How is high-quality soundproofing of walls in an apartment made? Modern materials and their characteristics

DEven in a dream, people perceive any loud sounds. Living in multi-storey buildings becomes uncomfortable. Extraneous sounds are heard not only from the street, but also from neighboring apartments through the walls. To solve this problem, noise insulation of the walls in the apartment is used. Modern materials make it possible to produce high-quality barriers against unpleasant noise effects.

The content of the article

- 1 Noise insulation of walls in an apartment: modern materials and their properties

- 2 Advantages and disadvantages of materials for noise insulation

- 3 Noise insulation of walls in an apartment modern materials: price and varieties

- 4 Soundproofing installation steps

- 5 Soundproofing panels for walls: useful tips

- 6 Video: testing sound insulation materials

Noise insulation of walls in an apartment: modern materials and their properties

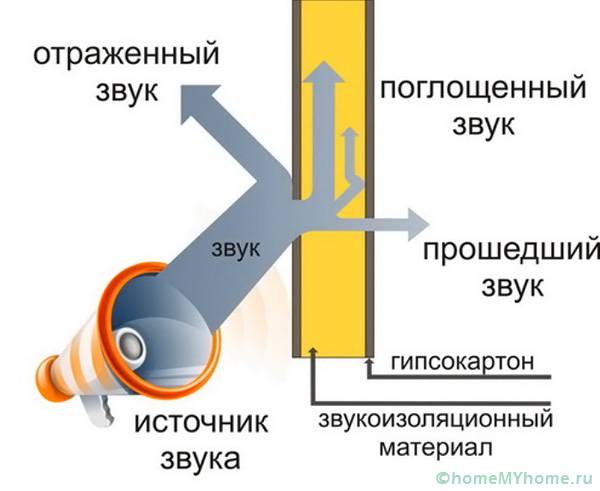

The most common is airborne noise, which manifests itself when passing cars, people talking and working household appliances. Impact noise occurs in the building itself during renovation work.

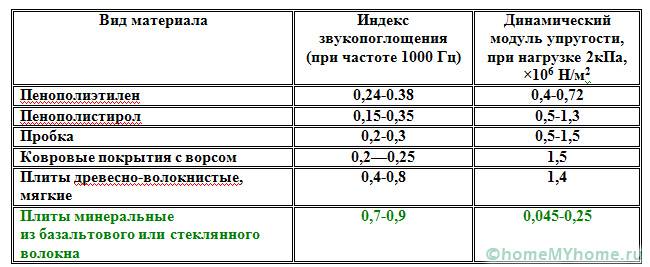

When installing sound insulation of walls in an apartment, modern materials are marked with a special sound insulation index, which allows you to determine how effective the material is against extraneous noise.

There are the following methods to help reduce the sound load:

- wall decoration with plates that are capable of absorbing sound waves, and look like porous layers;

- gluing thin roll plates that reflect sound.

Using a combination of these methods is especially helpful. Soundproofing materials are divided into three main groups:

- hard ones are distinguished by a porous filler, expanded clay, cork or foam;

- semi-rigid are made of polyurethane. This group includes expanded polystyrene and polystyrene;

- soft represent sound insulation made of fiberglass or mineral wool.

Helpful information! Before installing noise-insulating products, it is worth identifying the main sources of extraneous noise. This will allow you to spend less money on the arrangement.

Advantages and disadvantages of materials for noise insulation

Before soundproofing the walls in the apartment, high-quality modern materials are selected. It is important to be aware of the pros and cons of commonly used products:

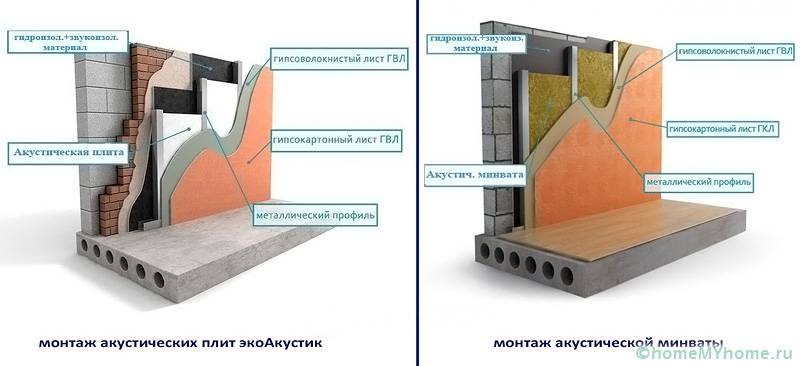

- combination use drywall, layers of mineral wool or cellulose insulation assumes high-quality protection against noise, as well as the creation of additional thermal insulation. The disadvantages include the complexity of the finish and the large thickness of the noise insulation sheet;

- the latest materials include decorative panels, which are made from softwood. They look like wall panels with special fasteners. This material does not require additional finishing;

- special membranes for sound insulation are distinguished by a small thickness of 35 mm. They can be used in combination with other materials. The formations are characterized by excellent density and elasticity;

- polyurethane boards are known for their good sound insulation properties. In this case, the thickness of the material is no more than 15 mm. They are characterized by ease of installation and ease;

- cork has excellent decorative properties and low sound insulation. It can be mounted by gluing;

- Fiberglass panels, which are placed between gypsum layers, have good sound insulation properties.

