Stomp in a good way: laying paving slabs in the courtyard of a private house with photo examples

Organization of the landscape no less important than interior decoration. Therefore, it is necessary to choose a quality material for decoration. Topic of today's publication: paving slabs in the courtyard of a private house. Photos of interesting options will help you make the right choice. The HomeMeHome editorial team will consider the main types of decor, their sizes, and processing technologies with all the details.

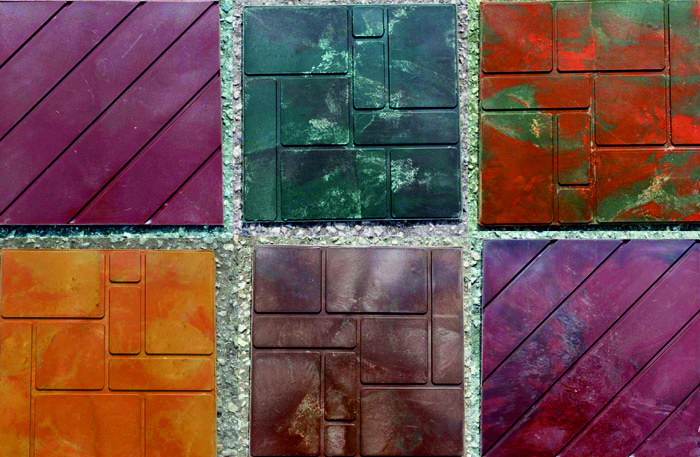

An interesting pattern can also be created with the help of unremarkable street tiles.

PHOTO: keramokub.ru

The content of the article

- 1 Production of paving slabs: its features

- 2 The main types of paving slabs with photo samples

- 3 What are the sizes of modern paving slabs

- 4 Paving the yard with sidewalk tiles

- 5 Paving slabs for paths in the country: an overview of models and prices

- 6 What paving slabs to choose: opinion of the homemaster.techinfolux.com/en/ editorial staff

- 7 Molds for making paving slabs with your own hands: video

- 8 Paving slab laying technology

Production of paving slabs: its features

In the manufacture of durable paving slabs, they always try to use high-quality building materials. These include sand, cement, sometimes a dye (when producing a decorative version).

Usually professional factories are engaged in this manufacture. Sometimes, even at home, a similar design system can be organized. For these purposes, special machines are used, with the help of which it is possible to obtain various models and collections for the manufacture of paving slabs.

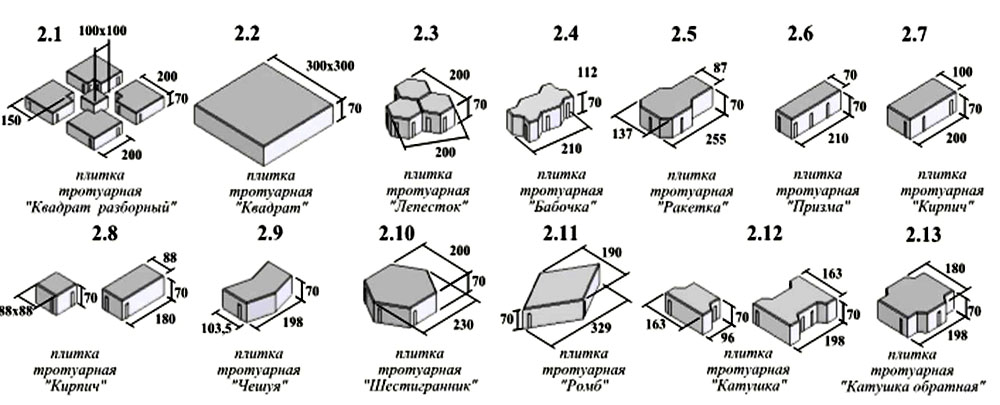

The main types of paving slabs with photo samples

Depending on the method of creating this building material for landscape design, various technologies are used. Some are considered budgetary, while others are highly rated. However, the latter, as a rule, are of higher quality and durability. Let's consider in more detail the existing types.

Vibrated paving slabs paving stones

It is made using the method of the same name - vibration casting. This finished design is more suitable for yard paths. The essence of the production method is as follows: the solution is poured into a special mold.

Under vibration, it gradually crumples and dries up, after which the form is replenished. When the specimen is ready, it is placed in a drying chamber.

