Plywood sheet thickness and dimensions: prices and assortment

Do you know what the thickness and dimensions of a plywood sheet are? Prices for different types and sizes vary greatly. In this review, we will consider all these points, as well as where it is worth using plywood sheets, what varieties have appeared recently, what properties they have, how much they cost and what to look for when buying. Despite the fact that the material is not new, modifications of it appear on the market that provide unique performance properties. We will talk about all this further.

The content of the article

Material structure

The material is a multi-layer structure made of three or more layers of prepared veneer, glued together with a special adhesive. The number of layers is always made odd. In order to increase the strength characteristics, the gluing is performed in such a way that the wood fibers are located perpendicularly between the layers to be joined. On the outside, a decorative surface can be made or impregnated with special compounds that increase moisture resistance, fire safety, or give the product any other properties. The main selection criteria are: plywood sheet thickness and dimensions, prices and performance characteristics.

Related article:

OSB sheets: thickness and dimensions, prices. In a separate publication you will find detailed information on OSB boards, their characteristics, dimensions and prices.

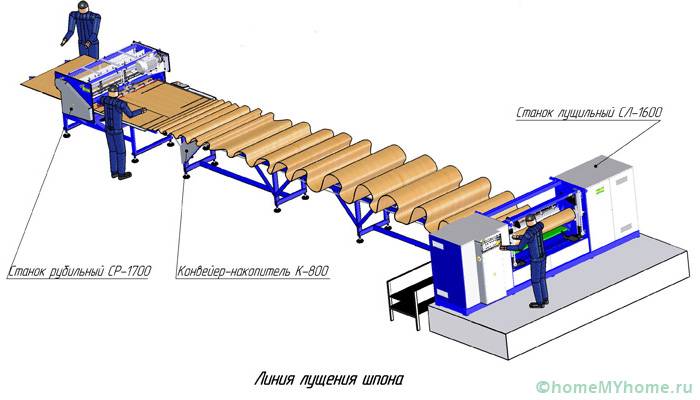

Production technology

Despite the relatively simple structure of plywood, the manufacturing process is rather laborious and complicated. Manufacturing technology consists of the following stages:

- Preparation of birch veneer logs for hydroprocessing at elevated temperatures in special cooking vessels.

- Removal of bark and bast from the surface of the workpiece, followed by passing through a special scanner, which makes it possible to determine the amount of the obtained ridge.

- Cutting of logs on special semiautomatic sawing units according to specified dimensions. Smooth sheets go to the next stage of production, and the waste is sent for recycling.

- Peeling on special machines, cutting with scissors according to the required dimensions, and then laying the veneer.

- Drying veneer in drying chambers under certain conditions.

- Sorting veneer into two main parts: one is designed for gluing edges and repairing veneer, and the other for subsequent sorting in accordance with GOST 1-96.

- Bonding workpieces on the "mustache" and on the edge.

- Veneer repair: selection of strips up to 4.9 cm wide with the same grain directions, color and type of wood.

- Mixing the adhesive solution and applying to the surface of the sheets.

- Build layers into packages.

- Gluing veneer on a pressing machine with exposure for 24 hours under constant pressure.

- The process of trimming and finishing.

- Product sorting, labeling and packaging before shipment to the warehouse.

Helpful information! The following types of wood are used for the production of plywood: deciduous and coniferous. The most expensive is considered to be birch, and the cheapest is based on conifers.

Types of plywood

After passing through all stages of production, plywood is divided into four grades according to the quality level:

- The first grade is distinguished by the presence of a minimum number of defects.

- The second grade may contain defective areas: cracks, leaks or spills of glue, as well as repaired parts.

Second grade. The surface is distinguished by noticeable differences in the pattern and the presence of subtle defects

- The third grade is distinguished by the presence of knots, wormholes with a total number of no more than 9 pieces per sheet.

- The fourth grade has a very mediocre quality, since it can contain various types of defects: wormholes, knots, significant surface roughness, uneven edges.

FBA (birch aviation)

In the manufacture of FBA, albuminocasein glue is used, which is distinguished by its environmental friendliness and ensuring minimum moisture resistant properties. Therefore, this brand is in demand only for installation in dry rooms with the possible appearance of a minimum amount of moisture, which significantly limits its scope. It has increased durability and aesthetic appearance. The FBA cost is at a fairly high level. It is used in the manufacture of furniture and interior decoration in the aircraft industry.

FSF (increased water resistance)

FSF is made from deciduous trees using phenol-formaldehyde bonding, which gives the finished material increased moisture resistance, wear resistance and mechanical strength. It is widely used in construction for leveling surfaces, creating interior partitions, in manufacturing and in roofing works to create lathing for flexible materials. The adhesive composition contains elements harmful to human health, which is a significant disadvantage for FSF.

