Chipboard grooved moisture resistant: features, prices, application

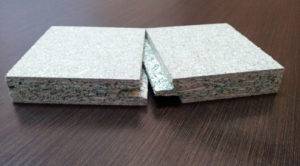

One of the relatively new and popular modern building materials, moisture-resistant tongue-and-groove chipboard, is successfully used for finishing, repair and construction work. In production, they use alder, birch or aspen wood, which makes the material durable and more environmentally friendly. And its tongue-and-groove is performed to reduce the price, increase the heat and sound insulation of premises for various purposes and simplify the connection of individual plates to each other. The versatility of tongue-and-groove chipboard ensures its use for various tasks - from the manufacture of subfloors to the decoration of partitions and walls.

The content of the article

Chipboard grooved moisture resistant: pros and cons

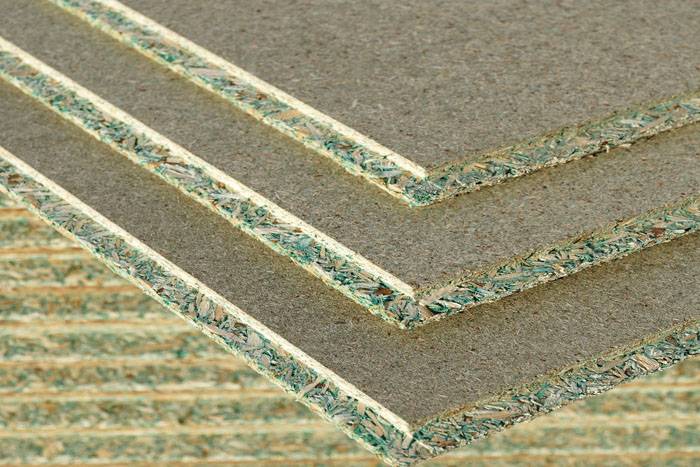

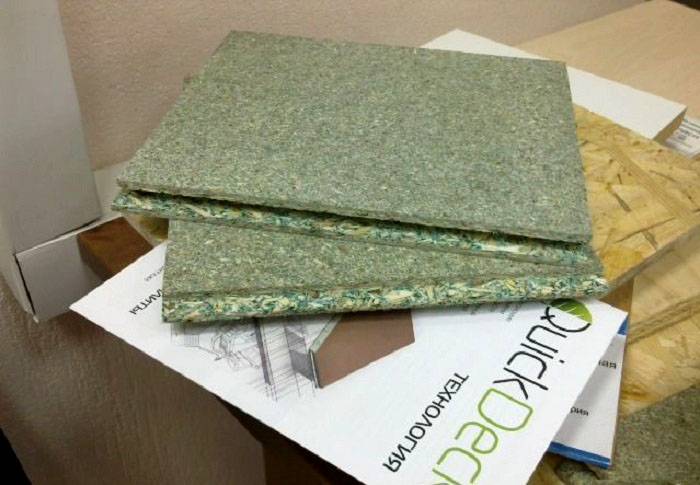

The name of the moisture-resistant tongue-and-groove chipboard was given to the plates, the characteristics of which are improved with the help of moisture-resistant polymeric materials and a four-sided tongue-and-groove system (tongue-groove). Thanks to these features, the material, which can be recognized by the green blotches on the surface, has the following advantages:

- easy recovery;

- resistance to decay, fungus and mold;

- low thermal conductivity, which provides savings on room insulation;

- environmental friendliness, which ensures the use of chipboard in schools, kindergartens, hospitals and other premises and buildings with high hygiene requirements;

- long service life;

- moisture resistance, the value of which is the highest for materials of the P5 class, which retain their geometric dimensions and structure even after a long stay in water.

Painted and laminated boards can be used as a topcoat. And among the few disadvantages of laying grooved chipboard, it is worth noting the need for additional protection of its ends from moisture and a small content of formaldehyde resins, which are used for pressing chips... Also, this material weighs more than similar-sized wood panels and is not suitable for installation on curved structures.

