MDF - what is it, sheet dimensions, thickness and price

For renovation different types are selected finishing materials... Sometimes the choice is complicated by the lack of knowledge about the properties of a particular product. Today, the homemaster.techinfolux.com/en/ editorial office invites you to find out what it is - MDF material, how it is used in decoration, what are its characteristics. This will help you decide whether to purchase these products, how to use them for repairs.

The content of the article

- 1 How MDF is made

- 2 What does MDF look like, what are its performance characteristics, are there any differences in types

- 3 Advantages and disadvantages of MDF: does the material only have advantages?

- 4 What is the difference between materials: MDF, chipboard, laminated chipboard

- 5 How to install MDF wall panels for interior decoration

- 6 How to mount MDF panels on the floor and ceiling

- 7 Video: the process of installing MDF panels

How MDF is made

The English words Medium Density Fiberboards in translation mean a fiberboard with a medium density. The material has been known as MDF since 1966, and in the CIS it became popular in 1997.

In general, the production resembles the technology for creating chipboard and Fibreboard from pressed shavings, but the strength is twice as high.

The creation process is divided into stages.

- First, the necessary raw materials are prepared: a large number of round logs, peeled from bark, are needed. They are mechanically chopped to chips, which are sorted and washed. After that, it is heated with steam.

- The fibers are now being prepared. For this, the material is ground in a refiner. The crushed product is bound with lignin and by means of natural resins formed from heating wood. After that, the material needs to be dried and pulled out of the air mass.

- At the third stage, the carpet is formed and prepressed.They use a forming machine in their work.

- After that, the main press is connected to work, on which the MDF tape will move. It will be cut with a saw and cooled for about 25 minutes.

At the end of all stages, sanding of the panels is required. So the thickness is leveled, smoothness is gained and external defects disappear. The slab can be immediately sent for sale or modified with decorative finishes. The panels are painted, laminated (with PVC film), veneered.

An example of using MDF: the enamel on the panels perfectly suits the conditions of the kitchen, fulfilling its aesthetic function

As a result of all actions, a durable product is obtained that does not deteriorate from temperature extremes, does not warp or crack.

What does MDF look like, what are its performance characteristics, are there any differences in types

MDF panels are used widely and everywhere. Consider what performance characteristics of the material attract attention. In what areas of repair and decoration are they used?

How MDF panels are used for interior wall decoration

MDF panels for walls come in different sizes and three types. As a finishing material, this is a good acquisition, because it just cannot be broken or bent, and the condition of the plates remains in its original form for a long time.

Panels can be slatted, sheet or tiled. The rack-and-pinion type is the most common in use due to the ease of installation: the ridge falls into the groove.

The tile type resembles tile, but of a large size. Tiled types are mounted in the same way as rack and pinion.

The walls can be veneered with a 3 mm layer of veneer with imitation of wood, laminated with PVC foil, which will make the interior stylish.

Photo printing on MDF is firmly in vogue. To protect the drawing, acrylic-based varnish is applied to the boards

You can find slabs with a 3D effect, which is still an innovation. This is much more interesting than simple painted panels, which allows you to create an original design in the room.

Ceiling and floor material: MDF panels

For ceiling and floor, slabs are suitable materials due to their characteristics. The strength was mentioned above, it is worth adding that such a finish contributes noise and sound insulation.

If you add special soundproofing materials, then there will be real silence in the apartment, and the noise of neighbors from above and the noise will become just a memory.

Timber panel is ideal for subfloor laying due to its high strength, perfect flatness, resistance to temperature extremes.

MDF skirting board

The finely dispersed fraction of MDF skirting board and its exterior decorative finish with paper impregnated with dyes makes the product attractive for the finishing touch in home decoration. The manufacturing technology will not allow the decorative layer to come off over time, since a melamine coating is applied to it.

This protection will not allow moisture or dirt to get into the skirting board. It is also resistant to fading

It has become fashionable to use white MDF skirting board: due to the melamine coating, dirt practically does not appear on it.

Despite the positive qualities of such a finishing material, its disadvantage is fragility: it does not resist mechanical damage well enough.

Apron for kitchen from MDF

It makes sense to consider the proposal to execute kitchen apron from MDF. Usually, for this purpose, a laminated or veneered version is purchased, which turns the kitchen space into an elegant room.

Unfortunately, this material is flammable.If you want to protect yourself, then you should close the apron behind the stove with tempered glass.

Can you opt for patterned panels? This is a budget decor, but rather unstable if the design is printed on film. And if the application was made on acrylic plastic with a protective layer of varnish, then such an apron will last longer. Alternatively, the design can be hidden under several layers of lacquer, sintered together using the hot lining method.

