Rational decoration of the facade of a private house: photo and review of modern facing materials, comparative analysis of prices

A competently executed facade of a private house fully meets the basic requirements. It protects walls from external influences, insulates the house, and is an excellent decorative decoration. In today's material, we will present the most common options for exterior decoration of a house, photos that allow you to evaluate the decorative features of different materials, and a comparative analysis of the cost of various coatings.

The content of the article

- 1 Facade finishing requirements

- 2 Facade cladding selection criteria

- 3 Finishing materials for facades of private houses - analysis of types of facade cladding

- 4 Modern cladding of the facade of the house, which material is better - comparison of options

- 5 Harmonious combined facade decoration

- 6 Review of prices for facade materials for exterior home decoration

- 7 Video: finishing materials for facade work

Facade finishing requirements

The basic requirements for finishing facade surfaces are regulated by the Code of Rules 71.13330.2017. On the basis of this document, it is prescribed to use materials in the form of mastic or glue of class C1 (on the lower floors) and C2 (above the first floor) for fixing facing boards that require an adhesive layer.

If the outside of the house is finished with natural stone, then the slabs are first washed and dried. For artificial materials, additional moisture is not required. When the area of the board material is more than 900 cm², the adhesive solution must be applied both to the wall and to the wrong surface of the material. When using artificial slabs or natural stone with a thickness of more than 12 mm, fasteners are installed.

Note! In cases of using facing products with different colors and textures, you must first develop a pattern selection scheme. In the process of work, they immediately clean the influx of mastic and adhesive solutions, preventing them from hardening. The seams must be the same width.

The rules regulate the limiting values of deviations of some parameters when facing facades.

| Veneered surface type | Maximum deviations, mm | Maximum irregularities of the lined surface, measured by a two-meter rail, mm | ||

|---|---|---|---|---|

| Joint width | Vertical cladding surfaces per meter of length | The location of the seams from the horizontal and vertical for each meter of length | ||

| Mirrored | ±0,5 | 2 | 1,5 | 2 |

| Polished | ±0,5 | 4 | 1,5 | 2 |

| Lumpy, punctate, furrowed | - | 8 | 3 | 4 |

| Sanded | - | 3 | 3 | 4 |

| Rock texture | ±2 | - | 3 | - |

| Artificial stone and granite | ±0,5 | - | - | - |

| From marble | ±0,5 | - | - | - |

| From glass-ceramic, ceramic and other products | ±0,5 | 2 | 21,5 | 32 |

Facade cladding selection criteria

The selection of facing material is carried out in accordance with certain criteria, the list of which includes the following characteristics:

- the degree of complexity of installation;

- total cost of work;

- durability of preservation of external decor;

- strength;

- high sound insulation characteristics;

- providing reliable thermal insulation;

- flammability;

- resistance to ultraviolet radiation;

- weight.

Finishing materials for facades of private houses - analysis of types of facade cladding

The construction market offers a fairly extensive range of finishing materials focused on the execution of cladding of private houses. This allows you to choose not only the color palette of the future facade of the house, but also take into account your own preferences and financial capabilities.

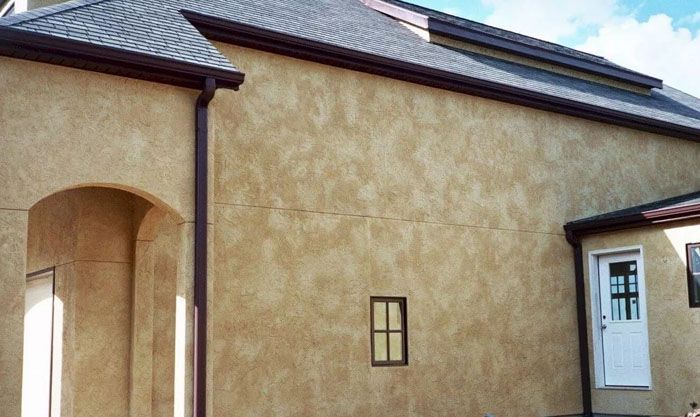

Plaster

Facade surfaces for which finishing is used decorative plaster, acquire a stylish, even appearance. Several varieties of this finishing material are used.

Mineral plaster

A mixture for the production of a mineral variety of plaster is made on the basis of white Portland cement, supplemented with marble chips or quartz sand and lime hydrant. Water-repellent additives, plasticizers are included.