Application of chipboard with tongue and groove

The scope of application of the material is residential and office buildings, office premises, sports facilities, warehouses and shopping centers. At the same time, tongue-and-groove chipboard is suitable for the following structures:

- ceilings. To do this, it is worth using plates of a minimum, 12 mm thickness, which are easy to connect and easily replace drywall... They are also used to level the ceiling surface before applying topcoats;

- foundations. The slabs themselves are not included in the construction of the bases, however, removable formwork is made from them;

- walls and partitions. Plates increase heat-shielding properties and level the surface before painting, wallpapering or installing panels;

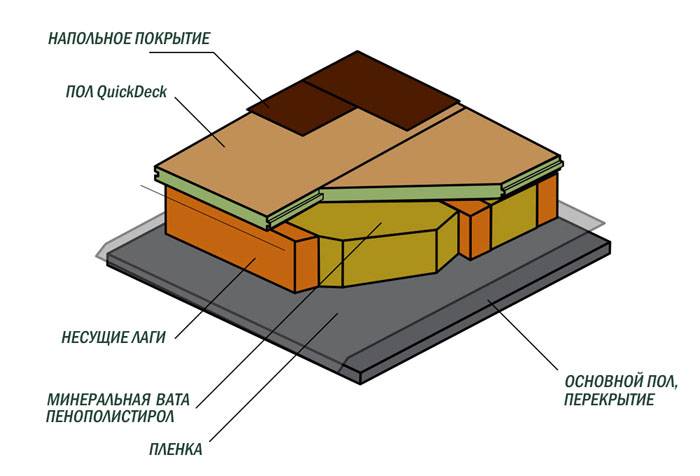

- floor coverings. Dry prefabricated screed, "floating floors" and raised floors are made of grooved chipboard for the floor. With its help, coverings of sports grounds, tennis courts and podiums are also strengthened.

Another way to use the material is to perform roofing work. Due to the increased density and ease of installation of the slabs, they are the best option for roof insulation. A relatively small mass allows you to reduce the load on the rafter structures and save on their manufacture.

Related article:

OSB plate: sizes and prices. The presented review will help you study the characteristics and capabilities of this raw material, as well as choose the best option for construction work.

Moisture-resistant tongue-and-groove chipboard: dimensions, price, brands

With standard thicknesses from 12 to 22 mm (and non-standard ones used by some manufacturers of 10 and 38 mm), tongue-and-groove plates have two main standard sizes:

- 600 x 2440 mm;

- 600 x 1830 mm.

Due to its small dimensions, the weight of one slab is small and reaches only 5 kg for a 16 mm thickness. Ceiling elements weigh even less - up to 4 kg. This feature increases the ease of installation of structures.

On the domestic market, you can find products from different manufacturers. The assortment of each company differs in both the cost and the thickness of the sheets - only the length and width of the sheets are the same. If you are going to buy chipboard for furniture, the price per sheet is indicated in the table below. The most common slabs of the following brands:

| Brand | Material | Minimum price, rub. |

|---|---|---|

| QuickDeck | Chipboard 12 mm | 270 |

| Laminated chipboard 16 mm | 324 | |

| "StroyExpert" | Chipboard 12 mm | 335 |

| "Sphere" | Chipboard 12 mm | 340 |

| "PlitTorg-S" | Laminated chipboard 12 mm | 580 |

The most popular brand, which can be found in almost every building supplies store, is QuickDeck. The material retains its characteristics for at least 6 years when used for floor coverings in rooms with high traffic of people. And the walls finished with it do not require major repairs for at least 20 years.

Important! Chipboard of the domestic brand QuickDeck is distinguished by the best ratio of cost to quality and fully complies with European standards. However, the products of several other brands are represented by a large assortment.

Related article:

OSB sheets: thickness and dimensions, prices. In the article, we will take a closer look at how to choose the right sheets, for this we will deal with the existing classifications, characteristics, and also the areas of application of the material.

Material reviews

The reviews left about the tongue-and-groove chipboard are mostly positive. The only drawbacks that consumers notice are the small assortment of standard sizes and the relatively high cost of the material. Reviews of chipboard can be presented in the form of the following table:

| Consumer | Feedback | Benefits | disadvantages |

|---|---|---|---|

| Alexey, St. Petersburg | Used standard 16mm wall and floor tiles. I got an excellent floor with a pitch of 300 mm between the lags. However, the painted walls made of grooved chipboard disappointed - the paint cracked at the seams and the walls had to be additionally putty. | Ideal for floors. | Not suitable for paintable walls. |

