DIY step-by-step siding installation: instructions for dummies

When finishing facades it is necessary to choose a material that will provide a high degree of protection of the walls from the negative effects of the environment and will be able to maintain decorative properties throughout the entire period of operation. That is why many people choose siding for finishing not only new buildings, but also for the restoration of erected buildings and objects. The simple assembly technology of the "constructor" type will allow you to quickly and inexpensively complete the installation of siding with your own hands - the instruction for dummies describes in detail all stages of work.

The popularity of siding can hardly be overestimated due to its versatility, accessibility and aesthetics.

The content of the article

Advantages of using panels for facade decoration

Finish withiding panels buildings, in comparison with other materials, has the following advantages:

- High resistance to negative external factors: atmospheric precipitation, sudden temperature changes, some chemical compounds and ultraviolet radiation. The material retains its strength and decorative properties throughout the entire period of operation declared by the manufacturer.

- The structure of the sheathing and lathing has a minimum weight, which allows finishing objects with unburied foundations without additional reinforcement of the supporting structure.

- No need to level the facade walls thanks to the installation on the battens. This significantly reduces the time of work, and also allows you to lay heat and waterproofing layers in the space between the wall and the siding.

- The undemandingness of the veneer to care or any maintenance.

- High level of fire safety and resistance to minor mechanical stress.

- The presence of a wide range of decorative colors will allow you to choose the necessary one without any problems and make a unique design of the house, without spending money on purchasing and painting in the desired color. Moreover, unique textured images with imitation of natural materials are also available, characterized by clear and rich patterns.

- Simple installation technology available for development to people who have not previously encountered construction work.

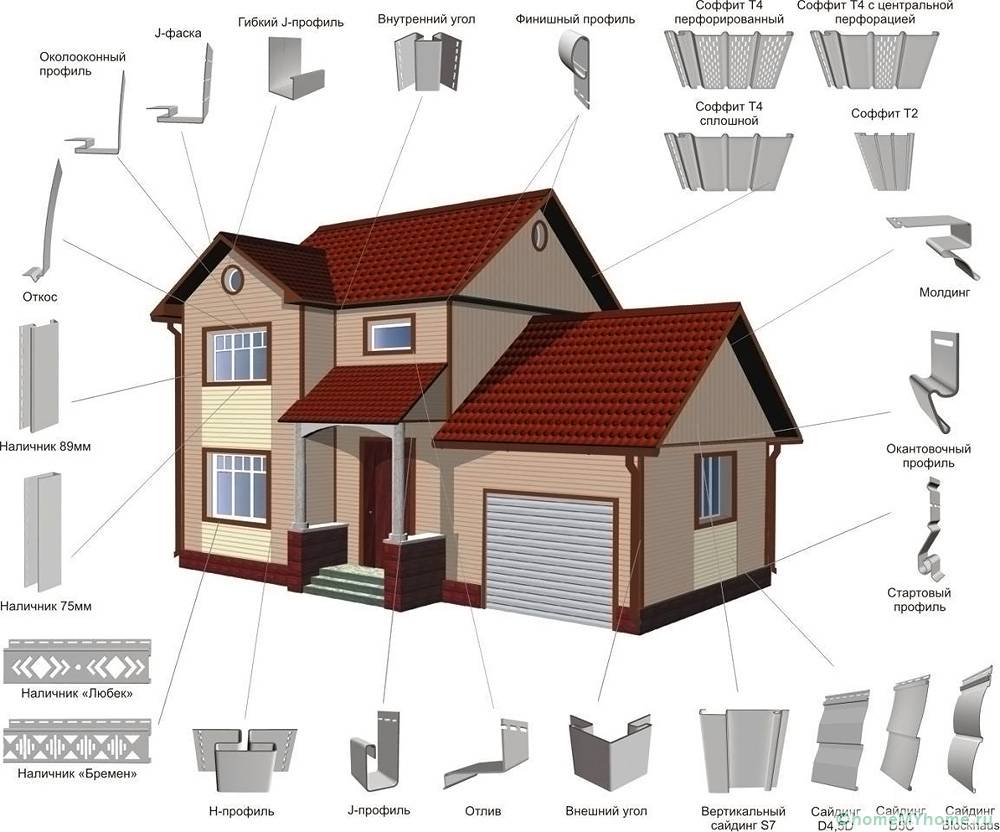

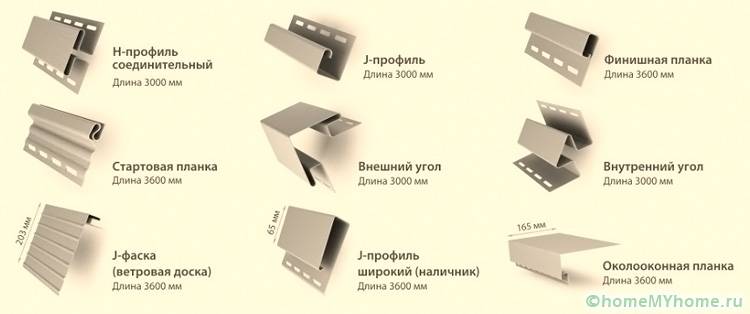

Types of additional components

In order to simplify the installation of facade cladding, a lot of additional components are produced, designed to ensure tight abutment to various elements of the house, assembly of surfaces of complex shapes, as well as reliable engagement with the main wall. material.

