Choosing insulation for the walls of the house outside: price, types and review of manufacturers

Home insulation is one of the most important factors affecting the economy of the family budget. After all, if the house is blown from all sides, heating costs increase many times over. Experienced craftsmen do not advise to insulate the premises from the inside - this leads not only to a decrease in the usable area, but also to the destruction of walls due to the formation of condensation between the walls and thermal insulation, which means that such work should be done outside the buildings. Types of insulation for walls outside, the price and materials for making thermal insulation are the topic of our conversation today.

The content of the article

- 1 Why walls need to be insulated outside

- 2 What insulation for the outer walls of the house to choose

- 3 Types of materials for wall insulation outside

- 3.1 Styrofoam or expanded polystyrene - in which cases it is better to use it

- 3.2 Extruded polystyrene foam - what is it

- 3.3 Polyurethane foam - what are its disadvantages and advantages

- 3.4 Mineral wool, its varieties and the possibility of using it for thermal insulation

- 3.5 Liquid insulation for walls - how to use it and how much it fulfills its functions

- 4 Major manufacturers of thermal insulation materials - an overview

- 5 Features of wall insulation outside the house - ventilated facade

- 6 Three-layer wall construction - installation features

- 7 Calculation of insulation for the walls of the house: convenient online calculators

- 8 Installation of external insulation for walls

- 9 Where to buy insulation for the walls of the house outside

- 10 Finally

- 11 Video: how to choose insulation

Why walls need to be insulated outside

The reason for the external insulation is that the thermal insulation for the walls, made inside the room, does not allow the internal air to warm up the structure. As a result, in the cold season, condensation forms on the cooled wall, from the inside. Thermal insulation prevents it from evaporating, which entails not only the formation of mold and mildew between the insulation and the wall. This leads to a fairly rapid destruction of the wall.In addition, literally after a year or two, a persistent smell of dampness begins to appear in the home, which is quite difficult to get rid of.

The exact opposite result is obtained when the walls are insulated from the outside. In this case, the walls warm up normally even in severe frosts - thermal insulation does not allow them to cool down and at the same time they remain completely dry - after all, the insulation does not allow cold air to penetrate inside. It is for this reason that insulation of facades, not the walls from the inside.

But in this case, the question arises, what about the finish? Modern thermal insulation materials are perfect for plastering or pasting them with decorative tiles. Only some preparation is required, which was already mentioned in one of our articles. Well, what kind of thermal insulator should be used for insulation is up to the home craftsman himself. We, in turn, will try to facilitate this choice and talk about the various materials used for these purposes.

What insulation for the outer walls of the house to choose

These materials differ not only in cost, but also in their options finishing... One can be completely plastered, and the second can only be covered with decorative panels. So, before deciding on one or another heat insulator, it is worth deciding which finishing method will be applied to it.

It doesn't matter what the house is built of - wood, brick or concrete. For any of them, you can pick up such a heater that will not allow dampness, cold and wind to get inside the home. Such work is especially relevant if the structure is old - these are especially prone to freezing. It is also worth noting the extreme need for installation insulation for walls outside at home in the country, in which no one lives in winter. In the case of well-done work, the temperature inside the building in spring will be much higher, and the humidity will be lower.

Types of materials for wall insulation outside

The most common materials used as thermal insulation are:

- Expanded polystyrene or polystyrene;

- Extruded polystyrene foam (penoplex);

- Polyurethane foam;

- Mineral wool;

- Liquid thermal insulation.

These materials, in addition to different costs, have different from each other thermal conductivity... This indicator is very important - the lower it is, the better the building will be insulated. Consider what this indicator is for the indicated thermal insulators:

| Insulation | Density, kg / m3 | Thermal conductivity, W / m × s | Water vapor permeability, m × h × Pa |

|---|---|---|---|

| Mineral wool | 50-200 | 0,48-0,070 | 0,49-0,60 |

| Expanded polystyrene | 33-150 | 0,031-0,05 | 0,013-0,05 |

| Extruded polystyrene foam | 45 | 0,036 | 0,013 |

| PVC foam | 125 | 0,052 | 0,23 |

| Polyurethane foam | 30-80 | 0,020-0,041 | 0-0,05 |

| Polyurethane foam mastic | 1400 | 0,25 | 0,00023 |

| Roofing material | 600 | 0,17 | 0,001 |

| Polyethylene | 1500 | 0,3 | 0,00002 |

Already from these data on the density of materials, it can be concluded which is the best insulation for the walls of the house outside under the plaster, and which is well suited for ventilated facades. What are the other characteristics of these heat insulators?