When selecting a material, one should take into account not only affordability, but also the ease of installation and possible dimensions of the material.

Helpful information! Not all materials for room insulation have sound-absorbing properties.

Noise insulation of walls in an apartment modern materials: price and varieties

Many homeowners make soundproofing of the walls in the apartment. Modern materials, the price of which is notable for their availability, may refer to innovative technologies.

The following recent options can be considered:

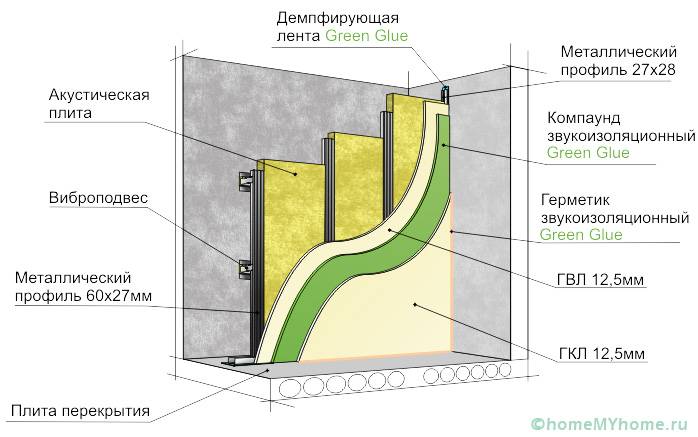

- a viscous mass of Green Glue is applied to the back surface of the drywall;

- the noise block is a thin vinyl material, the thickness of which is slightly more than two mm;

- a polyethylene foam plate is used as an additional material.

It is often not enough to use only one material, therefore, several options are used in one technology. Some soundproofing manufacturers are especially popular.

| Manufacturer | Material | Cost per sq.m., rub. |

|---|---|---|

| ISOVER (France) | Fiberglass | 150-200 |

| Rockwool (Poland) | Mineral wool | 115 |

| Acoustic group (Russia) | ZIPS panels | 1200 |

| Ecophon (Sweden) | Acoustic panels | 700-1000 |

Soundproofing installation steps

Sound insulation of walls in the apartment is distinguished by its effectiveness. Modern materials help to perform high-quality installation. Before conducting noise insulation it is necessary to prepare the surface. After removing the old wallpaper, the sockets are soundproofed.

The preparatory stage involves fixing all pipes to the wall surface. Soundproofing finishing consists of the following stages:

- first, preparatory work is performed, which consists in removing holes and cracks;

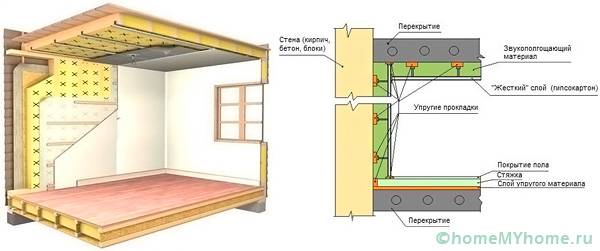

- mounting metal profile using the building level, for this special fasteners are prepared and the use of noise-absorbing gaskets;

- sound insulation is mounted inside the structure;

- sheets of mineral wool or fiberglass are laid between the profiles;

- are attached on top drywall sheets.

When using special boards, they are glued to the wall. A frame is attached on top, on which drywall is mounted. All joints are covered with putty. In this case, the tightness of the fastening of the guide profiles must be taken into account in order to prevent the occurrence of vibration. If panels with decorative cladding are used, then drywall is not needed. A similar material is attached to the wall using liquid nails. If the surface of the walls is not even, then the lathing is performed.

The combined version of noise insulation is effective. It uses two types of material. A membrane can be attached to mineral wool sheets. Then the structure is covered with drywall. Soundproofing with cork panels is made using special glue. The surface of the wall is coated with a solution, and then the prepared elements are pressed against it. Installation is carried out with an offset of half the slab. The styling is very tight. No gaps should appear. Cork details are characterized by aesthetics. After their installation, no additional finishing is required.

Helpful information! A good soundproofing effect will be achieved by using two sheets of drywall.

Soundproofing panels for walls: useful tips

Soundproof panels for walls allow you to quickly and efficiently install sound insulation. Such materials have the following advantages:

- light weight, one person can handle such panels;

- ease of installation;

- good noise protection and excellent thermal insulation properties;

- panels are easy to handle.

Soundproofing elements are characterized by their versatility. They can be used in any premises: apartments, industrial buildings and residential buildings. Such panels are produced by pressing and processing using different temperature conditions. The products have a small thickness and are mounted on the wall with dowels. In this case, the joints are sealed with putty. This material is made on the basis of fiberboard.

Compliance with the technology of all layers allows you to create a durable and high-quality structure

Helpful information! For best results, the panels are installed on the noise side. Finishing is done not only on the walls, but also on the ceiling and floor.

If done correctly, noise isolation can be the best solution to eliminate extraneous sounds.

Video: testing sound insulation materials