Related article:

Garden paths with your own hands at low cost. From a separate publication, you will learn how to make a garden path yourself, spending a minimum of money and time.

Vibro-pressed paving slabs

With the help of vibrocompression, it is possible to obtain a truly durable structure. This will withstand not only a person, but also the mass of a massive vehicle. This option is distinguished by a long service life and frost resistance. Usually the surface of the material is rough. May have different pigments.

The strength state of such a material can be checked by striking two combined tiles.

PHOTO: lesoprodukt12.ru

However, this tile has some drawbacks. These include the limited size and shape, as well as high cost.

Polymer sand and rubber paving slabs

One of the unusual ways of forming landscape material. The technology consists in thorough sifting and calcining the sand. Polyethylene is subsequently added to it. This mixture lends itself to heating up to a limit of 250 ° C. After that, the collection is sent to the press right in the forms.

This tile is painted by adding a few drops of pigment to the still uncured solution

PHOTO: wasteinfo.ru

This model is resistant to sudden temperature changes, is capable of being in frost for a long time, and does not absorb moisture at all. Therefore, the service life of such material is quite sufficient.

As for the rubber options for street finishing of the territory, then recycled car tires serve as the basis for their creation. The latter are turned into crumb rubber, and then mixed with the required amount of adhesive. This solution is placed in a press, and subsequently the prepared boards are dried.

They try to create such options bright and interesting. They are usually used for laying in playgrounds.

PHOTO: yandex.uz

A low-quality rubber-based material usually gives itself out on quick melting in the sun.

Natural stone tiles

Such a model is obtained by crushing real natural material. This produces fragments of the desired size.

Granite, shungite, slate are used as the basis for manufacturing. The disadvantage of such a product is that at the time of laying and paving, too wide seams are obtained.

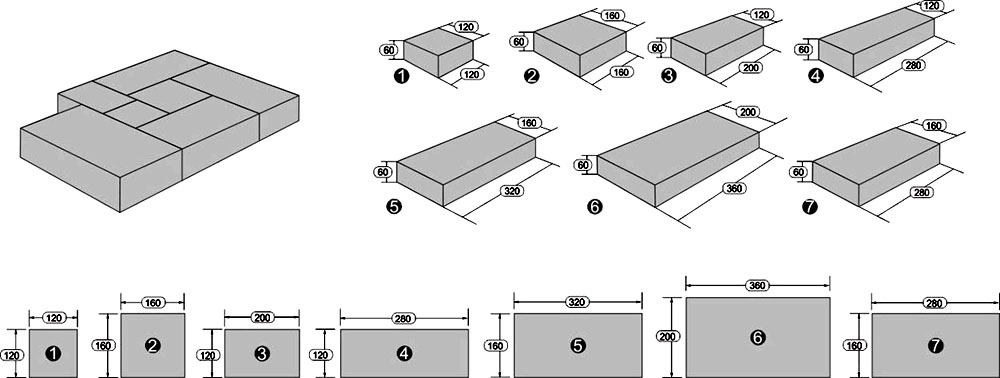

What are the sizes of modern paving slabs

As a rule, they try to produce tiled street material in strictly designated formats, which are described below.

- Paving slabs 300 × 300 × 30 mm. It is a square, which can have a different structure and pattern. Mostly available in gray and red shades.

- Paving slabs with dimensions of 500 × 500 × 50 mm. Such models are convenient not only for wide courtyard paths and entrances. They can be used to organize a high-quality and durable blind area.

- Tiles 400 × 400 mm². Designed exclusively to improve the paths to the cottages and other oversized parts of the courtyard areas.

- Material with dimensions of 100 × 200 mm or 100 × 100 mm² is an excellent option for laying narrow sidewalks under a fence near a house. You can also use this option instead of asphalt when organizing entrances or parking lots.

As for the height, this parameter varies. The minimum size is 3-5 cm.

Paving the yard with sidewalk tiles

Not everyone knows how to properly lay paving slabs in the yard. However, regardless of the shape or design of the raw material, different paving options can be applied. For the private sector, there are several of the following types.