Styrofoam or expanded polystyrene - in which cases it is better to use it

This material is, in fact, small air bubbles in a polystyrene shell. It is the air without movement that performs the function of insulation. Polyfoam has a fairly low cost, which adds to its popularity. Although it is not devoid of shortcomings.

The main ones can be called fragility and, as it is not surprising, that he is very fond of rats and mice. It is not uncommon for rodents to make holes for themselves in it, which later allow them to move freely throughout the house.This is especially bad when modern material is used as walls, consisting of two sheets of oriented building boards, between which there is expanded polystyrene.

However, as a wall insulation outside, foam is very good. It is quite suitable for subsequent plastering or exterior decoration using artificial stone, or wall panels and siding.

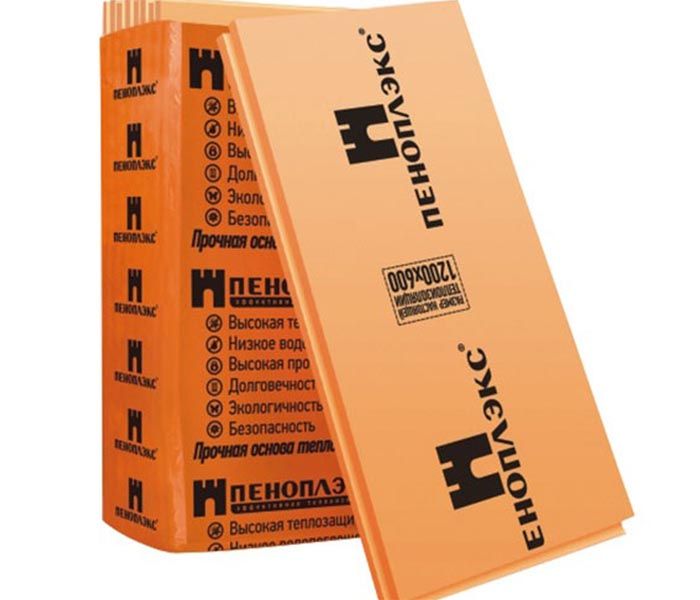

Extruded polystyrene foam - what is it

This material has a higher cost, but at the same time its technical characteristics are much better. The most famous of such heaters for walls outside can be safely called penoplex. It is strong enough, although it has a porous structure. It is also very convenient in plastering. Installation is carried out on special mastics, glue bases without the use of acetone, but the best option for external finishing can be called special plastic anchors.

For rodents and various pests, such insulation is not of interest. In addition, in its manufacture, such substances are used that are not susceptible to the formation of fungus. In fact, there is only one minus - high flammability. The weight of the slabs is small, which, together with its strength, allows one person to carry out work on the outside insulation of the house with penoplex without any help.

Polyurethane foam - what are its disadvantages and advantages

Such material has been known for a long time and has found application not only as a thermal insulator. It is used as a filler in armchairs and sofas, car and bus seats. To put it simply, this is foam rubber, which is probably known to every person.

It can be used as insulation only under the panels. Its soft structure does not allow plastering. Although some home craftsmen, using foam rubber as a heat insulator, then close it plywood or chipboard, which allows the subsequent plastering of the wall.

It's important to know! Its huge disadvantage is its instability to high temperatures. In addition, "due to" its chemical composition, this thermal insulator, when ignited, emits very toxic substances, which are quite easy to poison, in contrast to extruded polystyrene foam, which is not subject to combustion.