Window sill laminated from MDF

The window sill is always under the influence of sunlight, near open windows, heating batteries. This makes it necessary to use high-quality material for the construction, which will not need to be polished and painted from year to year in order to preserve its aesthetics and quality. Laminated MDF is reliable, good in appearance, wear-resistant.

Interior doors MDF

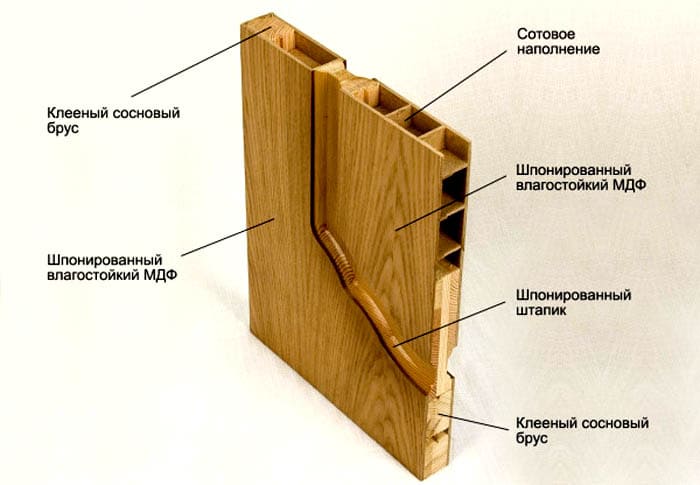

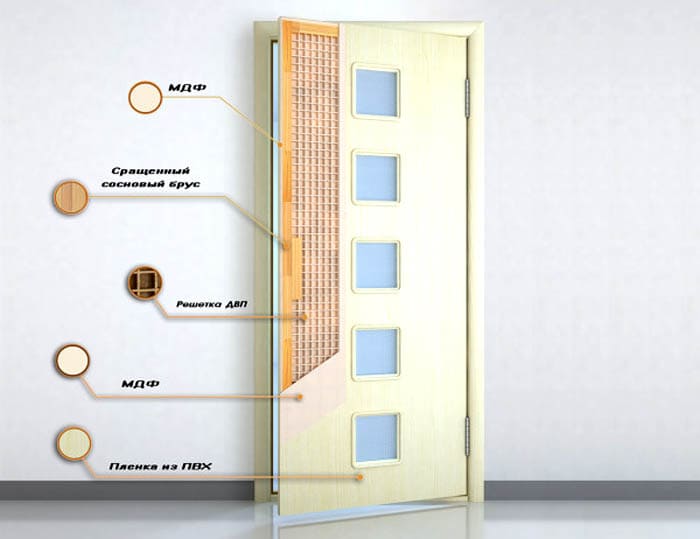

Such products from MDF are popular, there are two types of such structures: paneled and panelboard.

Panel doors look like a smooth single canvas, with or without decorative inserts.

The frame of such products is made of a solid pine bar, placed around the perimeter. And on top of the frame, two MDF plates are attached

The hollow space is filled with cardboard or hardboard. If there are many cells inside, the design is lightweight. It is called Masonite. More solid and weighty options consist exclusively of MDF inside.

Paneled interior doors are a combination of an array along the perimeter and inserts in the middle.

Outside, the doors are faced with natural veneer, eco-veneer, PVC film, laminate or enamel. In any case, the topcoat is varnish.

The use of MDF in the manufacture of furniture

Furniture and furniture facades are made of MDF. By all criteria, this is an excellent material, in addition, there is the possibility of fine processing and milling, which creates fancy shapes and elements on furniture.

The material is plastic, so you can get convex or concave furniture facades from MDF, which will be a real godsend for the designer's ideas.

Advantages and disadvantages of MDF: does the material only have advantages?

Products are considered comprehensively, therefore we will discuss the advantages and disadvantages of the products.

Pros:

- environmental friendliness of the product due to its manufacturing technology;

- ease of installation;

- the ability to create any designs in different ways;

- a large selection of decorative design;

- sound and heat insulation;

- compatibility with other finishing materials.

Minuses:

- poor edge processing leads to product damage, which makes MDF not particularly suitable for use in rooms with high humidity;

- weak resistance to mechanical damage such as shock;

- easily flammable, which entails spending on protective materials for wiring and cables.

So, it is worth weighing the pros and cons before you go to buy this finishing material.

What is the difference between materials: MDF, chipboard, laminated chipboard

It is not for nothing that the products have a different name: so we will learn to distinguish different products from each other. Since the names are different, therefore, their characteristics are different, and this is already a serious question in the matter of repair work.