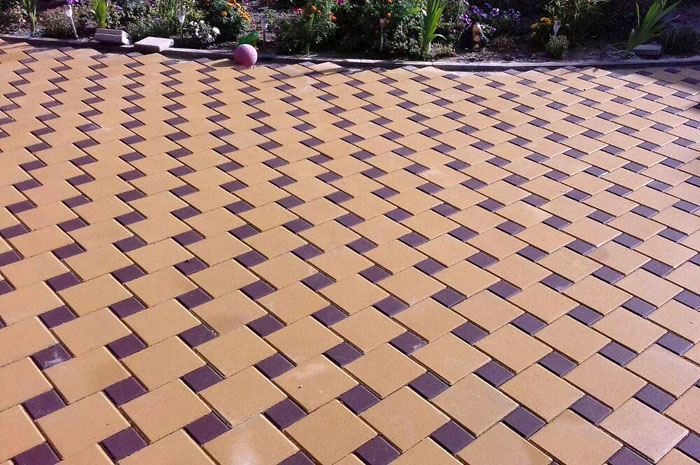

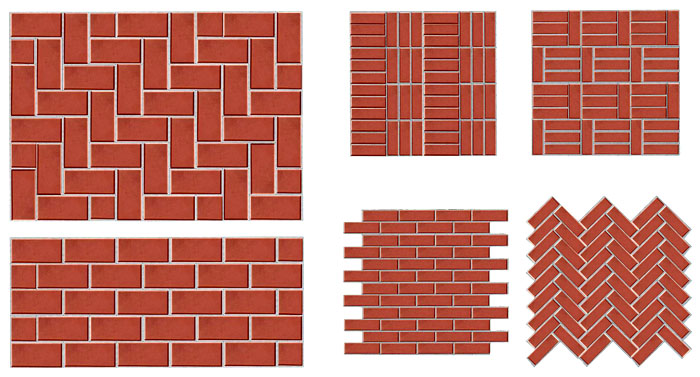

Herringbone and braid

With the help of these technologies, unusual patterns are created that cannot be repeated by friends and acquaintances without knowing some secrets. For example, a herringbone paving model.

This is a simple construction. It is created by laying the tile material at an angle of 45º or 90º. This option will be available subject to the use of narrow rectangular tiles.

Paving slabs are one of the most interesting and designer ones. A cheaper option is to come up with weaving from two colors of the material yourself. If you do not want to work on this process, there is always the opportunity to purchase raw materials with a ready-made pattern.

On a note! If there are irregularities and holes in the yard, which is lined with paving slabs, they must be removed: cut off or add soil.

Randomness and chess

The chaotic pattern is considered one of the simplest. It does not require a special approach. Even if you make a mistake when laying a colored tile, against a general gray background, it will be invisible. However, this decor option is suitable for long, wide paths. Unfortunately, not everyone has one in the yard.

For staggered tiling, it is recommended to use material of the same shape and size. It is desirable that they have contrasting shades. Such a yard never gets old, looks elegant and attractive.

Volumetric compositions and circular order

If you need to create a visual volume in a certain area of the local area, you should use different paving technologies and play of tile shades. Even resizing the raw material itself is encouraged.

To accurately implement this figure, you need a preliminary marking of the territory. The dimensions and diameter of the future pavement circumference must be determined.

Paving slabs for paths in the country: an overview of models and prices

Among the wide range of tile products, it is very easy to get confused when choosing. Therefore, our editors recommend that you pay attention to several successful collections in the next section.

Paving slabs FELDHAUS KLINKER

Clinker option or paving stones. Has a yellow-sand tint, all the details of the collection are similar in tone, are not contrasting. This option is suitable for decorating courtyards in summer cottages.

The advantages include:

- high strength;

- elementary installation;

- moisture resistance;

- the possibility of laying on solid ground.

The option is suitable for installation using several different technologies.

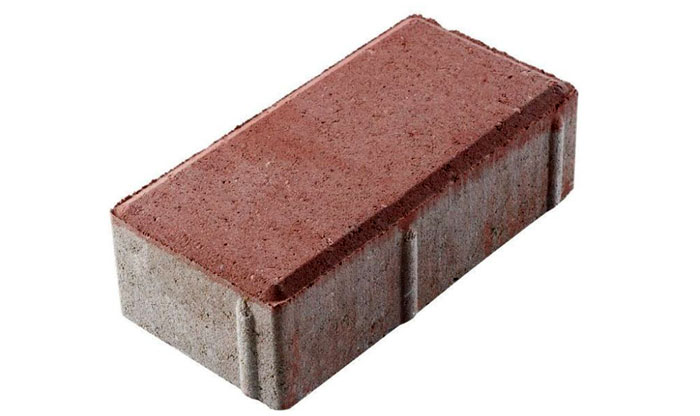

Paving slabs (paving stones) Abc

High quality German model. Available exclusively in gray or brown. Withstands heavy loads, frost and moisture resistant.