It is sold in the form of a dry powder, which has a low cost. This is one of the advantages influencing the choice of such a material. The resistance of the mineral plaster coating to temperature extremes is highly appreciated. The fungus does not settle on it. The mass prepared in accordance with the instructions is easily applied to the prepared surfaces.

Assessed as a disadvantage, the appearance of cracks on the coating due to vibration effects, a low operational life - about ten years, the need for self-preparation of the solution, large labor costs when applying the composition. A limited color range is also considered a minus, although, if desired, the wall can be easily painted after the coating dries.

Acrylic plaster

A feature of acrylic plaster is the use of synthetic resins as a binder. Finished decorative facades made of this material are plastic and durable, and have such an advantage as the ability to "breathe". Plastered surfaces after rain, snow dry quickly, which ensures the durability of the coating.It is frost-resistant, does not deform even at significant intervals of temperature fluctuations. By purchasing a ready-made white composition, you can choose different shades by introducing dyes.

The disadvantages include the rapid accumulation of dust, which must be removed with a jet of water from a hose. Do not carry out work involving open fires near surfaces finished with acrylic plaster in order to avoid a fire.

Silicate plaster

For the manufacture of a silicate type of plaster, a solution of sodium and potassium silicates is used, which is heat treated in an autoclave. In order to impart the necessary characteristics, plasticizers, mineral fillers, and coloring agents are added to the mixture. Among the advantages is the possibility of using silicate plaster on different surfaces. It fits well on brick, concrete, drywall.

The decorative facade cladding made with silicate plaster is breathable, which is important for the safety of the wall structures. It does not deform and does not shrink, exhibits high resistance to various atmospheric influences, is fire resistant, does not attract dust. Usually sold off-the-shelf.

The main disadvantage is the insufficient plasticity of the finished coating, which is why cracks appear on the facades over time.

Silicone plaster

Silicone plaster is based on silicone resins, which provide high elasticity of the material and give it outstanding water-repellent properties. Cracks do not appear on the plastic coating, the bright shade remains saturated, despite prolonged exposure to sunlight and atmospheric precipitation. Due to the high vapor permeability, the walls of the house retain their operational characteristics for a long time. The silicone plaster cover is not susceptible to mold growth.

There are practically no drawbacks to this unique modern type of plaster. The only drawback may be the higher cost compared to analogues.

Natural and artificial stone

Among the indisputable advantages of natural stone used for cladding the facade, there are environmental safety, reliability, practicality, durability. With his help, the building receives a prestigious noble appearance. In winter, such a house will always be warm, and in summer it will remain cool.

Among the minuses, the most significant is the solid weight, which requires a solid foundation. Also, this material is quite expensive. A worthy replacement can be an artificial stone, which is easy to assemble, is well processed, does not require careful leveling of the rough surface. An important advantage is the aesthetic appearance. Artificial stone no less reliably protects walls from precipitation, shows high resistance to temperature changes. It is an environmentally friendly non-flammable material.

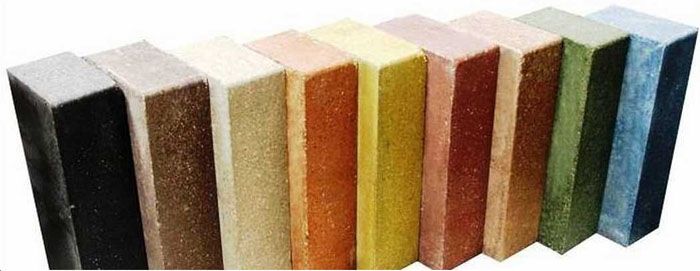

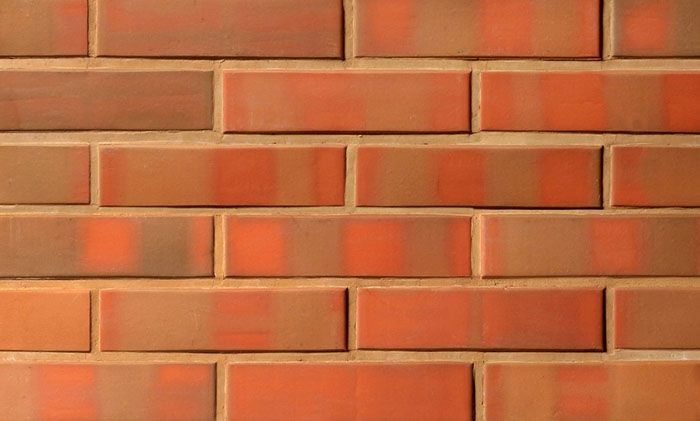

Facade cladding brick showing finishes

There are several varieties of bricks, oriented to provide reliable finishing of facade surfaces. This building material has the ability to create a unique outdoor decor in any color combination.