Important information! The material of the components must match the siding in order to maintain uniform thermal performance and prevent deformation due to differences in thermal expansion coefficients. Therefore, it is recommended to use only original accessories and fasteners.

List of additional components:

- The starting and finishing strip allows you to avoid distortions and other errors during installation, as well as improve the decorative properties of the finish.

- Corner elements. Designed to decorate the corners of the building and hide the crate. Protect from the ingress of dust and moisture on the inner surface of the panels.

- Window and door platbands are designed for finishing the adjacent openings. J-profiles can also be used for these purposes, but they have inferior aesthetic properties.

- Window and door profiles are used for finishing and protecting slopes from the external environment. Due to their use, slopes look natural and aesthetically pleasing.

- J profile. It is used for fixing the side-by-side panels. It has versatility, therefore, it is also used instead of platbands, finishing and corner profiles, even though there are specialized elements.

- J chamfer. Special element designed for installation as a curtain rod. It is a specialized replacement for the J-profile in the installation of a roof connection.

- Ebb tide. They are used to remove moisture from the roof, as well as decorate window and door openings.

- Ceiling spotlights... Designed for finishing ceilings of open structures: verandah, terraces, summer kitchens, etc. Can be made solid or perforated. They perform not only decorative functions, but also provide ventilation of the space between the wall and the siding along the crate, and also protect the internal structures from pests.

- Moldings. Used to connect horizontal and vertical panels.

- H-profile. It is used to extend panels along the length.

Without these elements, it will not be possible to sheathe the house with high quality and beautifully

Siding installation price per m2 for work

Siding of objects with the involvement of professional teams of builders will be performed efficiently and in the shortest possible time. At the same time, it is not necessary to order the execution of a full range of works, but only individual services are enough.

The cost of work will depend on the following factors:

- The number of window and door openings, the cladding of which requires a significant waste of time and the use of special additional elements.

- Wall areas.

- The complexity of the work. This concept includes the presence of walls with complex plane transitions, the need to install insulating layers, the type of wall material and other factors.

- The type of material selected.

In each case, the miscalculation will be performed by a specialist of the selected company.The table below shows the prices for siding installation, price per m2 to work.

The approximate cost of carrying out the main and auxiliary work during the installation of siding for Moscow| Facade works | Unit rev. | price, rub. |

|---|---|---|

| Installation of vinyl siding on walls | m2 | 250 |

| Installation of vinyl siding on roof hemming | m2 | 300 |

| Installation of fiber cement siding | m2 | 680 |

| Installation of hydro-vapor barrier film | m2 | 60 |

| Installation of wooden lathing on wood | m2 | 100 |

| Installation of wooden lathing on brick or concrete | m2 | 200 |

| Installation of insulation 50 mm | m2 | 90 |

| Insulation installation 100 mm | m2 | 170 |

| Fire-bio processing of a bar | running meters | 14 |

| Fire-bio treatment of wood surfaces | m2 | 80 |

| Fire-bio processing boards | running meters | 19 |

| Installation of metal sills | running meters | 100 |

| Installation of ventilation grilles | PC. | 140 |

Preparatory work

Before carrying out the installation work on the facade cladding, it is necessary to carry out a number of preparatory work. They include the following stages: the choice of the type of panels and lathing, the calculation of materials and additional elements, as well as the determination of the number of thermal and waterproofing layers.

Panel type selection

The choice of material for cladding largely determines the service life of the entire structure, strength and performance characteristics. The choice is currently limited to the following options:

- Wood. Differs in a high level of thermal insulation, environmental friendliness and excellent decorative qualities. Its cost is minimal compared to other types of siding. However, it has a short service life (up to 8 years) and requires periodic maintenance (treatment with antiseptics and painting).

- Metal. It has strength and durability, resistance to mold, fungi and pests, and is also able to withstand significant temperature changes. It is very sensitive to damage, since even a small scratch on the protective layer can lead to the onset of corrosion processes.

- Vinyl. It is the most profitable option, as it is devoid of all the disadvantages of wood and metal siding. It has a minimum weight, is resistant to any precipitation, is environmentally friendly, and has a maximum service life of up to 50 years. Differs in the presence of a wide range of colors. With such advantages, the cost of this material is relatively low, therefore it is it that experts recommend choosing it. Do-it-yourself video of vinyl siding installation will allow you to appreciate all the advantages of this material.

Calculation of the amount of materials

The amount of material can be calculated quite simply if you have a building project on hand. Otherwise, you will have to measure the length and width of each of the walls, as well as window and door openings. Based on the data obtained, a sketch or drawing should be made. After that, the amount of material that will be used to create the lathing is determined, taking into account the uniform arrangement of vertical or horizontal guides with an interval of 40-50 cm and fastenings along the guides with the same interval.

Helpful information! It is possible to use the project of the building for calculations only if it was erected no later than 2-3 years. This is due to the possible appearance of defects on the walls (for example, cracks caused by the subsidence of the foundation), which, after elimination, can cause the walls to widen by several centimeters. When installing the facade cladding of a building, this is critical because you will have to find a way out of the situation already during the installation process.

