Fiberboard - what is it: sheet dimensions, thickness and price of a similar material

Any home craftsman at least once in his life was faced with the need to align floors, walls or ceilings. And the question here is not how to do it, but rather what material this work will be done with. Of course, different plastics can be used or plasterboard, but this material is not suitable for the floor. And here fiberboard or fiberboard can come to the rescue. Currently, this material is widely used due to the wide range of sizes and coatings. So, today's topic is fiberboard, what is it, sheet dimensions, thickness and price of this material on the Russian market.

The content of the article

- 1 Fiberboard - what is it: the advantages and disadvantages of fiberboard

- 2 What types of fibreboards have and how strength depends on thickness

- 2.1 Soft fiberboard, its features and characteristics

- 2.2 Semi-solid fiberboard - its advantages and disadvantages

- 2.3 Solid fiberboard and its characteristics

- 2.4 Fiberboard is superhard and what are its differences from others

- 2.5 Laminated fiberboard - its properties and applications

- 2.6 Fiberboard and particleboard: the difference between these materials

- 3 Fibreboard applications and how they depend on sheet thickness

- 4 Features of working with fiberboard, as well as what difficulties may arise in this case

- 5 Dependence of the price of a fiberboard sheet on size and thickness - a brief overview

- 6 Summarizing

- 7 Video: how to trim fiberboard evenly at home

Fiberboard - what is it: the advantages and disadvantages of fiberboard

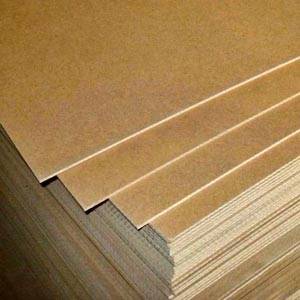

At its core, fiberboard is woodworking waste. It is impossible not to note the minimum amount of glue in it, which speaks of environmental friendliness. Depending on the coating, which is varied, sometimes it is impossible to determine by its appearance that it is fiberboard.It will not be possible to get rid of only general reasoning here, and therefore it is necessary to understand in more detail.

In the production of fiberboard, a special method of hot pressing of wet sawdust with a small addition of glue is used at rather high temperatures. That is why it will not work to say with accuracy what kind of fiberboard material it is. On the one hand, there is glue in this wood, but on the other, there is not as much of it as in chipboard (we will also talk about this material today).

One thing is certain. Fiberboard (Fibreboard) is a fairly easy-to-install material that has sound and thermal insulation properties. But first things first.

What types of fibreboards have and how strength depends on thickness

If we talk about the cost of such a building material, then its range is quite wide and depends not only on the coating of the slab, but also on the structure. The fact is that fiberboard can be of four types:

- Soft;

- Semi-solid;

- Solid;

- Super hard.

It is these parameters that determine the field of application of fiberboard and its cost. Therefore, you can buy fiberboard at a price of 170 rubles per sheet, or you can find it for 2500 rubles.

Important information! The hardness of the slab, oddly enough, is inversely related to its thickness. This means that the thicker the fiberboard, the softer it is, in contrast to other materials.

Soft fiberboard, its features and characteristics

This material is not used for finishing works, since it has a soft and porous structure. But on the other hand, it has become widespread as insulation and noise isolator. It is in great demand due to the absence of various chemical components, which means it is environmentally friendly. The only drawback is complete moisture intolerance. When wet, the plate begins to fall apart almost immediately.

Interesting! Quite a lot of such products were produced in the 60-70s of the last century, but after this period, such material was practically forgotten. Widespread production of soft fiberboard resumed already in 2011, and since that time it has been gaining momentum.

As a heat insulator, fiberboards are superior in quality even to mineral ones, which are most often used in construction. That is why many experts believe that fiberboard will completely replace other heaters in the future. In addition, the undoubted advantages include the fact that ordinary humidity, at which a person feels comfortable, is ideal for such stoves. At the same time, when it decreases, the fiberboard begins to give up the moisture that has accumulated in it, thereby restoring the balance.

You can buy soft fiberboard for an average of 500-700 rubles. per sheet size 1200x2700x12mm.

Semi-solid fiberboard - its advantages and disadvantages

This material is already more durable, although the thickness may not differ from the soft one. It should be understood that with an increase in strength, the heat and sound insulation capacity decreases, which means that the areas of its application will be slightly different.

Used as a semi-solid board in the furniture industry for drawers, shelves and back panels. It is more resistant to moisture than soft. Such plates are marked as "NT".

