Insulation for the floor in a wooden house: which is better and how to choose?

It is impossible to create a cozy atmosphere in your own home without high-quality floor insulation, since it is when the feet are frozen that most people feel discomfort or get sick. It is always pleasant to walk barefoot on a warm floor, especially when it is snowing or pouring rain. However, to achieve such results, it is necessary to choose a floor insulation in a wooden house, which is better in terms of characteristics and has the simplest installation technology.

The content of the article

What are the requirements for heaters?

Since in a wooden house the floors are also laid from boards, then to heaters special requirements are imposed:

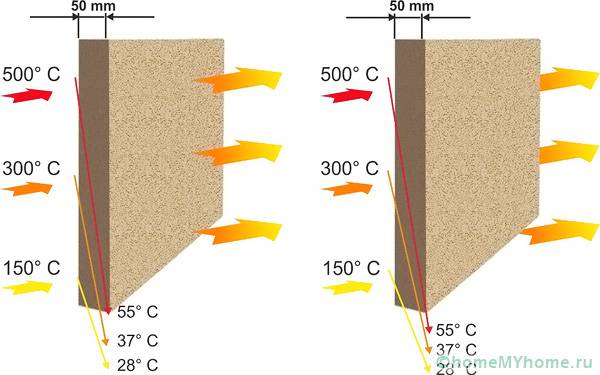

- It is necessary to ensure the maximum level of fire safety, since wood is a highly flammable material. It is recommended to choose non-flammable or at least non-flammable insulation material.

- Resistance to moisture and resistance to its accumulation is required. This is due to the fact that wood has the property of absorbing and releasing moisture at different temperatures, and if the insulation becomes the reason for its accumulation along the contact boundary, then the boards will begin to rot.

- Thermal insulation must retain its basic properties throughout the entire service life, but at least longer than the service life of wooden floors.

- Sufficient mechanical strength is required to resist caking or loss of thermal insulation properties.

- The composition should be free from harmful chemicals, especially volatile and volatile.

Important! In addition to the requirements for heaters, it is also necessary to take care of creating appropriate conditions for their operation.

Insulation for the floor in a wooden house, which one is better to choose?

To choose insulation for the floor in a wooden house, which is better and cheaper, you need to know what its main types are. By the method of delivery, they are divided into the following:

- Mats or slabs... They are lightweight slabs that hold a certain shape and retain their geometry during installation. Usually they are characterized by minimal thermal conductivity and low weight. These include Penoplex plates, expanded polystyrene, mineral wool, etc. Install them on a flat surface with minimal roughness. Their simultaneous use with others is allowed types of insulation... Both natural and artificial materials can be used in the manufacture of mats.

- Rolls... They are rolls based on composite materials, cork, mineral wool, etc. They can have different thicknesses and usually have softness and minimum density. That is, they are lightweight and fit even on uneven surfaces without much difficulty. Thanks to the standard length, it is possible to install without transverse joints, which significantly improves the level of thermal insulation. However, they are not resistant to moisture and therefore require special attention to the installation of the waterproofing layer.

Helpful information! In some cases, mineral wool insulation is produced with a layer of a foil layer, which must be on top when laying. It is designed to protect against moisture.

- Polymer-based fluids... Supplied in a sealed container in the form of cans or containers, inside of which there is a special composition capable of forming a solid substance with a foamed structure when interacting with air. It can be used to apply thermal insulation layers of any complexity, since it has increased adhesion to almost all building materials, and is also able to fill irregularities or hard-to-reach places. Penoizol is a striking example of a polymer composition. For its application, it is necessary to use special sprayers. If you want to choose an insulation for the floor in a wooden house that is optimal in cost, which one is better applied to a wooden base, then you should pay attention to other heat-insulating materials. Such insulation is expensive in comparison with other materials for thermal insulation.