After calculating the amount of materials for the lathing, you need to calculate the number of panels. This can be done quite simply by dividing the total area of the walls, minus the areas of the openings, into the dimensions of one panel. It is recommended to add a margin of about 10-15% to the obtained value, which will take into account possible damage during delivery or installation.

It is recommended to create a list of additional elements with an indication of their quantity, so as not to forget to purchase them at the same time as the cladding panels.

Calculator for calculating the amount and cost of siding per home

List of required tools

For installation work, you will need the following tools:

- Metal shears for cutting trim strips or guides.

- Bubble or laser level to check the correct position of the panels.

- A screwdriver with a set of bits for self-tapping screws for fastening the battens.

- Chalk or marker for marking.

- Building corner to get even corners.

- Plumb line and rope for adjusting the position of the guides when installing the battens.

Preparing walls for installation

First you need to dismantle the roofing, window and door parts that protrude beyond the plane of the wall: skirting boards, ebb, drainage pipes with fixings from the roof, etc. This will allow you to get unhindered access to the walls. If any finishing layers have been installed or applied, then it is also recommended to clean them up to the main wall material.

A thorough inspection of the strength and reliability of the supporting structures will ensure that there are no problems during the operation of the siding, which are associated with the implementation of its complete or partial dismantling. If cracks, irregularities or other defects are found, they will need to be eliminated.

DIY siding installation - instructions for dummies

After the successful completion of the preparatory work, you need to plan the installation work. To do this, you need to place building materials near the object in order to have convenient access to them. The stages of installation work are as follows:

- Installation of the crate.

- Installation of profiles

- Installation of additional elements.

- Paneling.

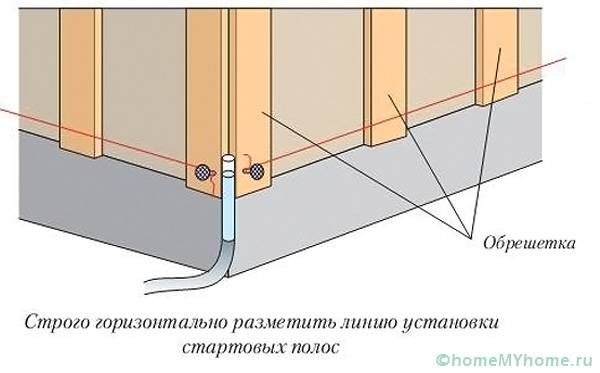

Installation of crate

It is recommended to install the cladding panels horizontally, since with this arrangement it is quite easy to build up the cladding. Therefore, the lathing guides must be vertical. Of course, vertical cladding is also allowed, but in this case, the appearance of the building will have an unaesthetic appearance due to the visual effect of narrowing the walls.

Installation of lathing for siding can be performed on nails, dowels or screws, depending on the material of the walls. First, the wall is marked with chalk or a marker, in accordance with the drawing made during the calculations. When attaching to dowels, we pre-drill holes in the wall.

We install the slats from one of the corners of the building. First, we fix the upper part, then align the position vertically using a plumb line. Then we finally fix the guide. Then, along the lower level of the fixed rail, we pull the rope in a strictly horizontal position to simplify the alignment of all subsequent rails.

The subsequent slats are installed according to the marking with control of their position.

Important information! All lathing guides on each wall must be located in the same plane. Any distortions, even minimal ones of more than 2-3 mm, are unacceptable, since these defects will appear on the siding in the form of a deterioration in the aesthetics of the appearance or the impossibility of fixing the planks properly.

If it is required to install a hydro and thermal insulation layer, then this should be done on top of the installed crate. In this case, the waterproofing is laid over the walls and crate, then insulation mats are tightly inserted into the gap between the guides and, if necessary, closed with a second layer of waterproofing.If expanded polystyrene or polystyrene is used as insulation, then you can save on waterproofing, but pay special attention to the joints and abutments so that the gaps are completely absent. Instructions for dummies for installing siding with their own hands must take into account hydro-vapor barrier device before installing the facade material.

Related article:

Insulation for the walls of the house outside for siding. How to choose a high-quality insulation and what types exist? Read more in a separate publication of our portal.

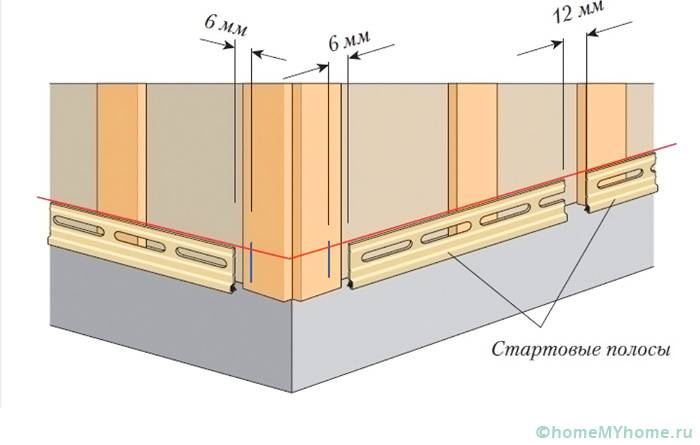

Installing profiles

On top of the lathing we install J-profiles on which the facing panels will be attached. Since all structural elements were strictly aligned along a stretched horizontal rope, there will be no problems with the installation of the profiles.

