Facade plaster for outdoor use: types and technology of application

The facade of the building is the pride of any owner of a country house. Correctly selected material will protect the walls from mechanical damage, the effects of precipitation, and make the appearance of the house presentable. One of the most demanded materials is facade plaster for outdoor use. It is easy to use and has a number of advantages, which will be discussed in the article. The homemaster.techinfolux.com/en/ editorial team has prepared a short review on the choice of the best plaster for the facade. In the article we will tell you how to choose the right finishing material depending on the material of the house, we will study plastering technology, as well as get acquainted with the current prices for this type of plaster.

The content of the article

- 1 Advantages and disadvantages of facade plaster for outdoor use

- 2 How to choose facade plaster for outdoor use

- 3 Surface preparation for material application

- 4 Application of the mixture to surfaces of various materials

- 5 Plastering technology when creating decorative surfaces

- 6 Types of facade paint on plaster for outdoor use

- 7 The price of facade plaster and finishing works

Advantages and disadvantages of fasad plaster for outdoor use

Any finishing material should be considered comprehensively, because it can have both pros and cons. Plaster for facades has a large number of positive qualities, therefore, today it is considered the most demanded, in comparison with other materials.

The main benefits include:

- Protection of walls from moisture. Drying, the plaster ceases to come into contact with water. It does not collapse from rain or snow.

- Resistant to temperature extremes.The material is not afraid of either heat or severe cold, it is also resistant to significant temperature changes throughout the year.

- The ability to apply the mixture to any surface, including wood and insulation, which makes it versatile and irreplaceable.

- High resistance to mechanical stress. Dried plaster is a hard shell.

- High adhesion to the wall base. As a liquid, the coating penetrates fine surface cracks and depressions for superior durability.

- The composition after hardening becomes safe for humans, does not emit harmful substances.

- Vapor permeability ensures wall breathing and comfortable living in the house.

- In addition, a layer of plaster creates protection against sound waves as well as against cold.

- The material washes well, does not absorb dirt.

- It is easy to use and has a large number of colors and textures, so everyone can create their own style in the design of the building.

Plaster for finishing building facades is divided into several types, and each of them, unfortunately, has minor flaws. These include:

- Some types of material do get dirty, which is especially noticeable against light and dark backgrounds. For cleaning, use water without detergents, dirt easily comes off.

- Mineral plaster has a poor color palette. In order to diversify it, you will have to apply a special paint on top of the layer.

- Some types of material are expensive.

Obviously, this finishing material has no obvious disadvantages. It's time to talk in detail about its types.

Types and features of decorative plaster for outdoor use

The material is divided into several types depending on its composition, each of which has its own peculiarity. In order to choose the right composition for a particular object, you should carefully read the characteristics of the species.

The main types widely represented on the modern building materials market:

- acrylic;

- silicate;

- silicone;

- mineral.

Since they all differ from each other in composition, technical characteristics and a number of properties, each of them should be discussed separately.

Acrylic plaster for outdoor use

Part decorative material a binder is included for wall decoration. In the case of this type of plaster, acrylic resins are used.

Due to the fact that the composition is based on a liquid resin, this type of material is sold ready-made in buckets. After opening, it can be immediately applied to the surface. A layer of plaster will set in two hours. Main characteristics:

- impact resistance;

- vapor permeability;

- plastic;

- resistance even to aggressive environments.

In view of these qualities, acrylic coating is also used to strengthen the surface of the walls.

It additionally contains additives that prevent the spread of bacteria, it also gives off excess moisture, and at the same time the wall breathes well.

Silicate facade plaster

In this case, potassium water glass is used as a binder. It is electrostatically neutral to repel dirt. Silicate plaster does not get dirty and breathes well.

Most often, this type of material is a substitute for acrylic finish in cases where the latter cannot be applied. The optimum temperature for work ranges from +5 to + 25 ° C with a humidity of not more than 70%.

Facade silicone plaster

One of the most expensive is silicone-based plaster.This material is very expensive, but has many advantages:

- wide range of colors;

- dirt is easily washed off with water;

- elasticity.

In addition, it allows steam to pass through, which means that the walls breathe. Its only significant drawback is its high cost.

