Soundproofing the ceiling in the apartment under the stretch ceiling with your own hands

INit is difficult to achieve high-quality sound insulation in urban houses. Extraneous sounds especially bother residents of panel houses, in which the requirements for sound insulation are lower by definition. In order to make their apartment comfortable and provide silence, the owners have to take care of the soundproofing on their own. Noise insulation of the ceiling in an apartment under a stretch ceiling is the easiest to mount, since no additional strength requirements are imposed on the insulating layer.

The content of the article

Video: sound insulation of stretch ceilings

Types of noise insulation under a stretch ceiling

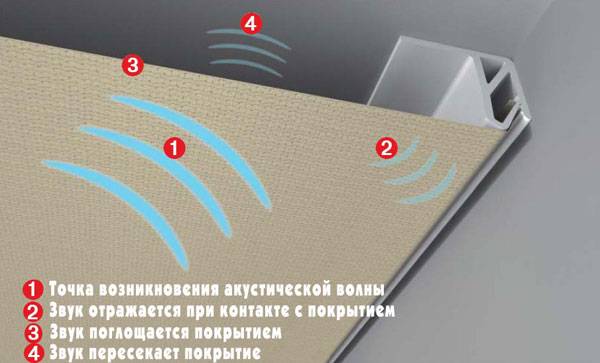

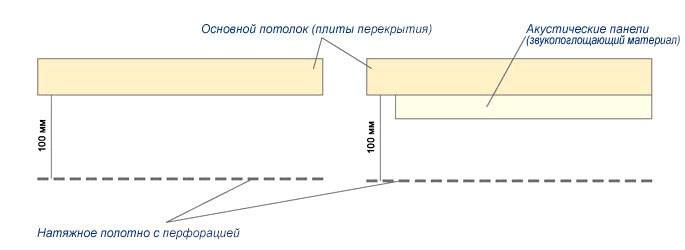

Modern construction technology involves the use of metal-reinforced structures. Steel perfectly conducts any sounds, while vibration is transmitted to the entire structure. In apartment buildings, floor panels become the main conductors of noise. Stretch ceilings are a design that assumes the location of the canvas at a certain distance from the floor slab, while a gap of sufficient width is formed for the device of high-quality sound insulation.

Soundproofing the ceiling in an apartment under a stretch ceiling is the easiest thing to do, since no other type of ceiling gives such freedom of choice of insulating materials.

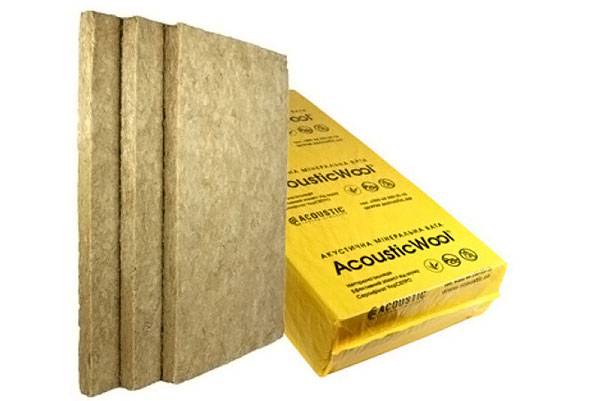

Mineral mats

For insulation work, porous materials are suitable, which are also excellent insulation materials. Insulation boards, which are widely used in construction work, can serve as excellent sound insulators, since their fibers absorb sound waves. Soundproofing the ceiling in an apartment under a stretch ceiling is most often performed using this type of materials.

Mineral materials based on fiberglass or basalt have a number of positive qualities:

- resistant to combustion, does not melt, does not emit hazardous gases;

- has a high coefficient of absorption of sound waves;

- repels insects, fungi and mold do not develop on it, even if moisture gets in.

Styrofoam

Polyfoam is a lightweight and easy-to-use porous material, with which you can save residents from extraneous sounds and significantly insulate the room. Polyfoam is easy to work with, it is lightweight, easily and quickly fixed to the surface.

Since the foam boards are rigid in shape, fastening can be done without glue, only with dowels. Due to the rigidity, the surface of the foam can be plastered or pasted over with additional layers of materials, which improves the quality of sound insulation. With all the advantages, noise insulation of the ceiling in apartments under a stretch ceiling from foam is rarely done, since it has a significant drawback - flammability. When exposed to fire, it instantly ignites, burns with the release of a huge amount of heat and poisonous gases.