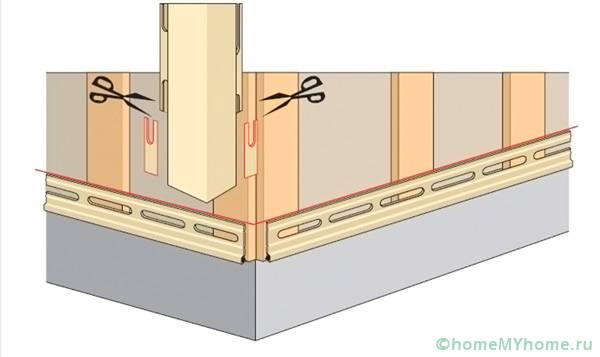

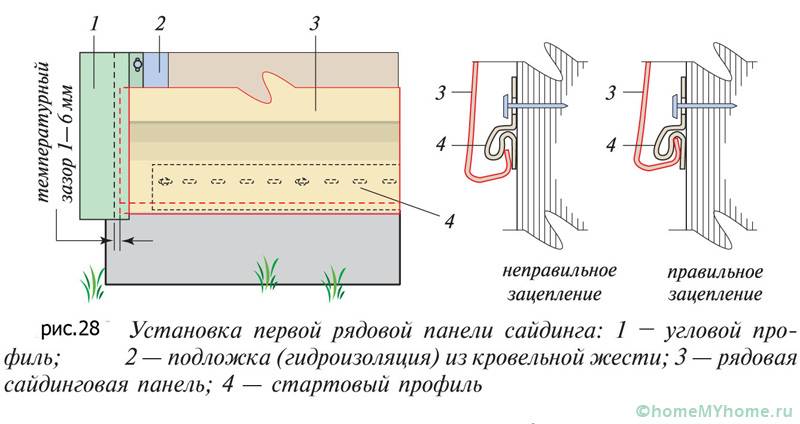

We start the installation from the bottom of the structure. We take the starting profile and fix it at a height of the crate of 5 cm, having previously screwed two self-tapping screws at this height on both sides of the wall as a guide. At the same time, we provide enough space for the installation of corner profiles. You can cut off the excess part immediately after fixing or before installation. Self-tapping screws or nails should be placed approximately in the middle of the special hole for securing the profile.

Helpful information! An interval of 8-10 mm must be respected between the horizontal and corner profiles, which will take into account the thermal expansion of the metal. The indentation can be omitted if you correctly cut the corner profile in the right places, and then cover the cut lines with a protective layer.

After fixing the starting profiles, we proceed to installing the external corner profiles. First, we mark the soffits to determine the edges of the elements, and then install the corner profile with a gap of 3 mm to the soffit or roof. We fasten it in the same way as for the starting bar. Be sure to center the profile before tightening. Internal corner profiles are mounted in the same way as external ones.

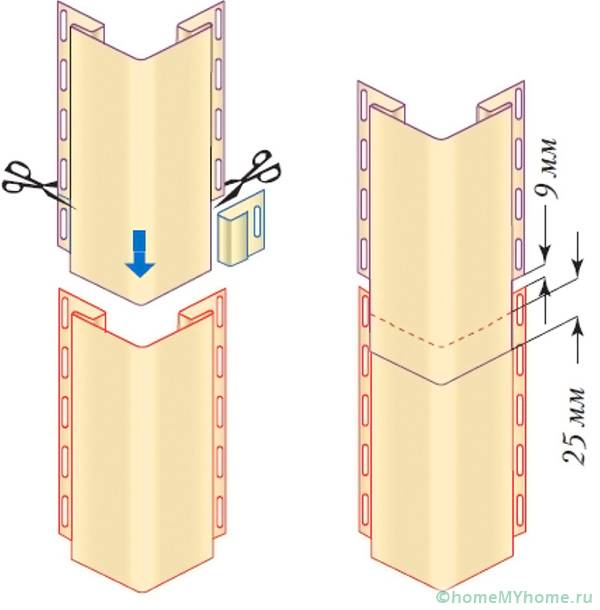

In some cases, when the height of buildings is from one floor along the length, the corners can be more than 3 m and it becomes necessary to perform a profile extension. In such situations, it is necessary to trim each subsequent profile so that it can be inserted into the previous one. To do this, use metal scissors to cut off the side parts for attaching the siding, leaving only the front corner part. The cutting length must be at least 25 mm. Additionally, you will need to leave a gap between the two elements of about 9 mm.