Solid fiberboard and its characteristics

The varieties of solid fiberboard are quite extensive. At the same time, the previous, semi-solid, in fact, also applies to them. If we talk about the markings of such material, then there are a lot of them. That is why it is worth dwelling on them in more detail.

| Marking | Description |

|---|---|

| T | Plain board without coating |

| TS | The front side is covered with a thin layer of wood |

| T-P | The face layer is painted |

| T-SP | The front layer is painted with wood pulp |

| T-B | Uncoated slab, moisture resistant |

| T-SV | Front layer - wood, increased moisture resistance |

Such boards are used not only in the furniture industry, but also in finishing works. For example, you can buy white fiberboard for 300-400 rubles. (with a size of 1220 × 2745 × 3.2 mm). As you can see, the cost of such a material is quite acceptable.

Fiberboard is superhard and what are its differences from others

Another type of hard plates, which is marked:

- CT - this means that the board does not have any coating;

- ST-S - Covered with a thin layer of wood.

The main advantage of this material is its strength. That is why it is used for finishing the floor. A similar chipboard has found application in electrical engineering. The fact is that it has increased moisture resistance. And this, coupled with its strength, makes the stove an excellent dielectric.

Laminated fiberboard - its properties and applications

This material is quite moisture resistant. Its face can withstand washing without any problems, even with the use of gel-based cleaners. For this reason, such fiberboard has become quite widespread in the field of interior decoration. The manufacture of such plates is a little more complicated than that of ordinary material, and their cost is slightly higher. And yet this does not diminish the popularity of laminated fiberboard among finishers and DIYers.

As for the colors, a huge assortment of them is presented on the shelves of Russian construction stores, and therefore it will not be difficult to choose the right one for any interior. You can buy laminated fiberboard with dimensions of 2070 × 1830 × 6 mm at a price of 700 to 900 rubles. depending on the region. There are also panels from this material on sale. Such dimensions of a laminated fiberboard sheet and the price are average. Depending on the brand and quality, the cost may be higher. Sometimes some plates can reach 3000 rubles.

Fiberboard and particleboard: the difference between these materials

Not everyone knows how fiberboard differs from particleboard. In fact, there are many differences between these materials. To begin with, you should understand that chipboard is a particle board, which means that it is made from larger fractions. In this case, the usual binding properties of wood cannot be dispensed with. For this reason, it becomes necessary to add various synthetic adhesives. Of course, chipboard is more moisture resistant, but this is a double-edged sword. Due to the addition of glue to the composition, the elasticity decreases and the weight of the board increases, which does not add convenience when working with it.

If you think about which is better - chipboard or fiberboard, then there is no single answer. It all depends on the area of application and the wishes of the master. After all, each of these materials has its own advantages and disadvantages. Moreover, their coverage can be completely identical.

Also, some novice home craftsmen ask this question: plywood - is it chipboard or fiberboard? But we are talking about completely different materials. For the manufacture of plywood, wood veneer is used, which is glued in layers. Moreover, each of them is perpendicular to the previous one. Such material is more durable and more difficult to manufacture. Consequently, the cost of the sheet is also higher. Likewise, the moisture resistance of plywood is much better.

Related article:

Chipboard grooved moisture resistant: advantages and disadvantages, sizes, average prices, reviews, secrets of correct installation of plates with your own hands and other useful tips - read our review.

Fibreboard applications and how they depend on sheet thickness

As already mentioned, the thickness of the fiberboard sheet plays a rather significant role in the field of application. For example, for interior wall decoration, you should not use 12 mm chipboard. Here 3-4 mm is quite enough. If we talk about standards, then it is 2745 × 1220 × 3.2 mm.Of course, the thickness may differ, but the dimensions of the fiberboard sheet in width and length are exactly the same.

But this only applies to sheet material. Do not forget about panels for interior decoration, as well as slabs. But we will talk about this a little later, but now it is worth considering all the areas of application of such material. First, let's take a look at the interior wall decoration.

Decorating with wall panels, slabs or sheets - which is more convenient?

Of course, the most common material for this work is panels, which can be different:

- LDF - the softest panel, with a density of 600-800 kg / m3;

- MDF is slightly denser and heavier. Its density is 750-950 kg / m3;

- HDF is the densest and heaviest material (over 950 kg / m3). Such panels are most suitable for the floor, although many perform wall decoration with them.

Related article:

From this article you can learn about MDF: what is it, important characteristics of this material, its advantages over alternative options and a lot of other useful information.

Important! It should be understood that the cost also depends on the density. It is for this reason that it makes no sense to use heavier materials for decoration, for example, a hallway. Here, LDF panels will be enough.

Nowadays, wall plates from a similar material are gaining popularity, which many do not distinguish from panels. The difference between them is that they are most often moisture resistant, have somewhat large dimensions and are mounted on a leveled surface using adhesives. Finishing with sheets is too good a decision. Their size and weight add to the inconvenience of installation.