Clinker brick

For production clinker brick a special kaolin type of clay is used, which is brought to full baking during the firing process. This method provides high strength of clinker brick cladding, which does not collapse even after tens of years under the influence of frost, thaw, precipitation and winds. This material perfectly protects the walls, has a stylish look reminiscent of old buildings.

Shades of bricks depend on the inclusion of various substances in the clay. For example, iron or aluminum oxide after firing provides an expressive cherry hue of varying degrees of saturation, reaching a dark purple tone. Carbon monoxide imparts achromatic shades - black, gray. All characteristic brick color variations... The decor is preserved throughout the entire long service life.

Among the disadvantages are quite complex installation work, high cost, the need for additional thermal and sound insulation.

Ceramic brick

If you need to choose options for outdoor finishing a wooden house, then you should pay attention to ceramic brick... The base material for its manufacture is clay of a fine homogeneous fraction. The finished facing material has good strength, tolerates mechanical stress without damage, is resistant to ultraviolet radiation, and has high frost resistance.

During the production process, special requirements are imposed on the front surface, which can be wavy, rough or smooth. The facing turns out to be "breathable", which protects the walls from destruction. By adding coloring compositions to the clay, various shades of the material are obtained.

Hyper-pressed brick

Being a relatively new finishing material, hyper-pressed brick is of interest for its outstanding characteristics. The raw material for it is a cement-lime mixture with some fillers. For example, they can be blast-furnace slag, screening out of granite, shell rock and other natural varieties, on which the color of the finished finishing material depends. A hyper-pressed brick is made by the method of semi-dry pressing. The raw material is pre-crushed. With little moisture (water in the mixture is only about 10%) under high pressure in special matrices, bricks are formed from it. Then them additionally for complete hydration cement kept in a steam chamber.

Among the advantages of hyper-pressed bricks are moisture resistance, strength, incombustibility, frost resistance, easy installation, durability, environmental safety. Wide range of colors attracts. If work is planned on finishing with this material, then it is worth looking at the entire assortment, since it is possible to choose different textures of the front surface and various forms of material.

Among the disadvantages is a rather high weight, which requires a reliable foundation. Due to the high density, additional measures must be taken to ensure thermal insulation. Also, the cost of such a brick is quite high.

Silicate brick

For the manufacture of sand-lime brick sand and lime are needed. From these components, with the addition of a standardized amount of water, a silicate mass is obtained for further formation of bricks from it under a press.

The advantages are high thermal insulation characteristics, good noise insulation, strength, high density, variety of colors. Attracted by the ease of installation, provided by precise geometric dimensions.

The disadvantages of silicate bricks, when compared with a ceramic analogue, include lower fire resistance, water resistance and frost resistance. If the sand-lime brick finish often gets wet, then chips, pores, caverns appear, and dirt and dust begins to accumulate.

Facade porcelain stoneware

The basis of porcelain stoneware, in addition to white clay, is feldspar, quartz sand, water. The mixture undergoes high-temperature firing and then pressing. The result is solid slabs.

Ceramic granite, grace

with its texture, it looks prestigious and impressive on the facades of any buildings. This material does not deform under the influence of various aggressive substances and moisture, frost, hot sunlight. It perfectly protects walls, belongs to the most durable cladding varieties.

The disadvantages are the high cost, the complexity of the installation, which requires a certain qualification of the workers performing the finishing of the facade. The disadvantages are the high weight of porcelain stoneware slabs.

Ceramic tiles for finishing the facade of the house

Ceramic facade tiles can be called the leader of facing materials, thanks to their environmental safety, presentable appearance, a wide range of compositional and color solutions. With proper installation, the tiles allow you to easily transform the appearance of the house and reliably protect it from various atmospheric influences.

Among the rich assortment, you can pick up products of various prices, ranging from budget options. An important advantage of ceramic tiles is a long service life, light weight, fire resistance, water resistance, preservation of color shades, and no deformation when exposed to negative temperatures.

It is necessary to take into account such disadvantages of tiles as increased fragility and fragility, so all work is carried out carefully. Also, care is taken during transportation.

Decorative siding

When deciding how to decorate the facade of the house, many turn to the range of siding, which has a varied color palette and varies in cost depending on the material.