Mineral plaster for facades

The basis of these products is cement. It is he who has unprecedented strength. If you are interested in quality such as strength, feel free to choose this type of material. The product is presented on the market in the form of a powder mixture, it must be diluted with water in a certain proportion. Such external plaster serves for the house for more than 10 years, almost does not absorb moisture, is not afraid of microorganisms and fungi.

As a rule, the use of this type of material will oblige the owner to additionally purchase frost-resistant facade paint for outdoor use. The fact is that the color range of such finishing mixtures leaves much to be desired due to their composition. For this, only silicate paint is used, because the other will not allow the plaster to breathe. Next, we will consider how to make the right choice and what to build on when choosing this product.

Related article:

Decorative plaster for interior wall decoration. This article will discuss the types of wall plaster, the tools required for its application, and the technology for applying the coating.

How to choose facade plaster for outdoor use

Building materials stores offer a wide selection of products for every taste and wallet, but when choosing a facade decorative plaster, one should not rely only on color preferences. In this case, it is important what the operating conditions and goals of the customer are.

When choosing a mixture, pay attention to the following indicators:

- water absorption rate (the lower the better);

- protection from ultraviolet rays;

- high degree of adhesion;

- low degree of shrinkage, which will allow not to crack for a long time;

- high degree of breathability.

Self-application of the material is possible, however, absolute non-professionalism in this matter will be marked by unevenness, noticeable joints.

Additionally, pay attention to the shelf life, frost resistance, consumption and other technical parameters. From them it is easy to determine how much work is possible in your home, and how much you need to buy a kilogram of mixture.

Surface preparation for material application

After the house is built, you will need to choose a design solution that would suit the owner. To do this, you can choose the finish yourself, even draw a layout or contact professional designers. The latter option will not only allow you to get an interesting finish, but also find out the amount of materials required.

Surface preparation depends on whether other mixtures have been previously applied to it. If the walls have previously been finished, they will have to be leveled as much as possible, removing the top layer in whole or in part. Then the surface is cleaned from dirt with a brush and degreased. Then apply a primer recommended by the plaster manufacturer. As a rule, companies produce primers under the same brand. It will provide an excellent bond between the material and the surface.

If the house is just built, start preparatory work by cleaning the walls with a brush and then you can prime them. This completes the preparation of the front surface of the house. External plaster can be sold both as a ready-made solution and as a dry mix, from which the solution is made independently.

Application of the mixture to surfaces of various materials

One of the advantages we voiced earlier is the ability to apply external plaster to any surface. In this case, you should know how to properly work with the resulting mixture.

Before starting work, you should adhere to important rules:

- do not apply at temperatures below + 5 ° C;

- maintain the recommended moisture content (standard - no higher than 70%);

- work must be continuous, as this will affect the formation of visible joints;

- after the building is built, it is allowed to stand, as the material will shrink.

These rules are simple, and they apply to all types of finishing mixtures.

Applied to insulation

In the conditions of harsh winters, many home owners have to use not only internal insulationbut also outside. When the choice of insulation they are guided by the one that can be covered with a wet solution afterwards. Most often used:

- basalt slabs;

- mineral wool;

- expanded polystyrene.

The latter is the cheapest material, however, it is flammable. It is convenient to apply the elastic mortar to the boards. The facade is pre-prepared.

Important! Remember that the insulation under the plaster should first be planted on glue, and then additionally, after 24 hours, secured with dowels in the form of umbrellas.

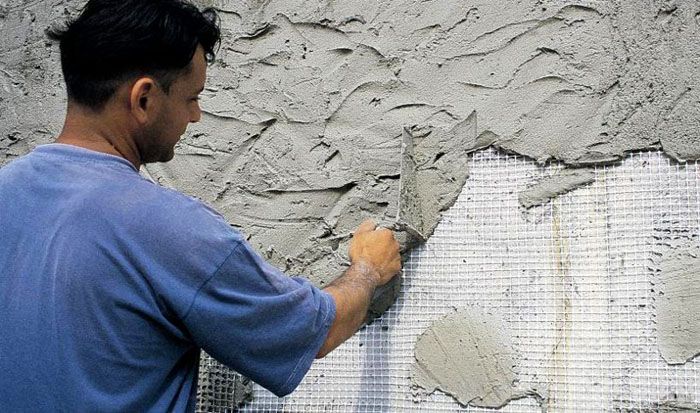

As soon as the insulation is fixed, proceed to surface reinforcement. To do this, apply:

- fiberglass mesh;

- reinforcing composition.

