Insulation of the facade with penoplex: technology of work

In addition to coziness, warmth and comfort remain indispensable attributes of a home. If the tenants create a friendly atmosphere in the house, then the sound and heat insulation characteristics directly depend on the facing material. In modern construction, it is widely used penoplex, which is expanded polystyrene. This material has excellent characteristics and is used to insulate facades, floors, walls, ceilings. In fact, the scope of its application is wide enough to be used in structural work, in the construction of buildings, pits, pools, etc. Let's take a closer look at what types of penoplex are, how the facade is insulated with penoplex technology, as well as the pros and cons of this facing material.

The content of the article

Penoplex classification

There are five types of material in total, which differ in density. The density indicator is the most important characteristic when choosing the type of foam, on which the strength of the coating depends. The table below will help you figure out what are the differences between the types of penoplex from each other:

| Name | Density indicator | Flammability class | Application area |

| Penoplex 31 C | 28-30 kg / m3 | D 4 | - Insulation of the foundation at the initial stage of construction; - Insulation of facades, floors, ceilings; - Construction of water supply and sewerage systems in a private house; - Construction of swimming pools; - Construction of various underground systems: wells, reservoirs for water accumulation, etc. |

| Penoplex 35 | 28-37 kg / m3 | G 1 | - Wall insulation; - Floor insulation. |

| Penoplex 45 C | 35-40 kg / m3 | D 4 | It is used to insulate the foundation, which in use will experience extreme stress due to the heaviness of the floors. |

| Penoplex 45 | 38-45 kg / m3 | D 4 | It is used for the construction of swimming pools, wells, water supply systems. It is also an excellent heat-resistant material used to insulate walls, ceilings and facades. Withstands loads of up to 50 tons, so it is mounted as a base for floors. |

| Penoplex 75 | 40-53 kg / m3 | G 1 | It has amazing durability, so it is used for the construction of runways, landing hangars, etc. |

Most often for facade insulation penoplex, the technology of which does not cause difficulty even for beginners, the material of calibers 31 C, 35, 45 C is used. Now we will find out how the procedure of installing the penoplex on the front of the house takes place.

How to insulate the facade with penoplex?

This instruction will help you install the foam boards yourself:

- First, you should start leveling the irregularities of the facade. To do this, you can use plaster mortar or special linings that are glued to the surface of the front of the house. Please note that after using the plaster mixture with the installation of the penoplex, it will be necessary to wait 3-4 weeks;

- The installation procedure begins with fixing the basement profiles. This is done with dowel nails;

- Having previously measured the dimensions of the facade, cut the foam plates according to the dimensions obtained. Please note that window and door openings should be pasted over only with whole plates of foam;

- The material is fixed from bottom to top with a special adhesive for facing materials. To make the surface smooth and neat, it should be sanded with sandpaper;

- The slabs take three days to dry, after which they need to be fixed with dowels-nails in the center and on the sides.

- The final stage is facing the facade with any material of your choice. This role can be played by wood, stone, siding, special fiber cement facade panels, and many other types.

As we can see, the insulation of the facade with penoplex, the technology of which you now know, is not a difficult process, for which a minimum of devices and skills are needed.

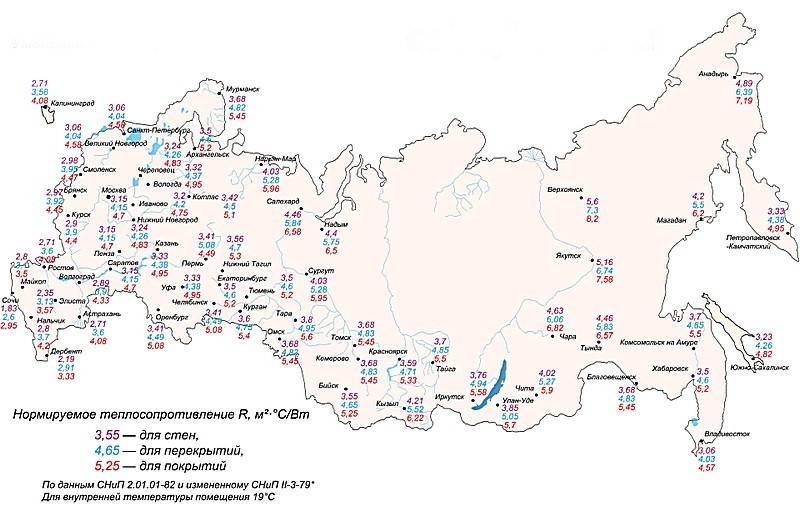

Calculator for calculating the thickness of wall insulation with Penoplex

Advantages and disadvantages of penoplex

Penoplex, like any other material, has not only advantages, but also disadvantages. Let's consider them.

Penoplex advantages:

- Possesses good thermal insulation properties due to a special manufacturing technology and a unique composition;

- Penoplex is an extremely moisture resistant material. It does not absorb water: on the contrary, when in contact with vapors, the components of the penoplex reject them;

- Also, the material is not susceptible to mechanical damage. The fact that the usual type of foam with a density of 28 kg / m3 can withstand a weight of 15 tons speaks for itself;

- Due to the fact that the material does not collapse under the influence of ultraviolet rays, moisture, mechanical damage, its service life is very long: it does not need to be replaced for about 10-15 years.

Disadvantages of Penoplex:

The only drawback of this material is its relatively high cost. However, this criterion is relative, since it is impossible to find a stronger and more durable product than penoplex on the modern building materials market.

Insulation of the facade with penoplex, the technology of which is presented above, is nothing complicated if you are familiar with the types and characteristics of this building material.

conclusions

- In total, there are five types of foam, three of which are widely used for facade insulation;

- Penoplex is a heavy-duty material that can withstand a load of up to 50 tons;

- The service life of the material is 10-15 years. These indicators are two to three times ahead of the durability of other facing materials.

Video tutorial on the technology of facade insulation with foam