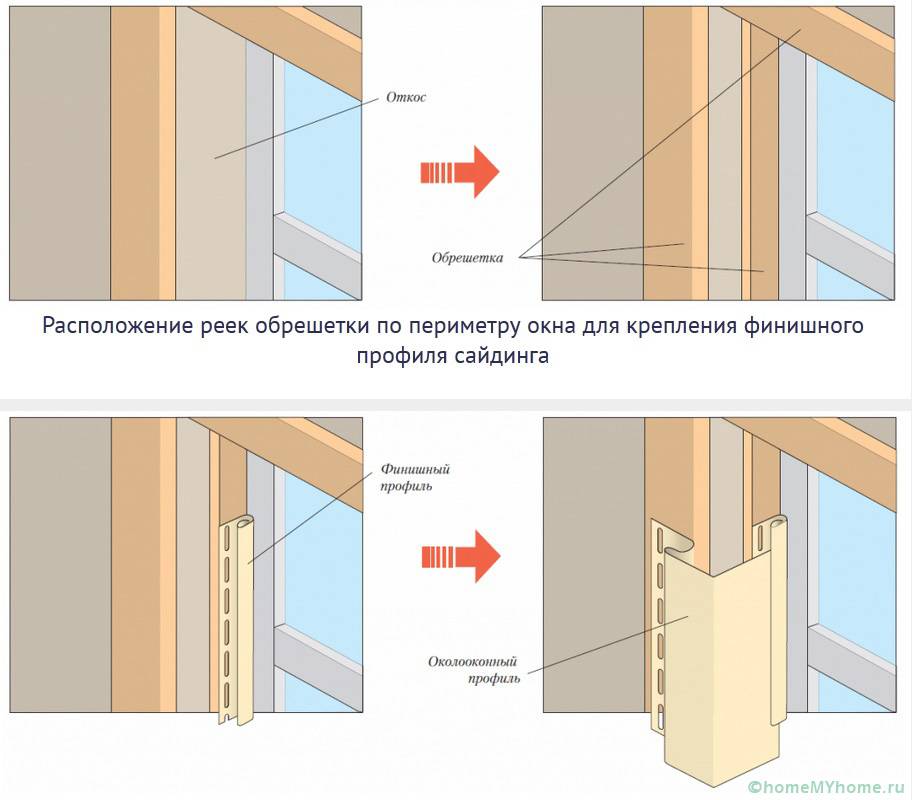

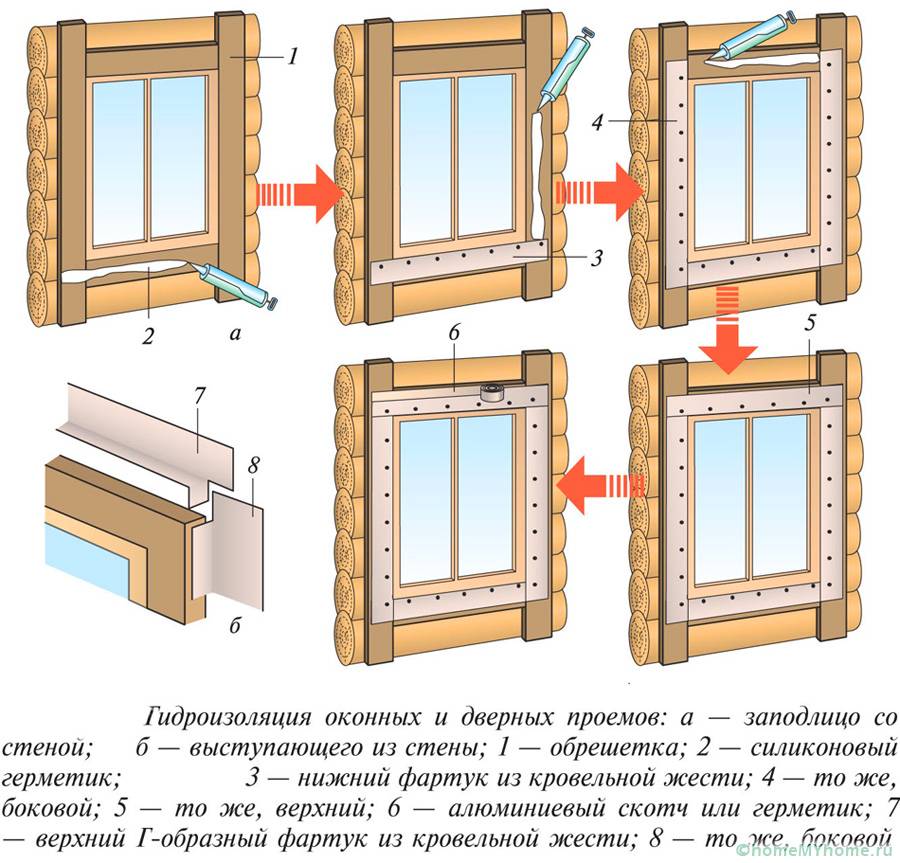

Installation of additional elements for window openings

Windows in various types of buildings can be installed in various types of openings, which determine the method of installation and the use of additional elements. Therefore, the installation of near-window siding strips has the following features:

- With the dimensions of the slopes of the opening more than 19 cm, it is necessary to fix the outer corners around the perimeter and mount the facing strips on them. Outside slopes are decorated with standard elements. In some cases, they need to be trimmed slightly. Insert the cladding panel into the corner profile and the locking connection of the starting strip, and then fix it to the crate.

- If the size of the slope is from 5 to 19 cm, then Euro-planks with a standard length of 220 mm are used for the installation of siding in the upper and lower parts, which are cut off in place. In order to save money, the use of J-profiles and plastic linings is allowed. Mounting is similar to the first option.