The mesh is immersed in the composition and then attached to the surface. The reinforcing layer should be 2 mm thick. Drying of the composition lasts three days. It is advisable to carry out reinforcement work in cloudy but not rainy weather.

Brick application

Brick houses are reliable, warm in winter and cool in summer. There are two ways to apply mortar to brickwork:

- machine;

- manual.

It is important that the brick layer is the same, otherwise all the irregularities will become noticeable after drying, it will be difficult to fix them. After cleaning the wall, put up plaster beacons... They are fastened using a plumb line, which will show where and how much the wall is deflected. You can work with plaster using a long rule.

A solution of the mixture is thrown between the beacons, smoothing is done from the bottom up. A short video will allow you to learn more about the progress of work:

Application to concrete

The concrete surface is extremely uneven. You can't call it smooth. To carry out such work, you must first carefully prime the surface of the walls. It is recommended to use only high-quality material and not save at this stage. The products of the Lakra brand under the name "Concrete-contact" are perfect for priming.

It is also recommended to reinforce the walls with a mesh. Before starting work, the walls are moistened with water. The application process is carried out with rubbing movements.

Facade plaster for aerated concrete

Surface of aerated concrete has a number of features. A house built from such material is not protected from moisture, because the blocks perfectly absorb water. In this case, even a simple gray decorative plaster will be a justified measure. In this case, it is important to choose the right solution for aerated concrete, because:

- it is a smooth material, not every solution will stick to it;

- it absorbs moisture from the solution, after which it cracks;

- it must have the same vapor permeability coefficient with the solution.

Important! Aerated concrete blocks cannot be plastered with a cement mixture.

When choosing a material, use only one that is specially designed for application on aerated concrete. The application technology is simple and similar to that used for finishing brick walls.

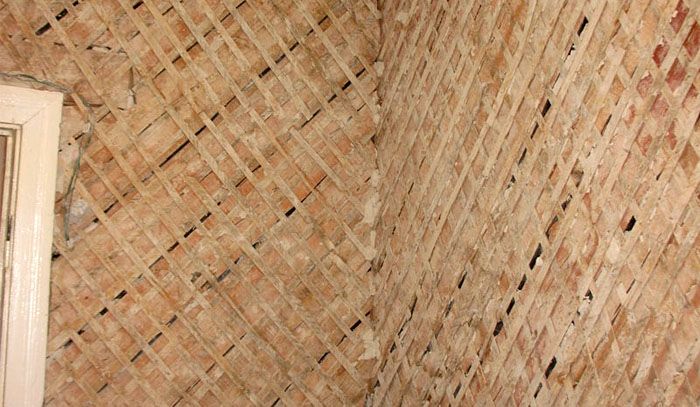

Wood application

Those who have finished the "shingle" know how difficult the work of finishing wooden walls is. Plaster for wooden walls is justified, because it will qualitatively protect them from microbes and fungi. It is advisable to apply the mixture only after the house has shrunk, which takes about a year and a half for the tree.

Choose a solution only of the following types:

- plaster;

- lime;

- cement.

Working with wooden surfaces involves a difficult preparatory stage. It is as follows:

- elimination of large cracks;

- fixing a mesh made of metal or wooden strips;

- installation of beacons;

- primer.

Now you can start plastering. For outdoor work, special technologies are often used to create decorative surfaces with an unusual pattern.

