall insulation, this factor can be decisive when choosing.

Video review: extruded polystyrene foam

Penoplex sheet sizes: how to choose the right one?

The special technology for the production of extruded polystyrene allows the formation of a material with a unique structure, which ensures high strength of the plates and guarantees a unique thermal conductivity. As a rule, a material of small thickness is used for thermal insulation of various surfaces.When choosing a suitable option, you should focus on the manufacturer's recommendations.

If an object is to be insulated, the operation of which will be carried out in a temperate climate, plates with a thickness of 35-50 mm can be used. Their technical characteristics will provide the required level of thermal insulation of walls or roofs.

For regions located in cold climatic zones, it is worth purchasing a 70 mm thick insulation. Even if the frost is more than -30 ° C, a comfortable temperature will be maintained inside the building.

For foam boards, the dimensions are standardized. The manufacturer offers slabs 1.2 m long and 0.6 m wide in various thicknesses. The last dimension can be in the range of 20-150 mm. The choice of a suitable thickness should be made taking into account the operating conditions of the insulated surface.

Before purchasing thermal insulation material, you should calculate the required amount. To do this, you need to know the area of the surface to be insulated. Be sure to find out, choosing 50 mm penoplex, how many m² are in the package. This will determine the number of packages that are worth purchasing. Sheets are also sold individually, and therefore the missing quantity can be purchased additionally.

For those who buy penoplex, how many pieces in a package matter. This indicator depends on the thickness and type of slabs. For a material with a thickness of 50 mm, the ratio is as follows:

| Insulation type | Picture | Number of plates in a package, pieces |

|---|---|---|

| Comfort |  | 7 |

| Wall |  | 10 |

| Foundation |  | 8 |

Penoplex 50 mm price: the main factors affecting the cost

For penoplex, the sizes and prices are in direct proportion. The thicker the plate, the more you will have to pay for it when buying insulation. In addition, the type of material has a significant impact. In the production process, certain components are introduced into the composition of the raw materials used. This inevitably affects the cost of the material produced.

Advice! To find out how much penoplex costs, just tell the seller the required thickness of insulation and its type.

If you are interested in the price for a sheet of foam of a certain type and thickness, you can focus on the following data:

| Name | Sheet thickness, mm | Number of sheets in a package, pcs | Sheet cost, rub. |

|---|---|---|---|

Comfort Comfort | 20 | 18 | 77 |

| 30 | 12 | 115 | |

| 40 | 9 | 153 | |

| 50 | 7 | 187 | |

| 100 | 4 | 385 | |

Foundation Foundation | 50 | 8 | 199 |

Knowing the price per piece and the size of the penoplex, it is not difficult to calculate the cost of surface insulation work. Insulating material should be purchased with a margin. This will ensure high-quality surface insulation.