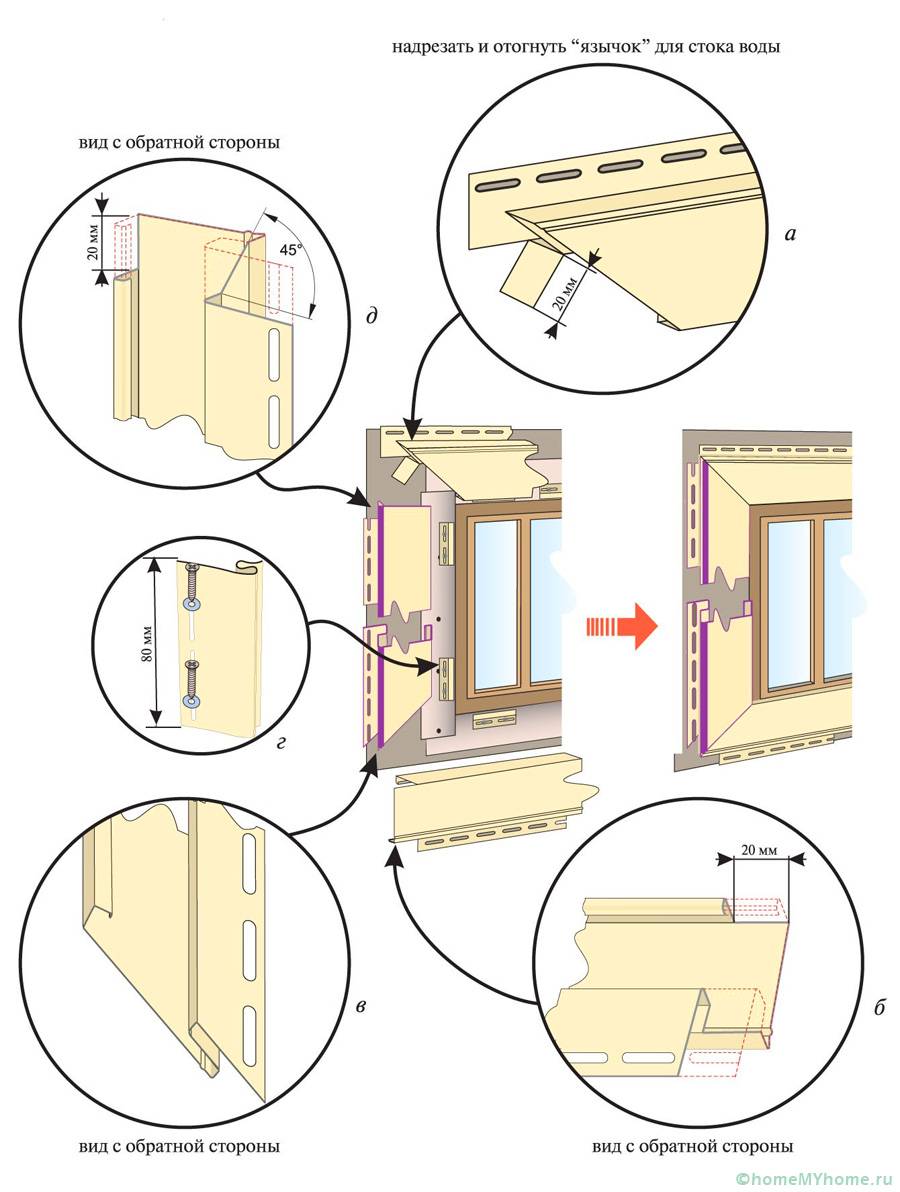

- There are no slopes, and the window is installed flush with the wall, or its size is up to 5 cm.In this case, fit the appropriate size platbands with a width of 62 mm. An alternative can be J-profiles, which are installed and fastened in the same way as described above.In order to neatly connect the profiles, it is necessary to make small cuts on each side of them, bend down, settle the excess parts of the material and do the joining.

- Arched or arrow-shaped openings are sheathed with siding in the same way as walls on J-profiles, but they are neatly bent under the shape of the opening.

Siding

The first plank is usually installed on the side of the building that is least visible from the street and courtyard. This is necessary for beginners to get a little knack for correctly attaching the slats. Installation is carried out in the starting plate in a special clamp with fixation on self-tapping screws at the points of contact with the battens guides.