Many are now talking about the harm that phenol allegedly secreted by this material causes. However, the opinions of scientists are divided here. Some say that he is absolutely neutral, while others, on the contrary, argue that he causes colossal harm to the body. We will not take sides, limiting ourselves to stating facts - this material is nowadays used in almost all furniture, in cars and even as a filler for pillows. And if its harm was proved, then it is unlikely that a self-respecting manufacturer would dare to poison people.

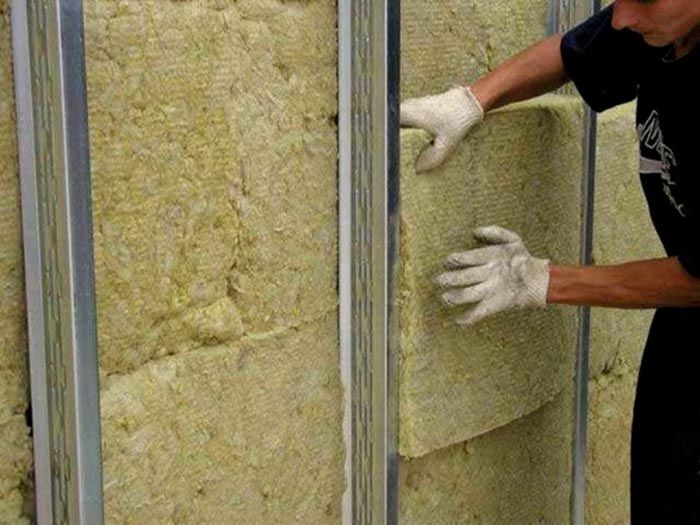

Mineral wool, its varieties and the possibility of using it for thermal insulation

This heat insulator can be used inside building blocks or in external thermal insulation of walls, followed by finishing with siding or wall panels. It is most widely used in the construction of ventilated facades and insulation soft roof... Most often, a variety of it is used for these purposes - slabs of a certain size of basalt insulation, the price of which is relatively low.

Mineral wool has a higher thermal conductivity and vapor permeability than previous options. It is due to this that it is the cheapest insulation. However, when using it, the heat in the house becomes quite enough. A rather unpleasant moment can be called the fact that when working with it, the body begins to itch.Of course, not as strong as it was with its predecessor - glass wool, but still sensitive. In addition, it is a rather brittle and fragile material. But still, for this type of insulation, such as a ventilated facade, such a thermal insulator is practically irreplaceable.

Liquid insulation for walls - how to use it and how much it fulfills its functions

In appearance, such a heat insulator resembles thick paint. There is no doubt about the quality of its performance of its functions. However, its popularity is reduced by its high cost - not everyone can afford it. It is for this reason that professionals advise to apply it only in the corners of the house and at the joints of the foundation and walls. It is better to cover the rest of the area with a more affordable insulation material; it will be very wasteful to choose it for insulation of all wall surfaces.

Such material can be divided into 2 groups - heat paint and liquid foam. Both of them do an excellent job not only with insulation, but also with waterproofing... It falls well on them plaster, which means they are compatible with any material. High adhesion allows the use of this heat insulator on any surface, be it stone, concrete, brick or wood.

Major manufacturers of thermal insulation materials - an overview

There are a lot of manufacturers of thermal insulation in Russia. And each of them is good in its own way, and therefore there is no point in compiling any rating. This means that today we will just say a few words about each of them.

- "Ecover" - a manufacturer of very good quality basalt slabs. In addition to wall, it produces roofing heat-insulating materials and sandwich panels.

- Knauf - the same mineral wool, however, the peculiarity of the manufacturer is that he produces it not in slabs, but in rolls. The layer thickness may vary.