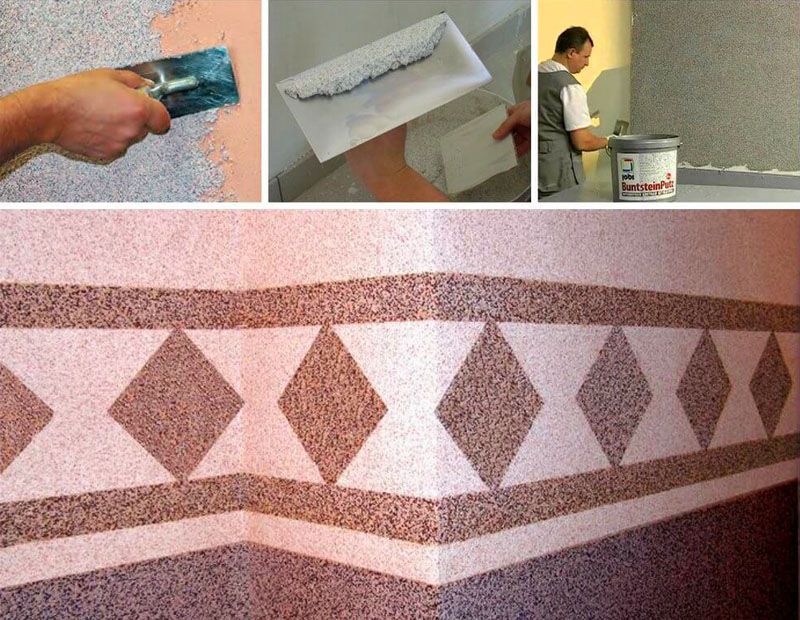

Plastering technology when creating decorative surfaces

There are a lot of styles of material application. Exists sophisticated techniqueswhen working alone is simply not acceptable.

Let's talk about the most common technologies:

- "Fur coat";

- "Bark beetle";

- "mosaic".

They will certainly decorate the facade of your house and make it unique.

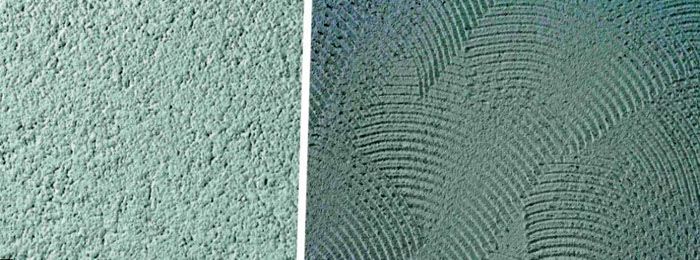

"Fur coat"

"Fur coat" is a variant of interior and exterior wall decoration with a rough surface. To do this, you do not need to look for a specialized material, the effect is achieved by a kind of application.

Covering the wall is not difficult, so this option is great for self-application. The layer turns out to be dense and thick, it serves as additional sound insulation for the house. For the "fur coat", not ready-made solutions are often used, but made independently on the basis of cement and sand.

Let's talk about four options for applying such a decorative layer:

- With a perforated roller or made of fur. For this, a liquid solution is used. If it seems thick, dilute it with water or another means. The mixture is applied to the wall spatula, and then it is rolled with a roller over the surface.

- Using a spatula, the mixture is applied to the wall, smoothed, and then with a trowel texture is created... This method is the easiest and can be used by beginners. To create the pattern, place the trowel against the wall while the plaster is wet, and then abruptly remove it. The result is a "fur coat".

- You can also create a drawing using a special spray gun. It is very convenient to work with mechanical means.

- The last option is to imitate a pattern with a broom. A new layer is sprayed onto the applied thin smooth layer by sharp strokes of a broom, previously lowered into a bucket of solution.