Fireproof FSF plywood

FSF-TV is distinguished by the presence of refractory impregnation, which makes the material resistant to fire. According to the flammability class, it belongs to the slow-burning class.It is widely used in the construction of passenger cars, in the construction of industrial warehouses and premises, as well as in the construction residential frame objects.

FBS (special bekelized)

FBS is characterized by increased fire resistance, mechanical abrasion resistance, moisture resistance and resistance to sudden temperature changes. It is a relatively new material, but already in demand due to its strength approaching low-alloy steels. It is made from pine or birch veneer, which is impregnated in a special way with water-soluble bekelite resins. This type of plywood holds the record for the service life, since its service life is more than 10 years. FBS applications are limited exclusively to professional areas of construction: the manufacture of formwork for monoliths or complex structures. Moisture-resistant bakelite plywood has a rather high cost: the price per sheet is from 1290 rubles.

Helpful information! FBS can be used in the most severe operating conditions at temperatures from -50 ° C to + 50 ° C and high humidity, as well as in regions with a maritime climate.

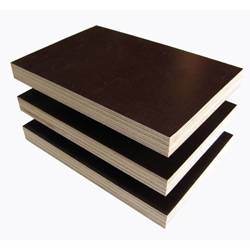

FOF - film faced plywood: sheet sizes and prices

FOF is an ordinary plywood sheet with high moisture resistance and excellent decorative properties. As an adhesive, formaldehyde resins are used, which make the material environmentally friendly. It is used for finishing walls, billboards, facing facades, for making furniture, etc. The main parameters by which laminated plywood is selected are sheet dimensions and price, as well as the quality of decorative finishing. The cost also depends on the type of wood used.

The main selection criteria: thickness and dimensions of plywood sheets, prices

First of all, you need to choose plywood according to its technical characteristics. That is, it must fully meet the operating conditions and have maximum protection. A competent choice of protective properties will save on the purchase of expensive types of material.

It is also worth paying attention to the thickness of the sheets, which determines the bearing capacity, as well as the strength of the structure. There is no single standard that regulates this parameter, so manufacturers independently decide on the choice of its optimal value. The minimum thickness is 3 mm, and the maximum is 76 mm. The cost is roughly proportional to the thickness. For example, the price for a 10 mm moisture resistant plywood sheet is from 310 to 560 rubles, and 20 mm moisture resistant plywood the price per sheet is from 460 to 721 rubles.

Attention! The dimensions of the sheets can be formed with longitudinal and transverse fibers, which determine how they are laid. The direction of the fibers can be determined by the corresponding markings.

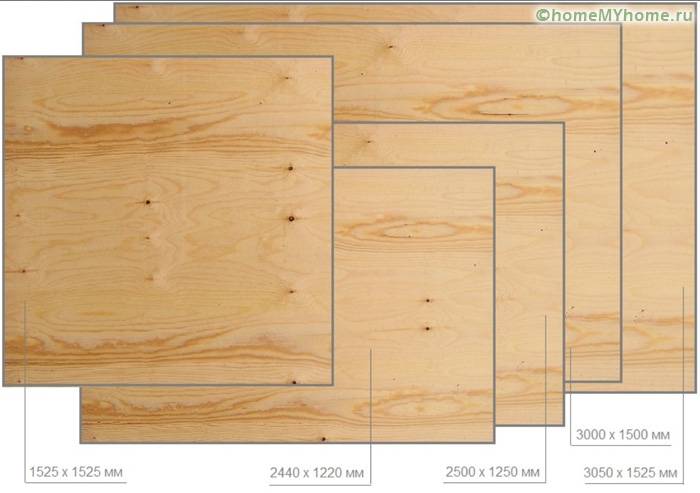

Another selection criterion is the selection of the required sheet size. To do this, you need to measure the area of each surface to be trimmed and select it so that the minimum amount of construction waste is formed. In other words, it is recommended to create a sketch or a laying scheme, especially if the surface shape is complex, and draw up a cost estimate based on them. There are the following standard sheet sizes in mm:

- 1220×2440;

- 1500×3000;

- 1525×1525;

- 1525×3000;

- 1525×3050.

Attention! The weight of a plywood sheet increases significantly with an increase in its area and thickness. At the same time, its portability may deteriorate and the complexity of installation may increase. Therefore, sheets with dimensions of 1525 × 1525 mm are considered the best options.

Sizes and prices

Approximate prices for plywood sheets are given in Table 1 for Moscow. They will allow you to competently draw up a cost estimate and choose the right material.

Table 1. Average cost of various types of plywood in Moscow

Conclusion

- The main types of plywood are described.

- Criteria for choosing a suitable material are given.

- The main parameters of the material are given: the thickness and dimensions of the plywood sheet, as well as prices.

Video: which plywood is better?