Fasteners of fiberboard panels are no different from PVC. This means that installation on a frame made of wood or metal profiles, as well as on various adhesive bases is possible. Laminated fiberboard panels for walls look no worse than plastic ones, but at the same time they are much more resistant to mechanical damage. Do not forget that wood is an environmentally friendly material, which means that it is more acceptable for interior decoration.

Let's see how similar work is done using the example of a regular loggia.

Step-by-step instructions for installing laminated fiberboard panels on a loggia

Based on this information, it can be understood that for the interior decoration of the walls of fiberboard panels, it is not required to have any special knowledge or experience. Such work can be done independently by any home craftsman. Of course, subject to care and accuracy.

The color and structure of fiberboard wall panels can be not only "wood-like" or plain monochromatic. In the meantime, prefabricated products with photo printing, as well as structural ones, made under natural stone or brickwork, are in rather great demand.

For a more budget-friendly finish, you can also use a slab or panel without any coating (marked "T"). In this case, after installation, wallpaper is glued onto fiberboard or painted.

Floor decoration and how to use such tiles for it

Quite often, fiberboard is used to level the floor. The fact is that in addition to the fact that the cost of this material is low, it also has a relatively low weight, which allows you to work with it even alone. It is also quite simple in slicing. True, in this matter, experts do not come to a common opinion, and therefore everyone uses for this purpose the tool that is convenient for him. For example, some say that a hacksaw is needed for metal, others use an electric jigsaw, others use an ordinary hacksaw, but still others say that only an assembly knife is enough. There are no wrongs in this dispute. Indeed, any of the methods is good in its own way and we will dwell on each of them in more detail a little later.

Now it's worth talking about the material itself. It is most practical to lay on fiberboard marked "ST" or "ST-S", which are superhard. The slab will be coated or not - it will depend on the wishes of the master. After all, if subsequent painting or laying on top of linoleum is planned, the factory coating is useless. Many argue which is better for the floor - fiberboard or particleboard. But even here there is no single answer. Again, everything depends on the preferences and desires of the master.

If you take old houses, especially in the private sector, the flooring in them leaves much to be desired. The boards dry up, bend and gaps appear between them. In this case, the best solution would be to lay linoleum. In this case, punching the nails deeper and slightly leveling the floors, you need to cover the cracks with an elastic putty. Well, you can finally level the surface by laying fiberboard under the linoleum on a wooden floor. This will be the cheapest and most convenient option.

If finishing with a similar material is conceived, then for this in our time there are special panels that imitate parquet, which are also very simple to install.

Fiberboard for ceilings and some of the nuances of installation

The same wall panels can be used to mount a fiberboard ceiling. In this case, the technology will be completely identical to the wall cladding. If you need a more budgetary repair option, it is quite possible to use fibreboard sheets. They will be attached to the same frame. The only difficulty is that one is unlikely to be able to do this kind of work.

Many people have a question - how to paint fiberboard? The most optimal here will be oil or nitro paint. Although, if a moisture-resistant material is chosen, a water-based one is also quite suitable. But it is worth remembering that from an excess of moisture, even the most expensive slab can deform and it will not be possible to return it to its original appearance.

It is also quite convenient that if you take a similar material for painting, then there is no need to purchase it with a margin. Indeed, at any time you can buy a fiberboard sheet in any store, regardless of the shade.

Fiberboard application in other fields

Surely everyone has seen other products made of similar material. This is not only furniture, but also various doors, boxes for tools or vegetables and much more. Many argue that it is possible to make homemade hives from fiberboard, although experienced beekeepers deny this. In their opinion, even the wrong type of wood and a drop of glue can harm bees. But let's leave this conversation, because it is quite far from our topic today. Let's go back to the living quarters.

So, fiberboard doors are quite common now. They still remain as entrance and interroom in many apartments. But the main problem is that if something heavy falls on them, they usually get a hole. And what to do in this case? Really change? As it turned out, no. Now we will try to find a solution to this problem, and at the same time we will figure out what nuances may arise when working with such material.

Features of working with fiberboard, as well as what difficulties may arise in this case

Let's start with the restoration of the door. After all, it can simply wear out, losing its original appearance from time to time. There are absolutely no difficulties in this work. It is only necessary to carefully remove the old paint from the door.

Important information! You shouldn't take coarse sandpaper to speed up this process. It is necessary to understand that the material is quite thin. That is why a smaller one is needed.

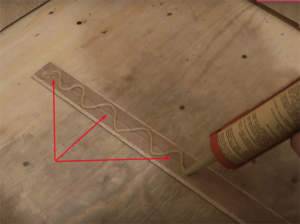

Before gluing the fiberboard to the fiberboard, remove the remaining dust from both surfaces. The gluing itself is carried out with the help of "liquid nails" applied by a "wave" to the cleaned surface. In this case, you also need to walk along the contour of the old door. The glue layer should not be thick.