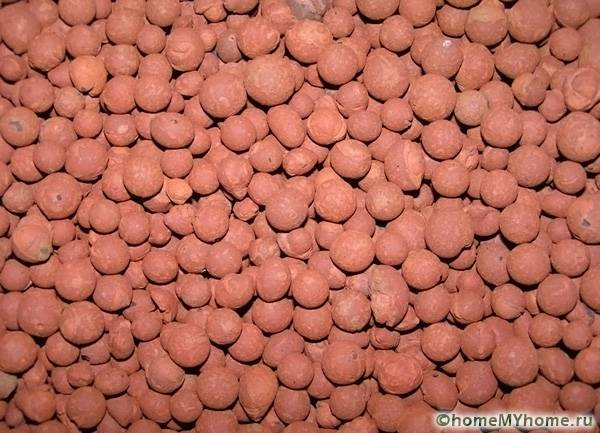

- Loose heaters... These include materials such as expanded clay, sawdust, slag, etc. Due to their flowability, they are able to fill any volume with sufficient density to ensure the minimum thermal conductivity... They can be laid directly on the ground or on a prepared base. The disadvantages of laying such insulation are the following: raising the level of the floors, as well as the need to install cross beams for laying the finished floor.

In each case, the insulation should be chosen in such a way that it is convenient to install it, it has more advantages from the application, and the disadvantages do not play a significant role. That is, it is recommended to lay plate heaters or rolls on flat floors, on an uneven rough base - bulk, and on complex bases - expanded polystyrene.

Do-it-yourself step-by-step process of floor insulation in a private house

Do-it-yourself floor insulation in a private house is done in stages in the following sequence:

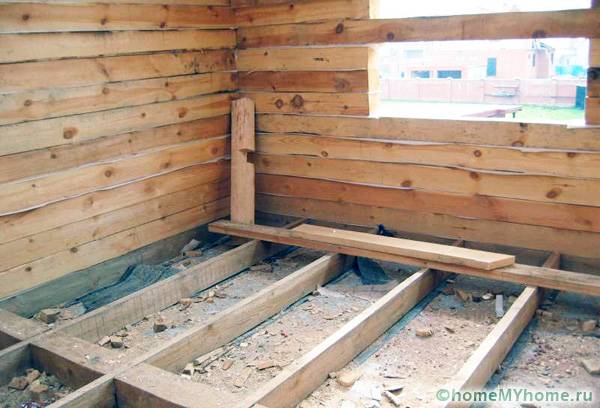

- A sub-floor is being prepared for the installation of logs, intended for use as the main structure for attaching insulation.

- In the presence of damaged structures, replacement or repair is made. The base for the insulation is carefully strengthened and, if necessary, leveled with your own hands.

- Fits waterproofing filmif the insulation is required to be protected from moisture.

- The insulation material is laid in accordance with the installation technology.

- Fits vapor barrier film.

- The final floor is being laid.

Related article:

Floor insulation in a wooden house from below. We will tell you how to perform competent thermal insulation of a wooden floor with all the nuances in a special publication of our portal.

Features of insulation with sawdust

Sawdust is one of the cheapest, but effective insulation materials. At cost, they are much cheaper than expanded clay or mineral wool, but at the same time they have practically the same coefficient of thermal conductivity. They are environmentally friendly and therefore do not pose a health hazard. Warming the floor with sawdust consists in pouring them into the space between the logs in an even layer. At the same time, there will be no difficulties with insulating hard-to-reach places, since the sawdust can easily be tamped there. A waterproofing material is laid on top of the laid sawdust.

Attention! Sawdust, like wood, has an increased fire hazard. Therefore, they must be impregnated with special impregnations. Otherwise, it is recommended to use non-flammable materials.