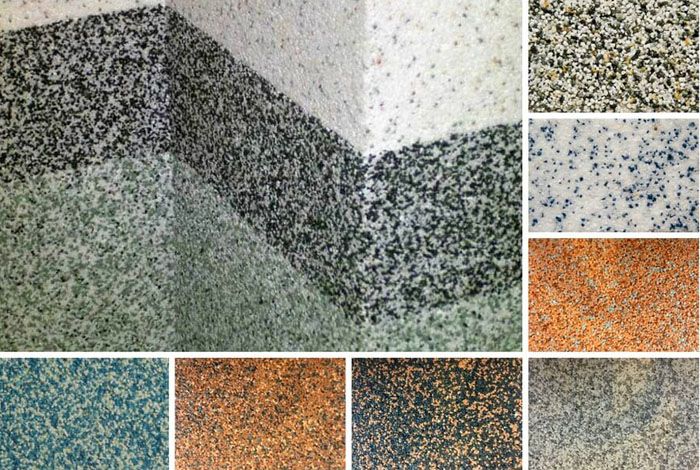

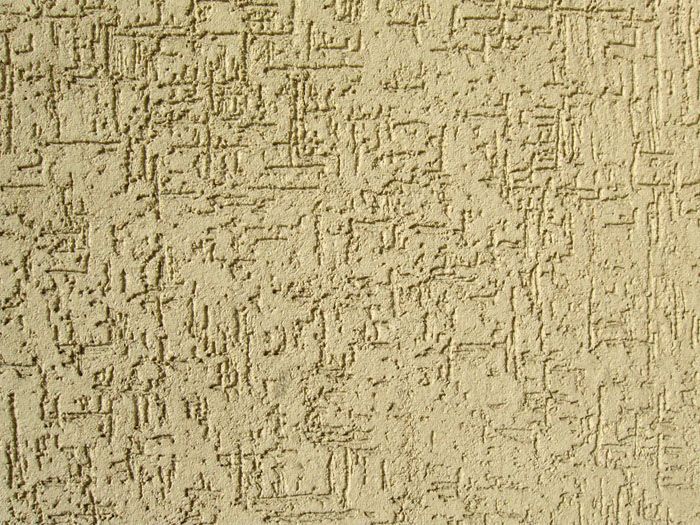

"Bark beetle"

Perhaps the most popular type of mortar application. Externally, the surface resembles wood, eaten by beetles - hence the name.

For such works, specialized ready-made solutions are offered, as well as dry mixtures. First, a smooth layer of plaster is applied. As soon as it starts to dry out and stops shining, they start rubbing with a trowel. From how the hand movements are made (horizontally, vertically, diagonally, in a circle), you get the design options for "rain", "lamb", "carpet".

A short video will help you decide on the technique:

Related article:

The technology of applying plaster "bark beetle" with your own hands. In the publication we will consider detailed step-by-step instructions for applying the "bark beetle", the nuances of painting the finished coating, an overview of manufacturers of textured plaster, average prices, and useful tips.

Mosaic

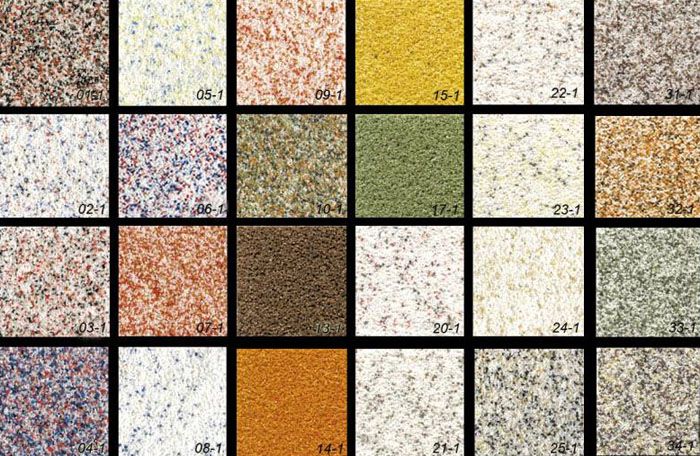

This option looks very impressive, but it came to us from antiquity. The material contains marble, malachite, lapis lazuli chips, fractions up to 3 mm.

The application technique is simple: using a grater, the mixture is pulled from one corner to another, without drying out. You need to work quickly so that the joints are not visible.

Types of facade paint on plaster for outdoor use

The problem of grayness and tarnishing of the plaster is solved with the help of specialized paint. It will give the surface extra durability. It is divided into three types:

- silicate;

- acrylic;

- silicone.

When choosing, pay attention to the resistance to atmospheric precipitation. Silicone and acrylic paint is virtually odorless.

Pay attention to the presence of a glossy gloss in the paint. It is good for use in the area of door and window openings, but unacceptable - on large surfaces. Redecoration of damaged plaster, leveling before painting is carried out using a facade putties for outdoor work.

Related article:

Finishing the facade of a private house. In the publication we will consider the basic requirements, criteria for choosing materials, a variety of finishing materials, their advantages and possible disadvantages, an overview of prices and photos of successful options.

The price of facade plaster and finishing works

Consider the price of bark beetle facade plaster and other application options. The cost is indicated taking into account staining.

| Name | Price (as of April 2018), RUB per m2 |

|---|---|

| Venetian plaster | 200 |

| Plaster "bark beetle" | 300 |

| Fur coat plaster | 250 |

| "Antika" | 300 |

| "Vintage" | 350 |

Although the cost of finishing the facade with decorative plaster is great, professionals work with it very quickly, and the result will exceed all expectations.