The difference between regular MDF and moisture resistant MDF

If you certainly wanted to decorate the bathroom with MDF panels, then you should choose a moisture-resistant option. The difference is in double-sided lamination, which protects the board from both sides.

The difference will be seen in the price. You should not trust dubious manufacturers that promise quality for little money.

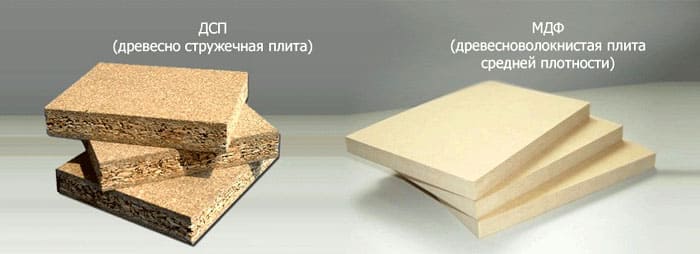

The difference between MDF and chipboard

Consider the difference Chipboard from MDF.Chipboard is made in a similar way, but with the addition of binders. It makes sense to find out which is better: chipboard or MDF, with a similar manufacturing method.

Chipboard holds the parts screwed into it much worse, and attached elements often disappear in furniture: there is little joy to see the cupboard door that has fallen off in the kitchen. It is not possible to re-attach the missing part, the holes break easily. MDF has a high density, which eliminates this problem.

Environmental friendliness is also a significant difference. Health care should always come first.

What is better MDF or chipboard for furniture

The question also arises, what is the difference between MDF and chipboard. Chipboard is a chipboard covered with a laminating layer. This has improved the characteristics of the material. You can purchase a ready-made version of the stove, and at a nice price. But the moisture resistance of chipboard is still lower, therefore it is better not to purchase such products for a bathroom or kitchen.

The environmental friendliness of laminated chipboard is low, when buying, we must study the quality certificates

How to install MDF wall panels for interior decoration

The most common finish with this material is wall mounting. Let's study the nuances of the work.

How to fix MDF panels to the wall on the frame

Wall panels can be attached to the frame vertically and horizontally, therefore the placement of the battens is important. If a horizontal orientation is required, then the guides are set to a vertical position, and vice versa.

The frame is fixed over the insulation, and the lathing step should be 500-600 mm.

Important! It is necessary to maintain the exact distance between the guides of the battens!

To set a strict vertical, they use a plumb line, for horizontal - a building level. If possible, it is better to use a laser device, but a regular bubble device will do.

After marking, the guides are fixed, and the first of them should be installed at the junction of the corner or along the floor surface.

The frame can be made of metal or wood. In any case, first you need to conduct all communications under it, determine the locations of sockets and switches

The panels are cut out and marked with a tape measure and a corner, then they are passed along the markings jigsaw or a hacksaw. The panel is fixed self-tapping screws, and on the opposite side, at the intersection with the guides, you need to insert cleats for fixing with staples or nails.

The spikes of the panels are driven into the groove, which itself fixes the plates. The last panel in the corner is cut, but with a gap of 5 mm, and is fixed with self-tapping screws through the plate.

Holes for switches and sockets are pre-cut.

Installation on glue

You can install the panels with glue, which is even easier. But it will not be possible to insulate the room. For the first slab, you need to fill a vertical or horizontal, depending on the orientation of the panels.

Before pasting, the surface of the walls must be primed. The glue is applied to the back side either pointwise or wave-like. The lining is firmly pressed against the wall, then it must be torn off and left for 3-5 minutes. After the time has expired, you must return the tile to its place and hold it for a few seconds still.

Advice! It is better to apply glue to 9-10 canvases at once, press them down and tear them off.

How to mount MDF panels on the floor and ceiling

It is quite easy to install the panels on the ceiling, the main thing is that the surface does not crumble. In work, they use a pencil, a level, a tape measure, a ruler, a puncher, a screwdriver, and metal scissors. You need to purchase profiles, screws and suspension parts, panels themselves, skirting boards, plugs, connectors.

- Assemble the frame using the level and making marks around the perimeter. The distance from the ceiling should be approximately 5 cm.

- Check for hidden wiring with a special device.

- Fasten the starting profile on dowels or self-tapping screws with a fastener pitch of 400 mm.

- Install the ceiling profile by placing it in the starting profile with a step of 400-600 mm. Fix the ceiling profile to direct hangers with self-tapping screws.

- The panels are fastened using the thorn-groove technology. The first plate is fixed with self-tapping screws. The fixing step is about 200 mm. The next tile is inserted into the groove of the previous one and fixed with clamps.

Video: the process of installing MDF panels

Make repairs efficiently and correctly, then you won't have to regret and redo!