Vinyl siding

Cheap and visually appealing vinyl siding, focused on cladding the facades of houses, has certain advantages. You can choose options stylized as a log, timber, stone. The assortment includes various colors and ornaments. The weight of this material is very low, you can easily mount it yourself. As a result, the most unpresentable house takes on a surprisingly aesthetic appearance.

Attention! But it should be borne in mind that the material has serious drawbacks. In severe frosts, vinyl cracks and becomes brittle. If the weather is very hot, the panels soften and deform.

The color of the material in direct sunlight gradually fades. It is necessary to take into account the short operational period and the need for careful calculation of the siding and its components.

Related article:

DIY siding installation. Step-by-step photo instructions for dummies on installing siding with practical advice in a separate publication of our portal.

Wood siding

The predecessor of all other types of similar finishes, wood siding has not lost its popularity. For the manufacture of modern products, wood cellulose mixture is pressed with heating, which makes the panels durable. Additives are added to improve performance. The raw materials are pre-purified from impurities and resins harmful to health, which makes wood siding an environmentally friendly material. The coating from it, due to its natural structure, looks cozy and natural.

Among the disadvantages is the need for periodic processing with compounds that protect against fire, mold and repel insects. Also, the wood cladding requires painting, as it periodically fade in the sun. It is not recommended to sheathe the walls of private houses from Fiberboard, foam or fiberglass.

Metal siding

If we compare metal siding with analogues, then it is the most resistant to natural influences, has a service life of 30 years or more. The material is durable, withstands shock loads well, does not become brittle when heated and cooled. All impurities are easily washed off with a water jet from a hose. Metal siding is resistant to decay, it will not be damaged by rodents and insects. This material is fire resistant, does not melt in the presence of an open flame nearby. Does not fade when exposed to sunlight.

The disadvantages include the possibility of rusting due to exposure to moisture, higher cost. A special knife is required for cutting, and installation cannot be carried out without professional skills. When attaching the cladding, it is mandatory to install thermal insulation.

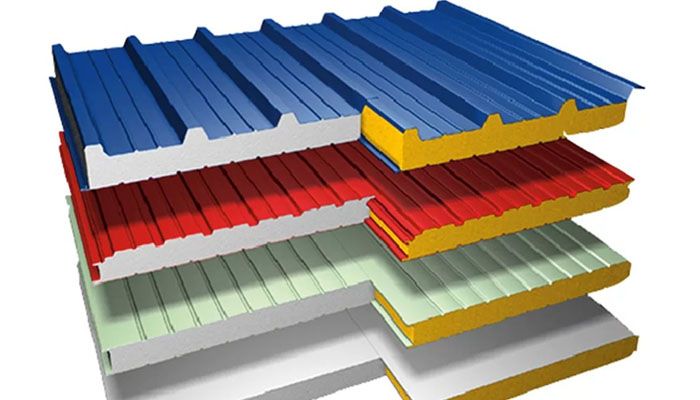

Sandwich panels

Due to the three-layer structure, including a metal or polymer shell located on both sides, and a heater between them, sandwich panels have excellent thermal insulation qualities. Used in the role of insulation mineral wool, penoplex or polyurethane foam.

It is a worthy material for finishing the facades of private houses, the positive characteristics of which are quick installation, low weight, good noise insulation, environmental safety. Affordable cost is an important factor. After correct installation on a frame (wood or metal), sandwich panels serve flawlessly for a long time.

The downside may be the possibility of freezing joints, if the installation was performed with violations.

Ventilated facades

Multicomponent ventilated facades protect walls when temperatures drop and extend their life. They are a system with special gaps that provide ventilation of the insulation. It is recommended to use galvanized or aluminum profiles for the frame.

The advantages of ventilated facades are a long service life of at least 50 years. In winter, they save heat well, are non-flammable and environmentally friendly. With temperature differences, cracks do not form on the surface. They are attracted by simple installation techniques, which can be carried out at any time. If necessary, the cladding can be easily dismantled.

The disadvantage of a ventilated facade is the possibility of condensation between the wall and the insulation, if the installation was carried out incorrectly. From this, the walls begin to freeze, and moisture forms on them, which reduces the service life.

