How to make a facade insulation with mineral wool with your own hands?

House insulation is a very important finishing component. It should be done if the home is located in the cold regions of the country. It is not difficult to insulate the facade with mineral wool with your own hands, it is only important to know the main characteristics of the material and the technology of installation work. In order to establish ourselves in the choice, we want to tell you about the advantages and disadvantages of the material.

The content of the article

What is

Today, in the market of materials for insulation, mineral wool is becoming a real leader, according to the latest data, 80% of consumers choose it for facade insulation. Several types of material fall under the definition of mineral wool, which differ in the available characteristics, here they are:

- Glass wool is made from several components such as soda, sand, limestone, borax. Even in modern industries, glass breakage is often used, moreover, it can make up to 75% of the total composition of the material. Glass wool has high strength and resilience. It is able to withstand a temperature range of + 450-600 degrees. It has no disadvantages: it is fragile and brittle. These tiny debris dig into the skin and cause itching. So the most dangerous is the air mixed with such microparticles, they can irritate the lungs. When working with such mineral wool to insulate the facade, if you do it yourself, you must use special, tight clothing, a respirator and goggles.

- Slag wool is a material made from blast furnace slag. The temperature of use, not higher than 300 degrees, is the smallest indicator of all types. It is highly hygroscopic and, for this reason, is not suitable for facade insulation.

- Stone - made from rocks. It is easier to work with than the first two types, since it does not inject. The fibers can withstand high temperatures, but the binder component is only 250, so it is important that during installation the layers insulation not deformed. This type is most often called mineral wool in the construction markets.

Advantages and disadvantages of the material

Having chosen mineral wool for insulating the facade and doing everything with your own hands, you need to know about the advantages and disadvantages of the material.

The advantages include excellent thermal insulation properties. It doesn't burn. Even if unexpected ignition occurs, the material will not become a conduit for the spread of fire. When exposed to high temperatures, it will not emit harmful substances. Minvata has high vapor permeability. Steam penetrating under layer of plaster and the insulation is immediately removed. It absorbs noise. Due to the structure, which has pores, one can claim excellent acoustic properties and high sound insulation. Mineral wool layers are resistant to deformation, this property will prolong the operation. What is important for owners of private houses, rodents do not like insulation, they will not damage it and do not make a nest in it. Plus, the price of the material is relatively low when compared with other types.

If you look at the disadvantages, then we can highlight that with many years of use, the carcinogens that are in the composition of mineral wool can adversely affect the human body. Although manufacturers claim that harmful substances are in the composition in minimal quantities. Subject to the installation and operation conditions, they cannot harm. The only way out is to buy insulation from well-known manufacturers who value their reputation and have proven themselves well.

Installation of mineral wool on the facade

Do-it-yourself facade insulation with mineral wool can be done by everyone. The work implementation technology includes the following stages:

- Preparing the walls. How exactly this is done will depend on the type of walls of the structure. If they are made of wood, then they must be treated with an antiseptic to prevent the development of microorganisms, fungi and mold. If there are damaged areas, then they must be removed. If the walls are out bricks or foam block, then the release from plaster or paint is enough. Regardless of the type of facade, damp walls need to be dried, removed platband, slopes and other fasteners and decor that can spoil vapor barrier and insulation layers.

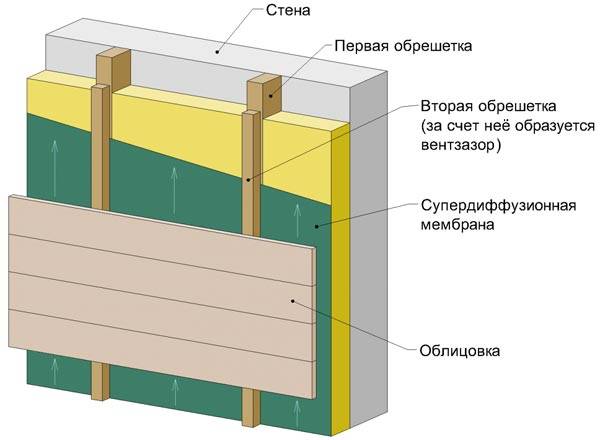

- A semi-permeable membrane is mounted on the walls. Moreover, it must be laid with the smooth side to the insulation. It provides steam removal from the walls of the house through the insulation, if the walls are perfectly flat, this stage can be skipped.

- Next, you need to spawn wood slats or metal profiles... They are fixed on the wall using self-tapping screws or dowels. It is important to take into account that the length of the gaps in the crate should be 1-2 cm less than the layer of material, this is necessary in order for the layers to fit tightly into the frame. The thickness of the lath should be the same as that of the insulation. To keep everything smooth, you need to use the "level" tool and control it. In case of revealing obvious irregularities in the facade, the slats can be fastened using hangers for drywall, with their help you can level the surface.

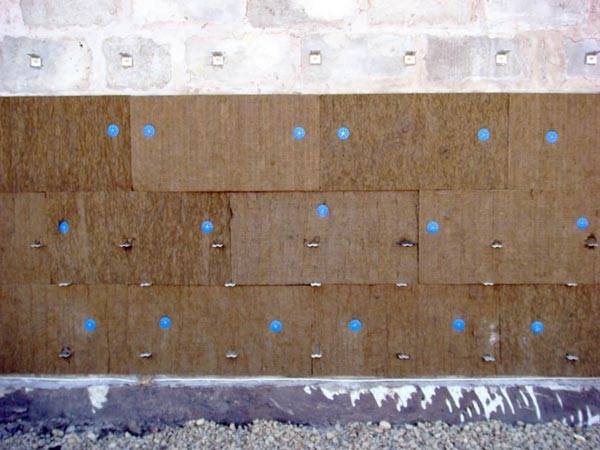

- You need to lay insulation in the space between the slats. You need to move from bottom to top, in the process you need to fix it. For this, special adhesives or dowels with large caps are used.

- At the very beginning, whole pieces are laid, then you can proceed to filling the space under and above the window openings, above the door.

- On top of the mineral wool, another layer of film is laid - this is for wind and waterproofing. It must also be able to let steam through. This layer needs to be reinforced using staples to the slats, and it does not need to be pulled.

- The last step is the installation of a ventilated facade. It means that between insulation and cladding there must be a gap of at least 5 cm.To organize it, profiles or counter rails are stuffed on top of the rails. As facing materials, you can use the popular fiber cement panels, or any other type of material.

conclusions

Insulation of the facade with mineral wool can be carried out without the involvement of specialists, and with your own hands. This insulation contains carcinogens in its composition, which is why it is important to withstand all stages of installation, since in this case, harmful substances will not poison the inhabitants of the house.

Video lesson on thermal insulation of the facade with mineral wool