The main advantages include:

- high strength grade;

- attractive appearance;

- safe surface.

The standard size of one such tile is 200 × 100 × 40 mm.

Rubber tiles 500 × 500 mm²

The model is commercially available in several different shades.The thickness of this material is 30 mm. Suitable for arranging children's playgrounds in the yard.

The pluses include:

- increased moisture resistance;

- warranty period 10 years;

- the presence of a rigid base for laying.

Withstands temperature extremes ranging from + 60 ° C to -45 ° C.

How much paving slabs will cost depends on the material processing technology.

What paving slabs to choose: opinion of the homemaster.techinfolux.com/en/ editorial staff

After weighing all the advantages and price categories of the declared models, our experts noted that the Abc model, which is made in Germany, is considered the most durable. It will be an excellent decoration for the yard and will serve for many years. As for the rubber options, it is advisable to mount them only in areas where children play.

Molds for making paving slabs with your own hands: video

If it was decided to create the tile material with your own hands, then you can not do without special forms. The most detailed information can be found in the video review below.

Sometimes skillful craftsmen and lovers of fantasizing get by with improvised means.

Paving slab laying technology

If you have a question of how to lay paving slabs with your own hands, you must act according to a special principle. If all the requirements are met, the surface of the site is perfectly flat and attractive.

Related article:

Laying paving slabs with step-by-step video instructions. A practical step-by-step guide to self-laying tiles in a separate material on our portal.

Site preparation

Before laying the paving slabs with your own hands, you must completely prepare the site. For this, all irregularities are removed, if necessary, soil is poured. In short, a perfectly flat surface is created. To do this, work with a level.

Depending on the functions of the site, the size of the preparation site will vary. Usually its depth is no more than 20 cm, while the parking space should deepen by as much as 27-30 cm.

Important! The cost of laying paving slabs includes preparation for work.

After preparing the pit, the soil is compacted quite tightly. It is watered from a hose with a sprinkler, after which it is passed by a special machine (rammer). This approach is essential for the durability of the coating without subsidence. Depending on the conditions in which the site is located, there will be a price for laying a square meter of paving slabs.

Laying paving slabs with your own hands

Before you lay the paving slabs with your own hands, the enclosing curbs are initially installed. Together with this, they are considering the arrangement of the drainage system. Her role will be played by the graphy of the small faction. It is poured with an even pillow, at least 8 cm thick. Then they act in stages.

- First of all, the paving slabs are laid out in the preferred pattern. It depends on which product option was chosen. Due to the fact that most tiles have straight edges, a lot of installation patterns can be used.

- Preparation of all tools and materials. For paving, you need to have cement, sand, curbs and tiles on hand. A nylon thread is useful for installing beacons, and a rubber hammer will help tamp the tiles into the ground.

- Preparation of the base. It has a special circuit. For this, building materials are laid in several layers. The level of sand poured over the ground is 3-4 cm, the next layer is crushed stone (2 cm), again a sand pillow (2-3 cm), a cement-sand mortar is 3-5 cm.Otherwise, all layers may vary depending on the condition of the soil.

- Directly installation. The main condition is that paving slabs are laid on a dry concrete base exclusively from oneself. This will not break the level of the pillow.

- At the end of the work, all layers are covered with sand or masonry mixture. Each tile is carefully swept with a lush broom. After that, you need to rinse the yard well with a watering can and dry the area.

In general, these are all the requirements that must be observed with the correct laying of paving slabs with your own hands. As you know, in some cases it is possible to deviate from the norms if the soil is sufficiently dense and does not have an aquifer nearby.

Dear readers, we have talked about the most important points of how to lay paving slabs. Do you have your own opinion or personal experience? Do not hesitate, tell us, we will discuss in the comments.