Modern cladding of the facade of the house, which material is better - comparison of options

The variety of options for finishing the facades of houses with modern materials complicates the choice, therefore it is important to first analyze their range and determine the priority criteria.

| Material name | Key benefits | disadvantages |

|---|---|---|

| Plaster: mineral; acrylic; silicate; silicone. | Aesthetic appearance Breathable cover | Possibility of getting damage from mechanical stress |

| A rock: natural; artificial. | Naturalness Environmental Safety High resistance to external influences | High price The need for installation skills |

| Facing brick: clinker; ceramic; hyper-pressed; silicate. | Safe Frost resistant With high decorative qualities | A solid foundation is needed Careful docking |

| Porcelain stoneware | Excellent durability Resistance to any weathering Durability | Significant weight High price |

| Ceramic facade tiles | Good decorative qualities, durability Low price | The need for thorough preparation of the base You need to have styling skills Fragility of the material |

| Decorative siding: vinyl; wooden (larch); metal. | Easy installation Low price Nice decor | Some species have a short service life Poor UV resistance |

| Sandwich panels | Environmental Safety Fast assembly Good noise isolation Durability | Can freeze joints |

| Ventilated facade | Long operational life High performance of thermal insulation Available mounting | Condensation may form in the gaps |

Even a brief overview analysis allows one to draw certain conclusions. More information can be found in the article in the descriptions dedicated to specific types of facing varieties.

Harmonious combined facade decoration

If there are difficulties with what material to finish all parts of the structure, you can choose different types of finishes, harmoniously combining them. How such an exclusive facade of private houses will look like, the photos below will demonstrate from various angles.

Inserts from a different type of material can serve as additional decor. This technique is more common when finishing the basement of a private house in order to ensure reliable protection of the foundation and basement.

You can select different materials for a combined finish. It is important not to create variegation by performing a harmonious arrangement of individual elements. The result is an exclusive design style that attracts attention with originality and demonstrates the artistic ability and taste of the owners.

Review of prices for facade materials for exterior home decoration

When deciding how to sheathe a house outside cheaply and beautifully, you should analyze the prices for the most popular facing materials.

| Material name | Price per m², rub. | The cost of turnkey works, taking into account insulation per m², rubles. |

|---|---|---|

| Plaster | ||

| Mineral | 350−750 | ˃850 |

| Acrylic | 1600−1905 | ˃2100 |

| Silicate | 2600-2615 | ˃3100 |

| Silicone | 2406−3900 | ˃3500 |

| A rock | ||

| Natural | 1400−2750 | ˃7340 |

| Artificial | 550-2350 | ˃4550 |

| Facing brick | ||

| Clinker | 1250−2650 | ˃2600 |

| Ceramic | 400-800 | ˃1400 |

| Hyperpressed | 665-1250 | ˃1700 |

| Silicate | 280-350 | ˃1000 |

| Porcelain stoneware | 630-1850 | ˃3680 |

| Ceramic facade tiles | 958-2350 | ˃1700 |

| Decorative siding | ||

| Vinyl | 185 | ˃750 |

| Wooden (larch) | 590-1950 | ˃2000 |

| Metal | 450-600 | ˃1550 |

| Sandwich panels | 600-1800 | ˃3100 |

| Ventilated facade | 1150-1500 | ˃650 |

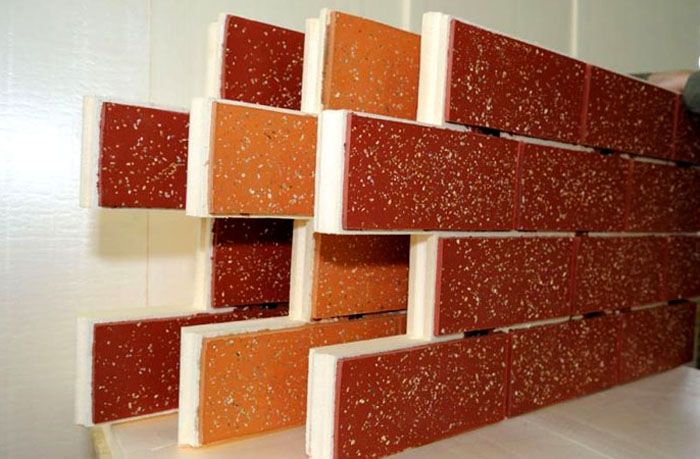

Among the improved varieties of the new generation of cladding, it should be noted that Russian-made facade thermal panels, the price of which varies from 2050 to 7000 rubles. per m2. This material is a gas-filled plastic with a decorative surface of mineral chips or tiles of different color and texture.

The finishing material of the new generation - thermal panel - has a varied decor of the front surface

Choosing the right kind of decoration for your own home is a serious job that requires a comprehensive analysis of many factors. We will be interested in your experience, express your opinion, share tips and tricks, ask questions in the comments.

Related article:

Facade panels for exterior decoration of the house. From this publication you will learn all about the types of facade panels, materials, advantages and disadvantages.