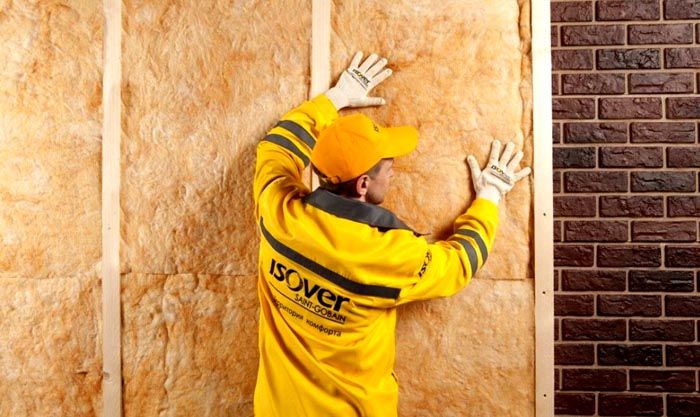

- Isover - glass wool and its varieties. Such a thermal insulator has a very big drawback - it requires the organization of moisture removal

- "Penofol" - basalt slabs are of quite high quality, but the insulating material made of extruded polystyrene foam brought great popularity to this brand.

- Technonikol - a brand known throughout Russia and having factories in many regions. In addition to roofing material and other roofing materials, it produces EPS boards and basalt insulation.

- URSA - mainly basalt and fiberglass slabs of excellent quality

- "Penoplex" - the name has become a household name. All their EPS boards are now called "Penoplex", regardless of the manufacturer

- Ecoteplin - unique and completely natural tile materials, which include linen fibers, borax and starch.

- "Astratek" - liquid heaters that have no analogues in Russia. High-quality thermal insulation is achieved already with a layer of only 3 mm.

Related article:

Penoplex: technical characteristics. By choosing slabs of suitable thickness, you can ensure a sufficient level of thermal insulation of the walls, floor, ceiling. Let's talk about this insulation in more detail in our review.

The list of manufacturers is endless, we have named only a few of the most famous.

Features of wall insulation outside the house - ventilated facade

Mineral wool is used for the ventilated facade. In simple words, without using construction terms, a frame is assembled on the wall from a metal profile with cells in the size of mineral, fiberglass or basalt slabs, or the same profiles are attached in a line from the bottom to the top of the building, between which the insulation is laid. After it closes with a special hydro and vapor barrier film... The cladding is made with ceramic-granite tiles (usually 50x50 cm), which are fixed to the same guides with the help of special metal clamps called "crabs".

Thus, the developer achieves a solution to several problems at once - insulation, vapor barrier and finishing.

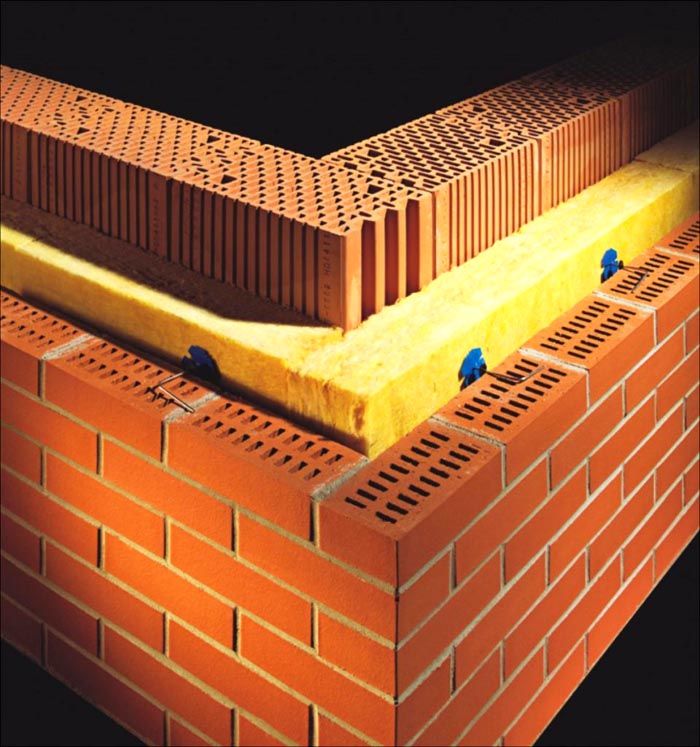

Three-layer wall construction - installation features

Thus, the walls of low-rise buildings are often insulated from bricks or foam block... The technology is pretty simple. The building, made of rough brick, is insulated from the outside using any polymer thermal insulator, and then covered with facing brick. But although the quality of such insulation is not bad, this method also has its drawbacks. The main one is the low durability of the insulation in comparison with the building and facing material. Despite this, the popularity of such insulation is quite high.