After that, it remains only to firmly press the surfaces against each other. It will be possible to use the door in an hour, but it will be better to wait for the prescribed day. In the same way, you can solve the question of how to seal a hole in a fiberboard door, but in this case, experts recommend that you first fill the hole with polyurethane foam.

Important! You don't need to use a lot of polyurethane foam. Otherwise, the door can be crushed from the inside while it dries.

Another frequently asked question - is it possible to glue wallpaper on fiberboard? In fact, this would be a pretty good finish for this kind of material. However, some surface preparation is required to avoid future peeling of the wallpaper. Preparation may be the simplest - some advise covering the fiberboard with linseed oil. But nevertheless, it will be better to first prime the plates, then putty, well, before gluing the wallpaper, apply the primer again.

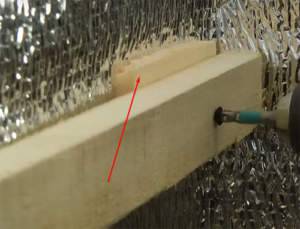

Well, back to the question of how to cut fiberboard at home. As mentioned, there are 4 options and each one is good in its own way. For example, if you use an assembly knife, there is practically no debris left, and electric jigsaw allows you to complete all the work many times faster. That is why, no matter what tool a home craftsman chooses, the main thing is that it is convenient to work. The rest is already secondary.

Dependence of the price of a fiberboard sheet on size and thickness - a brief overview

Usually, speaking about the cost of a particular material, the master means a comparison of various types and manufacturers. This is what we will now try to do - to figure out how the price of a fiberboard sheet depends on the size and thickness with photo examples.

| Photo | Manufacturer | Size, mm | Colors | Cost, rub. |

|---|---|---|---|---|

| Russia | 1220x2440x3.2 | No | 150 |

| USA | 1220x2440x6 | Brick red | 2800 |

| Russia | 1700x2745x3.2 | No | 250 |

| Russia | 2745х1700х3.2 | Any plain | 300 |

| USA | 1220x2440x6 | Brick white | 1600 |

Thus, it becomes clear that the range of prices for such products is quite large.

Standard dimensions of fiberboard sheet - are they always respected

As it was already possible to understand from the table above, the dimensions of fiberboard are not always standard. Sometimes you can find other dimensions. But here it is better to choose so that you do not have to (if possible, of course) cut it lengthwise when laying - this is quite inconvenient. It is much better if the size of a fiberboard sheet in width coincides with half, a third, or maybe the whole width of the room or surface. In this case, you can save a lot of effort and time during installation.

As for such a parameter as the thickness of the fiberboard sheet, here, as already mentioned, the choice is quite large. Therefore, everyone can choose what he needs.

Fiberboard price per sheet - what else does it depend on

The cost of such a material, as already mentioned, in addition to thickness, may depend on the manufacturer's firm, coating and color, as well as density. It is for this reason that it is impossible exactly how much a fiberboard sheet costs. The price can vary significantly. But still, let's try to understand this issue in more detail.

For example, how much does a fiberboard sheet with a decorative coating cost? If we take a domestic manufacturer, then this is about 250 rubles. If we pay attention to the imported stove, then for such a product we will have to pay about 1000 rubles.

When planning interior decoration, you also need to think about whether the home master can do all the installation work with his own hands. If not, then the salary of professionals will need to be added to the cost of fiberboard sheets. That is why it is worth calculating all costs in advance and adjusting them to the repair budget. In such a project, you should indicate the entire number of chipboard sheets and their prices, the size of the room to be finished and possible unnecessary expenses that may arise during the work.

Important advice! If you have a choice between a regular uncoated material and a more expensive one, then you should not save. The fact is that despite the higher price for a sheet of laminated chipboard, it is more profitable to purchase it. After all, when purchasing an ordinary one, paint is also needed, and as a result, it will be more expensive and look better, and its service life is much longer.

Summarizing

In general, chipboard is ideal for interior decoration. Moreover, even for rooms with high humidity, such as a bathroom or a toilet, you can choose a suitable option. In addition, the cost of fiberboard is quite acceptable. And this allows you to make a fairly high-quality and at the same time budget finishes. The main thing in the installation process is to follow the simple rules that were set out in the article and do everything carefully and accurately. Although this advice can be applied to any job. We hope that the information was useful to someone. If you have any questions, we will be happy to answer them in the discussions for this article. We will be grateful if any of the home craftsmen post their photo report on the similar work done. We are looking forward to your advice and comments. Well, in conclusion, we suggest watching a short video.

Video: how to trim fiberboard evenly at home