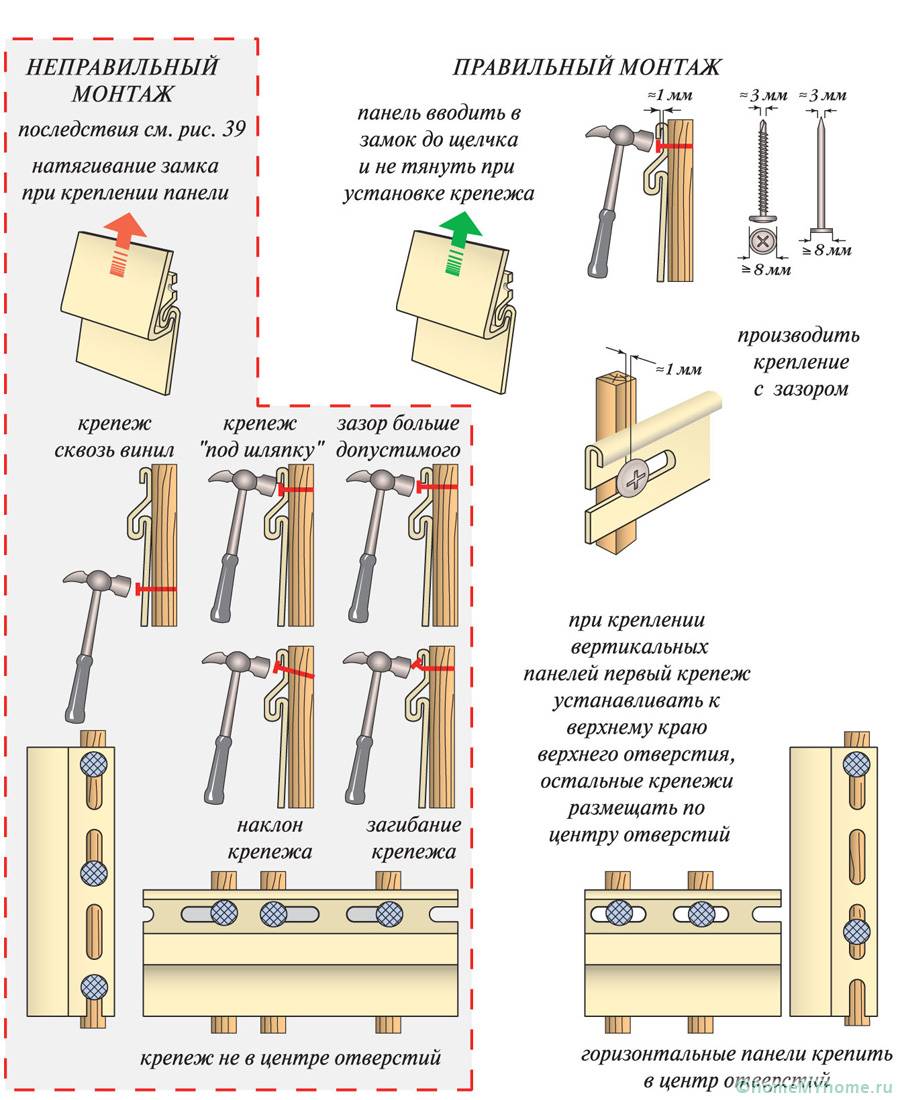

Correct engagement is important to avoid distortion and loss of structural strength. It is imperative to observe the technological indents of 6-9 mm. When tightening self-tapping screws, it is strictly forbidden to deform the panels, as they will then become unusable.

We build up the subsequent planks with an overlap with engagement to the bottom row with special locks. The locks and fastening frames must be shortened beforehand. Every third row must be checked for distortions. When approaching the opening, cut off the excess part of the plank.

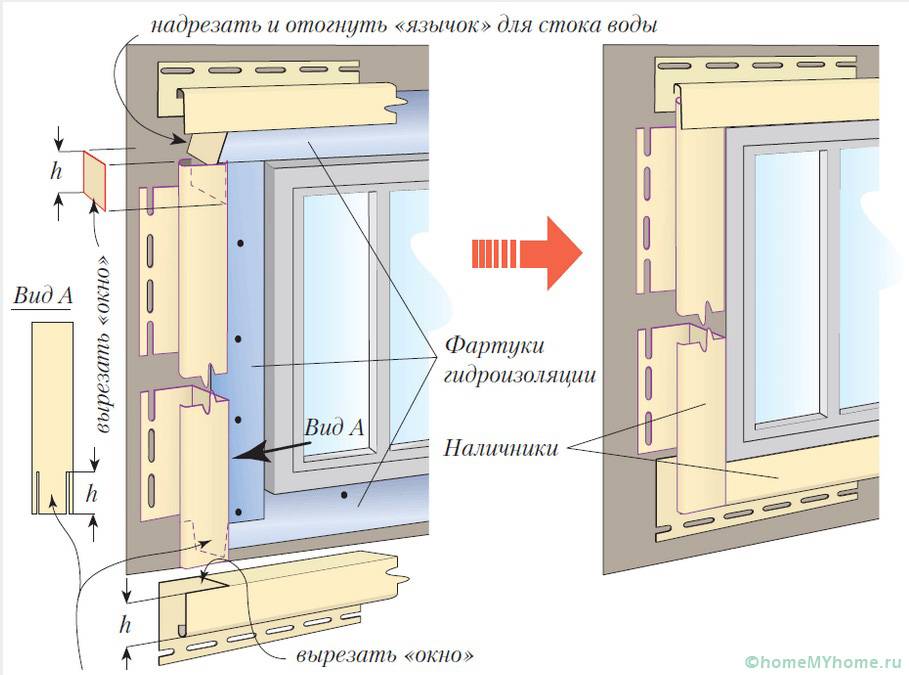

Windows are sheathed with siding only after the installation of the low tide. For this, the opening is measured and the elements are cut to size with a bend at the point of attachment at a right angle and from the side of the drain. After that, the ebb is attached to the frame using an adhesive or liquid nails in order to achieve high tightness and contact density.

A J-profile is installed on the sides of the window opening. Measure the height of the window frame, and then cut the profile to size. The lower parts are slightly folded back for a tight fit with the ebb. A finishing bar is attached to the bottom of the profile along the width of the opening, and to the top - the starting bar.

For cladding doorways, proceed in the same way as in the case of a window - install J-profiles and corner additional elements, if there are slopes. More precisely, the installation of siding with your own hands is described by the instruction in video format.

