OSB plate: sizes and prices, technical characteristics

Did you know that some quality building materials are made from waste? For example, for the manufacture of OSB (oriented strand board), various wastes from the production of woodworking are used. And then the raw materials are widely used for the construction of buildings for various purposes. OSB is also used for the installation of all kinds of partitions, walls and battens. Interestingly, in terms of technical parameters, the material is superior Fiberboard and chipboard. When choosing an OSB board, dimensions and prices are important. The presented review will help you study the characteristics and capabilities of this raw material, as well as choose the best option for construction work.

The content of the article

OSB plate: what is it and selection criteria

To successfully use such materials in construction, you need to find out what OSB plates are and what they are made of. Sheets are made from pieces of wood. These are large-sized shavings of different species. The particles are bonded with a special resin, wax and under the influence of pressure and high temperature. The slab is a multi-layer structure, with the individual layers in different directions. All components of the OSB sheet are environmentally friendly and safe.

This option has a lot in common with chipboard, from which it differs in the location of the chips in different layers. Also OSB related material with plywood, but differs in characteristics and cost.

Are you wondering why a recycled wood product is so popular? It's all about the extraordinary advantages of this raw material compared to the rest:

- the ability to choose products by strength and thickness;

- the sheets are resistant to bending when wet, which allows the sheathing of various curved surfaces;

- OSB is a plate with a homogeneous structure and strong fixation of individual elements, which eliminates delamination;

- easy to process;

- special impregnation protects against the growth of pathogenic microflora;

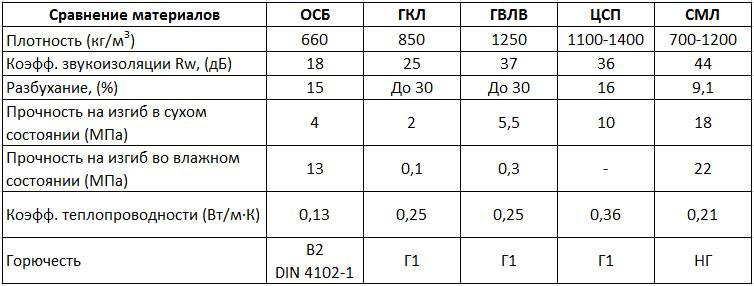

- the material has high rates of sound insulation and thermal insulation;

- the sheathed surface is resistant to moisture, so wet cleaning can be done on it.

Note! Since OSB is lightweight, installation on wood devices is done without additional reinforcement.

Classification of OSB boards and methods of their production

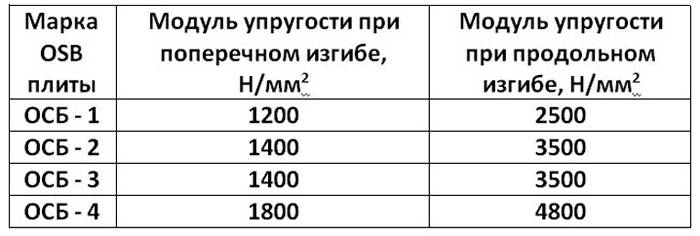

When choosing OSB slabs, sizes and prices matter, but varieties are also important. Four groups are distinguished:

- OSB1 is a lightweight board used in the furniture industry or as a packaging material. Operated in low humidity conditions;

- OSB 2 is a denser sheet with more layers. Can be used in dry rooms as cladding;

- OSB 3 is used in rooms with high humidity levels. The slab is able to withstand moderate mechanical stress. Used for partitions, load-bearing structures and various walls;

- OSB 4 has additional reinforcement and increased moisture resistance. It is used as a building material. Sheets are capable of withstanding significant loads.

The first stage of production involves choosing the right wood. Logs of small trees are sawn and then cut into machine tool are crushed to shavings. Then the material is dried and transferred to a special machine, where large and small chips are separated. Binder solutions are then added to the chips to give the sheet strength and moisture resistance. The resulting mixture is mixed with resins and paraffin in a special drum. Then the slab is formed. In this case, the chips are stacked in layers in different directions.

Interesting information! The most popular option is OSB 3 sheets, which have universal characteristics. They are used in the construction of low-rise buildings.

OSB sheet characteristics: standard sizes

OSB is not harmful to health. It is worth considering that the material is so in demand due to its characteristics:

- Convenient and reliable plate sizes;

- can be processed and easily sawn. In this case, cracks and chips do not occur;

- ease of finishing. After installation, the sheets can be simply painted or any facing materials can be applied;

- being tested for fire resistance;

- boards are durable, as they can withstand loads up to 650 kg / m3;

- light weight, which does not cause problems when transporting materials;

- OSB sheets are capable of withstanding loads. It is a rigid compound in which any fasteners are mounted.

When choosing the sizes and prices of OSB boards, you can focus on certain data. For example, the size of the plates in length and width does not have a single standard. Most often cutting on individual requests is offered.

An important parameter is the sheet thickness, which can be in the range of 2-26 mm:

- 2-16 mm - thin plates with low weight and low strength. Used for surface cladding with light loads. These can be furniture elements, ceilings or the base of the roof;

- 17-32 mm - plates with high bending strength and resistance to moisture. Sheets are used to create vulture panels and surface finishes with high loads.

Helpful information! Finished products are cut using a dimensional grid. In this case, even edges remain, and the cuts are grooved.

Where are OSB boards used?

OSB plates are used universally in many types of construction work. It is also necessary in the manufacture of furniture, for finishing inside various vehicles and for packaging.

You can purchase goods for the following purposes:

- lathing device for the roof;

- installation of floor coverings on the draft;

- sheathing of different types of walls;

- overlapping device;

- installation of supporting structures for finishing materials;

- boxes, pallets and other types of packaging;

- in furniture production as supporting elements;

- sandwich panels for frame buildings;

- special strength I-beams.

The most popular OSB 3 board is used for roofing, furniture production, floors and ceilings.

How to choose the right OSB board: sizes and prices

Depending on the purpose of using the plates, the dimensions of the materials are selected. It should also be borne in mind that the price for different manufacturers will differ. The size of a 9 mm OSB sheet can be purchased at an average cost of 550-750 rubles per piece.

If you have no experience in construction, then purchase plates of standard parameters. If the dimensions are the same and standard, then it is easier to calculate the required amount. Choose material of suitable size and thickness. If the need arises, the sheets can be cut additionally.

The cost depends on many factors. One of them is the country of origin. European and American materials are more expensive than alternatives. Also, the price is influenced by the thickness of the plates and the brand.

In the table you can see the prices for materials from individual manufacturers and their characteristics.

Table 1. Average cost of OSB boards

| Picture | Products | Dimensions, mm | price, rub. |

|---|---|---|---|

| Kronospan | 2240*1220*12 | 450 |

| Arbec Norbord | 2240*1220*6,3 | 430 |

| Glunz | 2500*1250*9 | 710 |

| Kalevala | 2800*1250*12 | 780 |

| Kronospan | 2240*1220*22 | 990 |

Helpful hints

For a good purchase, you must analyze the parameters and indicators of OSB boards: sizes and prices, as well as technological parameters. When choosing sheets for laying flooring, you should use the following guidelines:

- it is better to choose materials from Canadian and European manufacturers;

- the flooring is made on a concrete screed or logs;

- OSB 3 sheets are more suitable for flooring;

- when planning the location of the slabs, it is worth choosing an option in which there is less waste.

Helpful information! If necessary, the plate is cut with a saw. It is better not to use a jigsaw, as it will not provide a flat surface.

High-quality OSB boards will help create strong and durable structures. And the slabs of what dimensions and manufacturers to choose is up to you.