| Sergey, Voronezh | He made clean floors from this material, covered with one layer of varnish. There are no problems with the floor, it looks great, it washes well, it fits quickly - 30 sq. m laid in one working day. | Good laying speed, affordable price. The material is not as echoing when walking as laminate flooring. | When used, I did not find it. |

| Nikolay, Khimki | Used the material about a year ago for the construction of the floor. Used daily. Doesn't creak like some brands of inexpensive laminates. When laying, it was conveniently cut, but when water got from the shoe, the seam swelled a little. | Simple assembly and processing. Quite good moisture resistance. | The seams require additional processing, since water falling on them can damage the chipboard. |

| Maxim, Nizhny Novgorod | This is the second time I have been using tongue-and-groove chipboard. I get a solid and even floor. After accidental water ingress, nothing happens to the surface. Even the leaking ceiling and the puddle that formed on the floor did not swell the material. And, thanks to the tongue and groove, a minimum of time is spent on installation. | The presence of a tongue. Satisfactory moisture resistance. | It did not work to dock with sheets of the same size (600x2440x16) from another manufacturer, left over from the last repair. |

| Alexey, Moscow | Easy to lay on the floor on logs with a distance of 400 mm. I got a very flat surface on which I laid linoleum. However, water falling onto the untreated floor caused a loss of smoothness. | Fast installation of a quality subfloor. | High price. Inability to use to get a good finish floor. |

| Oksana, Saratov | With the help of grooved slabs of different thicknesses, the builders made in my apartment the floors, the walls, and the ceiling. It turned out to be a good replacement for both drywall and flooring | Convenient, practical, affordable | Small assortment. When buying, we faced the lack of the required thickness in some stores. |

| Andrey, Moscow | Good stuff, I recommend it to everyone. He sheathed them a hallway in the country and a relaxation room in a bathhouse. | Convenient dimensions - easy to transport even on your own car. Perfect joint compatibility, easy installation. | The same small size, which is a plus for transportation, can be called a minus for finishing. |

| Mikhail, Arkhangelsk | I made the floors in a private house alone. I was pleased with the result - the floors do not creak, do not deteriorate from moisture. | Convenient size for single mounting - easy to carry and install. | The joints of the sheets are not perfectly flat in the plane. |

Features of the choice of tongue-and-groove moisture-resistant chipboard for the floor

When choosing slabs that play the role of a rough floor covering, pay attention to their moisture resistance:

- the PA brand has the maximum resistance to moisture, however, the price of moisture-resistant chipboard per sheet is much higher;

- the PB slab is less moisture resistant, which is why it is less often used in rooms with high humidity.

Important! Choosing between the relatively expensive first grade and the more profitable second one, you should pay attention to the absence of unpolished areas and chips. Such slabs are used for finishing floors and have a high surface quality. The second grade can only be used to obtain a finishing surface.

Another factor is taking into account the concentration of formaldehyde. Class E1 has no more than 10 mg of substances per 100 g of particle board, E2 - up to 30 mg, E3 - up to 60 mg. The lower the indicator, the more environmentally friendly, and, therefore, safe to operate the plates.

Installation recommendations

Due to the dimensions of the tongue-and-groove chipboard, the installation of the subfloor using it is easily performed alone without the involvement of third-party helpers. Although, to obtain a satisfactory result, a strict sequence of work must be followed. The installation steps can be summarized in the following table:

The installation process for floating floors is different from conventional work. At the same time, the moisture-resistant chipboard for floors replaces the dry screed. A "floating" structure is called because there is no rigid connection between the coating and the concrete base. It consists of several layers of material, the last of which is chipboard. And the laying process itself looks like this:

With the same materials for ceilings, partitions and walls, work gets done even faster. Due to the fact that the installation of sheets on vertical structures does not require the manufacture of lathing, installation becomes easier, and the cost of repairs is reduced. For fastening to the wall, use standard self-tapping screws, the distance between which should be within 300-400 millimeters. The thickness of the ceiling slabs should be no more than 12 mm, and for their fastening, not a crate, but a rack frame is installed.

Video: QuickDeck tongue-and-groove chipboard as a subfloor

conclusions

Knowing the features of the plates and the rules for their installation, you can use this material to level various structures, saving time and money on repair work. The characteristics of the chipboard make it possible to use it in almost any room. However, to obtain the desired result, you should choose materials that correspond to the tasks to be performed in terms of class, moisture resistance and thickness.