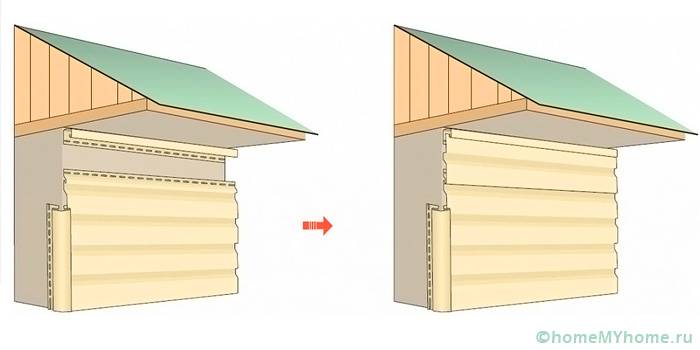

When approaching the junction of the roof at a distance of one or two planks, it is necessary to stop the sheathing and think over the competent implementation of the docking. To do this, you need to measure the distance from the lock of the penultimate row to the finish bar. From the obtained value, it is necessary to subtract 10-20 mm by the indent. Then the whole panel should be marked out and the upper lock connection should be cut off from it. In the upper part, we make hooks (incisions with bending towards the front) with a step of 200 mm. We insert the finished strip into the penultimate panel with snapping into the lock.

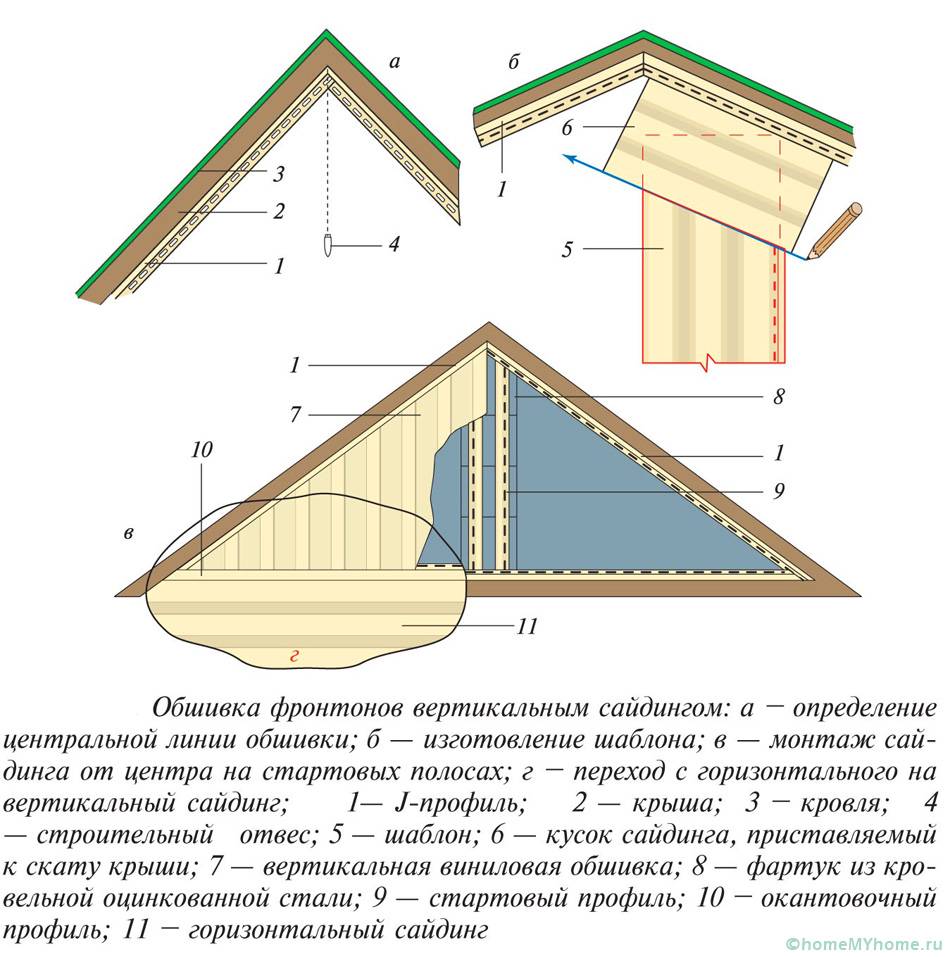

To cover the gable, we install an internal corner element at the junction with the wall and an external one at the end of the roof or a J-profile. The cladding is done in the same way as for the walls.

Recommendations and tips for installing panels

Do-it-yourself siding installation, according to the instructions for dummies, requires compliance with the following rules and recommendations:

- When installing metal or vinyl panels, it is imperative to observe the clearance with the fasteners, as they can expand due to thermal vibrations.

- When fixing vinyl panels, be sure to use only the special holes and never make them yourself.

- Locking connections should be tight, but not overtightened with significant effort.

- When attaching the profiles to nails, it is recommended to leave a gap of 1 mm between them and the head.

- It is highly discouraged to seal sheathing overlaps with sealants, as this can cause unwanted deformations due to the difference in thermal expansion coefficients, and also complicate dismantling, if necessary, to inspect the condition of the wall.

- All fasteners should be located exactly in the center of the holes.

- Sheathing is done from bottom to top or left to right.

Conclusion

Do-it-yourself siding installation is described in detail - instructions for dummies with tips and tricks. It tells how to properly carry out the preparatory work and avoid many problems during installation. Particular attention was paid to the sheathing of the openings and the implementation of the abutment to the roof. Good luck with the repair!

Video: siding installation technology