Acoustic foam mats

Acoustic foam rubber is mats with a special surface shape. The tapered projections and recesses themselves serve as effective sound absorbers, and when combined with a porous material such as foam, the effect of these mats becomes very noticeable. Profile height ranges from 2.5 to 10 centimeters, the pattern resembles an egg cassette.

Installation is carried out using a special adhesive, and the work does not require special preparation or physical strength. The only drawback of the material is flammability, the foam rubber flares up instantly and when burning it melts and drops red-hot drops of polymer, which is why the use of foam rubber as an insulator is limited.

Roll soundproofing

A thin, strong and flexible polymer that often has a factory-applied adhesive layer. Installation of such a soundproofing is quick, additional fixing with dowels is performed with a large step, which speeds up the process. The thickness of the roll material is not large, therefore soundproofing can be performed even in confined spaces. The soundproofing of the ceiling made of rolled materials in the apartment under the stretch ceiling is made on a mineral basis, and a polymer is used as a binder, so the insulator does not ignite immediately, burns very slowly, does not form drops and pungent smoke, which makes it ideal in terms of fire safety.

Stages of installation of sound insulation

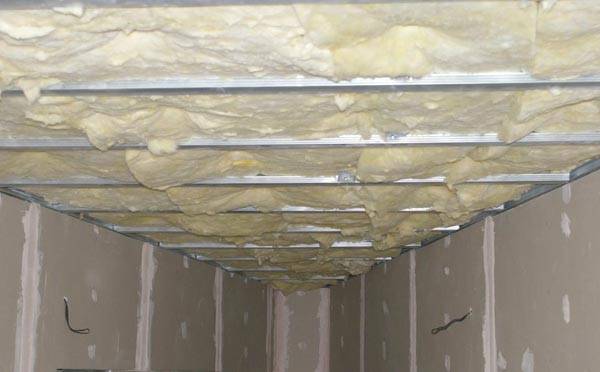

The installation method is selected depending on the type of soundproofing material. Rigid panels, such as polystyrene, are fastened using special dowels, soft mats - basalt slabs - are mounted using wooden guides, and glue is most often used to fasten roll insulators. Despite the general recommendations, in each case it is necessary to develop an individual method of work.

Fastening with polymer adhesives

For each type of material, special adhesives have been developed that provide high-quality adhesion, but at the same time do not destroy the sound insulation itself. Mineral slabs and glass wool are amorphous materials, the only ones that are not destroyed by aggressive chemical compounds, so the composition of the glue is not particularly important for them. Styrofoam and foam rubber corrodes acid, which may be contained in some formulations. Roll materials are also planted only on the glue recommended by the manufacturers.

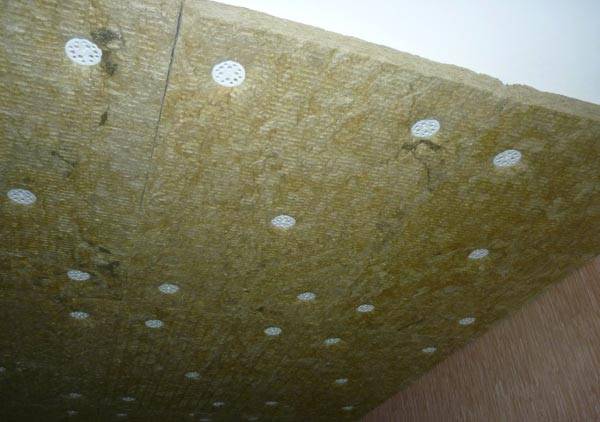

Fixing with dowels

For soundproofing and insulation, a special method of fastening is used - with the help of mushroom dowels.

With this method of fastening, the main thing is to correctly calculate the step. If the insulating material is lightweight and rigid, then the dowels can be placed no more often than every 60 cm. It is better to fix soft mineral plates more reliably, reducing the pitch to 30-40 cm. Usually such dowels are used in conjunction with glue, such fastening will be especially reliable.

As a rule, the installation of the ceiling frame is carried out after the sound insulation has been installed. The maximum width of the insulating layer is 10 cm.

Choosing the optimal wiring diagram

When choosing a mounting scheme, you should pay attention to the following points:

- ensure a snug fit to the base, fix the materials only on the floor slab cleaned of finishing, so the quality of sound insulation will be significantly higher;

- ensure sufficient strength so that during operation, in the event of water ingress or over time, the insulating material does not lag behind the overlap.

Video: how to make heat and sound insulation of the ceiling