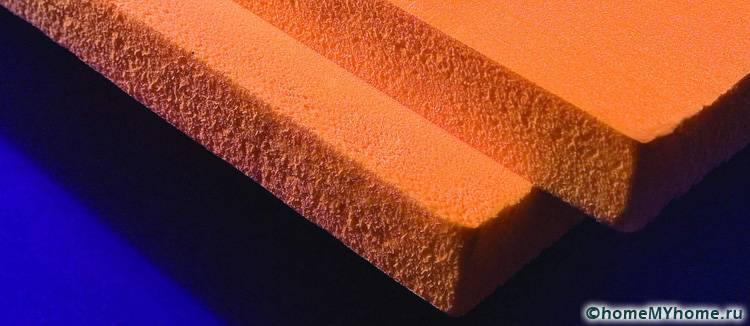

Floor insulation with penoplex

The method of laying foam boards is quite simple. First, you need to lay it along the log in one layer, then foam the joints with polyurethane foam, and then lay the second layer, but with bandaging the seams.

Application advantages penoplex the following:

- Resistant to moisture and rodents.

- Long service life.

- It has sufficient protection against mechanical stress.

- Does not crumble over time and does not lose its properties.

Laying roll materials based on mineral wool or stone wool

Rolled insulation is one of the most popular today, as it has excellent insulating properties and a long service life at a relatively low cost. Moreover, they are non-flammable and do not emit harmful substances.

Helpful information! Some experts believe that mineral wool is harmful to human health, since formaldehyde is used in its production. However, in practice it turns out that this volatile substance evaporates even during its stay in the production premises.

Since mineral wool, when moisture gets on it, loses its thermal insulation properties, it must be properly waterproofed from the external environment and vaporized from the interior. The rolls are laid in one layer between the logs directly on the waterproofing layer, but so that the cotton falls tightly to the walls without the slightest gaps. A layer of vapor barrier is laid on top. The technology is relatively simple and therefore even non-specialists will not have any questions about how to properly insulate the floors in wooden houses.

Overview of manufacturers and product prices

The following manufacturers of high-quality thermal insulation materials are most popular in Russia:

- Isover Is a French brand of the Saint-Gobain concern, which has existed for over 350 years and has managed to prove its reliability and high quality products. One of the priority areas is the production of glass wool insulation. In fact, products from this manufacturer are the benchmark for competitors. At the same time, the cost of glass wool is within reasonable limits and is quite affordable for purchase.

- Linerock - a separate product line of the Saint-Gobain concern. It is a high quality mineral wool slabs, which are also designed to provide high-quality sound insulation of premises. The manufacturer is domestic with the main production facilities located in St.Chelyabinsk. The cost of products is quite acceptable, since foreign counterparts are several times more expensive.

- Company Euroizol produces high-quality mineral wool insulation in the form of slabs. They are distinguished by increased fire safety, resistance to water absorption and compression. In this case, the cost of the insulating material is at a high level, however, if we compare the terms of its operation with analogues of other companies, then Euroizol will win in all technical parameters.

- Products from Rockwool is branded and in demand all over the world. The main activity of the company is the production of basalt thermal insulation materials. They are distinguished by their unpretentiousness to difficult operating conditions and preservation of their properties for several decades. However, their cost turns out to be quite democratic and affordable for any resident of Russia.

There are also other well-known companies on the market. However, the cost of the product is too high and therefore it is less in demand in the construction of wooden houses. It is recommended to choose insulation for the floor in a wooden house at its cost, and also pay attention to which one copes with the insulation functions better. Table 1 shows approximate prices for insulation materials.

Table 1. Average cost of thermal insulation materials.

This table shows how much the prices for thermal insulation materials differ. Therefore, choosing a suitable insulation for the floor in a wooden house, which is better and which is worse, is recommended in accordance with the climatic conditions, the cost of the object and the requirements for ensuring comfortable conditions in the room.

Conclusion

- The criteria for choosing a heater for a wooden house are described.

- The main advantages and disadvantages of each of the materials are shown.

- Some nuances of installation of heaters are given.

- The costs of some popular types of thermal insulation materials are shown in the table.

Video: floor insulation over a cold basement