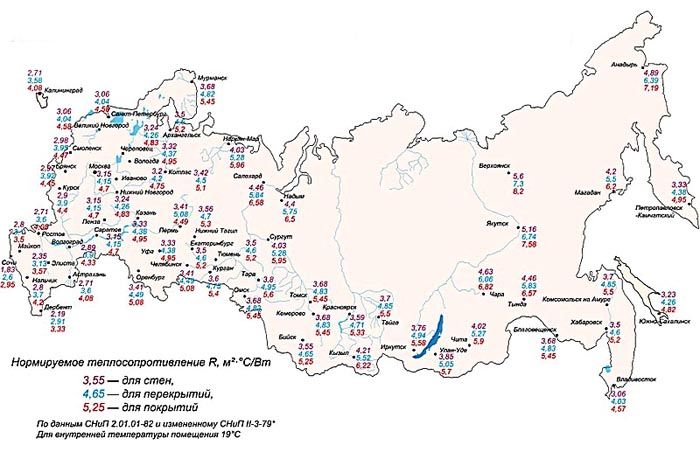

Calculation of insulation for the walls of the house: convenient online calculators

It is not difficult to calculate the required dimensions of the slabs along the length and width of the wall. A much bigger problem here is the calculation of the required thickness, which depends on many different parameters, including the region in which the residential building is located. That is why we suggest you use our online calculators, which will do all the calculations themselves.

Online calculator for calculating the thickness of the insulation of the walls of a wooden house

Online calculator for calculating the thickness of wall insulation with Penoplex

Installation of external insulation for walls

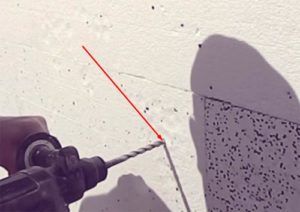

The technologies for such installation may differ, depending on the option of subsequent finishing. If facing with brick or siding is planned, then it is allowed to fix the thermal insulator on glue bases (without acetone) or mastic. But this method will not work if you plan to plaster or tiling, or decorative panels "like a brick"... In this case, the initial installation is carried out on the same glue, and after that, holes are drilled into which special plastic anchors are inserted. They then provide a reliable fixation of the insulating material. We bring to your attention a small educational program on this topic with photo illustrations.

Related article:

In our article you will find out what types of penoplex are, how it happens insulation of the facade with penoplex (technology), as well as the pros and cons of this facing material.

Where to buy insulation for the walls of the house outside

You can purchase such material both via the Internet and in any construction market. Here the question is a little different - the cost can vary significantly. Usually, when buying a heat insulator online, especially in large quantities, you can save a decent amount. This happens due to the fact that the Internet seller does not need to pay salaries to subordinates and spend money on renting premises for a retail outlet. This means that purchases are obtained with significant benefits. The same applies to the price of insulation for the walls of the house inside.

Insulation for the walls of the house outside: price according to online catalogs

Let's try to summarize information on prices for various heat insulators that we could find on the Internet.

| Material | Dimensions, mm | Cost, rub / piece |

|---|---|---|

| Extruded polystyrene foam | 1200x600x30 | 150 |

| Mineral slab | 1200x600x40 | 100 |

| Styrofoam | 1200x500x20 | 15-20 |

| Mineral wool (roll) | 8200x120x50 | 100 |

Separately, you can indicate a novelty - sprayed insulation-aerosol "POLINOR" at a price of 500 rubles per cylinder (1 kg).

Finally

Wall insulation Is a rather important process that should not be neglected. And since this work is not so difficult, it is better to do it yourself. This will save a decent amount that professionals will demand for their work.

We hope that the information presented today was useful to you. If you have any questions, our team will be happy to answer them in the discussions below. We also hope that you will share your experience on the topic, if you have it - this can help other readers in choosing a material and producing works.

And finally, we suggest watching a short video on the topic of choosing a thermal insulator for insulating the walls of a house.